Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling

Abstract

:1. Introduction

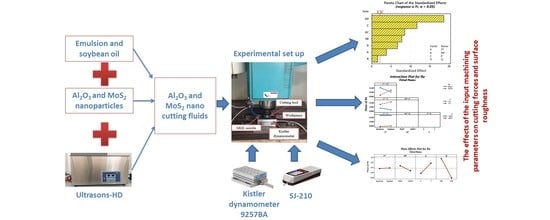

2. Material and Method

Experimental Set Up

3. Results and Discussion

- (a)

- The Effect of Fluid Types

- (b)

- The Effect of Nanoparticles

- (c)

- The Effects of Air Pressure and Air Flow Rate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pereira, O.; Martín-Alfonso, J.; Rodríguez, A.; Calleja-Ochoa, A.; Fernández-Valdivielso, A.; de Lacalle, L.L. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Lee, P.-H.; Nam, J.S.; Li, C.; Lee, S.W. An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. 2012, 13, 331–338. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T. Investigation of MQL-employed hard-milling process of S60C steel using coated-cemented carbide tools. J. Mech. Eng. Autom. 2016, 6, 128–132. [Google Scholar]

- Rahim, E.A.; Dorairaju, H. Evaluation of mist flow characteristic and performance in Minimum Quantity Lubrication (MQL) machining. Measurement 2018, 123, 213–225. [Google Scholar] [CrossRef]

- Khan, M.; Mithu, M.; Dhar, N. Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Process. Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Rahim, E.A.; Sasahara, H. A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol. Int. 2011, 44, 309–317. [Google Scholar] [CrossRef]

- Wang, J.G.; Zhang, J.Z. On formation and breakup of boundary lubricating layer. Lubr. Eng. 2005, 6, 4–8. [Google Scholar]

- Abdalla, H.S.; Patel, S. The performance and oxidation stability of sustainable metalworking fluid derived from vegetable extracts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 2027–2040. [Google Scholar] [CrossRef]

- Obikawa, T.; Kamata, Y.; Shinozuka, J. High-speed grooving with applying MQL. Int. J. Mach. Tools Manuf. 2006, 46, 1854–1861. [Google Scholar] [CrossRef]

- Park, K.-H.; Olortegui-Yume, J.; Yoon, M.-C.; Kwon, P. A study on droplets and their distribution for mini mum quantity lubrication (MQL). Int. J. Mach. Tools Manuf. 2010, 50, 824–833. [Google Scholar] [CrossRef]

- Kamata, Y.; Obikawa, T. High speed MQL finish-turning of Inconel 718 with different coated tools. J. Mater. Process. Technol. 2007, 192–193, 281–286. [Google Scholar] [CrossRef]

- Park, K.-H.; Olortegui-Yume, J.; Joshi, S.; Kwon, P.; Yoon, M.-C.; Lee, G.-B.; Park, S.-B. Measurement of Droplet Size and Distribution for Minimum Quantity Lubrication (MQL). In Proceedings of the 2008 International Conference on Smart Manufacturing Application, Goyang-Si, Korea, 9–11 April 2008; pp. 447–454. [Google Scholar]

- Tawakoli, T.; Hadad, M.; Sadeghi, M. Influence of oil mist parameters on minimum quantity lubrication—MQL grinding process. Int. J. Mach. Tools Manuf. 2010, 50, 521–531. [Google Scholar] [CrossRef]

- Zaman, P.B.; Dhar, N.R. Design and evaluation of an embedded double jet nozzle for MQL delivery intending machinability improvement in turning operation. J. Manuf. Process. 2019, 44, 179–196. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S. Hard turning using HiPIMS-coated carbide tools: Wear behavior under dry and minimum quantity lubrication (MQL). Measurement 2014, 55, 536–548. [Google Scholar] [CrossRef]

- Mia, M.; Dey, P.R.; Hossain, M.S.; Arafat, T.; Asaduzzaman; Ullah, S.; Zobaer, S.M.T. Taguchi S/N based optimization of machining parameters for surface roughness, tool wear and material removal rate in hard turning under MQL cutting condition. Measurement 2018, 122, 380–391. [Google Scholar] [CrossRef]

- Al Bashir, M.; Mia, M.; Dhar, N.R. Effect of Pulse Jet MQL in Surface Milling of Hardened Steel. J. Mech. Eng. 2016, 45, 67–72. [Google Scholar] [CrossRef] [Green Version]

- Davim, J.P.; Sreejith, P.S.; Silva, J. Turning of Brasses Using Minimum Quantity of Lubricant (MQL) and Flooded Lubricant Conditions. Mater. Manuf. Process. 2007, 22, 45–50. [Google Scholar] [CrossRef]

- de Lacalle, L.L.; Angulo, C.; Lamikiz, A.; Sanchez, J.A. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Pereira, O.; Celaya, A.; Urbikaín, G.; Rodríguez, A.; Fernández-Valdivielso, A.; de Lacalle, L.N.L. CO2 cryogenic milling of Inconel 718: Cutting forces and tool wear. J. Mater. Res. Technol. 2020, 9, 8459–8468. [Google Scholar] [CrossRef]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; De Lacalle, L.N.L. Internal cryolubrication approach for Inconel 718 milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- Pereira, O.; Català, P.; Rodríguez, A.; Ostra, T.; Vivancos, J.; Rivero, A.; López-De-Lacalle, L. The Use of Hybrid CO2+MQL in Machining Operations. Procedia Eng. 2015, 132, 492–499. [Google Scholar] [CrossRef] [Green Version]

- Pereira, O.; Rodríguez, A.; Abia, A.I.F.; Barreiro, J.; de Lacalle, L.L. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Pervaiz, S.; Deiab, I.; Rashid, A.; Nicolescu, M. Minimal quantity cooling lubrication in turning of Ti6Al4V: Influence on surface roughness, cutting force and tool wear. J. Eng. Manuf. 2015, 231, 1542–1558. [Google Scholar] [CrossRef]

- Maruda, R.; Krolczyk, G.; Feldshtein, E.; Nieslony, P.; Tyliszczak, B.; Pusavec, F. Tool wear characterizations in finish turning of AISI 1045 carbon steel for MQCL conditions. Wear 2017, 372–373, 54–67. [Google Scholar] [CrossRef]

- Maruda, R.; Krolczyk, G.M.; Wojciechowski, S.; Żak, K.; Habrat, W.; Nieslony, P. Effects of extreme pressure and anti-wear additives on surface topography and tool wear during MQCL turning of AISI 1045 steel. J. Mech. Sci. Technol. 2018, 32, 1585–1591. [Google Scholar] [CrossRef]

- Sinha, M.K.; Madarkar, R.; Ghosh, S.; Rao, P.V. Application of eco-friendly nanofluids during grinding of Inconel 718 through small quantity lubrication. J. Clean. Prod. 2017, 141, 1359–1375. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Samion, S.; Ghaderian, J.; Yazid, M.N.A.W.M. Recent progress on the application of nanofluids in minimum quantity lubrication machining: A review. Int. J. Heat Mass Transf. 2017, 108, 79–89. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.; Biswal, B.; Sahoo, N.; Pradhan, A. Performance evaluation of various cutting fluids using MQL technique in hard turning of AISI 4340 alloy steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood, P.; Sharma, V.S. Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J. Clean. Prod. 2016, 135, 1276–1288. [Google Scholar] [CrossRef]

- Sharma, P.; Sidhu, B.S.; Sharma, J. Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J. Clean. Prod. 2015, 108, 72–79. [Google Scholar] [CrossRef]

- Vasu, V.; Reddy, G.P.K. Effect of minimum quantity lubrication with Al2O3 nanoparticles on surface roughness, tool wear and temperature dissipation in machining Inconel 600 alloy. Proc. Inst. Mech. Eng. Part N J. Nanoeng. Nanosyst. 2011, 225, 3–16. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A. Towards Sustainable Machining of Inconel 718 Using Nano-Fluid Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2018, 2, 50. [Google Scholar] [CrossRef] [Green Version]

- Chatha, S.S.; Pal, A.; Singh, T. Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J. Clean. Prod. 2016, 137, 537–545. [Google Scholar] [CrossRef]

- Wong, K.V.; De Leon, O. Applications of Nanofluids: Current and Future. Adv. Mech. Eng. 2010, 2, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Minh, D.T.; The, L.T.; Bao, N.T. Performance of Al2O3 nanofluids in minimum quantity lubrication in hard milling of 60Si2Mn steel using cemented carbide tools. Adv. Mech. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Ngoc, T.B. Effectiveness of alumina nanofluid on slotting end milling performance of SKD 11 tool steel. J. Comput. Appl. Res. Mech. Eng. 2020, 9, 359–369. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Van Thanh, D. Evaluation of minimum quantity lubrication and minimum quantity cooling lubrication performance in hard drilling of Hardox 500 steel using Al2O3 nanofluid. Adv. Mech. Eng. 2020, 12, 1–12. [Google Scholar] [CrossRef]

- Gupta, A.; Kumar, R.; Kumar, H.; Garg, H. Comparative performance of pure vegetable oil and Al2O3 based vegetable oil during MQL turning of AISI 4130. Mater. Today Proc. 2020, 28, 1662–1666. [Google Scholar] [CrossRef]

- Gaurav, G.; Sharma, A.; Dangayach, G.; Meena, M. Assessment of jojoba as a pure and nano-fluid base oil in minimum quantity lubrication (MQL) hard-turning of Ti–6Al–4V: A step towards sustainable machining. J. Clean. Prod. 2020, 272, 122553. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Sidhu, H.S. Experimental investigation on the performance of MQL drilling of AISI 321 stainless steel using nano-graphene enhanced vegetable-oil-based cutting fluid. Tribol. Int. 2020, 151, 106508. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Sidhu, H.S. Performance evaluation of the minimum quantity lubrication with Al2O3-mixed vegetable-oil-based cutting fluid in drilling of AISI 321 stainless steel. J. Manuf. Process. 2021, 66, 238–249. [Google Scholar] [CrossRef]

- Okafor, A.C. Cooling and machining strategies for high speed milling of titanium and nickel super alloys. In High Speed Machining; Academic Press: Cambridge, MA, USA, 2020; pp. 127–161. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Da Silva, R.B.; Sales, W.F.; Machado, A.R. Overview of the Machining of Titanium Alloys. In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2017; pp. 487–506. [Google Scholar]

- Duc, T.M.; Long, T.T.; Dong, P.Q. Effect of the alumina nanofluid concentration on minimum quantity lubrication hard machining for sustainable production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5977–5988. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.; Sayuti, M. Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. J. Clean. Prod. 2014, 66, 685–691. [Google Scholar] [CrossRef]

- Jarahnejad, M.; Haghighi, E.B.; Saleemi, M.; Nikkam, N.; Khodabandeh, R.; Palm, B.; Toprak, M.S.; Muhammed, M. Experimental investigation on viscosity of water-based Al2O3 and TiO2 nanofluids. Rheol. Acta 2015, 54, 411–422. [Google Scholar] [CrossRef]

- Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011. [Google Scholar]

- Dong, P.Q.; Duc, T.M.; Long, T.T. Performance Evaluation of MQCL Hard Milling of SKD 11 Tool Steel Using MoS2 Nanofluid. Metals 2019, 9, 658. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Duc, T.; Long, T.; Tuan, N. Novel Uses of Al2O3/Mos2 Hybrid Nanofluid in MQCL Hard Milling of Hardox 500 Steel. Lubricants 2021, 9, 45. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Chien, T.Q. Performance Evaluation of MQL Parameters Using Al2O3 and MoS2 Nanofluids in Hard Turning 90CrSi Steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef] [Green Version]

- Jadhav, P.; Deivanathan, R. Numerical analysis of the effect of air pressure and oil flow rate on droplet size and tool temperature in MQL machining. Mater. Today Proc. 2021, 38, 2499–2505. [Google Scholar] [CrossRef]

| Input Machining Parameters | Unit | Symbol | Type/Level | |

|---|---|---|---|---|

| Fluid type | FT | Emulsion | Soybean | |

| Nanoparticle | NP | Al2O3 | MoS2 | |

| Air pressure | MPa | P | 5 | 7 |

| Air flow rate | l/min | Q | 100 | 200 |

| Std Order | Run Order | PtType | Blocks | Input Machining Variables | Response Variables | ||||

|---|---|---|---|---|---|---|---|---|---|

| FT | NP | P (MPa) | Q (l/min) | Ra (µm) | Fr (N) | ||||

| 1 | 24 | 1 | 1 | Emulsion | MoS2 | 5 | 100 | 0.143 | 421.58 |

| 2 | 13 | 1 | 1 | Soybean | MoS2 | 5 | 200 | 0.075 | 331.70 |

| 3 | 6 | 1 | 1 | Emulsion | Al2O3 | 5 | 200 | 0.069 | 205.20 |

| 4 | 10 | 1 | 1 | Soybean | Al2O3 | 5 | 100 | 0.126 | 311.93 |

| 5 | 7 | 1 | 1 | Emulsion | MoS2 | 7 | 200 | 0.136 | 398.11 |

| 6 | 12 | 1 | 1 | Soybean | MoS2 | 7 | 100 | 0.132 | 281.96 |

| 7 | 20 | 1 | 1 | Emulsion | Al2O3 | 7 | 100 | 0.116 | 489.07 |

| 8 | 14 | 1 | 1 | Soybean | Al2O3 | 7 | 200 | 0.115 | 407.32 |

| 9 | 8 | 1 | 1 | Emulsion | MoS2 | 5 | 100 | 0.135 | 385.12 |

| 10 | 23 | 1 | 1 | Soybean | MoS2 | 5 | 200 | 0.072 | 356.09 |

| 11 | 15 | 1 | 1 | Emulsion | Al2O3 | 5 | 200 | 0.064 | 196.16 |

| 12 | 19 | 1 | 1 | Soybean | Al2O3 | 5 | 100 | 0.122 | 312.55 |

| 13 | 5 | 1 | 1 | Emulsion | MoS2 | 7 | 200 | 0.091 | 361.81 |

| 14 | 16 | 1 | 1 | Soybean | MoS2 | 7 | 100 | 0.143 | 284.58 |

| 15 | 9 | 1 | 1 | Emulsion | Al2O3 | 7 | 100 | 0.126 | 473.74 |

| 16 | 2 | 1 | 1 | Soybean | Al2O3 | 7 | 200 | 0.106 | 396.10 |

| 17 | 21 | 1 | 1 | Emulsion | MoS2 | 5 | 100 | 0.126 | 404.88 |

| 18 | 18 | 1 | 1 | Soybean | MoS2 | 5 | 200 | 0.072 | 346.25 |

| 19 | 3 | 1 | 1 | Emulsion | Al2O3 | 5 | 200 | 0.071 | 175.57 |

| 20 | 17 | 1 | 1 | Soybean | Al2O3 | 5 | 100 | 0.102 | 304.60 |

| 21 | 1 | 1 | 1 | Emulsion | MoS2 | 7 | 200 | 0.096 | 358.23 |

| 22 | 22 | 1 | 1 | Soybean | MoS2 | 7 | 100 | 0.139 | 305.17 |

| 23 | 4 | 1 | 1 | Emulsion | Al2O3 | 7 | 100 | 0.121 | 449.93 |

| 24 | 11 | 1 | 1 | Soybean | Al2O3 | 7 | 200 | 0.103 | 403.74 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 0.014038 | 0.002005 | 16.76 | 0.000 |

| Linear | 4 | 0.011994 | 0.002999 | 25.07 | 0.000 |

| FT | 1 | 0.000007 | 0.000007 | 0.06 | 0.811 |

| NP | 1 | 0.000590 | 0.000590 | 4.93 | 0.041 |

| P | 1 | 0.002542 | 0.002542 | 21.25 | 0.000 |

| Q | 1 | 0.008855 | 0.008855 | 74.02 | 0.000 |

| 2-Way Interactions | 3 | 0.002043 | 0.000681 | 5.69 | 0.008 |

| FT*NP | 1 | 0.001683 | 0.001683 | 14.07 | 0.002 |

| FT*P | 1 | 0.000345 | 0.000345 | 2.88 | 0.109 |

| FT*Q | 1 | 0.000015 | 0.000015 | 0.13 | 0.728 |

| Error | 16 | 0.001914 | 0.000120 | ||

| Total | 23 | 0.015952 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 152,436 | 21,776.6 | 96.56 | 0.000 |

| Linear | 4 | 44,346 | 11,086.5 | 49.16 | 0.000 |

| FT | 1 | 3207 | 3206.9 | 14.22 | 0.002 |

| NP | 1 | 500 | 500.3 | 2.22 | 0.156 |

| P | 1 | 30,683 | 30,682.7 | 136.05 | 0.000 |

| Q | 1 | 9956 | 9956.3 | 44.15 | 0.000 |

| 2-Way Interactions | 3 | 108,090 | 36,029.9 | 159.77 | 0.000 |

| FT*NP | 1 | 13,564 | 13,563.7 | 60.14 | 0.000 |

| FT*P | 1 | 16,362 | 16,362.0 | 72.55 | 0.000 |

| FT*Q | 1 | 78,164 | 78,164.0 | 346.60 | 0.000 |

| Error | 16 | 3608 | 225.5 | ||

| Total | 23 | 156,044 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duc, T.M.; Long, T.T.; Tuan, N.M. Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling. Fluids 2021, 6, 248. https://doi.org/10.3390/fluids6070248

Duc TM, Long TT, Tuan NM. Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling. Fluids. 2021; 6(7):248. https://doi.org/10.3390/fluids6070248

Chicago/Turabian StyleDuc, Tran Minh, Tran The Long, and Ngo Minh Tuan. 2021. "Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling" Fluids 6, no. 7: 248. https://doi.org/10.3390/fluids6070248

APA StyleDuc, T. M., Long, T. T., & Tuan, N. M. (2021). Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling. Fluids, 6(7), 248. https://doi.org/10.3390/fluids6070248