Effects of Loading Rate on the Relaxation and Recovery Ability of an Epoxy-Based Shape Memory Polymer

Abstract

:1. Introduction

2. Material and Testing Methods

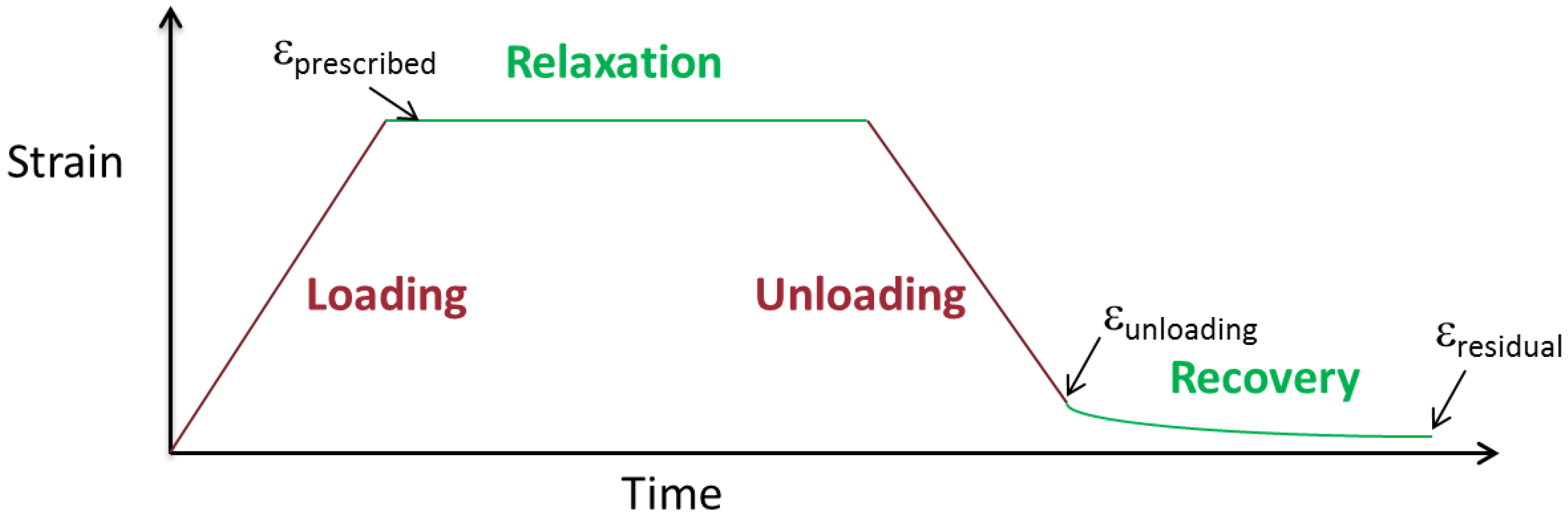

3. Quantification of Shape Memory Behavior

4. Experimental Observations

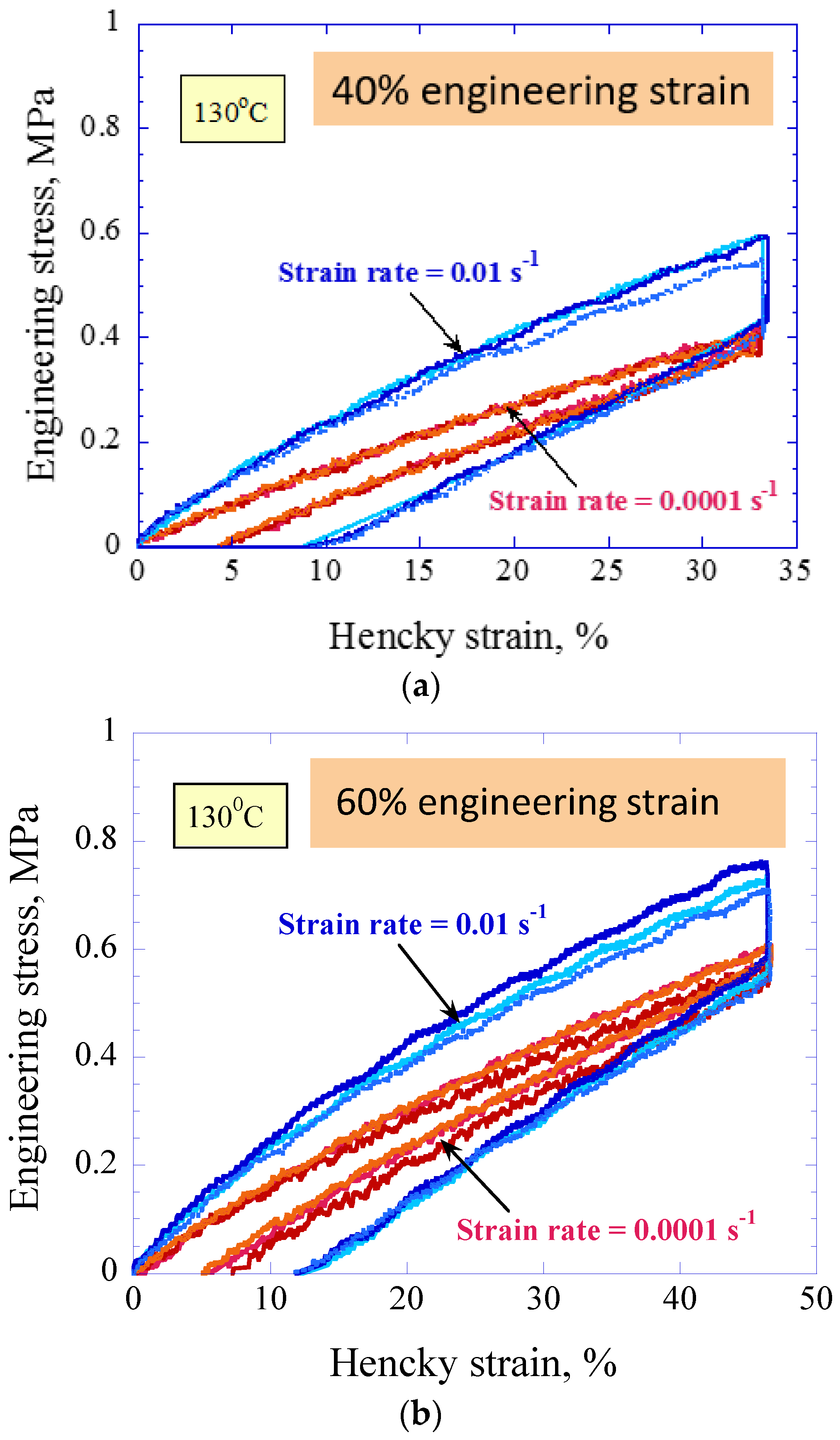

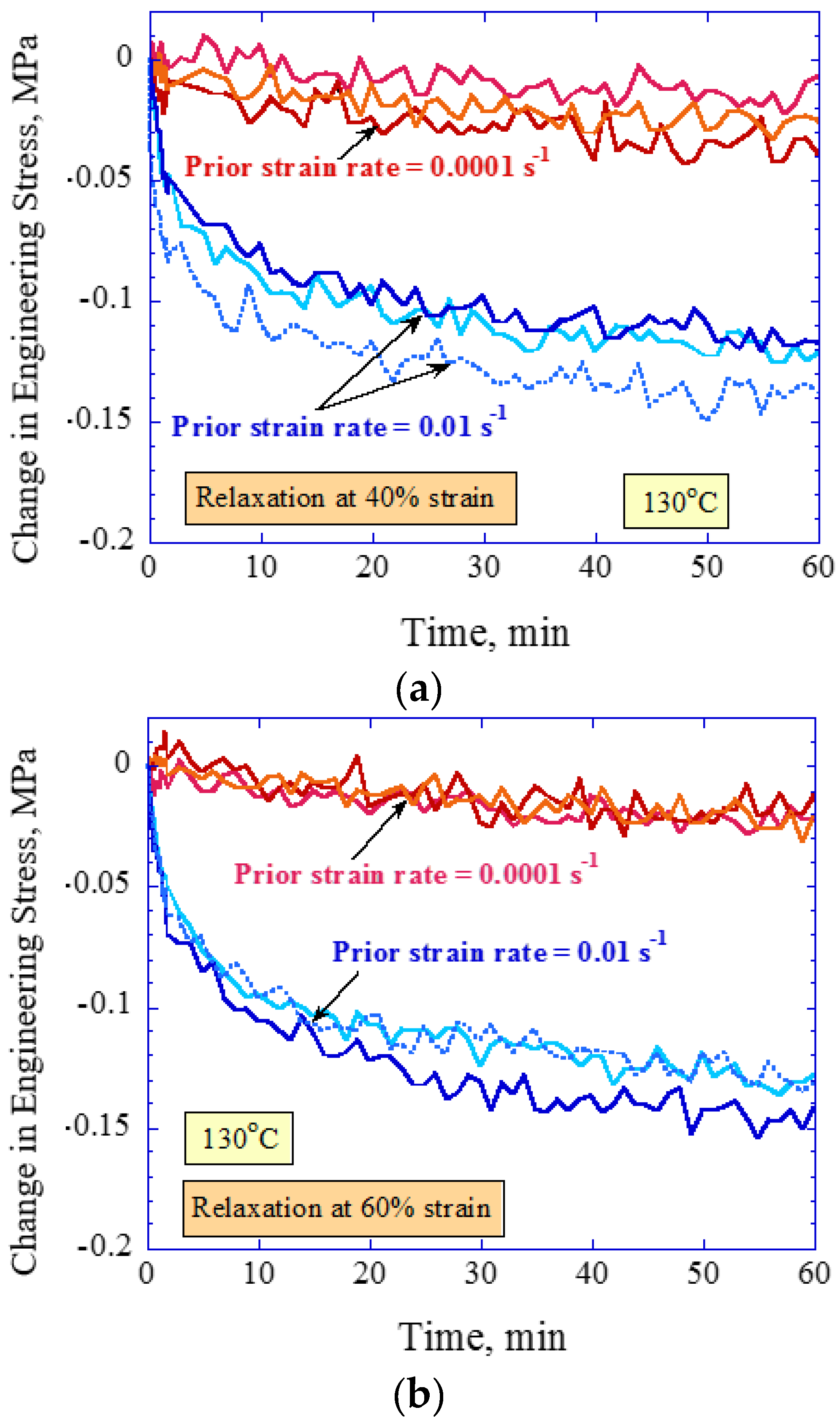

4.1. “Rubbery” Loading and Unloading with Periods of Relaxation

4.2. “Rubbery” Recovery Following Relaxation and Unloading

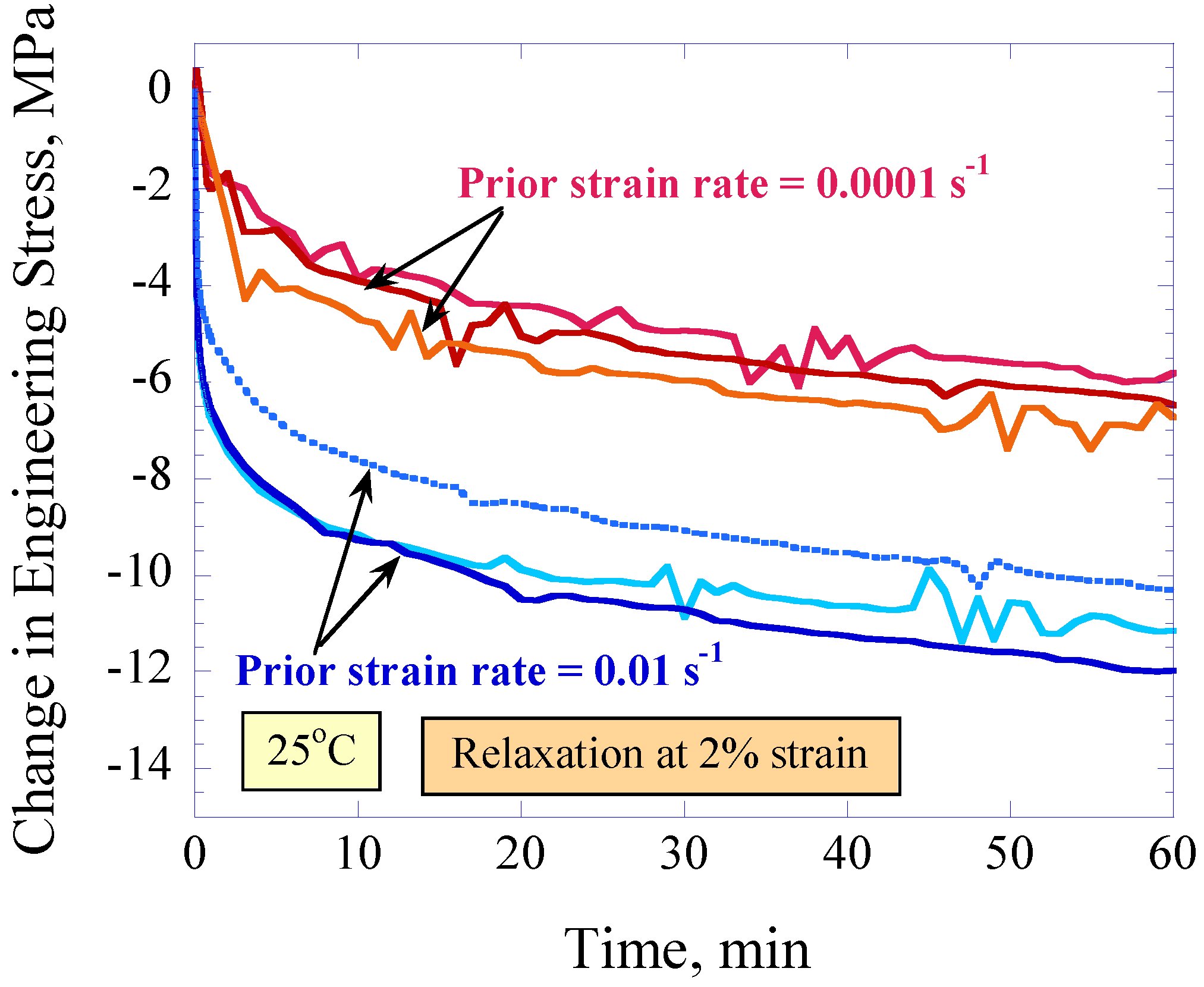

4.3. “Glassy” Loading and Unloading with Periods of Relaxation

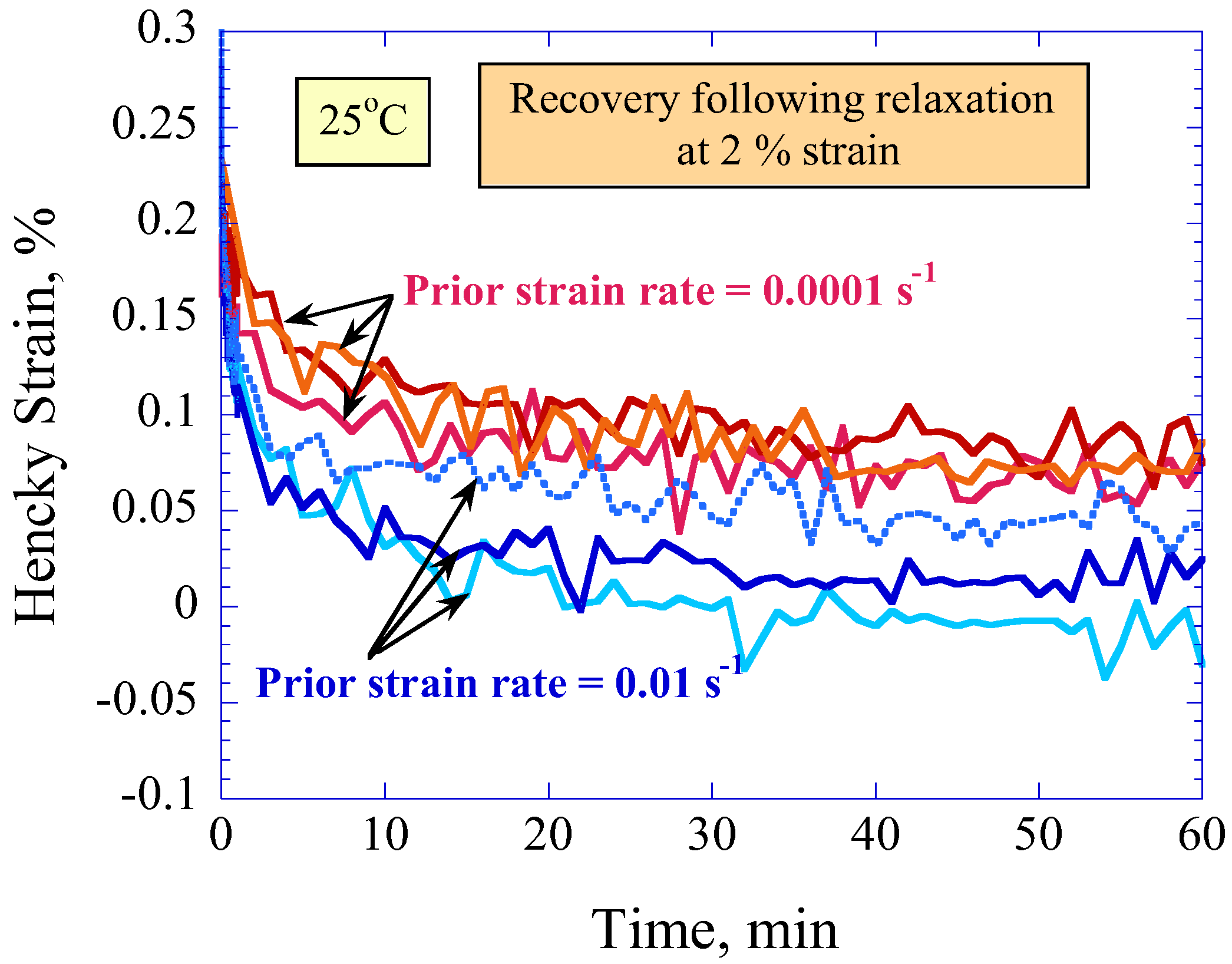

4.4. “Glassy” Recovery Following Relaxation and Unloading

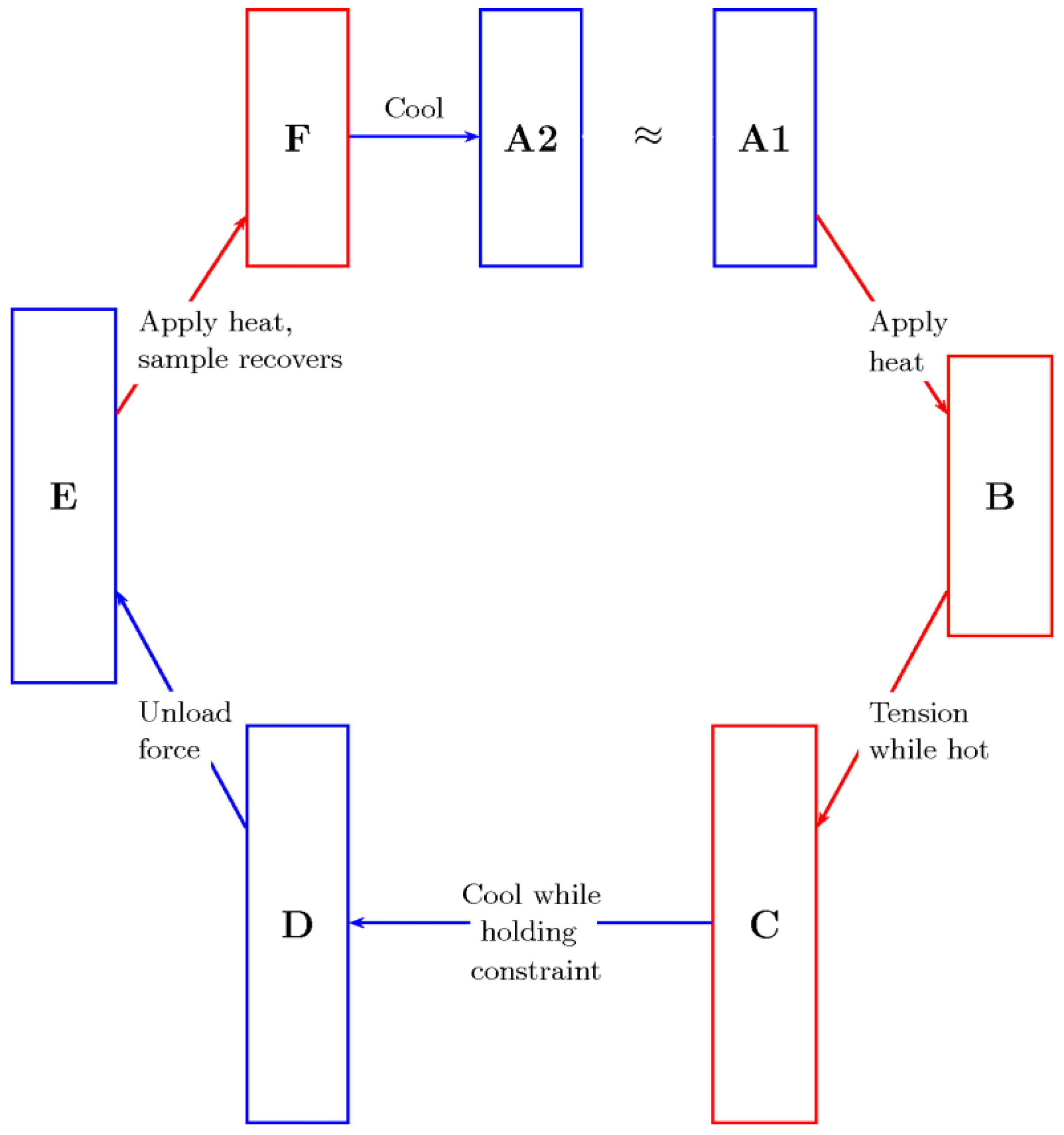

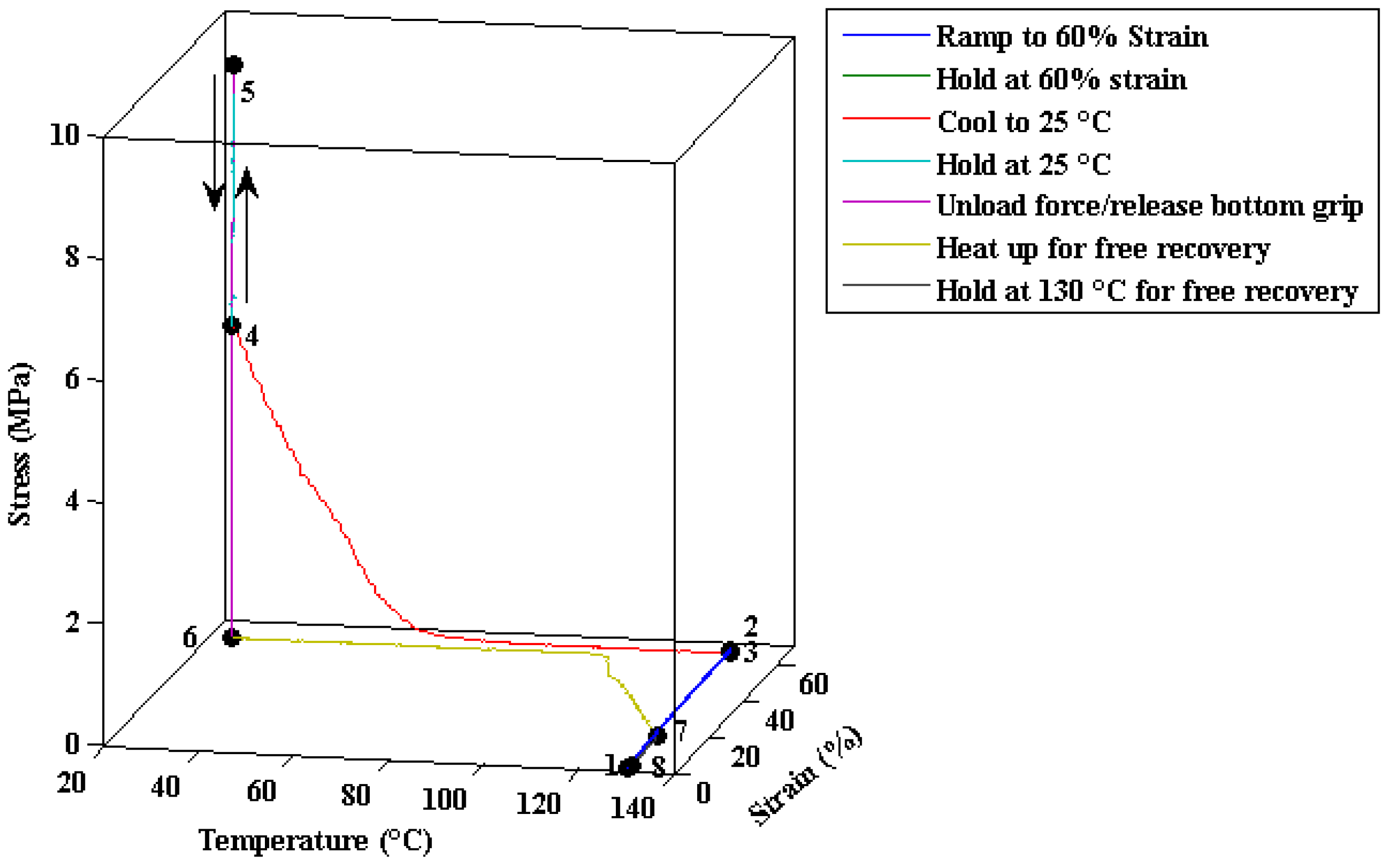

4.5. Loading and Unloading with Periods of Cooling during Relaxation (Shape Memory Cycles)

4.6. Recovery During Shape Memory Cycle

5. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shakinpoor, M.; Schneider, H.J. (Eds.) Intelligent Materials; RSC Publishing: Cambridge, UK, 2008. [Google Scholar]

- Tandon, G.P.; McClung, A.J.W.; Baur, J.W. Shape-Memory Polymers for Aerospace Applications: Novel Synthesis, Modeling, Characterization and Design; DEStech: Lancaster, PA, USA, 2016. [Google Scholar]

- Everhart, J.J.; Havens, D.E.; Hanson, S.F.; Priest, J.W.; Fiegenbaum, C.R.; Barnell, T.J. Reconfigurable Shape Memory Polymer Tooling Supports. U.S. Patent US8608890 B2, 17 December 2013. [Google Scholar]

- Bordonaro, C.M.; Krempl, E. Effects of strain rate on the deformation and relaxation behavior of 6/6 nylon at room temperature. Polym. Eng. Sci. 1992, 32, 1066–1072. [Google Scholar] [CrossRef]

- Kitagawa, M.; Matsutani, T. Effect of time and temperature on nonlinear constitutive equation in polypropylene. J. Mater. Sci. 1988, 23, 4085–4090. [Google Scholar] [CrossRef]

- Zhang, C.; Morre, I.D. Nonlinear mechanical response of high density polyethylene. Part I. Experimental investigation and model evaluation. Polym. Eng. Sci. 1997, 37, 404–413. [Google Scholar] [CrossRef]

- McClung, A.J.W.; Ruggles-Wrenn, M.B. The Rate (Time)-Dependent Mechanical Behavior of the PMR-15 Thermoset Polymer at Elevated Temperature. Polym. Test. 2008, 27, 908–914. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.; Balaconis, J. Some aspects of the mechanical response of BMI 5250-4 neat resin at 191 °C: Experiement and modeling. J. Appl. Polym. Sci. 2008, 107, 1378–1386. [Google Scholar] [CrossRef]

- Song, B.; Chen, W.; Chen, M. Novel model for unaxial strain-rate-dependent stress-strain behavior of ethylene-propylene-diene monomer rubber in compression or tension. J. Appl. Polym Sci. 2004, 92, 1553–1558. [Google Scholar] [CrossRef]

- Yi, J.; Boyce, M.; Lee, G.; Balizer, E. Large deformation rate-dependent stress-strain behavior of polyurea and polyurethanes. Polymer 2006, 47, 319–329. [Google Scholar]

- MTS Systems Corporation. 632.53 High-Temperature Axial Extensometer Data Sheet. 2013. Available online: http://www.mts.com/ucm/groups/public/documents/library/dev_003704.pdf (accessed on 9 September 2013).

- Atli, B.; Gandhi, G.; Karst, G. Thermomechanical characterization of shape memory polymers. J. Intell. Mater. Syst. Struct. 2009, 20, 87–95. [Google Scholar]

- Volk, B.L.; Lagoudas, D.C.; Chen, Y.C. Thermomechanical characterization of the nonlinear, rate dependent response of shape memory polymers. SPIE Proc. 2008, 6929. [Google Scholar] [CrossRef]

- Abrahamson, E.R.; Lake, M.S.; Munshi, N.A.; Gall, K. Shape memory mechanics of an elastic memory composite resin. J. Intell. Mater. Syst. Struct. 2003, 14, 623–632. [Google Scholar] [CrossRef]

- McKnight, G.; Doty, R.; Herrera, G.; Henry, C. Elastic Modulus and Strain recovery testing of variable stiffness composites for structural reconfiguration applications. SPIE Proc. 2007. [Google Scholar] [CrossRef]

- Beblo, R.; Gross, K.; Weiland, L.M. Mechanical and curing properties of a styrene-based shape memory polymer. J. Intell. Mater. Syst. Struct. 2010, 21, 677–683. [Google Scholar] [CrossRef]

- McClung, A.J.W.; Tandon, G.P.; Baur, J.B. Non-Contact Technique for Characterizing Full-Field Surface Deformation of Shape Memory Polymers at Elevated and Room Temperatures. Polym. Test. 2011, 30, 140–149. [Google Scholar] [CrossRef]

- McClung, A.J.W.; Tandon, G.P.; Baur, J.W. Strain Rate- and Temperature-Dependent Tensile Properties of an Epoxy-Based, Thermosetting, Shape Memory Polymer (Veriflex-E). Mech. Time-Depend. Mater. 2012, 16, 205–221. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Berlin, Germany, 2009. [Google Scholar]

- McClung, A.; Tandon, G.P.; Foster, D.C.; Baur, J. Influence of Post-cure and Repeated Cycling on Thermomechanical Characterization of Shape Memory Polymers and Composites. In Proceedings of the Society for the Advancement of Material and Process Engineering, Seattle, WA, USA, 17–20 May 2010. [Google Scholar]

- Sakai, T.; Tao, T.; Somiya, S. Estimation of creep and recovery behavior of a shape memory polymer. Mech. Time-Depend. Mater. 2015, 19, 569–5779. [Google Scholar] [CrossRef]

- McClung, A.J.W.; Tandon, G.P.; Baur, J.W. Deformation Rate-, Hold Time-, and Cycle-Dependent Shape Memory Performance of Veriflex-E Resin. Mech. Time-Depend. Mater. 2013, 17, 39–52. [Google Scholar]

- Lei, M.; Yu, K.; Lu, H.; Qi, H.J. Influence of structural relaxation on thermomechanical and shape memory performances of amorphous polymers. Polymer 2017, 109, 216–228. [Google Scholar] [CrossRef]

- Park, H.; Harrison, P.; Guo, Z.; Lee, M.G.; Yu, W.R. Three-dimensional constitutive model for shape memory polymers using multiplicative decomposition of the deformation gradient and shape memory strians. Mech. Mater. 2016, 93, 43–62. [Google Scholar] [CrossRef]

- Yu, K.; McClung, A.J.W.; Tandon, G.P.; Baur, J.W.; Qi, H.J. A thermomechanical constitutive model for an epoxy based shape memory polymer and its parameter identification. Mech. Time-Depend. Mater. 2014, 18, 453–474. [Google Scholar] [CrossRef]

- Yang, Q.; Li, G. Temperature and rate dependent thermomechanical modeling os shape memory polymers with physics based evolution law. Int. J. Plast. 2016, 80, 168–186. [Google Scholar] [CrossRef]

- Rogovoi, A.A.; Stolbova, O.S. Modeling Thermomechanical Processes in Shape Memory Polymers under Finite Deformations. J. Appl. Mech. Tech. Phys. 2015, 56, 1059–1070. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-Memory Polymers. Angew. Chem. Int. Ed. 2002, 41, 2035–2057. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of Progress in Shape-Memory Polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Meng, H.; Li, G. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49–50, 79. [Google Scholar] [CrossRef]

- Tobushi, H.; Hara, H.; Yamada, E.; Hayashi, S. Thermomechanical Properties in a Thin Film of Shape Memory Polymer of Polyurethane Series. Smart Mater. Struct. 1996, 5, 483–491. [Google Scholar] [CrossRef]

- Ohki, T.; Ni, Q.Q.; Ohsako, N.; Iwamoto, M. Mechanical and Shape Memory Behavior of Composites with Shape Memory Polymer. Compos. Part A 2004, 35, 1065–1073. [Google Scholar] [CrossRef]

- Feldkamp, D.M.; Rousseau, I.A. Effect of the Deformation Temperature on the Shape-Memory Behavior of Epoxy Networks. Macromol. Mater. Eng. 2010, 295, 726–734. [Google Scholar] [CrossRef]

- Rousseau, I.A.; Xie, T. Shape Memory Epoxy: Composition, Structure, Properties and Shape Memory Performances. J. Mater. Chem. 2010, 20, 3431–3441. [Google Scholar]

- Baer, G.; Wilson, T.S.; Matthews, D.L.; Maitland, D.J. Shape-Memory Behavior of Thermally Stimulated Polyurethane for Medical Applications. J. Appl. Polym. Sci. 2007, 103, 3882–3892. [Google Scholar] [CrossRef]

- Schmidt, C.; Neuking, K.; Eggeler, G. Functional Fatigue of Shape Memory Polymers. Adv. Eng. Mater. 2008, 10, 922–927. [Google Scholar] [CrossRef]

- Castro, F.; Westbrook, K.F.; Hermiller, J.; Ahn, D.U.; Ding, Y.; Qi, H.J. Time and Temperature Dependent Recovery of Epoxy-Based Shape Memory Polymers. J. Eng. Mater. Technol. 2011, 133, 2. [Google Scholar] [CrossRef]

- McClung, A.J.W.; Tandon, G.P.; Baur, J.W. Relaxation and Recovery Behavior of an Epoxy Based Shape Memory Polymer Resin; Society for Experimental Mechanics ( SEM ) Proceedings: Costa Mesa, CA, USA, 2012. [Google Scholar]

| Temperature (°C) | Rate (s−1) | Loading (MPa) | Unloading (MPa) | Relaxation Strain (%) | Unloading (MPa) | Relaxation Strain (%) |

|---|---|---|---|---|---|---|

| 130 | 0.01 | 2.28 ± 0.09 | 1.79 ± 0.05 | 40 | 1.61 ± 0.06 | 60 |

| 130 | 0.0001 | 1.52 ± 0.12 | 1.27 ± 0.04 | 40 | 1.32 ± 0.02 | 60 |

| 25 | 0.01 | 3420 ± 140 | 2940 ± 90 | 2 | ||

| 25 | 0.0001 | 2930 ± 50 | 2750 ± 100 | 2 |

| Temperature (°C) | Rate (s−1) | Relaxation Strain (%) | Change in Stress (MPa) |

|---|---|---|---|

| 130 | 0.01 | 40 | 0.12 ± 0.01 |

| 130 | 0.0001 | 40 | 0.03 ± 0.01 |

| 130 | 0.01 | 60 | 0.14 ± 0.01 |

| 130 | 0.0001 | 60 | 0.02 ± 0.01 |

| 25 | 0.01 | 2 | 11.2 ± 0.9 |

| 25 | 0.0001 | 2 | 6.35 ± 0.5 |

| Temperature (°C) | Rate (s−1) | εprescribed (%) | εunloading (%) | εresidual (%) | εresidual/εprescribed (%) |

|---|---|---|---|---|---|

| 25 | 0.0001 | 2 | 0.21 ± 0.02 | 0.08 ± 0.01 | 4.0 |

| 25 | 0.01 | 2 | 0.29 ± 0.02 | 0.03 ± 0.06 | 1.5 |

| 130 | 0.0001 | 40 | 4.31 ± 0.32 | 2.18 ± 0.61 | 5.45 |

| 130 | 0.01 | 40 | 8.85 ± 0.43 | 1.47 ± 0.51 | 3.68 |

| 130 | 0.0001 | 60 | 5.52 ± 0.40 | 3.80 ± 0.15 | 6.34 |

| 130 | 0.01 | 60 | 11.1 ± 0.28 | 1.62 ± 0.39 | 2.7 |

| State in Figure 2 | State in Figure 9 | Temperature | Force | Cross-Head Displacement | Strain |

|---|---|---|---|---|---|

| A1 to B | Heat at 2.5 °C/min from 25 °C to 130 °C | Hold at zero | |||

| B | Hold at 130 °C for 60 min | Hold at zero | |||

| B to C | 1 to 2 | Hold at 130 °C | Increase to 60% strain at 0.5 mm/min | ||

| C | 2 to 3 | Hold at 130 °C | Hold at 60% strain for 60 min | ||

| C to D | 3 to 4 | Cool at 2.5 °C/min from 130 °C to 25 °C | Hold at 60% strain | ||

| D | 4 to 5 | Hold at 25 °C for 60 min | Hold at 60% strain | ||

| 5 to 6 | Hold at 25 °C | Decrease at 50 mm/min until force in sample is zero | |||

| Unclamp bottom grip from sample | |||||

| D to E | 6 to 7 | Heat at 2.5 °C/min from 25 °C to 130 °C | No force applied, only top of sample is gripped | ||

| E | 7 to 8 | Hold at 130 °C for 60 min | No force applied, only top of sample is gripped | ||

| E to F | Cool at 2.5 °C/min from 130 °C to 25 °C | No force applied, only top of sample is gripped | |||

| F | Hold at 25 °C for 60 min | No force applied, only top of sample is gripped | |||

| Test Conditions | Temperature (°C) | εf (%) | Rr,tot (%) |

|---|---|---|---|

| Following Stress Relaxation | 130 | 1.220928 | 97.97 |

| Following Stress Relaxation | 25 | 0.013124 | 99.34 |

| Following SMC | 0.049861 | 99.92 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McClung, A.J.W.; Tandon, G.P.; Baur, J.W. Effects of Loading Rate on the Relaxation and Recovery Ability of an Epoxy-Based Shape Memory Polymer. Fluids 2017, 2, 13. https://doi.org/10.3390/fluids2020013

McClung AJW, Tandon GP, Baur JW. Effects of Loading Rate on the Relaxation and Recovery Ability of an Epoxy-Based Shape Memory Polymer. Fluids. 2017; 2(2):13. https://doi.org/10.3390/fluids2020013

Chicago/Turabian StyleMcClung, Amber J.W., Gyaneshwar P. Tandon, and Jeffery W. Baur. 2017. "Effects of Loading Rate on the Relaxation and Recovery Ability of an Epoxy-Based Shape Memory Polymer" Fluids 2, no. 2: 13. https://doi.org/10.3390/fluids2020013