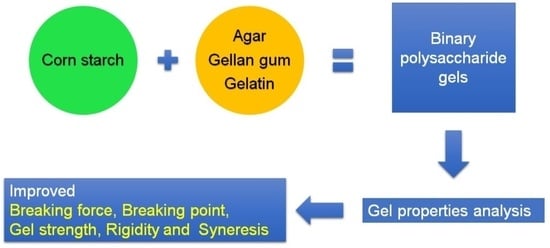

The Effect of Hydrocolloids on Penetration Tests and Syneresis of Binary Gum Gels and Modified Corn Starch–Gum Gels

Abstract

:1. Introduction

2. Results and Discussion

2.1. Measurement of Textural Properties and % Syneresis of Mixed Gels

2.2. Textural Properties and Syneresis Percentage of Combined Use of Modified Corn Starch and Gum Gels

3. Conclusions

4. Materials and Methods

4.1. Raw Materials

4.2. Preparation of Hydrocolloid Gels

4.3. Measurement of Textural Properties

- Gel strength (g × mm) = breaking force (g) × breaking point (mm)

- Rigidity (g/mm) = breaking force (g)/breaking point (mm)

4.4. Evaluation of Syneresis

4.5. Statistical Analysis

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmood, K.; Kamilah, H.; Shang, P.L.; Sulaiman, S.; Ariffin, F.; Alias, A.K. A review: Interaction of starchy non-starch hydrocolloid blending and the recent food applications. Food Biosci. 2017, 19, 110–120. [Google Scholar]

- Fonkwe, L.; Narsimhan, G.; Cha, A.S. Characterization of gelation time and texture of gelatin and gelatin-polysaccharide mixed gels. Food Hydrocoll. 2003, 17, 871–883. [Google Scholar] [CrossRef]

- Walayat, N.; Liu, J.; Nawaz, A.; Aadil, R.M.; Lopez-Pedrouso, M.; Lorenzo, J.M. Role of Food hydrocolloids as antioxidants along with modern processing techniques on the surimi protein gel textural properties. Antioxidants 2022, 11, 486. [Google Scholar] [CrossRef]

- Zasypkin, D.V.; Dumay, E.; Cheftel, J.C. Pressure- and heat- induced gelation of mixed β-lactoglobulin/xanthan solutions. Food Hydrocoll. 1996, 10, 203–211. [Google Scholar] [CrossRef]

- Sworn, G.; Stouby, L. Gellan gum. In Hook of Hydrocolloids, 3rd ed.; Phillips, G.O., Williams, P.A., Eds.; Elsevier: Cambridge, MA, USA, 2021; pp. 855–885. [Google Scholar]

- Chandrasekaran, R.; Radha, A. Molecular architectures and functional properties of gellan gum and related polysaccharides. Trends Food Sci. Technol. 1995, 6, 143–148. [Google Scholar] [CrossRef]

- Li, A.; Gong, T.; Li, X.; Guo, Y. Preparation of thermally stable emulsion gels based on glucono-δ-lactone induced gelation of gellan gum. Int. J. Bio. Macromol. 2020, 156, 565–575. [Google Scholar] [CrossRef]

- Sanderson, G.R.; Bell, V.L.; Clark, R.C.; Ortega, D. The texture of gellan gum. In Gums and Stabilizers for the Food Industry 4; Phillips, G.O., William, P.A., Wedlock, D.J., Eds.; IRL Press: Ithaca, NY, USA; Oxford University: Oxford, UK, 1988; pp. 219–229. [Google Scholar]

- Ge, H.; Wu, Y.; Woshnak, L.L.; Mitmesser, S.H. Effects of hydrocolloids, acids and nutrients on gelatin network in gummies. Food Hydrocoll. 2021, 113, 106549. [Google Scholar] [CrossRef]

- Morris, V.J. Starch gelation and retrogradation. Trends Food Sci. Technol. 1990, 1, 2–6. [Google Scholar] [CrossRef]

- Oakenfull, D.; Pearce, J.; Burley, R.W. Protein gelation. In Food Protein and Their Applications; Damodaran, S., Paraf, A., Eds.; Marcel Dekker: New York, NY, USA, 1997; pp. 111–142. [Google Scholar]

- Qin, Y. Seaweed hydrocolloids as thickening, gelling, and emulsifying agents in functional food products. In Bioactive Seaweeds for Food Applications; Academic Press: London, UK, 2018; pp. 135–152. [Google Scholar]

- Stanley, N.F. Agars. In Food Polysaccharides and Their Application; Stephen, A.M., Ed.; Marcel Dekker: New York, NY, USA, 1995; pp. 187–204. [Google Scholar]

- Harris, P. Food Gels; Elsevier: New York, NY, USA, 1990. [Google Scholar]

- Labropoulos, K.C.; Niesz, D.E.; Danforth, S.C.; Kevrekidis, P.G. Dynamic rheology of agar gels: Theory and experiments. Part I. Development of a rheological model. Carbohydr Polym. 2002, 50, 393–406. [Google Scholar] [CrossRef]

- Ross, K.A.; Pyrak-Nolte, L.J.; Campanella, O.H. The effect of mixing conditions on the material properties of an agar gel-microstructural and macrostructural considerations. Food Hydrocoll. 2006, 20, 79–87. [Google Scholar] [CrossRef]

- Ikeda, S.; Nitta, Y.; Kim, B.S.; Temsiripong, T.; Pongsawatmanit, P.; Nishinari, K. Single-phase mixed gels of xyloglucan and gellan. Food Hydrocoll. 2004, 18, 669–675. [Google Scholar] [CrossRef]

- Tolstoguzov, V.B. Some physico-chemical aspects of protein processing in foods. Multicomponent gels. Food Hydrocoll. 1995, 9, 317–332. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, paste, and gel properties of starch-hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Kim, H.S.; BeMiller, J.N. Effects of hydrocolloids on the pasting and paste properties of commercial pea starch. Carbohydr. Polym. 2012, 88, 1164–1171. [Google Scholar] [CrossRef]

- Shi, X.; BeMiller, J.N. Effects of food gum and viscosities of starch suspension during pasting. Carbohydr. Polym. 2002, 50, 7–18. [Google Scholar] [CrossRef]

- Sodini, I.; Remeuf, F.; Haddad, S.; Corrieu, G. The relative effect of milk base, starter, and process on yogurt texture: A review. Crit. Rev. Food Sci. Nutr. 2004, 44, 113–137. [Google Scholar] [CrossRef]

- Sudhakar, V.; Singhal, R.S.; Kulkarni, P.R. Effect of sucrose on starch-hydrocolloid interactions. Food Chem. 1995, 52, 281–284. [Google Scholar] [CrossRef]

- Lal, S.N.D.; O’Connor, C.J.; Eyres, L. Application of emulsifiers in dairy products of high rheology. Adv. Colloid Interface Sci. 2006, 123–126, 433–437. [Google Scholar] [CrossRef]

- Supavititpatana, P.; Wirjantoro, T.I.; Apichartsrangkoon, A.; Raviyan, P. Addition of gelatin enhanced gelation of corn-milk yogurt. Food Chem. 2008, 106, 211–216. [Google Scholar] [CrossRef]

- Karim, A.A.; Norziah, M.H.; Seow, C.C. Methods for the study of starch retrogradation. Food Chem. 2000, 7, 9–36. [Google Scholar] [CrossRef]

- Schrieber, R.; Gareis, H. Gelatine Handbook; Wiley-VCH GmbH & Co.: Weinhem, Germany, 2007. [Google Scholar]

- Papageorgiou, M.; Kasapis, S.; Richardson, R.K. Steric exclusion phenomena in gellan/gelatin systems I. Physical properties of single and binary gels. Food Hydrocoll. 1994, 8, 97–112. [Google Scholar] [CrossRef]

- Mao, R.; Tang, J.; Swanson, B.G. Texture properties of high and low acyl mixed gellan gels. Carbohydr. Polym. 2000, 41, 331–338. [Google Scholar] [CrossRef]

- Tang, Q.; McCarthy, O.J.; Munro, P.A. Effect of pH on whey protein concentrate gel properties: Comparisons between small deformation (Dynamic) and large deformation (Failure) testing. J. Texture Stud. 1995, 26, 255–272. [Google Scholar] [CrossRef]

- Lee, M.H.; Baek, M.H.; Cha, D.S.; Park, H.J.; Lim, S.T. Freeze-thaw stabilization of sweet potato starch gel by polysaccharide gums. Food Hydrocoll. 2002, 16, 345–352. [Google Scholar] [CrossRef]

- Morrison, N.A.; Clark, R.C.; Chen, Y.L.; Talashek, T.; Sworn, G. Gelatin alternatives for the food industry. In Physical Chemistry and Industrial Application of Gellan Gum; Nishinari, K., Kremer, F., Lagaly, G., Eds.; Springer-Verlag: Heidelberg, Germany, 1999; pp. 127–131. [Google Scholar]

- Saartratra, S.; Puttanlekb, C.; Rungsardthong, V.; Uttapap, D. Paste and gel properties of low-substituted acetylated canna starches. Carbohydr. Polym. 2005, 61, 211–221. [Google Scholar] [CrossRef]

- Mali, H.; Ferrero, C.; Redigonda, V.; Beleia, A.P.; Grossmann, M.V.E.; Zaritzky, N.E. Influence of pH and hydrocolloids addition on yam (Dioscorea alata) starch pastes stability. LWT Food Sci. Technol. 2003, 36, 475–481. [Google Scholar] [CrossRef]

- Ferrero, C.; Martino, M.N.; Zaritzky, N.E. Corn starch-xanthan gum interaction and its effect on the stability during storage of frozen gelatinized suspensions. Starch/Starke 1994, 46, 300–308. [Google Scholar] [CrossRef]

- Charoenrein, S.; Tatirat, O.; Rengsutthi, K.; Thongngam, M. Effect of konjac glucomannan on syneresis, textural properties and the microstructure of frozen rice starch gels. Carbohydr. Polym. 2011, 83, 291–296. [Google Scholar] [CrossRef]

- Muadklay, J.; Charenrein, S. Effects of hydrocolloids and freezing rates on freeze-thaw stability of tapioca starch gels. Food Hydrocoll. 2008, 22, 1268–1272. [Google Scholar] [CrossRef]

- Weber, F.H.; Queiroz, F.P.C.; Chang, Y.K. Freeze-thaw stability of normal, waxy and high amylase corn starch gels with added guar and xanthan gums. Food Sci. Technol. 2008, 28, 413–417. [Google Scholar] [CrossRef] [Green Version]

- Charoenrein, S.; Tatirat, O.; Muadklay, J. Use of centrifugation-filtration fordetermination of syneresis in freeze-thaw starch gels. Carbohydr. Polym. 2008, 73, 143–147. [Google Scholar] [CrossRef]

| Breaking Force | Breaking Point | Gel Strength | Rigidity | |

|---|---|---|---|---|

| (g) | (mm) | (g × mm) | (g/mm) | |

| Gelatin/Agar ratios | ||||

| 0/0.5 | 67.1 ± 2.5 f | 2.84 ± 0.08 a | 191 ± 6 f | 23.71 ± 1.50 f |

| 0.1/0.4 | 50.1 ± 1.9 e | 3.21 ± 0.06 b | 161 ± 5 e | 15.62 ± 0.81 e |

| 0.2/0.3 | 40.3 ± 0.8 d | 3.87 ± 0.15 c | 156 ± 4 d | 10.42 ± 0.62 d |

| 0.3/0.2 | 31.1 ± 1.4 c | 4.69 ± 0.28 d | 146 ± 5 c | 6.75 ± 0.62 c |

| 0.4/0.1 | 19.7 ± 0.8 b | 5.34 ± 0.06 e | 105 ± 3 b | 3.73 ± 0.26 b |

| Gelatin/Gellan gum ratios | ||||

| 0.1/0.4 | 9.6 ± 0.3 e | 9.36 ± 0.48 e | 90 ± 3 e | 1.04 ±0.08 a |

| 0.2/0.3 | 9.2 ± 0.2 d | 8.75 ± 0.26 d | 80 ± 2 d | 1.06 ±0.06 a |

| 0.3/0.2 | 8.8 ± 0.2 c | 8.23 ± 0.16 c | 72 ± 2 c | 1.07 ± 0.05 a |

| 0.4/0.1 | 8.2 ± 0.1 b | 7.25 ± 0.28 b | 60 ± 2 b | 1.14 ± 0.04 b |

| 0.5/0 | 7.3 ± 0.3 a | 6.10 ± 0.20 a | 44 ± 2 a | 1.20 ± 0.05 b |

| Agar/Gellan gum ratios | ||||

| 0/0.5 | 10.2 ± 0.4 a | 10.2 ± 0.3 c | 103 ± 4 a | 1.00 ± 0.06 a |

| 0.1/0.4 | 14.0 ± 0.7 b | 8.37 ± 0.35 a | 117 ± 2 b | 1.68 ± 0.15 b |

| 0.2/0.3 | 15.3 ± 0.4 c | 8.43 ± 0.08 a | 129 ± 3 c | 1.81 ± 0.06 c |

| 0.3/0.2 | 16.1 ± 0.6 d | 8.52 ± 0.26 a | 137 ± 4 d | 1.89 ± 0.11 cd |

| 0.4/0.1 | 18.0 ± 0.3 e | 9.32 ± 0.26 b | 168 ± 4 e | 1.94 ± 0.08 d |

| Breaking Force | Breaking Point | Gel Strength | Rigidity | |

|---|---|---|---|---|

| (g) | (mm) | (g × mm) | (g/mm) | |

| Modified corn starch/Gellan gum ratios | ||||

| 0/0.5 | 10.2 ± 0.4 e | 10.20 ± 0.3 d | 103 ± 4 e | 1.00 ± 0.06 d |

| 0.1/0.4 | 9.3 ± 0.2 d | 9.42 ± 0.21 c | 87 ± 3 d | 0.99 ± 0.04 d |

| 0.2/0.3 | 8.7 ± 0.2 c | 9.37 ± 0.23 c | 82 ± 3 c | 0.94 ± 0.02 c |

| 0.3/0.2 | 7.7 ± 0.2 b | 8.83 ± 0.20 b | 68 ± 2 b | 0.88 ± 0.04 b |

| 0.4/0.1 | 6.1 ± 0.2 a | 7.45 ± 0.21 a | 46 ± 2 a | 0.83 ± 0.03 a |

| Modified corn starch/Agar ratios | ||||

| 0/0.5 | 67.1 ± 2.5 f | 2.84 ± 0.08 e | 191 ± 6 e | 23.71 ± 1.50 d |

| 0.1/0.4 | 58.1 ± 1.7 d | 2.54 ± 0.06 d | 147 ± 5 d | 22.91 ± 0.92 c |

| 0.2/0.3 | 49.3 ± 1.2 c | 2.12 ± 0.07 c | 104 ± 5 c | 23.20 ± 0.82 c |

| 0.3/0.2 | 40.1 ± 0.8 b | 1.88 ± 0.06 b | 75 ± 3 b | 21.45 ± 0.81 b |

| 0.4/0.1 | 29.4 ± 1.0 a | 1.49 ± 0.02 a | 43 ± 2 a | 19.70 ± 0.50 a |

| Modified corn starch/Gelatin ratios | ||||

| 0/0.5 | 7.3 ± 0.3 b | 6.10 ± 0.20 b | 44 ± 2 b | 1.20 ± 0.05 c |

| 0.1/0.4 | 7.3 ± 0.2 b | 6.35 ± 0.21 b | 46 ± 2 b | 1.16 ± 0.01 b |

| 0.2/0.3 | 7.2 ± 0.2 b | 6.23 ± 0.23 b | 45 ± 1 b | 1.16 ± 0.08 b |

| 0.3/0.2 | 6.4 ± 0.1 a | 5.97 ± 0.10 a | 38 ± 1 a | 1.08 ± 0.03 a |

| 0.4/0.1 | 6.2 ± 0.2 a | 5.93 ± 0.12 a | 37 ± 2 a | 1.06 ± 0.03 a |

| Composite Gels | Modified Corn Starch | Gelatin | Agar | Gellan |

|---|---|---|---|---|

| (% w/w) | (% w/w) | (% w/w) | (% w/w) | |

| Gelatin/agar | 0 | 0.5 | ||

| 0.1 | 0.4 | |||

| 0.2 | 0.3 | |||

| 0.3 | 0.2 | |||

| 0.4 | 0.1 | |||

| Gelatin/gellan | 0.1 | 0.4 | ||

| 0.2 | 0.3 | |||

| 0.3 | 0.2 | |||

| 0.4 | 0.1 | |||

| 0.5 | 0 | |||

| Agar/gellan | 0 | 0.5 | ||

| 0.1 | 0.4 | |||

| 0.2 | 0.3 | |||

| 0.3 | 0.2 | |||

| 0.4 | 0.1 | |||

| Modified corn starch/gellan | 0.1 | 0.4 | ||

| 0.2 | 0.3 | |||

| 0.3 | 0.2 | |||

| 0.4 | 0.1 | |||

| Modified corn starch/agar | 0.1 | 0.4 | ||

| 0.2 | 0.3 | |||

| 0.3 | 0.2 | |||

| 0.4 | 0.1 | |||

| Modified corn starch/gelatin | 0.1 | 0.4 | ||

| 0.2 | 0.3 | |||

| 0.3 | 0.2 | |||

| 0.4 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.-T.V.; Tsai, J.-S.; Liao, H.-H.; Sung, W.-C. The Effect of Hydrocolloids on Penetration Tests and Syneresis of Binary Gum Gels and Modified Corn Starch–Gum Gels. Gels 2023, 9, 605. https://doi.org/10.3390/gels9080605

Lin H-TV, Tsai J-S, Liao H-H, Sung W-C. The Effect of Hydrocolloids on Penetration Tests and Syneresis of Binary Gum Gels and Modified Corn Starch–Gum Gels. Gels. 2023; 9(8):605. https://doi.org/10.3390/gels9080605

Chicago/Turabian StyleLin, Hong-Ting Victor, Jenn-Shou Tsai, Hsiao-Hui Liao, and Wen-Chieh Sung. 2023. "The Effect of Hydrocolloids on Penetration Tests and Syneresis of Binary Gum Gels and Modified Corn Starch–Gum Gels" Gels 9, no. 8: 605. https://doi.org/10.3390/gels9080605