Quantitative CPP Evaluation from Risk Assessment Using Integrated Process Modeling

Abstract

:1. Introduction

- Multiplication of ordinal scaled valuesOrdinal data tells us the ranking of a property, but only relative to each other. Therefore, from a mathematical point of view, a multiplication of different ordinal scales values is not correct [7].

- Gaps within the scale

- RPNs with the same scores but derived differentlyThe S, O, and D factors always have different weights to their purpose and should not be considered as equally weighted. An assessment where S = 2, O = 7, and D = 4 results in an RPN value of 56. An equal RPN number can be generated by an assessment of S = 7, O = 4, and D = 2. Even though the RPN number is identical in both cases, the impact onto the CQA might be different due to its different factor estimation [11,12].

- Big influence by small changesSmall changes in one of the factors result in a significant shift in the final RPN. This shift also depends on the multiplication nature of the RPN calculation, which may be avoided for risk evaluation [13].

2. Materials and Methods

- Fulfill an FMEA (Section 2.1). As a simulation basis, an RA should be performed for each unit operation with respect to each CQA within the process.

- Estimate critical loss of CQA (or critical delta of CQA) per unit operation (Section 2.2). The critical loss of CQA resulting in OOS for each unit operation needs to be defined.

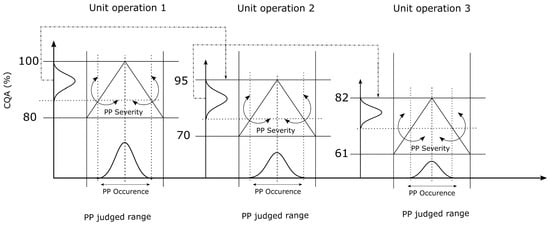

- Interpretation of S assessment (Section 2.3). We assume that the setpoint of the PP is chosen as the best operational condition. It is also assumed that deviating from the operation setpoint correlates with impact on the CQA. The S value describes the size of the effect affecting the OOS, and high S values indicate a higher contribution to a loss in OOS when deviating from the process setpoint. This assumption mainly considers the main effects of the PP.

- Interpretation of O assessment (Section 2.4). We assume the process expert evaluates the change of each PP within the judged range. A low O value means that the operation condition is distributed closely around the setpoint. A high O will result in a broader distribution around the setpoint.

- Use the output of the previous unit operation as input for the following one (Section 2.5). We assume that the starting data input for each unit operation is the output of the previous one [23]. The unit operation and its PP are connected based on the assumed process format.

2.1. Format of Risk Assessment

2.2. Critical Delta CQA

2.3. Severity Linearization

2.4. Occurrence Assumption

2.5. Integrated Process Modeling (IPM)

- The mean of the output distribution of the previous unit operation is used as the starting point of the next unit operation.

- CQA acceptance criteria is used as a lower boundary of the respective unit operation.

- The severity of each PP indicates the slope of the CQA decreasing effect (see Section 2.3).

- The occurrence of each PP results in the distribution within the PP’s judged range where the value is randomly estimated (see Section 2.4).

2.6. Case Study

2.7. Software

3. Results

3.1. In-Silico Simulation

3.2. Case Study

3.2.1. Yield Simulation

3.2.2. HCP Simulation

4. Discussion

4.1. CPP Assessment

4.1.1. Assessment Interpretation

- Using historical process data

- In the case of a new process, conducting one setpoint process and use the occurred CQA value as a reference value to estimate the specifications for CQA at DS

- Use literature data or pharmacopeia to set the specification limits for CQA at DS

- get a more profound process understanding

- identify the weighting of S and O to each CQA

- identify potentially critical PP based on a rational decision-making tool.

4.1.2. Integration of Factor D (Detectability)

4.2. Comparing RPN vs. IPM Approach

4.2.1. Multiplication of Ordinal Scaled Values

4.2.2. Gaps within the RPN Scale

4.2.3. Different Meaning Although RPN is Equal

4.2.4. Big Influence by Small Changes

4.2.5. All Assessed Factors are Weighted Equally

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guideline, I.H.T. Development and Manufacture of Drug Substances (Chemical Entities and Biotechnological/Biological Entities) Q11; European Medicines Agency: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Guideline, I.H.T. ICH Pharmaceutical Development Q8 (R2); European Medicines Agency: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Guideline, I.H.T. Quality Risk Management Q9; European Medicines Agency: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Zalai, D.; Dietzsch, C.; Herwig, C. Risk-based Process Development of Biosimilars as Part of the Quality by Design Paradigm. PDA J. Pharm. Sci. Technol. 2013, 67, 569–580. [Google Scholar] [CrossRef] [PubMed]

- Rathore, A.S. Roadmap for implementation of Quality by Design (QbD) for Biotechnology Products. Trends Biotechnol. 2009, 27, 546–553. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.K.K.; Dasgupta, D. Quality by Design approach to protein PEGylation: A review. J. Appl. Biol. 2017, 5, 58–89. [Google Scholar]

- Bowles, J.B. An assessment of RPN prioritization in a failure modes effects and criticality analysis. In Proceedings of the IEEE Reliability and Maintainability Symposium, Piscataway, NJ, USA, 27–30 January 2003; pp. 380–386. [Google Scholar]

- Braband, J. Definition and analysis of a new risk priority number concept. In Probabilistic Safety Assessment and Management; Spitzer, C., Schmocker, U., Dang, V.N., Eds.; Springer: London, UK, 2004; pp. 2006–2011. ISBN 978-1-4471-1057-6. [Google Scholar]

- Franceschini, F.; Galetto, M. A new approach for evaluation of risk priorities of failure modes in FMEA. Int. J. Prod. Res. 2001, 39, 2991–3002. [Google Scholar] [CrossRef] [Green Version]

- Zammori, F.; Gabbrielli, R. ANP/RPN: A multi criteria evaluation of the Risk Priority Number. Qual. Reliab. Eng. Int. 2012, 28, 85–104. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liou, J.J.H. A novel multiple-criteria decision-making-based FMEA model for risk assessment. Appl. Soft Comput. 2018, 73, 684–696. [Google Scholar] [CrossRef]

- Chang, K.-H.; Chang, Y.-C.; Tsai, I.-T. Enhancing FMEA assessment by integrating grey relational analysis and the decision making trial and evaluation laboratory approach. Eng. Fail. Anal. 2013, 31, 211–224. [Google Scholar] [CrossRef]

- Liu, H.-C.; Liu, L.; Liu, N. Risk evaluation approaches in failure mode and effects analysis: A literature review. Expert. Syst. Appl. 2013, 40, 828–838. [Google Scholar] [CrossRef]

- Sharma, K.D.; Srivastava, S. Failure Mode and Effect Analysis (FMEA) Implementation: A Literature Review. J. Adv. Res. Aeronaut. Space Sci. 2018, 5, 1–17. [Google Scholar]

- Liu, H.-C.; You, J.-X.; You, X.-Y.; Shan, M.-M. A novel approach for failure mode and effects analysis using combination weighting and fuzzy VIKOR method. Appl. Soft Comput. 2015, 28, 579–588. [Google Scholar] [CrossRef]

- Liu, H.-C.; You, J.-X.; Ding, X.-F.; Su, Q. Improving risk evaluation in FMEA with a hybrid multiple criteria decision making method. Int. J. Qual. Reliab. Manag. 2015, 32, 763–782. [Google Scholar] [CrossRef]

- Shahin, A. Integration of FMEA and the Kano model: An exploratory examination. Int. J. Qual. Reliab. Manag. 2004, 21, 731–746. [Google Scholar] [CrossRef]

- Zhou, Q.; Thai, V.V. Fuzzy and grey theories in failure mode and effect analysis for tanker equipment failure prediction. Saf. Sci. 2016, 83, 74–79. [Google Scholar] [CrossRef]

- Sharma, R.K.; Kumar, D.; Kumar, P. Modeling system behavior for risk and reliability analysis using KBARM. Qual. Reliab. Eng. Int. 2007, 23, 973–998. [Google Scholar] [CrossRef]

- Braglia, M.; Frosolini, M.; Montanari, R. Fuzzy TOPSIS approach for failure mode effects and criticality analysis. Qual. Reliab. Eng. Int. 2003, 19, 425–443. [Google Scholar] [CrossRef]

- Liu, H.-C.; Wang, L.-E.; Li, Z.; Hu, Y.-P. Improving Risk Evaluation in FMEA With Cloud Model and Hierarchical TOPSIS Method. IEEE Trans. Fuzzy Syst. 2019, 27, 84–95. [Google Scholar] [CrossRef]

- Bonate, P.L. A brief introduction to Monte Carlo simulation. Clin. Pharmacokinet. 2001, 40, 15–22. [Google Scholar] [CrossRef]

- Zahel, T.; Hauer, S.; Mueller, E.M.; Murphy, P.; Abad, S.; Vasilieva, E.; Maurer, D.; Brocard, C.; Reinisch, D.; Sagmeister, P.; et al. Integrated Process Modeling—A Process Validation Life Cycle Companion. Bioengineering 2017, 4, 86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- SciPy.org–SciPy.org. Available online: https://www.scipy.org/ (accessed on 12 December 2019).

- Welcome to Python.org. Available online: https://www.python.org/ (accessed on 12 December 2019).

- Borman, P.; Chatfield, M.; Jackson, P.; Laures, A.; Okafo, G. Reduced method robustness testing of analytical methods driven by a risk-based approach. Available online: http://www.pharmtech.com/reduced-method-robustness-testing-analytical-methods-driven-risk-based-approach (accessed on 8 December 2019).

| CQA1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| UO | PP | Judged Range Lower | Judged Range Upper | Setpoint | Severity | Occurrence | Detectability | Critical ∆CQA (%) |

| UO-1 | PP1 | 6 | 8 | 7 | 4 | 3 | 2 | |

| PP2 | 30 | 70 | 50 | 3 | 4 | 2 | ||

| 10 | ||||||||

| UO-2 | PP1 | 6.8 | 7.6 | 7.2 | 5 | 2 | 2 | |

| PP2 | 32 | 38 | 35 | 2 | 4 | 4 | ||

| 10 |

| Consecutive Order of the Unit Operation | Unit Operation | Unit Operation Abbreviation | Scope for the Simulation | Number of Assessed PPs | Number of Assessed CQAs |

|---|---|---|---|---|---|

| 1 | Fermentation | Ferm | No | 53 | 27 |

| 2 | Filtration | Filt | Yes | 5 | 28 |

| 3 | Concentration 1 | Conc1 | Yes | 7 | 24 |

| 4 | Concentration 2 | Conc2 | Yes | 7 | 24 |

| 5 | Chromatography 1 | Chr1 | Yes | 8 | 28 |

| 6 | Chromatography 2 | Chr2 | Yes | 7 | 28 |

| 7 | Formulation | form | No | 4 | 28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borchert, D.; Zahel, T.; Thomassen, Y.E.; Herwig, C.; Suarez-Zuluaga, D.A. Quantitative CPP Evaluation from Risk Assessment Using Integrated Process Modeling. Bioengineering 2019, 6, 114. https://doi.org/10.3390/bioengineering6040114

Borchert D, Zahel T, Thomassen YE, Herwig C, Suarez-Zuluaga DA. Quantitative CPP Evaluation from Risk Assessment Using Integrated Process Modeling. Bioengineering. 2019; 6(4):114. https://doi.org/10.3390/bioengineering6040114

Chicago/Turabian StyleBorchert, Daniel, Thomas Zahel, Yvonne E. Thomassen, Christoph Herwig, and Diego A. Suarez-Zuluaga. 2019. "Quantitative CPP Evaluation from Risk Assessment Using Integrated Process Modeling" Bioengineering 6, no. 4: 114. https://doi.org/10.3390/bioengineering6040114