Environmentally Concerned Logistics Operations in Fuzzy Environment: A Literature Survey

Abstract

:1. Introduction

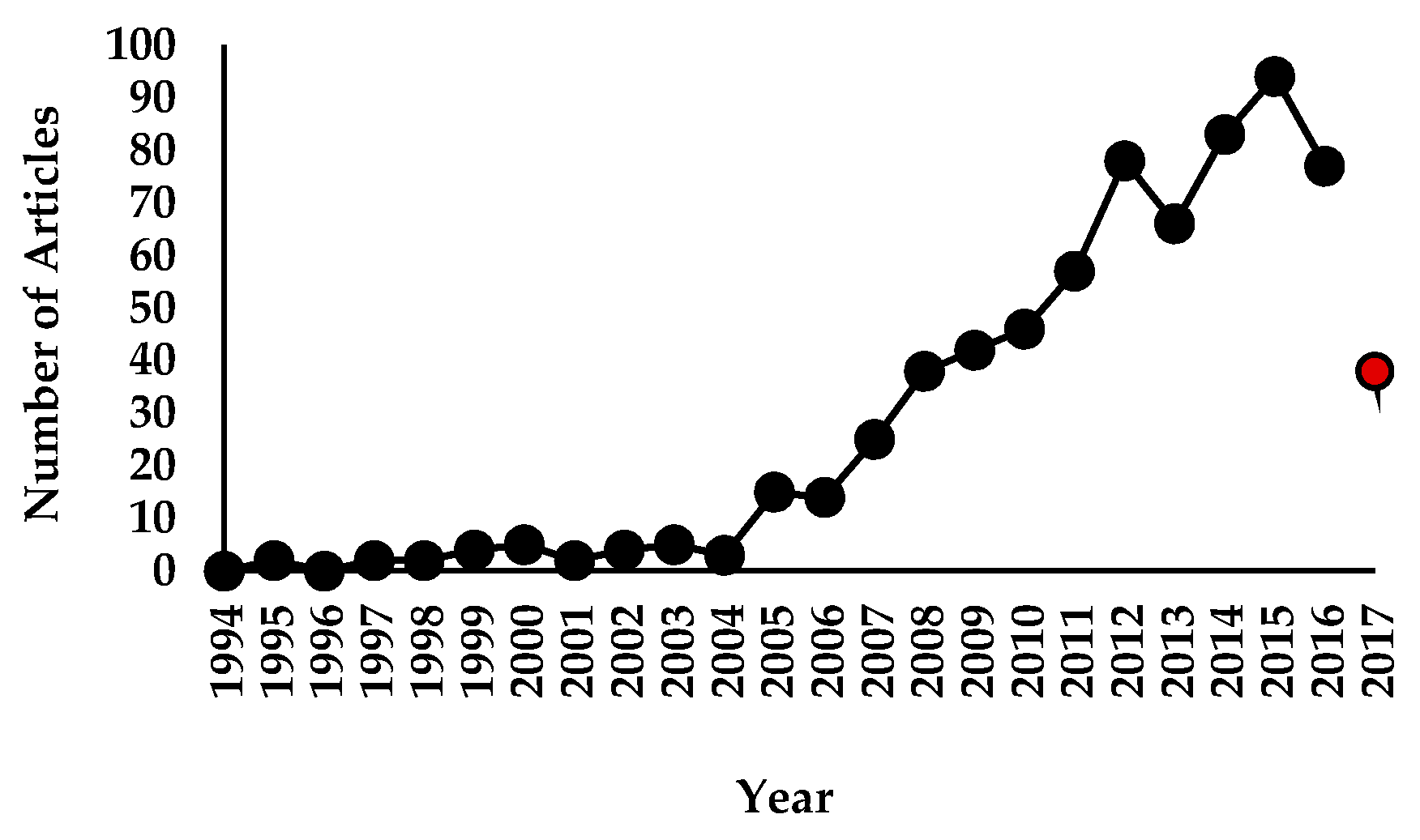

2. Background

3. Methodology

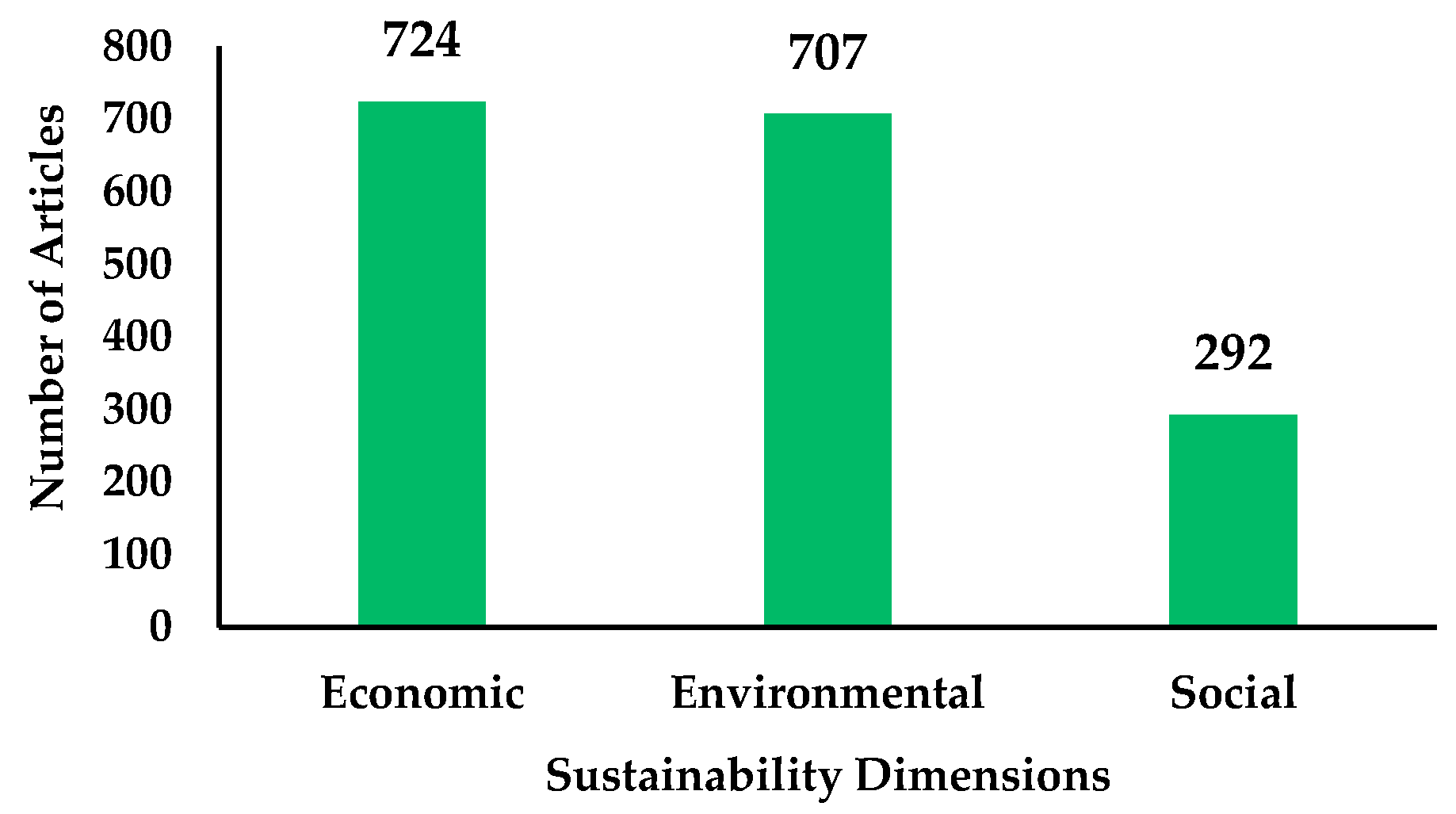

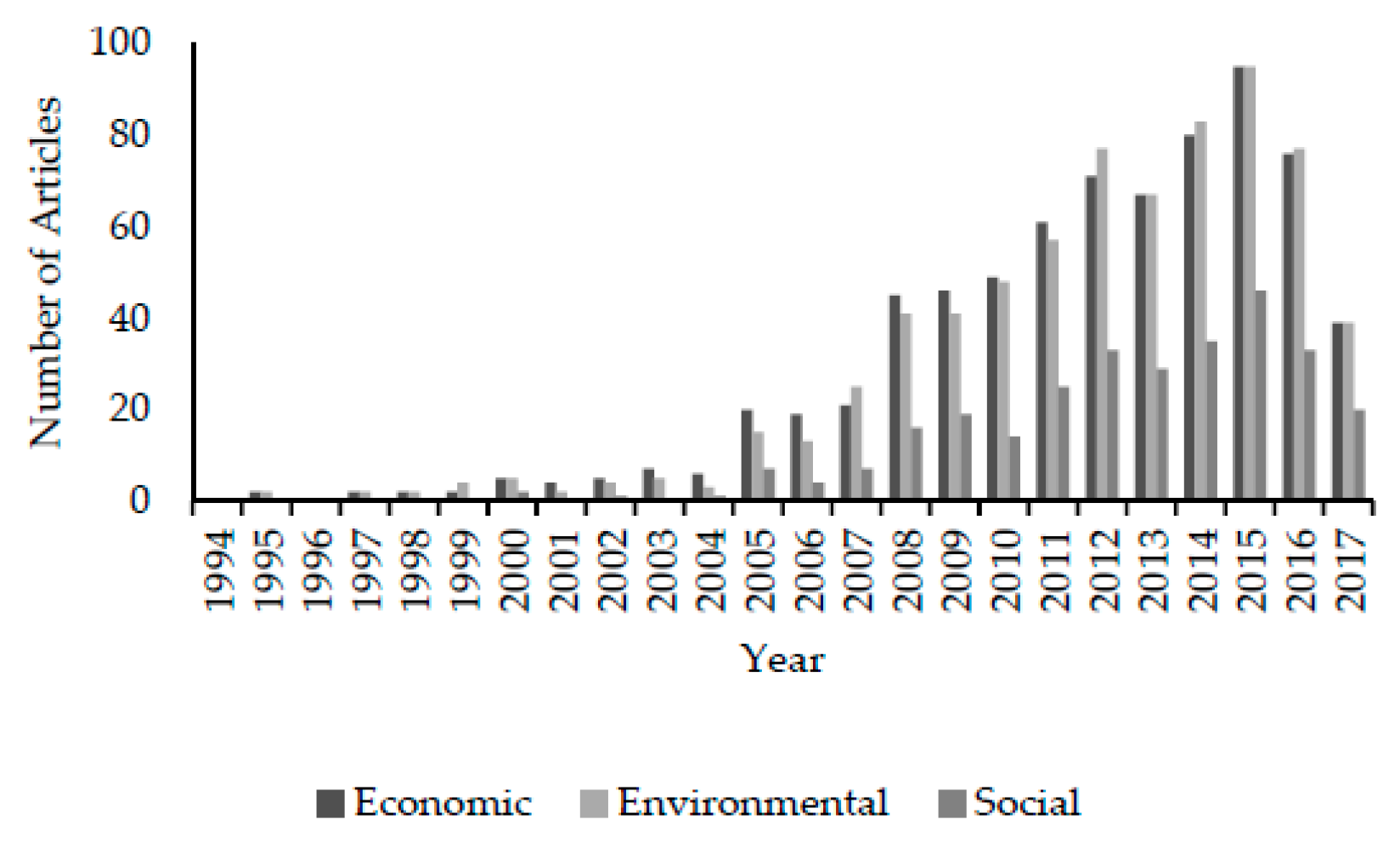

- Which dimensions of sustainability are mostly employed in the literature?

- Which methods and approaches are preferred in fuzzy ECLO models?

- Which future work suggestions should be examined?

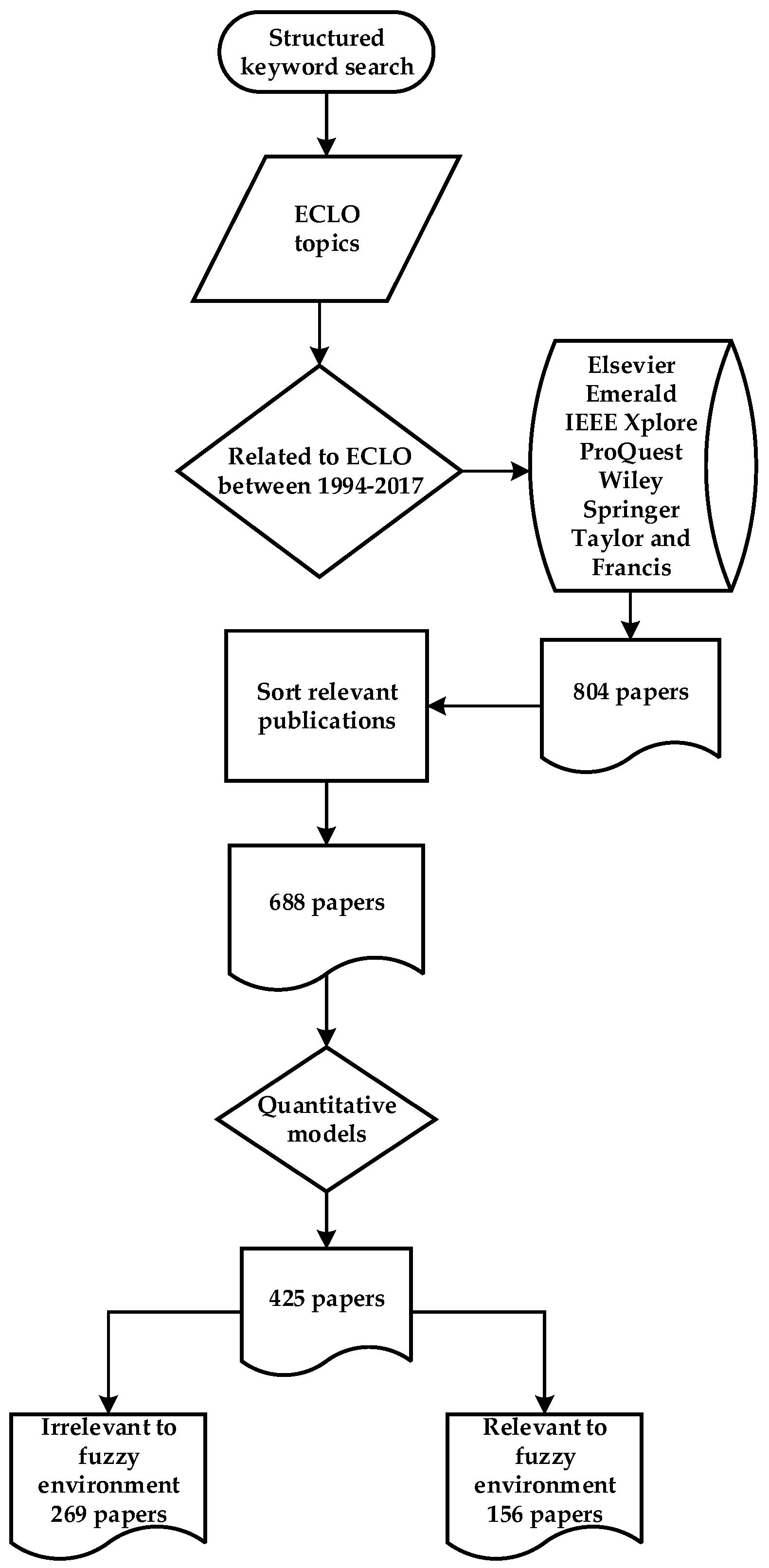

- Material collection: The material to be collected and the unit of analysis are defined and delimited.

- Descriptive analysis: Formal aspects of the material are assessed.

- Category selection: Structural dimensions including the major topics of analysis and related analytic categories with detailed classifications of each structural dimension are selected to be applied to the collected material.

- Material evaluation: The content of the papers is analyzed according to the structural dimensions and analytic categories to identify relevant issues and to interpret the results.

3.1. Content Analysis

3.1.1. Material Collection

- Papers must be written in the English language in peer-reviewed scientific journals, conference proceedings, or book chapters that cover the 24 year-period from 1994 to 2017.

- Publications that do not address environmental criteria of sustainability, and focus on economic, ethical behaviors, or political science are excluded from the analysis.

- The paper contains formal and quantitative model-based publications in the field of ECLO. Conceptual frameworks and empirical analyses that use statistical approaches are not considered.

- Publications which do not focus on supply chain or logistics as the main topic are excluded from the analysis.

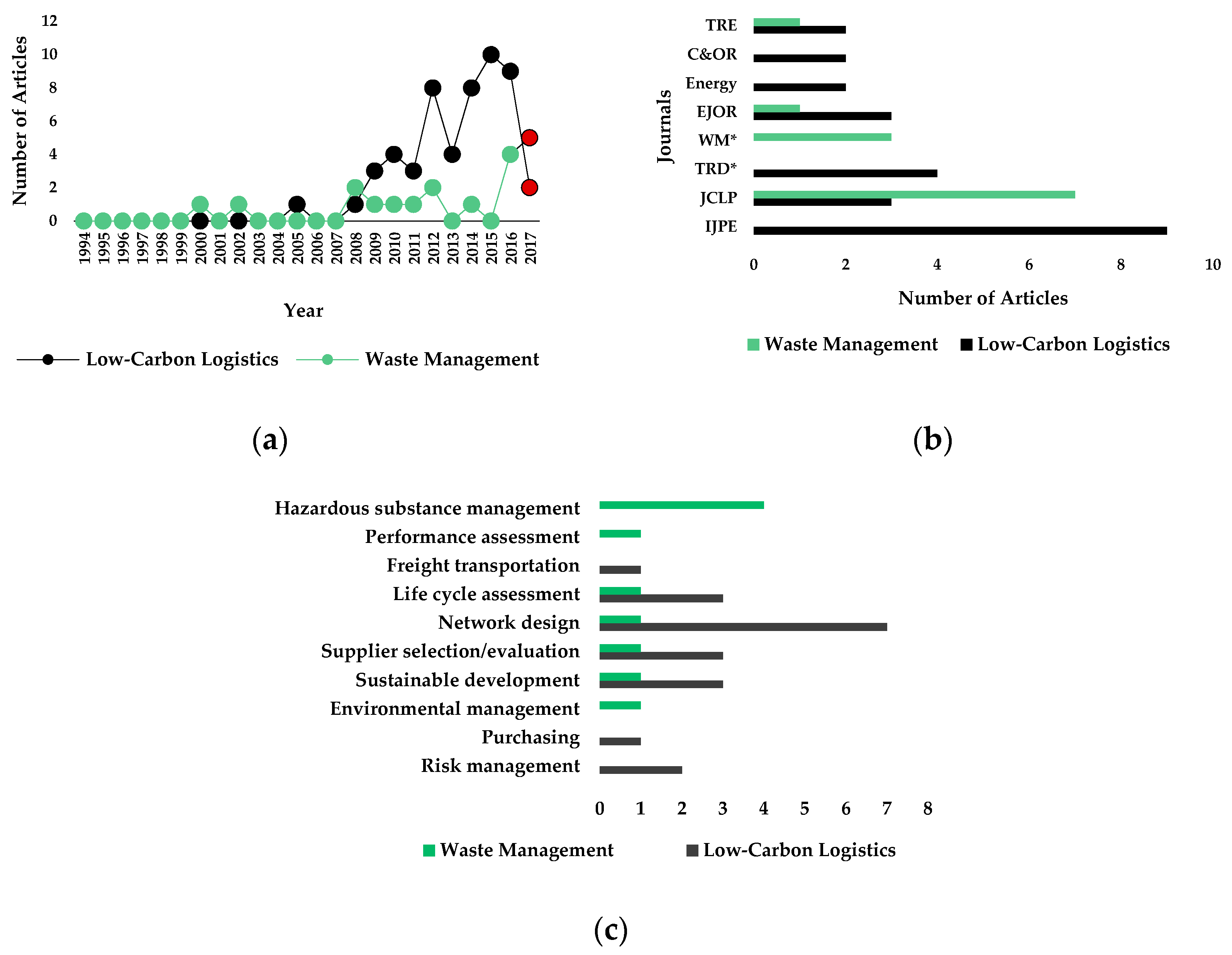

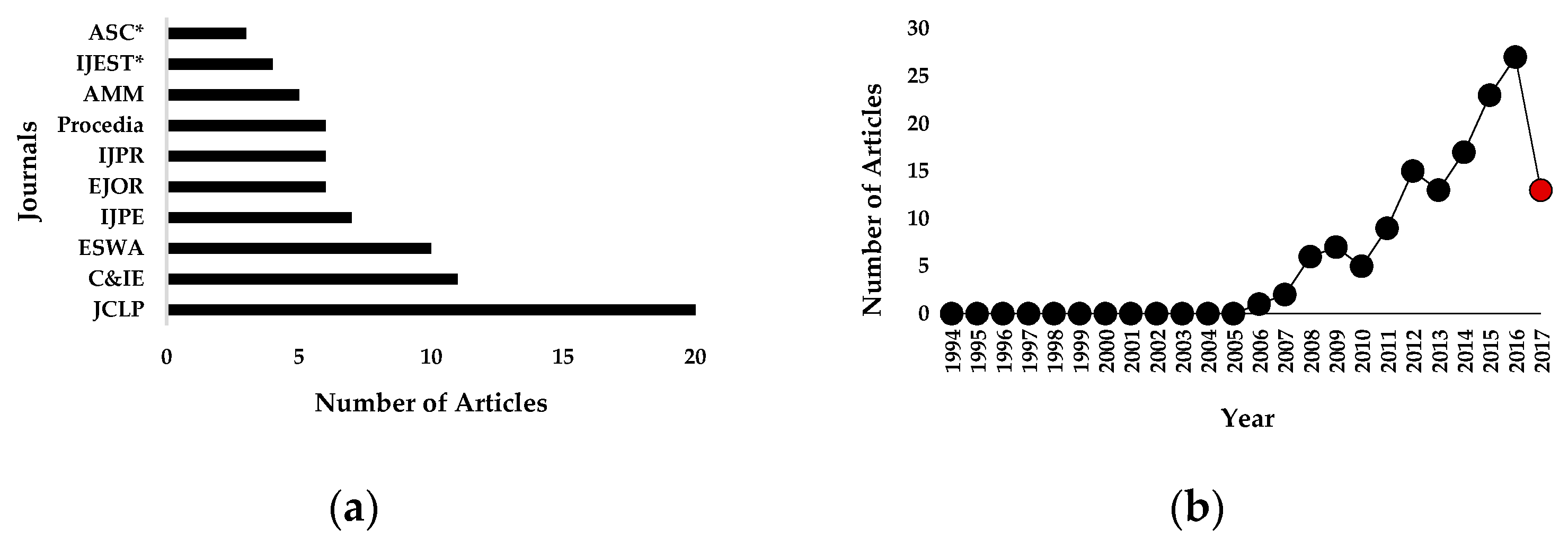

3.1.2. Descriptive Analysis

4. Research Methodology

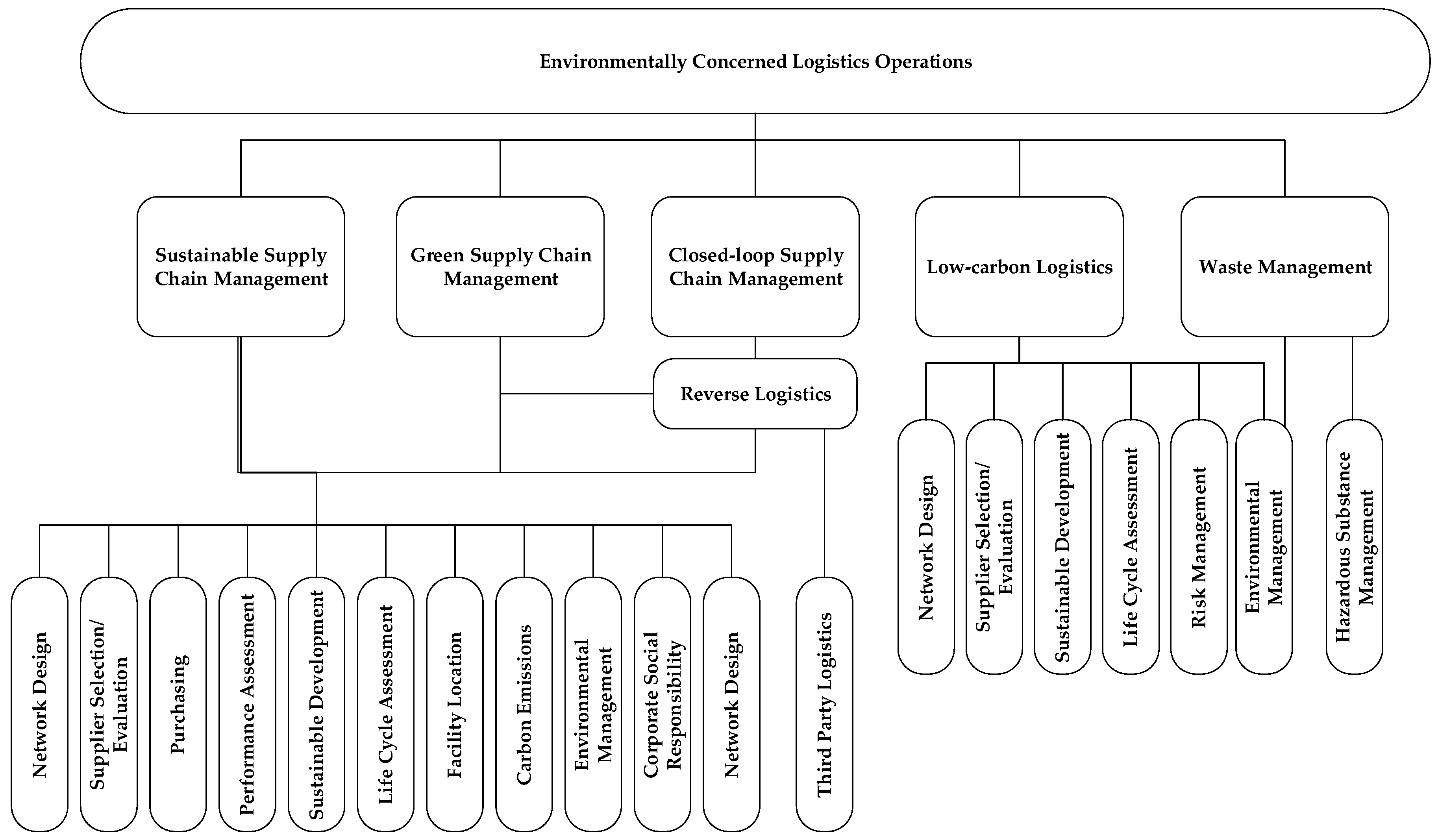

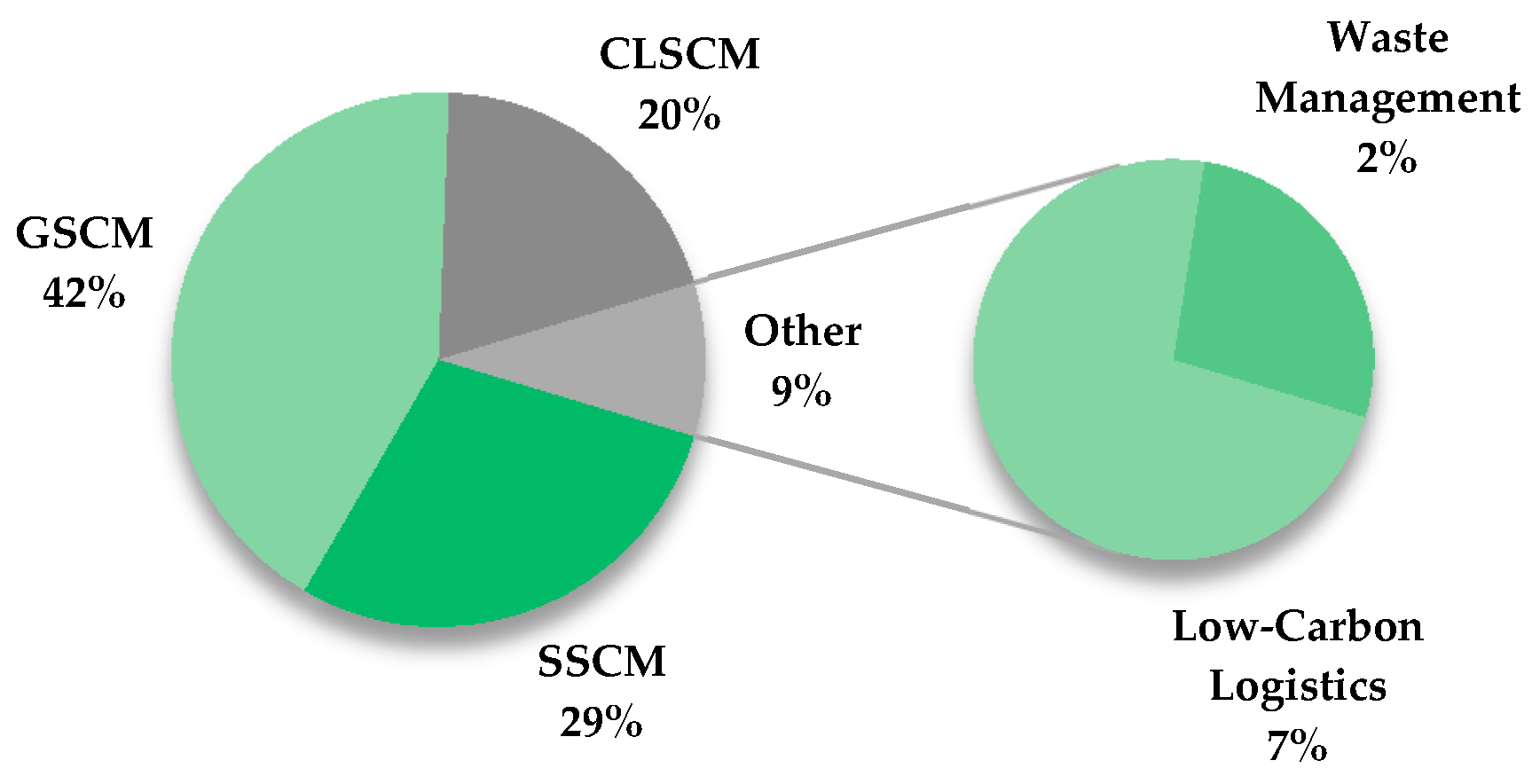

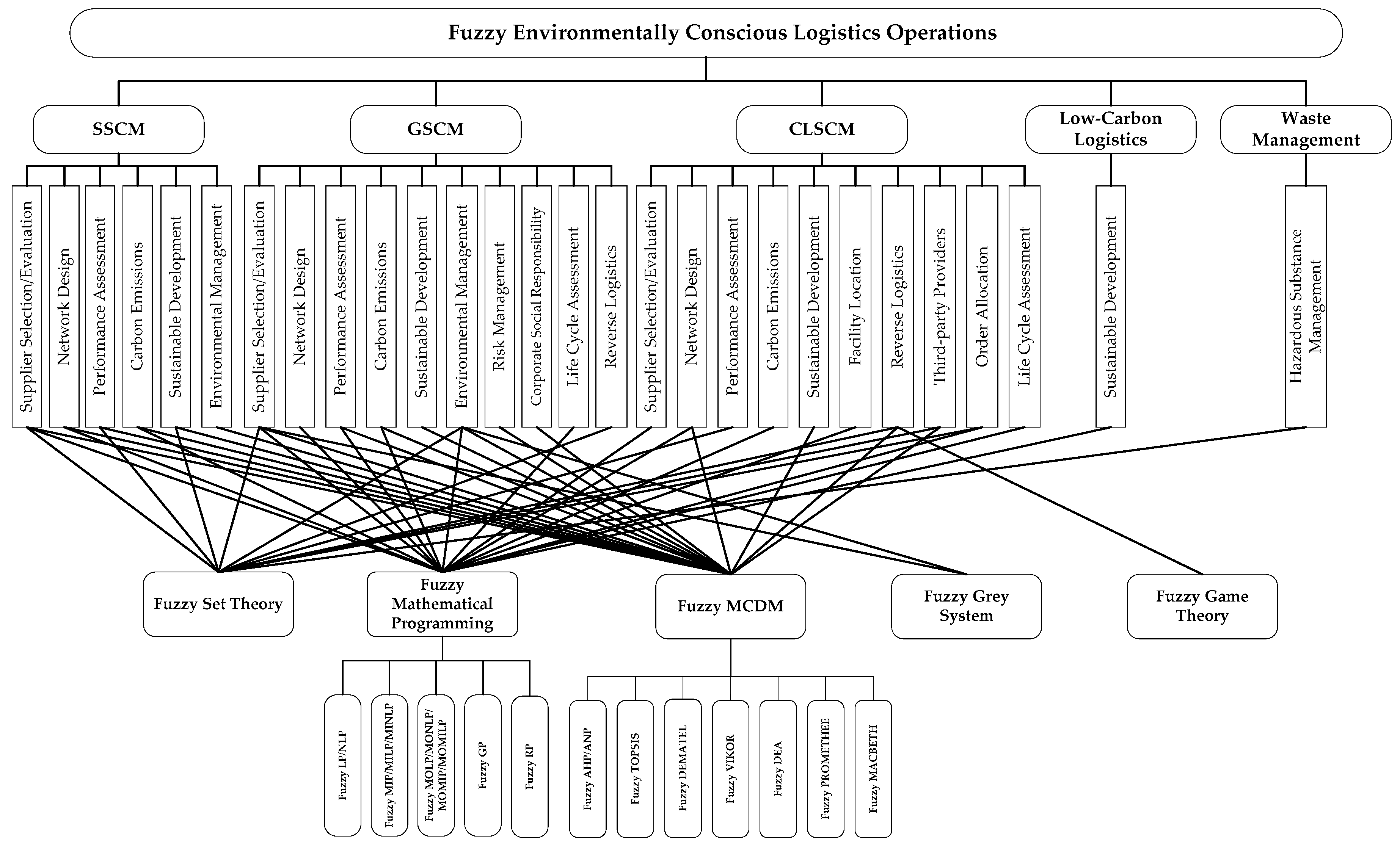

4.1. ECLO Dimensions

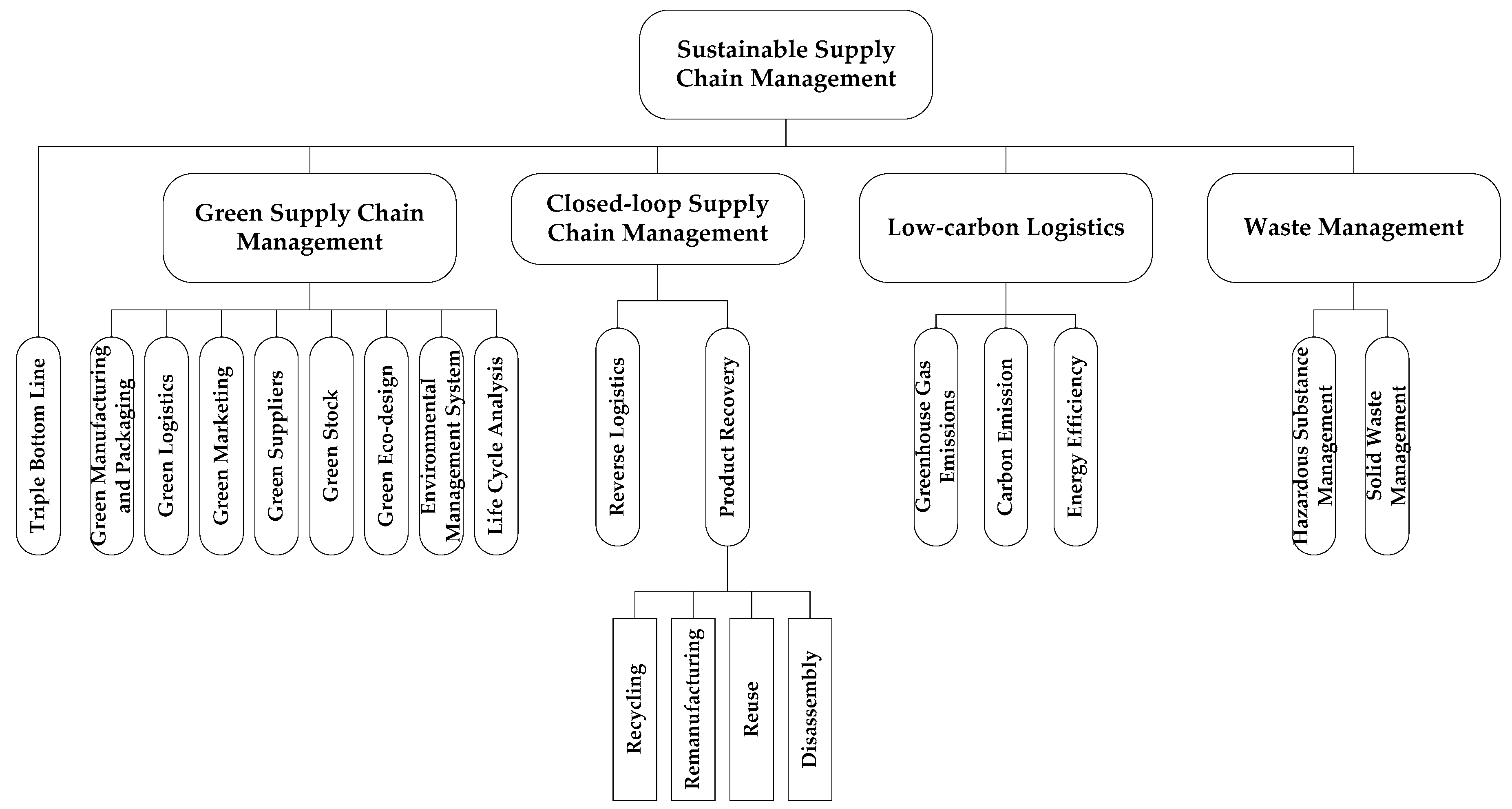

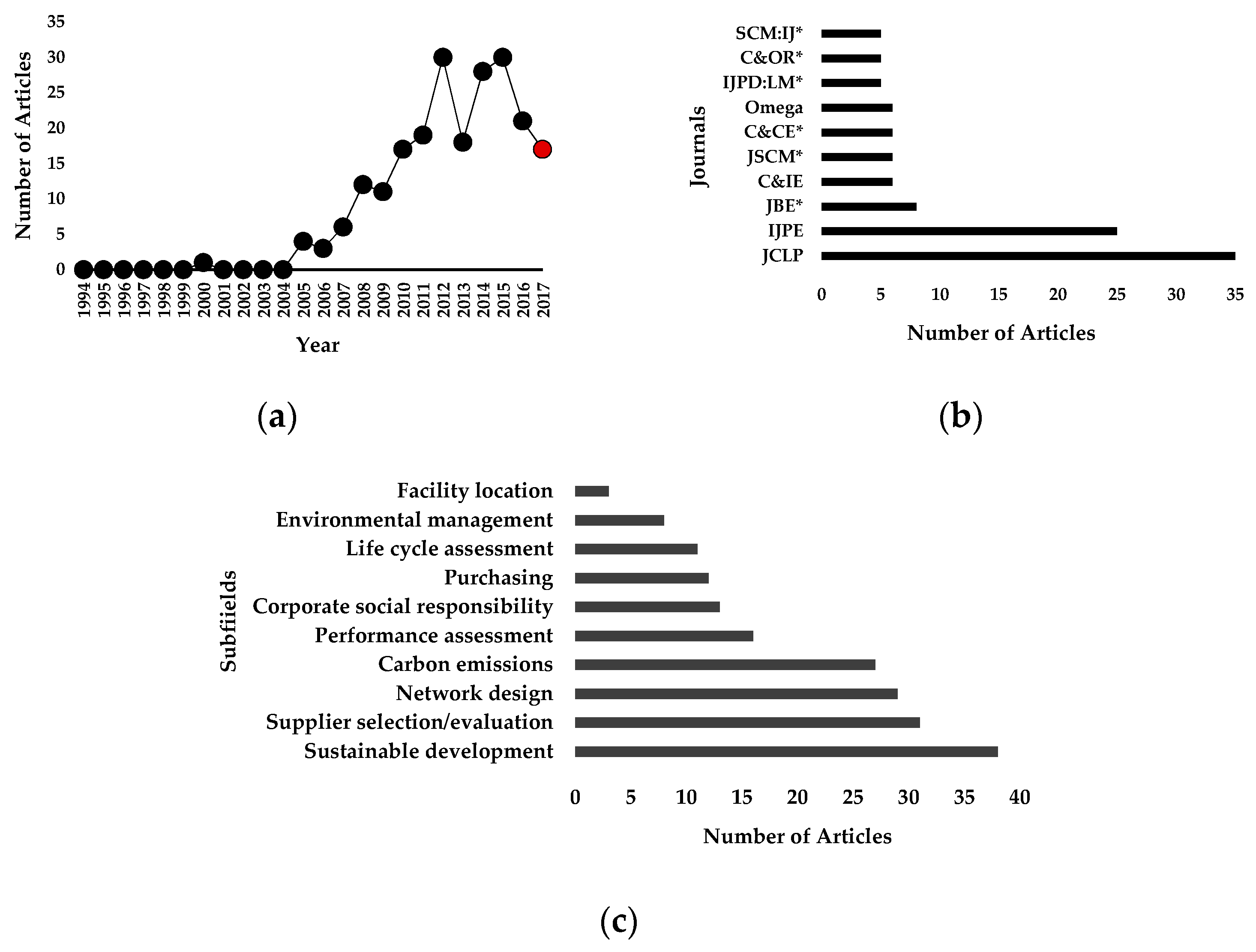

4.1.1. Sustainable Supply Chain Management

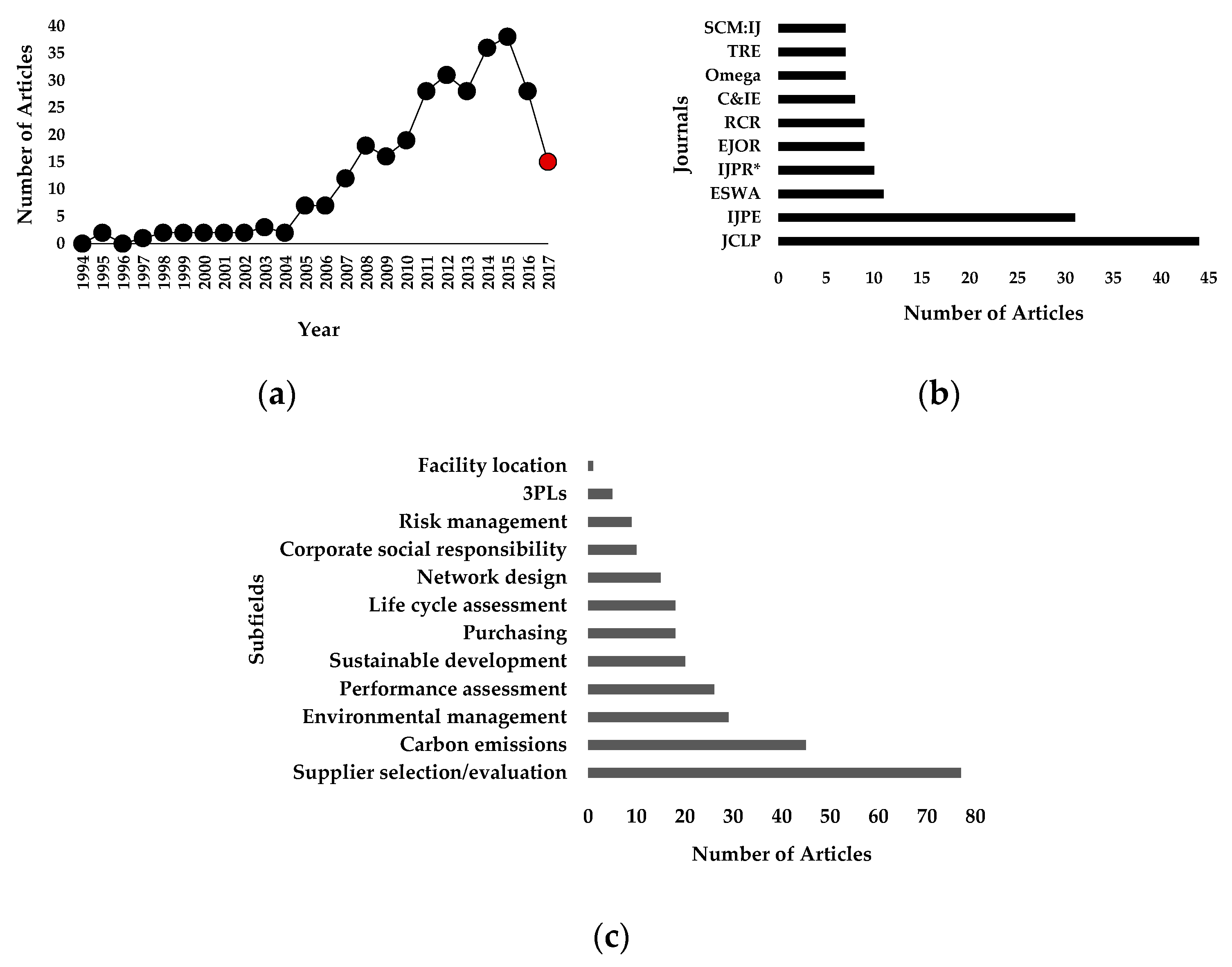

4.1.2. Green Supply Chain Management

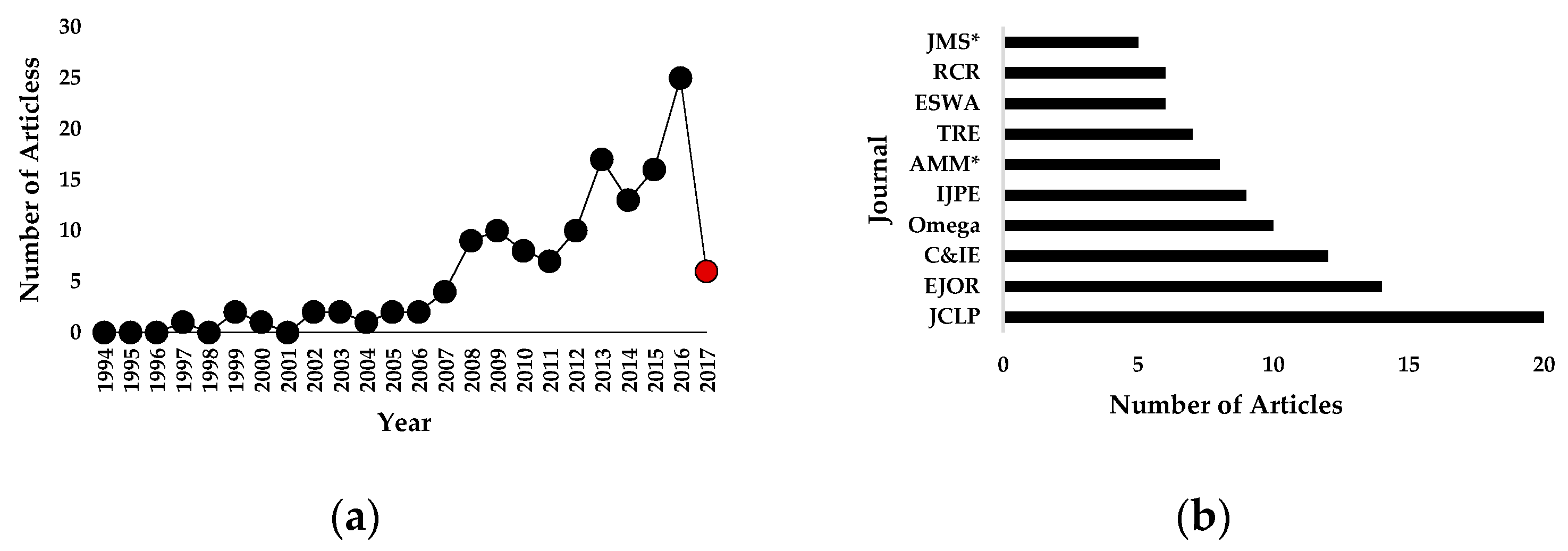

4.1.3. Closed-Loop Supply Chain Management

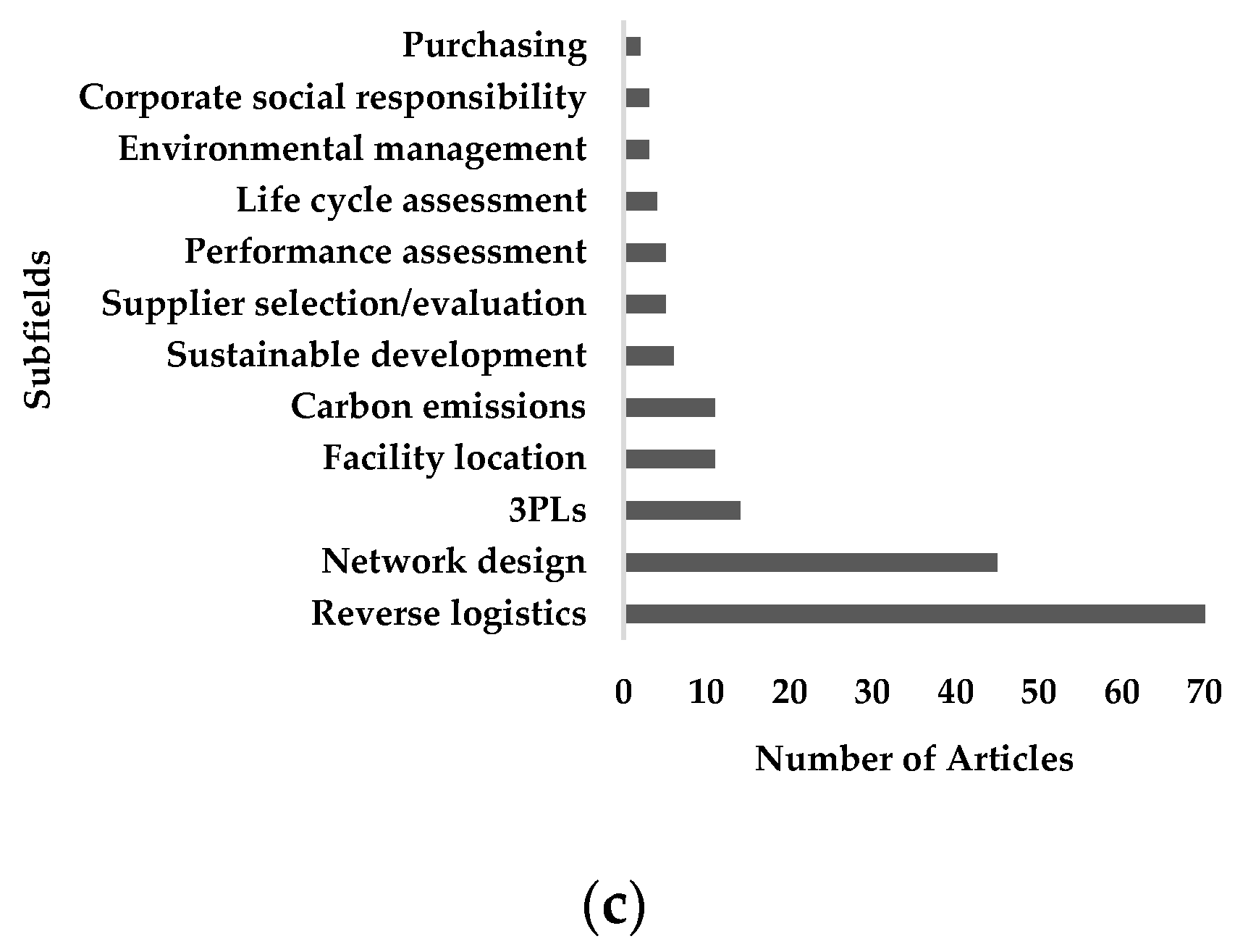

4.1.4. Low-Carbon Logistics and Waste Management

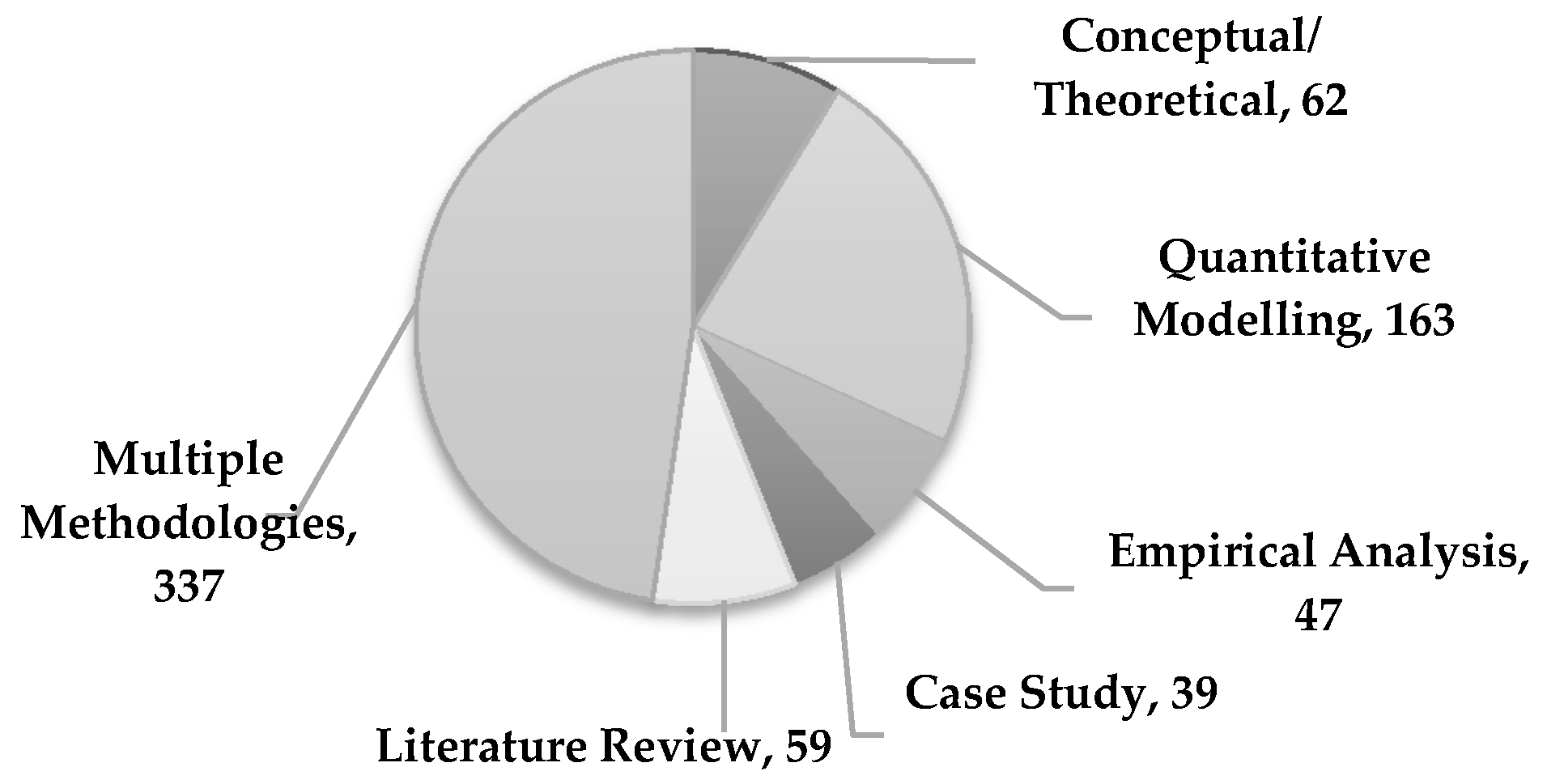

4.2. Research Methodology

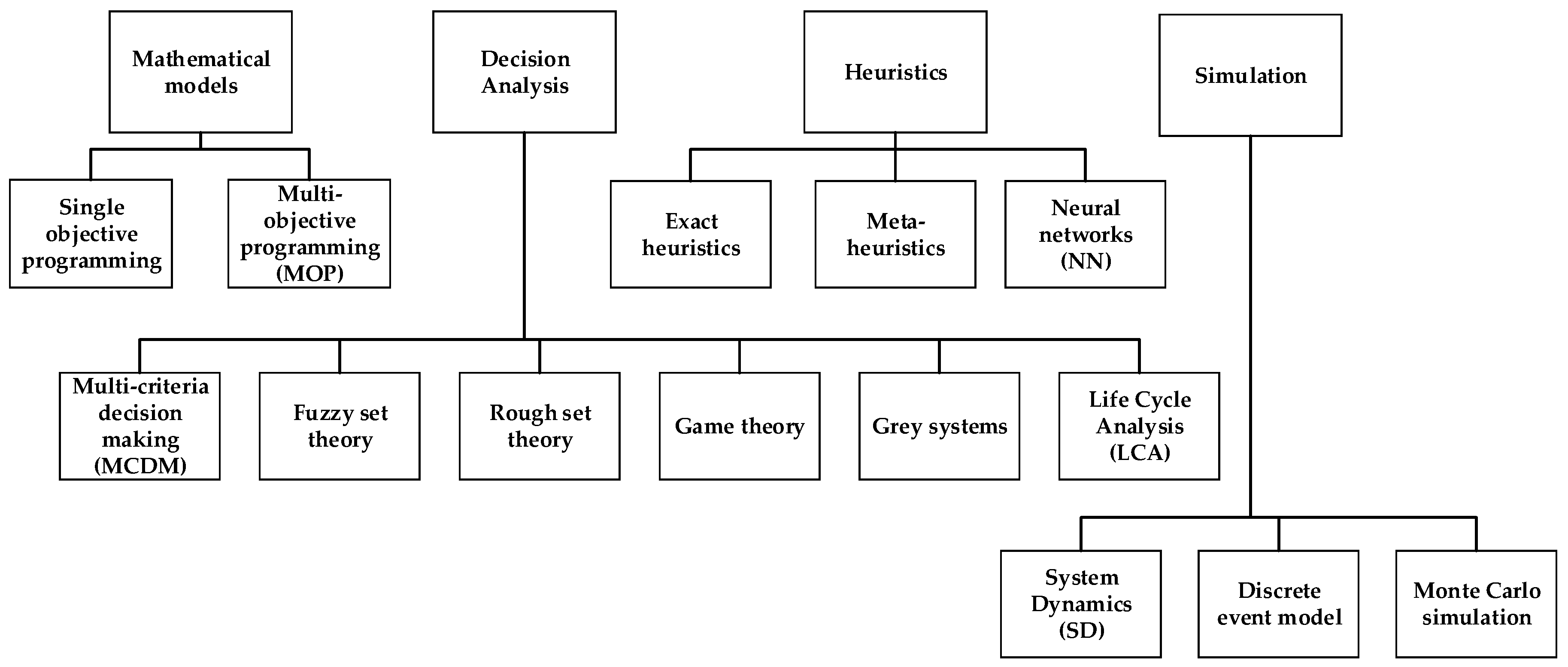

4.2.1. Quantitative Models

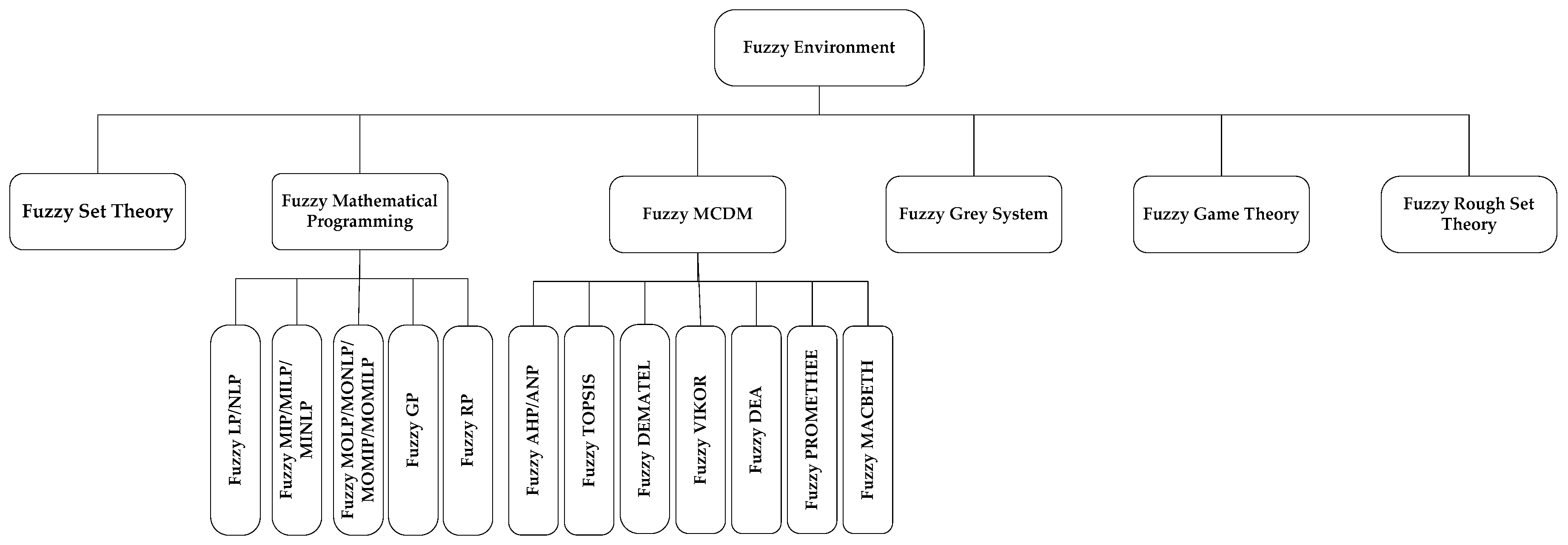

4.2.2. Fuzzy Set Theory

4.3. Industry Categorization

5. Summary and Discussion

Current Body of Literature and Future Research Areas

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Journals | No. of Articles |

|---|---|

| Applied Mathematical Modeling | 13 |

| Computers and Chemical Engineering | 12 |

| Procedia—Social and Behavioral Sciences | 12 |

| International Journal of Physical Distribution and Logistics Management | 11 |

| Journal of Business Ethics, Computers and Operations Research | 10 Each |

| Journal of Purchasing and Supply Management, Procedia CIRP | 9 Each |

| Journal of Supply Chain Management, Journal of Manufacturing Systems | 7 Each |

| Business Strategy and the Environment, International Journal of Environmental Science and Technology, Production Planning and Control: The Management of Operations, Transportation Research Part D: Transport and Environment | 6 Each |

| Applied Soft Computing, International Journal of Operations and Production Management, Journal of Environmental Management, Journal of Operations Management, The International Journal of Advanced Manufacturing Technology | 5 Each |

| Annals of Operations Research, Applied Energy, Benchmarking: An International Journal, Corporate Social Responsibility and Environmental Management, Resources Policy, Supply Chain Management | 4 Each |

| Ecological Economics, Energy, Journal of Manufacturing Technology Management, Journal of Transport Geography, The International Journal of Logistics Management, Fuzzy Sets and Systems, IFAC, Industrial Marketing Management, International Strategic Management Review, Sustainable Production and Consumption, Waste Management | 3 Each |

| AIChE Journal, Biomass and Bioenergy, Bioresource Technology, Business Process Management Journal, Decision Support Systems, European Journal of Purchasing and Supply Management, Ecological Indicators, Food Policy, Global Journal of Flexible Systems Management, Industrial Management and Data Systems, Industrial Marketing Management, International Journal of Hydrogen Energy, International Journal of Logistics Systems and Management, International Journal of Productivity and Performance Management, International Journal of Sustainable Engineering, Journal of Industrial Engineering and Management, Journal of the Operational Research Society, Logistics Research, Management Research Review, Mathematical Problems in Engineering, Operations and Supply Chain Management, Procedia Engineering, Grey Systems: Theory and Application, Industrial and Engineering Chemistry Research | 2 Each |

| Applied Mathematics and Computation, Arabian Journal for Science and Engineering, Business and Economics Research, Chaos, Solitons and Fractals, Chinese Journal of Chemical Engineering, CIRP Journal of Manufacturing Science and Technology, Computers in Industry, Corporate Environmental Strategy, Ecological Indicators, Energy Conversion and Management, Energy Economics, Energy Policy, Environmental Modeling and Assessment, Environmental Modeling and Software, European Management Journal, Greener Management International, Indian Journal of Management Science, Industrial Management and Data Systems, International Journal of Business Performance and Supply Chain Modeling, International Journal of Environmental Technology and Management, International Journal of Hospitality Management, International Journal of Industrial Engineering Computations, International Journal of Innovation, Management and Technology, International Journal of Logistics Management, International Journal of Management Reviews, International Journal of Operational Research, International Journal of Precision Engineering and Manufacturing, International Journal of Purchasing and Materials Management, International Journal of Retail and Distribution Management, International Journal of Services Technology and Management, International Journal of Sustainable Engineering, International Journal of Systems Science, International Journal of Technology Management and Sustainable Development, International Journal on Food System Dynamics, International Strategic Management Review, Journal of Advances in Management Research, Journal of Applied Logic, Journal of Business Economics, Journal of Computers, Journal of Engineering and Technology Management, Journal of Industrial Engineering, Journal of Intelligent Manufacturing, Journal of Land Use and Environmental Law, Journal of Logistics Management, Journal of Loss Prevention in the Process Industries, Journal of Managerial Issues, Journal of Manufacturing Technology, Journal of Materials Processing Technology, Journal of Multiple-Valued Logic and Soft Computing, Journal of Natural Gas Science and Engineering, Journal of Service Science and Management, Journal of Technology Management and Innovation, Journal of the Academy of Marketing Science, Journal of The Institution of Engineers (India): Series C, Knowledge-Based Systems, Lecture Notes in Engineering and Computer Science, Management and Production Engineering Review, Management of Environmental Quality: An International Journal, Mathematical and Computer Modeling, Measurement, Multimedia Tools and Applications, Neural Computing and Applications, OR Spectrum, PloS one, Renewable and Sustainable Energy Reviews, Renewable Energy, Sustainability, Sustainable Production and Consumption, Technological Forecasting and Social Change, Technology in Society, The International Food and Agribusiness Management Review, The Journal of Human Resource and Adult Learning, Transportation Journal, Waste Management | 1 Each |

| Proceedings | 31 |

| Books | 4 |

| Modeling Techniques | No. of Articles | Modeling Approach | No. of Articles | Solution Methods | No. of Articles |

|---|---|---|---|---|---|

| Mathematical programming | 209 | Single objective models | 86 | LP/NLP/MIP/MILP/MINLP | 23 |

| Multi-objective models | 123 | MOMIP/MOMILP/MOMINLP/MOLP/MONLP | 45 | ||

| Bi-objective/Multi-objective LP/NLP/MIP/MILP/RP/GP/DP/SP | 51 | ||||

| e-constraint method | 14 | ||||

| GP | 4 | ||||

| RP | 11 | ||||

| SP | 12 | ||||

| Fuzzy mathematical programming/Possibilistic programming | 46 | ||||

| Queuing theory | 4 | ||||

| Decision Analysis | 220 | MCDM | 176 | AHP/ANP | 105 |

| Fuzzy Sets | 156 | DEMATEL | 24 | ||

| Rough Sets | 7 | TOPSIS | 31 | ||

| Grey Systems | 20 | VIKOR | 10 | ||

| Game theory | 15 | DEA | 24 | ||

| LCA | 7 | QFD | 3 | ||

| PROMETHEE | 5 | ||||

| Multiple attribute utility theory | 3 | ||||

| Rough set theory | 7 | ||||

| Grey approach/Grey numbers | 8 | ||||

| Grey Relational Analysis | 9 | ||||

| Fuzzy entropy | 3 | ||||

| Fuzzy membership function/Linguistic preferences/Fuzzy arithmetic | 95 | ||||

| Fuzzy c-means clustering | 2 | ||||

| Intuitionistic fuzzy sets | 2 | ||||

| Game theoretical analysis | 4 | ||||

| Evolutionary game theory | 2 | ||||

| Game equilibrium analysis | 3 | ||||

| Variational inequality theory | 2 | ||||

| Two-stage game model | 4 | ||||

| Others (b) | 33 | ||||

| Heuristics | 61 | Exact heuristics | 16 | Lagrangian heuristics | 1 |

| Meta-heuristics | 45 | Greedy heuristics | 1 | ||

| NN | 8 | Branch and Bound | 3 | ||

| Memetic algorithm | 2 | ||||

| Genetic algorithm | 24 | ||||

| Simulated annealing | 3 | ||||

| Tabu search | 2 | ||||

| Variable neighborhood search | 3 | ||||

| Particle swarm optimization | 6 | ||||

| Artificial NN | 6 | ||||

| Others (c) | 16 | ||||

| Simulation | 10 | SD | 3 | ||

| Discrete event simulation | 4 | ||||

| Monte Carlo simulation | 3 |

| ECLO Field | No. of Articles | Subfields | No. of Articles | Fuzzy-Related Approach | No. of Articles | Industry | Articles |

|---|---|---|---|---|---|---|---|

| SSCM | 29 | Supplier Selection/Evaluation | 12 | Fuzzy sets | 5 | Manufacturing; Healthcare; Textile | [76,85,87,118,136] |

| Fuzzy AHP | 5 | Automotive; Apparel; Textile | [89,118,154,155,156] | ||||

| Fuzzy ANP | 1 | White goods | [88] | ||||

| Fuzzy DEA | 2 | Resin | [134,136] | ||||

| Fuzzy TOPSIS | 3 | Energy; Textile | [155,157,118] | ||||

| Fuzzy MOLP | 3 | Apparel | [89,154,158] | ||||

| Network Design | 4 | Fuzzy DEA | 1 | [159] | |||

| Fuzzy GP | 1 | Bioenergy; Energy | [158,160] | ||||

| Fuzzy MILP | 1 | Energy | [160] | ||||

| Fuzzy MOLP | 2 | Biofuel | [161,162] | ||||

| Performance Assessment | 5 | Fuzzy sets | 1 | [97] | |||

| Fuzzy AHP | 1 | Apparel | [154] | ||||

| Fuzzy ANP | 1 | Electronics | |||||

| Fuzzy DEMATEL | 1 | [163] | |||||

| Fuzzy MOLP | 1 | Apparel | [154] | ||||

| Fuzzy GRA | 1 | [144] | |||||

| Carbon Emissions | 4 | Fuzzy AHP | 1 | [89] | |||

| Fuzzy DEA | 1 | [159] | |||||

| Fuzzy LP | 1 | [89] | |||||

| Fuzzy MOLP | 1 | [161] | |||||

| Fuzzy MOMILP | 1 | Electronics | [164] | ||||

| Fuzzy SP | 1 | Electronics | [164] | ||||

| Sustainable Development | 4 | Fuzzy Sets | 2 | Logistics; Plastic | [165,166] | ||

| Fuzzy AHP | 2 | Energy; Automotive | [167,168] | ||||

| Fuzzy MOLP | 1 | Biofuel | [162] | ||||

| Environmental Management | 1 | Fuzzy TOPSIS | 1 | [120] | |||

| Order Allocation | 1 | Fuzzy AHP | 1 | Automotive | [169] | ||

| Fuzzy MOLP | 1 | Automotive | [169] | ||||

| Risk Management | 3 | Fuzzy DEMATEL | 1 | Electronics | [126] | ||

| Fuzzy LP | 1 | [170] | |||||

| Fuzzy MOLP | 1 | Biofuel | [162] | ||||

| GSCM | 74 | Supplier Selection/Evaluation | 32 | Fuzzy sets | 6 | Plastic | [86,99,102,170,171,172,144] |

| Fuzzy AHP | 8 | Electronics | [91,93,104,173,174,175,176,177] | ||||

| Fuzzy ANP | 5 | Automotive | [90,111,132,178,179] | ||||

| Fuzzy DEA | 1 | Textile | [135] | ||||

| Fuzzy DEMATEL | 3 | Automotive | [90,178,179] | ||||

| Fuzzy PROMETHEE | 1 | [111] | |||||

| Fuzzy VIKOR | 3 | Automotive; Food | [98,131,129] | ||||

| Fuzzy TOPSIS | 10 | Automotive; Electronics; Paper; Food | [9,90,173,92,132,180,181,182,129] | ||||

| Fuzzy GP | 1 | Electronics | [183] | ||||

| Fuzzy MOLP | 2 | Paper | [178,181] | ||||

| Fuzzy GRA | 2 | Electronics | [94,143] | ||||

| Environmental management | 20 | Fuzzy sets | 1 | [184] | |||

| Fuzzy AHP | 5 | Plastic; Chemical; Electronics | [185,186,187,188,189] | ||||

| Fuzzy ANP | 1 | Automotive | [128] | ||||

| Fuzzy DEA | 1 | Food | [133] | ||||

| Fuzzy DEMATEL | 4 | Automotive; Mining | [123,124,190,191] | ||||

| Fuzzy VIKOR | 1 | [53] | |||||

| Fuzzy TOPSIS | 4 | Mining; Packaging | [146,192,193,182] | ||||

| Fuzzy LP | 1 | [194] | |||||

| Fuzzy MILP | 1 | Bioenergy | [195] | ||||

| Fuzzy-Grey theory | 1 | [142] | |||||

| Fuzzy GRA | 1 | Electronics | [196] | ||||

| Fuzzy-Game theory | 1 | Electronics | [153] | ||||

| Fuzzy-Rough set | 1 | Mining | [146] | ||||

| Carbon emissions | 8 | Fuzzy AHP | 1 | Logistics | [138] | ||

| Fuzzy ANP | 2 | Electronics | [132,179] | ||||

| Fuzzy DEMATEL | 2 | Automotive | [46,179] | ||||

| Fuzzy PROMETHEE | 1 | Logistics | [138] | ||||

| Fuzzy TOPSIS | 2 | Paper; Electronics | [132,181] | ||||

| Fuzzy MOLP | 3 | Healthcare; Paper; Food | [58,181,197] | ||||

| Fuzzy GP | 1 | Food | [197] | ||||

| Fuzzy GRA | 1 | Electronics | [198] | ||||

| Risk Management | 5 | Fuzzy AHP | 4 | Plastic; Fashion; Steel; Automotive | [112,199,200,201] | ||

| Fuzzy DEMATEL | 1 | [190] | |||||

| Fuzzy I/O Analysis | 1 | Automotive | [201] | ||||

| Performance Assessment | 4 | Fuzzy ANP | 1 | [202] | |||

| Fuzzy GP | 1 | Electronics | [183] | ||||

| Fuzzy AHP | 2 | [177,84] | |||||

| Fuzzy VIKOR | 1 | [84] | |||||

| Sustainable Development | 4 | Fuzzy AHP | 3 | Plastic; Publishing | [166,203,204] | ||

| Fuzzy TOPSIS | 1 | Plastic | [166] | ||||

| Fuzzy GRA | 1 | Electronics | [201] | ||||

| Corporate social responsibility | 3 | Fuzzy AHP | 2 | Electronics | [91,175] | ||

| Fuzzy GRA | 1 | Electronics | [198] | ||||

| Life Cycle Assessment | 3 | Fuzzy MOLP | 2 | Healthcare | [205,206] | ||

| Fuzzy AHP | 1 | Automotive | [201] | ||||

| Fuzzy I/O Analysis | 1 | Automotive | [201] | ||||

| Network design | 3 | Fuzzy MOLP | 3 | Healthcare; Food | [205,206,197] | ||

| Fuzzy GP | 1 | Food | [197] | ||||

| Reverse Logistics | 1 | Fuzzy sets | 1 | Logistics | [207] | ||

| Others (b) | 9 | Fuzzy sets | 1 | Logistics | [208] | ||

| Fuzzy AHP | 3 | Logistics; Fashion | [104,112,138] | ||||

| Fuzzy ANP | 2 | Electronics | [209,210] | ||||

| Fuzzy DEMATEL | 3 | Automotive | [46,210,125] | ||||

| Fuzzy PROMETHEE | 1 | Logistics | [138] | ||||

| Fuzzy TOPSIS | 1 | [210] | |||||

| Fuzzy GP | 1 | Electronics | [183] | ||||

| Fuzzy-Rough set | 1 | [147] | |||||

| CLSCM | 45 | Network Design | 15 | Fuzzy AHP | 1 | Scooter | [211] |

| Fuzzy ANP | 1 | [212] | |||||

| Fuzzy LP | 1 | [213] | |||||

| Fuzzy MIP | 1 | Recycling | [214] | ||||

| Fuzzy MILP | 3 | [215,216,217] | |||||

| Fuzzy MOLP | 4 | Healthcare | [106,218,219,220] | ||||

| Fuzzy bi-objective MIP | 1 | Food | [221] | ||||

| Fuzzy GP | 2 | Recycling | [222,223] | ||||

| Fuzzy RP | 2 | Electronics | [224,225] | ||||

| Reverse Logistics | 21 | Fuzzy sets | 2 | Glass | [99,107] | ||

| Fuzzy AHP | 5 | Electronics; Pipe | [226,118,227,115,130] | ||||

| Fuzzy DEMATEL | Manufacturing | [228] | |||||

| Fuzzy MACBETH | 1 | Recycling | [140] | ||||

| Fuzzy TOPSIS | 2 | [229,119,130] | |||||

| Fuzzy VIKOR | 1 | [130] | |||||

| Fuzzy MIP | 6 | Automotive; Electronics | [230,231,232,216,217,233] | ||||

| Fuzzy MOLP | 2 | Healthcare | [234,220] | ||||

| Fuzzy MOMILP | 1 | [115] | |||||

| Fuzzy RP | 1 | [225] | |||||

| Fuzzy-Game theory | 1 | [152] | |||||

| Third party providers | 8 | Fuzzy sets | 1 | [101] | |||

| Fuzzy AHP | 4 | Electronics; Pipe | [114,228,115,119] | ||||

| Fuzzy TOPSIS | 2 | Recycling | [117,235] | ||||

| Fuzzy VIKOR | 1 | Electronics | [130] | ||||

| Fuzzy MOMILP | 1 | [115] | |||||

| Order allocation | 2 | Fuzzy sets | 1 | [107] | |||

| Fuzzy GP | 1 | Manufacturing | [82] | ||||

| Performance evaluation | 2 | Fuzzy sets | 2 | Automotive | [96,236] | ||

| Supplier Selection/Evaluation | 3 | Fuzzy LP | 1 | [237] | |||

| Fuzzy AHP | 1 | [115] | |||||

| Fuzzy MOMILP | [115] | ||||||

| Fuzzy GP | 1 | Manufacturing | [82] | ||||

| Carbon emissions | 2 | Fuzzy RP | 1 | Electronics | [224] | ||

| Fuzzy MILP | Electronics | [233] | |||||

| Facility location | 1 | Fuzzy MINLP | 1 | [238] | |||

| Life Cycle Assessment | 1 | Fuzzy GP | 1 | Recycling | [105] | ||

| Sustainable Development | 2 | Fuzzy AHP | 2 | Electronics | [211,239] | ||

| Fuzzy MIP | 1 | Automotive | [232] | ||||

| Low-Carbon Logistics | 2 | Sustainable development | 2 | Fuzzy LP | 1 | Energy | [240] |

| Fuzzy DEA | 1 | [241] | |||||

| Waste Management | 2 | Hazardous Substance Management | 2 | Fuzzy sets | 2 | Manufacturing; Logistics | [207,242] |

| Risk Management | 1 | Fuzzy AHP | 1 | Automotive | [202] | ||

| Fuzzy I/O Analysis | 1 | Automotive | [202] |

| ECLO Field | No. of Articles | Subfields | No. of Articles | MCDM Approach | No. of Articles |

|---|---|---|---|---|---|

| SSCM | 43 | Sustainable development | 16 | AHP/ANP | 8 |

| DEA | 3 | ||||

| DEMATEL | 1 | ||||

| TOPSIS | 1 | ||||

| Hybrid (AHP and TOPSIS) | 2 | ||||

| Best-Worst Analysis | 1 | ||||

| Supplier selection/evaluation | 11 | AHP/ANP | 5 | ||

| DEA | 2 | ||||

| DEMATEL | 2 | ||||

| TOPSIS | 2 | ||||

| Carbon emissions | 6 | AHP/ANP | 2 | ||

| DEA | 3 | ||||

| Hybrid (AHP and TOPSIS) | 1 | ||||

| Performance assessment | 6 | AHP/ANP | 1 | ||

| DEA | 2 | ||||

| DEMATEL | 1 | ||||

| MAUT | 1 | ||||

| AHP/ANP | 1 | ||||

| Network design | 4 | AHP/ANP | 1 | ||

| DEA | 3 | ||||

| Environmental management | 1 | TOPSIS | 1 | ||

| Order allocation | 1 | AHP/ANP | 1 | ||

| Risk Management | 2 | DEMATEL | 2 | ||

| GSCM | 104 | Supplier selection/evaluation | 50 | AHP/ANP | 19 |

| DEA | 5 | ||||

| DEMATEL | 3 | ||||

| PROMETHEE | 1 | ||||

| TOPSIS | 8 | ||||

| VIKOR | 3 | ||||

| Hybrid (AHP/ANP and DEA) | 3 | ||||

| Hybrid (ANP and PROMETHEE) | 1 | ||||

| Hybrid (ANP and DEMATEL) | 2 | ||||

| Hybrid (ANP and DEMATEL and TOPSIS) | 1 | ||||

| Hybrid (AHP/ANP and TOPSIS) | 2 | ||||

| Hybrid (ELECTRE and VIKOR) | 1 | ||||

| Hybrid (ANP and DEMATEL and VIKOR) | 1 | ||||

| Hybrid(ANP and DEMATEL and MAUT) | 1 | ||||

| Hybrid(TOPSIS and VIKOR) | 1 | ||||

| Environmental management | 25 | AHP/ANP | 11 | ||

| DEA | 1 | ||||

| DEMATEL | 5 | ||||

| PROMETHEE | 1 | ||||

| TOPSIS | 4 | ||||

| VIKOR | 1 | ||||

| Hybrid (AHP and VIKOR) | 1 | ||||

| Hybrid (ANP and DEMATEL) | 1 | ||||

| Carbon emissions | 13 | AHP/ANP | 2 | ||

| DEA | 3 | ||||

| DEMATEL | 2 | ||||

| TOPSIS | 1 | ||||

| Hybrid (AHP and PROMETHEE) | 1 | ||||

| Hybrid (ANP and DEMATEL) | 1 | ||||

| Hybrid (AHP/ANP and DEA) | 1 | ||||

| Hybrid (AHP and PROMETHEE) | 1 | ||||

| Hybrid (ANP and TOPSIS) | 1 | ||||

| Performance assessment | 6 | AHP/ANP | 2 | ||

| DEMATEL | 1 | ||||

| VIKOR | 1 | ||||

| Hybrid(AHP and TOPSIS) | 1 | ||||

| Hybrid(AHP and VIKOR) | 1 | ||||

| Sustainable development | 4 | AHP/ANP | 3 | ||

| Hybrid (ANP and TOPSIS) | 1 | ||||

| Corporate social responsibility | 6 | AHP/ANP | 2 | ||

| DEMATEL | 1 | ||||

| PROMETHEE | 1 | ||||

| Hybrid(ANP and DEA) | 1 | ||||

| Hybrid(ANP and DEMATEL and MAUT) | 1 | ||||

| Risk Management | 6 | AHP/ANP | 4 | ||

| DEMATEL | 1 | ||||

| TOPSIS | 1 | ||||

| I/O Analysis | 1 | ||||

| Innovation | 1 | AHP/ANP | 1 | ||

| Purchasing | 1 | DEMATEL | 1 | ||

| Network design | 1 | TOPSIS | 1 | ||

| CLSCM | 25 | Reverse logistics | 14 | AHP/ANP | 6 |

| DEMATEL | 1 | ||||

| MACBETH | 1 | ||||

| Graph theory and matrix | 1 | ||||

| Hybrid (AHP and DEA) | 1 | ||||

| Hybrid (AHP and TOPSIS) | 2 | ||||

| Hybrid(AHP and DEMATEL) | 1 | ||||

| Hybrid(AHP and VIKOR) | 1 | ||||

| 3PLs | 7 | AHP/ANP | 3 | ||

| TOPSIS | 2 | ||||

| Hybrid(AHP and VIKOR) | 1 | ||||

| Hybrid (AHP and TOPSIS) | 1 | ||||

| Supplier selection | 4 | AHP/ANP | 4 | ||

| Network design | 2 | AHP/ANP | 2 | ||

| Carbon emissions | 1 | AHP/ANP | 1 | ||

| Performance assessment | 1 | PROMETHEE | 1 | ||

| Sustainable development | 1 | AHP/ANP | 1 | ||

| Low-carbon logistics | 8 | Network design | 2 | AHP/ANP | 1 |

| DEA | 1 | ||||

| Supplier selection/evaluation | 3 | AHP/ANP | 1 | ||

| Hybrid (ANP and DEMATEL) | 1 | ||||

| Hybrid(AHP and DEA) | 1 | ||||

| Freight transportation | 2 | DEA | 1 | ||

| Hybrid (AHP and PROMETHEE) | 1 | ||||

| Purchasing | 1 | DEMATEL | 1 | ||

| Waste management | 2 | Supplier selection/evaluation | 1 | AHP/ANP | 1 |

| Sustainable development | 1 | PROMETHEE | 1 |

References

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Min, H.; Kim, I. Green supply chain research: Past, present, and future. Logist. Res. 2012, 4, 39–47. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C.; Pagh, J.D. Supply chain management: Implementation issues and research opportunities. Int. J. Logist. Manag. 1998, 9, 1. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management—A textile case. J. Clean. Prod. 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Brandenburg, M.; Rebs, T. Sustainable supply chain management: A modeling perspective. Ann. Oper. Res. 2015, 229, 213–252. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of the 21st Century; New Society: Stoney Creek, CT, USA, 1998. [Google Scholar]

- Kannan, D.; Jabbour, A.B.L.d.S.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Green supplier development: Analytical evaluation using rough set theory. J. Clean. Prod. 2010, 18, 1200–1210. [Google Scholar] [CrossRef]

- Govindan, K.; Cheng, T.C.E. Environmental supply chain management. Resour. Conserv. Recycl. 2011, 55, 557–558. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.d.S.; Frascareli, F.C.d.O.; Jabbour, C.J.C. Green supply chain management and firms’ performance: Understanding potential relationships and the role of green sourcing and some other green practices. Resour. Conserv. Recycl. 2015, 104, 366–374. [Google Scholar] [CrossRef]

- Shang, K.-C.; Lu, C.-S.; Li, S. A taxonomy of green supply chain management capability among electronics-related manufacturing firms in Taiwan. J. Environ. Manag. 2010, 91, 1218–1226. [Google Scholar] [CrossRef] [PubMed]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M.; Battaïa, O. Use of MCDM techniques in environmentally conscious manufacturing and product recovery: State of the art. J. Manuf. Syst. 2015, 37, 746–758. [Google Scholar] [CrossRef]

- Sasikumar, P.; Kannan, G. Issues in reverse supply chains, part I: End-of-life product recovery and inventory management—An overview. Int. J. Sustain. Eng. 2008, 1, 154–172. [Google Scholar] [CrossRef]

- Sbihi, A.; Eglese, R.W. Combinatorial optimization and Green Logistics. Ann. Oper. Res. 2010, 175, 159–175. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.-H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Igarashi, M.; de Boer, L.; Fet, A.M. What is required for greener supplier selection? A literature review and conceptual model development. J. Purch. Supply Manag. 2013, 19, 247–263. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Gao, D.; Xu, Z.; Ruan, Y.Z.; Lu, H. From a systematic literature review to integrated definition for sustainable supply chain innovation (SSCI). J. Clean. Prod. 2017, 142, 1518–1538. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From Paper to the Internet, 4th ed.; Sage: Thousand Oaks, CA, USA, 1998. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Morali, O.; Searcy, C. A Review of Sustainable Supply Chain Management Practices in Canada. J. Bus. Ethics 2013, 117, 635–658. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Booth, A.; Sutton, A.; Papaioannou, D. Systematic Approaches to a Successful Literature Review; Sage: Thousand Oaks, CA, USA, 2016. [Google Scholar]

- Hsieh, H.-F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef] [PubMed]

- Cronin, P.; Ryan, F.; Coughlan, M. Undertaking a literature review: A step-by-step approach. Br. J. Nurs. 2008, 17, 38. [Google Scholar] [CrossRef] [PubMed]

- Mayring, P. Qualitative Inhaltsanalyse (Qualitative Content aNalysis), 10th ed.; Beltz: Weinheim, Germany, 2008. [Google Scholar]

- Mayring, P. Qualitative Sozialforschung (Qualitative Social Research), 5th ed.; Beltz: Weinheim, Germany, 2002. [Google Scholar]

- Seuring, S.; Gold, S. Conducting content-analysis based literature reviews in supply chain management. Supply Chain Manag. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Farahani, R.Z.; Rezapour, S.; Drezner, T.; Fallah, S. Competitive supply chain network design: An overview of classifications, models, solution techniques and applications. Omega 2014, 45, 92–118. [Google Scholar] [CrossRef]

- Seuring, S.A. Assessing the rigor of case study research in supply chain management. Supply Chain Manag. 2008, 13, 128–137. [Google Scholar] [CrossRef]

- Neto, J.Q.F.; Bloemhof-Ruwaard, J.M.; van Nunen, J.A.E.E.; van Heck, E. Designing and evaluating sustainable logistics networks. Int. J. Prod. Econ. 2008, 111, 195–208. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Diabat, A.; Khodaverdi, R.; Olfat, L. An exploration of green supply chain practices and performances in an automotive industry. Int. J. Adv. Manuf. Technol. 2013, 68, 949–961. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst. Appl. 2015, 42, 7207–7220. [Google Scholar] [CrossRef]

- Mani, V.; Agrawal, R.; Sharma, V. Supplier selection using social sustainability: AHP based approach in India. Int. Strateg. Manag. Rev. 2014, 2, 98–112. [Google Scholar] [CrossRef]

- Guide, V.D.R.; van Wassenhove, L.N. The Evolution of Closed-Loop Supply Chain Research. Oper. Res. 2009, 57, 10–18. [Google Scholar] [CrossRef]

- Taticchi, P.; Tonelli, F.; Pasqualino, R. Performance measurement of sustainable supply chains. Int. J. Product. Perform. Manag. 2013, 62, 782–804. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Design of sustainable supply chains under the emission trading scheme. Int. J. Prod. Econ. 2012, 135, 37–49. [Google Scholar] [CrossRef]

- Abdallah, T.; Diabat, A.; Simchi-Levi, D. Sustainable supply chain design: A closed-loop formulation and sensitivity analysis. Prod. Plan. Control Manag. Oper. 2012, 23, 120–133. [Google Scholar] [CrossRef]

- Pop, P.C.; Pintea, C.-M.; Sitar, C.P.; Hajdu-Măcelaru, M. An efficient Reverse Distribution System for solving sustainable supply chain network design problem. J. Appl. Log. 2015, 13, 105–113. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. An inter-sectoral comparison of green supply chain management in China: Drivers and practices. J. Clean. Prod. 2006, 14, 472–486. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; van der Laan, E.; van Nunen, J.A.E.E.; van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- Marchet, G.; Melacini, M.; Perotti, S. Environmental sustainability in logistics and freight transportation. J. Manuf. Technol. Manag. 2014, 25, 775. [Google Scholar] [CrossRef]

- Kongar, E.; Haznedaroglu, E.; Abdelghany, O.; Bahtiyar, M.O. A novel IT infrastructure for reverse logistics operations of end-of-life pharmaceutical products. Inform. Technol. Manag. 2015, 16, 51–65. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Torabi, S.A.; Razmi, J. Credibility-based fuzzy mathematical programming model for green logistics design under uncertainty. Comput. Ind. Eng. 2012, 62, 624–632. [Google Scholar] [CrossRef]

- Sundarakani, B.; de Souza, R.; Goh, M.; Wagner, S.M.; Manikandan, S. Modeling carbon footprints across the supply chain. Int. J. Prod. Econ. 2010, 128, 43–50. [Google Scholar] [CrossRef]

- Foran, B.; Lenzen, M.; Dey, C.; Bilek, M. Integrating sustainable chain management with triple bottom line accounting. Ecol. Econ. 2005, 52, 143–157. [Google Scholar] [CrossRef]

- Ferretti, I.; Zanoni, S.; Zavanella, L.; Diana, A. Greening the aluminium supply chain. Int. J. Prod. Econ. 2007, 108, 236–245. [Google Scholar] [CrossRef]

- Igarashi, K.; Yamada, T.; Gupta, S.M.; Inoue, M.; Itsubo, N. Disassembly system modeling and design with parts selection for cost, recycling and CO2 saving rates using multi criteria optimization. J. Manuf. Syst. 2016, 38, 151–164. [Google Scholar] [CrossRef]

- Coley, D.; Howard, M.; Winter, M. Local food, food miles and carbon emissions: A comparison of farm shop and mass distribution approaches. Food Policy 2009, 34, 150–155. [Google Scholar] [CrossRef]

- Bloemhof-Ruwaard, J.M.; van Beek, P.; Hordijk, L.; van Wassenhove, L.N. Interactions between operational research and environmental management. Eur. J. Oper. Res. 1995, 85, 229–243. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Hu, A.H. Applying hazardous substance management to supplier selection using analytic network process. J. Clean. Prod. 2009, 17, 255–264. [Google Scholar] [CrossRef]

- Santibanez-Gonzalez, E.D.R.; Diabat, A. Solving a reverse supply chain design problem by improved Benders decomposition schemes. Comput. Ind. Eng. 2013, 66, 889–898. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Gomes, M.I.; Barbosa-Póvoa, A.P. Planning a sustainable reverse logistics system: Balancing costs with environmental and social concerns. Omega 2014, 48, 60–74. [Google Scholar] [CrossRef]

- Capocelli, R.M.; de Luca, A. Fuzzy sets and decision theory. Inform. Control 1973, 23, 446–473. [Google Scholar] [CrossRef]

- Lee, D.-H.; Dong, M.; Bian, W. The design of sustainable logistics network under uncertainty. Int. J. Prod. Econ. 2010, 128, 159–166. [Google Scholar] [CrossRef]

- Schultmann, F.; Zumkeller, M.; Rentz, O. Modeling reverse logistic tasks within closed-loop supply chains: An example from the automotive industry. Eur. J. Oper. Res. 2006, 171, 1033–1050. [Google Scholar] [CrossRef]

- Ko, H.J.; Evans, G.W. A genetic algorithm-based heuristic for the dynamic integrated forward/reverse logistics network for 3PLs. Comput. Oper. Res. 2007, 34, 346–366. [Google Scholar] [CrossRef]

- Kannegiesser, M.; Günther, H.O.; Autenrieb, N. The time-to-sustainability optimization strategy for sustainable supply network design. J. Clean. Prod. 2015, 108, 451–463. [Google Scholar] [CrossRef]

- Martí, J.M.C.; Tancrez, J.-S.; Seifert, R.W. Carbon footprint and responsiveness trade-offs in supply chain network design. Int. J. Prod. Econ. 2015, 166, 129–142. [Google Scholar] [CrossRef]

- Coskun, S.; Ozgur, L.; Polat, O.; Gungor, A. A model proposal for green supply chain network design based on consumer segmentation. J. Clean. Prod. 2016, 110, 149–157. [Google Scholar] [CrossRef]

- Vahdani, B.; Tavakkoli-Moghaddam, R.; Modarres, M.; Baboli, A. Reliable design of a forward/reverse logistics network under uncertainty: A robust-M/M/c queuing model. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 1152–1168. [Google Scholar] [CrossRef]

- Orji, I.J.; Wei, S. An innovative integration of fuzzy-logic and systems dynamics in sustainable supplier selection: A case on manufacturing industry. Comput. Ind. Eng. 2015, 88, 1–12. [Google Scholar] [CrossRef]

- Georgiadis, P.; Besiou, M. Sustainability in electrical and electronic equipment closed-loop supply chains: A System Dynamics approach. J. Clean. Prod. 2008, 16, 1665–1678. [Google Scholar] [CrossRef]

- Tian, Y.; Govindan, K.; Zhu, Q. A system dynamics model based on evolutionary game theory for green supply chain management diffusion among Chinese manufacturers. J. Clean. Prod. 2014, 80, 96–105. [Google Scholar] [CrossRef]

- Awudu, I.; Zhang, J. Uncertainties and sustainability concepts in biofuel supply chain management: A review. Renew. Sustain. Energy Rev. 2012, 16, 1359–1368. [Google Scholar] [CrossRef]

- Van der Vorst, J.G.A.J.; Tromp, S.-O.; van der Zee, D.-J. Simulation modelling for food supply chain redesign; integrated decision making on product quality, sustainability and logistics. Int. J. Prod. Res. 2009, 47, 6611–6631. [Google Scholar] [CrossRef]

- Hu, T.-L.; Sheu, J.-B.; Huang, K.-H. A reverse logistics cost minimization model for the treatment of hazardous wastes. Transp. Res. Part E Logist. Transp. Rev. 2002, 38, 457–473. [Google Scholar] [CrossRef]

- Moghaddam, K.S. Fuzzy multi-objective model for supplier selection and order allocation in reverse logistics systems under supply and demand uncertainty. Expert Syst. Appl. 2015, 42, 6237–6254. [Google Scholar] [CrossRef]

- Brandenburg, M. A hybrid approach to configure eco-efficient supply chains under consideration of performance and risk aspects. Omega 2017, 70, 58–76. [Google Scholar] [CrossRef]

- Sari, K. A novel multi-criteria decision framework for evaluating green supply chain management practices. Comput. Ind. Eng. 2017, 105, 338–347. [Google Scholar] [CrossRef]

- Amindoust, A.; Ahmed, S.; Saghafinia, A.; Bahreininejad, A. Sustainable supplier selection: A ranking model based on fuzzy inference system. Appl. Soft Comput. 2012, 12, 1668–1677. [Google Scholar] [CrossRef]

- Humphreys, P.; McCloskey, A.; McIvor, R.; Maguire, L.; Glackin, C. Employing dynamic fuzzy membership functions to assess environmental performance in the supplier selection process. Int. J. Prod. Res. 2006, 44, 2379–2419. [Google Scholar] [CrossRef]

- Ghadimi, P.; Heavey, C. 21st CIRP Conference on Life Cycle Engineering. Sustainable Supplier Selection in Medical Device Industry: Toward Sustainable Manufacturing. Procedia CIRP 2014, 15, 165–170. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. A novel fuzzy multi-criteria decision framework for sustainable supplier selection with incomplete information. Comput. Ind. 2011, 62, 164–174. [Google Scholar] [CrossRef]

- Shaw, K.; Shankar, R.; Yadav, S.S.; Thakur, L.S. Supplier selection using fuzzy AHP and fuzzy multi-objective linear programming for developing low carbon supply chain. Expert Syst. Appl. 2012, 39, 8182–8192. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. A novel hybrid MCDM approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS to evaluate green suppliers. Expert Syst. Appl. 2012, 39, 3000–3011. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.-Y.; Hsu, C.-F.; Hung, H.-C. A green supplier selection model for high-tech industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Awasthi, A.; Chauhan, S.S.; Goyal, S.K. A fuzzy multicriteria approach for evaluating environmental performance of suppliers. Int. J. Prod. Econ. 2010, 126, 370–378. [Google Scholar] [CrossRef]

- Lu, L.Y.Y.; Wu, C.H.; Kuo, T.-C. Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. Int. J. Prod. Res. 2007, 45, 4317–4331. [Google Scholar] [CrossRef]

- Bali, O.; Kose, E.; Gumus, S. Green supplier selection based on IFS and GRA. Grey Syst. Theory Appl. 2013, 3, 158–176. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inform. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y. An expert fuzzy rule-based system for closed-loop supply chain performance assessment in the automotive industry. Expert Syst. Appl. 2012, 39, 375–384. [Google Scholar] [CrossRef]

- Erol, I.; Sencer, S.; Sari, R. A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecol. Econ. 2011, 70, 1088–1100. [Google Scholar] [CrossRef]

- Akman, G. Evaluating suppliers to include green supplier development programs via fuzzy c-means and VIKOR methods. Comput. Ind. Eng. 2015, 86, 69–82. [Google Scholar] [CrossRef]

- Shan, L. Research on Green Logistics Service Providers Selection Based on Intuitionistic Language Fuzzy Entropy. J. Comput. 2012, 7, 540–546. [Google Scholar] [CrossRef]

- Lee, J.-E.; Chung, K.-Y.; Lee, K.-D.; Gen, M. A multi-objective hybrid genetic algorithm to minimize the total cost and delivery tardiness in a reverse logistics. Multimed. Tools Appl. 2015, 74, 9067–9085. [Google Scholar] [CrossRef]

- Govindan, K.; Murugesan, P. Selection of third-party reverse logistics provider using fuzzy extent analysis. Benchmarking 2011, 18, 149–167. [Google Scholar] [CrossRef]

- Kannan, D.; Govindan, K.; Rajendran, S. Fuzzy Axiomatic Design approach based green supplier selection: Acase study from Singapore. J. Clean. Prod. 2015, 96, 194–208. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J.; Torabi, S.A. Robust possibilistic programming for socially responsible supply chain network design: A new approach. Fuzzy Sets Syst. 2012, 206, 1–20. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Subulan, K.; Taşan, A.S.; Baykasoğlu, A. Designing an environmentally conscious tire closed-loop supply chain network with multiple recovery options using interactive fuzzy goal programming. Appl. Math. Model. 2015, 39, 2661–2702. [Google Scholar] [CrossRef]

- Vahdani, B.; Tavakkoli-Moghaddam, R.; Jolai, F. Reliable design of a logistics network under uncertainty: A fuzzy possibilistic-queuing model. Appl. Math. Model. 2013, 37, 3254–3268. [Google Scholar] [CrossRef]

- Amin, S.H.; Zhang, G. An integrated model for closed-loop supply chain configuration and supplier selection: Multi-objective approach. Expert Syst. Appl. 2012, 39, 6782–6791. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill International: New York, NY, USA, 1980. [Google Scholar]

- Saaty, T.L. The Analytic Network Process (ANP); RWS Publications: Pittsburgh, PA, USA, 1996. [Google Scholar]

- Pochampally, K.K.; Nukala, S.; Gupta, S.M. Strategic Planning Models for Reverse and Closed-Loop Supply Chains; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Tuzkaya, G.; Ozgen, A.; Ozgen, D.; Tuzkaya, U.R. Environmental performance evaluation of suppliers: A hybrid fuzzy multi-criteria decision approach. Int. J. Environ. Sci. Technol. 2009, 6, 477–490. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K.; Yee, R.W.Y.; Diaz-Rainey, I. A two-stage fuzzy-AHP model for risk assessment of implementing green initiatives in the fashion supply chain. Int. J. Prod. Econ. 2012, 135, 595–606. [Google Scholar] [CrossRef]

- Wu, W.-W. Choosing knowledge management strategies by using a combined ANP and DEMATEL approach. Expert Syst. Appl. 2008, 35, 828–835. [Google Scholar] [CrossRef]

- Efendigil, T.; Önüt, S.; Kongar, E. A holistic approach for selecting a third-party reverse logistics provider in the presence of vagueness. Comput. Ind. Eng. 2008, 54, 269–287. [Google Scholar] [CrossRef]

- Shakourloo, A.; Kazemi, A.; Javad, M.O.M. A new model for more effective supplier selection and remanufacturing process in a closed-loop supply chain. Appl. Math. Model. 2016, 40, 9914–9931. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications; Springer: Berlin, Germany, 1981. [Google Scholar]

- Kannan, G.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N.; Wong, K.Y.; Noori, S. A decision support model for sustainable supplier selection in sustainable supply chain management. Comput. Ind. Eng. 2017, 105, 391–410. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. An analysis of integrated robust hybrid model for third-party reverse logistics partner selection under fuzzy environment. Resour. Conserv. Recycl. 2016, 108, 63–81. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Gabus, A.; Fontela, E. World Problems, an Invitation to Further Thought within the Framework of DEMATEL; Battelle Geneva Research Center: Geneva, Switzerland, 1972. [Google Scholar]

- Gabus, A.; Fontela, E. Perceptions of the World Problematique: Communication Procedure, Communicating with Those Bearing Collective Responsibility; Battelle Geneva Research Centre: Geneva, Switzerland, 1973. [Google Scholar]

- Lin, R.-J. Using fuzzy DEMATEL to evaluate the green supply chain management practices. J. Clean. Prod. 2013, 40, 32–39. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Chiu, A.S.F. Exploring decisive factors in green supply chain practices under uncertainty. Int. J. Prod. Econ. 2015, 159, 147–157. [Google Scholar] [CrossRef]

- Lin, R.-J.; Chen, R.-H.; Nguyen, T.-H. Green supply chain management performance in automobile manufacturing industry under uncertainty. Procedia Soc. Behav. Sci. 2011, 25, 233–245. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Lim, M.K.; Hu, J.; Tan, K. Toward sustainability: Using big data to explore the decisive attributes of supply chain risks and uncertainties. J. Clean. Prod. 2017, 142, 663–676. [Google Scholar] [CrossRef]

- Opricovic, S. Multicriteria optimization of civil engineering systems. Fac. Civ. Eng. Belgrad. 1998, 2, 5–21. [Google Scholar]

- Büyüközkan, G.; Feyzioğlu, O. Evaluation of Suppliers’ Environmental Management Performances by a Fuzzy Compromise Ranking Technique. J. Mult. Valued Log. Soft Comput. 2008, 14, 309–324. [Google Scholar]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green supplier selection using fuzzy group decision making methods: A case study from the agri-food industry. Comput. Oper. Res. 2016. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. A combined MCDM approach for evaluation and selection of third-party reverse logistics partner for Indian electronics industry. Sustain. Prod. Consum. 2016, 7, 66–78. [Google Scholar] [CrossRef]

- Awasthi, A.; Kannan, G. Green supplier development program selection using NGT and VIKOR under fuzzy environment. Comput. Ind. Eng. 2016, 91, 100–108. [Google Scholar] [CrossRef]

- Kuo, R.J.; Wang, Y.C.; Tien, F.C. Integration of artificial neural network and MADA methods for green supplier selection. J. Clean. Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Mirhedayatian, S.M.; Azadi, M.; Saen, R.F. A novel network data envelopment analysis model for evaluating green supply chain management. Int. J. Prod. Econ. 2014, 147, 544–554. [Google Scholar] [CrossRef]

- Azadi, M.; Jafarian, M.; Saen, R.F.; Mirhedayatian, S.M. A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context. Comput. Oper. Res. 2015, 54, 274–285. [Google Scholar] [CrossRef]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N.; Khezrimotlagh, D.; Wong, K.Y. An integrated model for green supplier selection under fuzzy environment: Application of data envelopment analysis and genetic programming approach. Neural Comput. Appl. 2016, 27, 707–725. [Google Scholar] [CrossRef]

- Zhou, X.; Pedrycz, W.; Kuang, Y.; Zhang, Z. Type-2 fuzzy multi-objective DEA model: An application to sustainable supplier evaluation. Appl. Soft Comput. 2016, 46, 424–440. [Google Scholar] [CrossRef]

- Brans, J.-P.; Vincke, P.; Mareschal, B. How to select and how to rank projects: The PROMETHEE method. Eur. J. Oper. Res. 1986, 24, 228–238. [Google Scholar] [CrossRef]

- Tuzkaya, U.R. Evaluating the environmental effects of transportation modes using an integrated methodology and an application. Int. J. Environ. Sci. Technol. 2009, 6, 277–290. [Google Scholar] [CrossRef]

- E Costa, C.A.B.; Vansnick, J.-C. MACBETH—An interactive path towards the construction of cardinal value functions. Int. Trans. Oper. Res. 1994, 1, 489–500. [Google Scholar] [CrossRef]

- Dhouib, D. An extension of MACBETH method for a fuzzy environment to analyze alternatives in reverse logistics for automobile tire wastes. Omega 2014, 42, 25–32. [Google Scholar] [CrossRef]

- Deng, J.-L. Control problems of grey systems. Syst. Control Lett. 1982, 1, 288–294. [Google Scholar]

- Tseng, M.-L. Green supply chain management with linguistic preferences and incomplete information. Appl. Soft Comput. 2011, 11, 4894–4903. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, A.S.F. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.; Chiu, K.K.-S. Multi-attribute approach to sustainable supply chain management under uncertainty. Ind. Manag. Data Syst. 2016, 116, 777–800. [Google Scholar] [CrossRef]

- Pawlak, Z. Rough sets. Int. J. Comput. Inform. Sci. 1982, 11, 341–356. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Bai, C.; Sarkis, J.; Wang, X. Green supply chain practices evaluation in the mining industry using a joint rough sets and fuzzy TOPSIS methodology. Resourc. Policy 2015, 46, 86–100. [Google Scholar] [CrossRef]

- Bai, C.; Dhavale, D.; Sarkis, J. Complex investment decisions using rough set and fuzzy c-means: An example of investment in green supply chains. Eur. J. Oper. Res. 2016, 248, 507–521. [Google Scholar] [CrossRef]

- Myerson, R.B. Game Theory: Analysis of Conflict; Harvard University: Cambridge, MA, USA, 1991. [Google Scholar]

- Neumann, J.V.; Morgenstern, O. Theory of Games and Economic Behavior; Princeton University Press: Princeton, NJ, USA, 1944; Volume 60. [Google Scholar]

- Zhao, R.; Neighbour, G.; Han, J.; McGuire, M.; Deutz, P. Using game theory to describe strategy selection for environmental risk and carbon emissions reduction in the green supply chain. J. Loss Prev. Process Ind. 2012, 25, 927–936. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, J. Pricing decisions with retail competition in a fuzzy closed-loop supply chain. Expert Syst. Appl. 2011, 38, 11209–11216. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, J. Reverse channel decisions for a fuzzy closed-loop supply chain. Appl. Math. Model. 2013, 37, 1502–1513. [Google Scholar] [CrossRef]

- Yang, D.; Xiao, T. Pricing and green level decisions of a green supply chain with governmental interventions under fuzzy uncertainties. J. Clean. Prod. 2017, 149, 1174–1187. [Google Scholar] [CrossRef]

- Jakhar, S.K. Performance evaluation and a flow allocation decision model for asustainable supply chain of an apparel industry. J. Clean. Prod. 2015, 87, 391–413. [Google Scholar] [CrossRef]

- Azadnia, A.H.; Saman, M.Z.M.; Wong, K.Y.; Ghadimi, P.; Zakuan, N. Sustainable Supplier Selection based on Self-organizing Map Neural Network and Multi Criteria Decision Making Approaches. Procedia Soc. Behav. Sci. 2012, 65, 879–884. [Google Scholar] [CrossRef]

- Gold, S.; Awasthi, A. Sustainable global supplier selection extended towards sustainability risks from (1 + n)th tier suppliers using fuzzy AHP based approach. IFAC PapersOnLine 2015, 48, 966–971. [Google Scholar] [CrossRef]

- Öztürk, B.A.; Özçelik, F. Sustainable Supplier Selection with A Fuzzy Multi-Criteria Decision Making Method Based on Triple Bottom Line. Bus. Econ. Res. J. 2014, 5, 129–147. [Google Scholar]

- Balaman, Ş.Y.; Selim, H. A fuzzy multiobjective linear programming model for design and management of anaerobic digestion based bioenergy supply chains. Energy 2014, 74, 928–940. [Google Scholar] [CrossRef]

- Dotoli, M.; Epicoco, N.; Falagario, M. A Technique for Supply Chain Network Design under Uncertainty using Cross-Efficiency Fuzzy Data Envelopment Analysis. IFAC PapersOnLine 2015, 48, 634–639. [Google Scholar] [CrossRef]

- Balaman, Ş.Y.; Selim, H. Sustainable design of renewable energy supply chains integrated with district heating systems: A fuzzy optimization approach. J. Clean. Prod. 2016, 133, 863–885. [Google Scholar] [CrossRef]

- Firoozi, M.; Siadat, A.; Salehi, N.; Mousavi, S.M. A novel multi-objective fuzzy mathematical model for designing a sustainable supply chain network considering outsourcing risk under uncertainty. In Proceedings of the 2013 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok, Thailand, 10–13 December 2013; pp. 88–92. [Google Scholar]

- Babazadeh, R.; Razmi, J.; Pishvaee, M.S.; Rabbani, M. A sustainable second-generation biodiesel supply chain network design problem under risk. Omega 2017, 66, 258–277. [Google Scholar] [CrossRef]

- Uysal, F. An Integrated Model for Sustainable Performance Measurement in Supply Chain. Procedia Soc. Behav. Sci. 2012, 62, 689–694. [Google Scholar] [CrossRef]

- Zhalechian, M.; Tavakkoli-Moghaddam, R.; Zahiri, B.; Mohammadi, M. Sustainable design of a closed-loop location-routing-inventory supply chain network under mixed uncertainty. Transp. Res. Part E Logist. Transp. Rev. 2016, 89, 182–214. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. An integrated QFD framework with multiple formatted and incomplete preferences: A sustainable supply chain application. Appl. Soft Comput. 2013, 13, 3931–3941. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Prioritizing the responses to manage risks in green supply chain: An Indian plastic manufacturer perspective. Sustain. Prod. Consum. 2015, 1, 67–86. [Google Scholar] [CrossRef]

- Ren, J.; Manzardo, A.; Toniolo, S.; Scipioni, A. Sustainability of hydrogen supply chain. Part II: Prioritizing and classifying the sustainability of hydrogen supply chains based on the combination of extension theory and AHP. Int. J. Hydrog. Energy 2013, 38, 13845–13855. [Google Scholar] [CrossRef]

- Mangla, S.K.; Govindan, K.; Luthra, S. Prioritizing the barriers to achieve sustainable consumption and production trends in supply chains using fuzzy Analytical Hierarchy Process. J. Clean. Prod. 2017, 151, 509–525. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z.; Chan, F.T.S. A fuzzy AHP and fuzzy multi-objective linear programming model for order allocation in a sustainable supply chain: A case study. Int. J. Comput. Integr. Manuf. 2017, 30, 535–551. [Google Scholar] [CrossRef]

- Rodger, J.A.; George, J.A. Triple bottom line accounting for optimizing natural gas sustainability: A statistical linear programming fuzzy ILOWA optimized sustainment model approach to reducing supply chain global cybersecurity vulnerability through information and communications technology. J. Clean. Prod. 2017, 142, 1931–1949. [Google Scholar]

- Sahu, N.K.; Datta, S.; Mahapatra, S.S. Green supplier appraisement in fuzzy environment. Benchmarking 2014, 21, 412–429. [Google Scholar] [CrossRef]

- Ghorabaee, M.K.; Zavadskas, E.K.; Amiri, M.; Esmaeili, A. Multi-criteria evaluation of green suppliers using an extended WASPAS method with interval type-2 fuzzy sets. J. Clean. Prod. 2016, 137, 213–229. [Google Scholar] [CrossRef]

- Yazdani, M. An integrated MCDM approach to green supplier selection. Int. J. Ind. Engi. Comput. 2014, 5, 443–458. [Google Scholar] [CrossRef]

- Lakhal, S.Y.; H’Mida, S.; Islam, M.R. Green supply chain parameters for a Canadian petroleum refinery company. Int.J. Environ. Technol. Manag. 2007, 7, 56–67. [Google Scholar] [CrossRef]

- Huang, S.-Y.; Wang, C.-Y.; Chiou, C.-Y. FAHP Application for Green Supplier Selection in Electronic Industry. J. Hum. Resour. Adult Learn. 2014, 10, 49–60. [Google Scholar]

- Tzong-Ru, L.; Nha, L.T.P.; Genovese, A.; Lenny, S.C.K. Using FAHP to determine the criteria for partner’s selection within a green supply chain. J. Manuf. Technol. Manag. 2012, 23, 25–55. [Google Scholar]

- Grisi, R.M.; Guerra, L.; Naviglio, G. Supplier performance evaluation for green supply chain management. In Business Performance Measurement and Management; Springer: Berlin, Germany, 2010; pp. 149–163. [Google Scholar]

- Bakeshlou, E.A.; Khamseh, A.A.; Asl, M.A.G.; Sadeghi, J.; Abbaszadeh, M. Evaluating a green supplier selection problem using a hybrid MODM algorithm. J. Intell. Manuf. 2014, 1–15. [Google Scholar] [CrossRef]

- Hsu, C.W.; Chen, S.H.; Chiou, C.Y. A model for carbon management of supplier selection in green supply chain management. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 6–9 December 2011; pp. 1247–1250. [Google Scholar]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier's performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Govindan, K.; Sivakumar, R. Green supplier selection and order allocation in a low-carbon paper industry: Integrated multi-criteria heterogeneous decision-making and multi-objective linear programming approaches. Ann. Oper. Res. 2016, 238, 243–276. [Google Scholar] [CrossRef]

- Mavi, R.K.; Goh, M.; Mavi, N.K. Supplier Selection with Shannon Entropy and Fuzzy TOPSIS in the Context of Supply Chain Risk Management. Procedia Soc. Behav. Sci. 2016, 235, 216–225. [Google Scholar] [CrossRef]

- Tsai, W.H.; Hung, S.-J. A fuzzy goal programming approach for green supply chain optimisation under activity-based costing and performance evaluation with a value-chain structure. Int. J. Prod. Res. 2009, 47, 4991–5017. [Google Scholar] [CrossRef]

- Baoqin, Y.; Cui, S.; Xu, Z. The green supply chain management based on EMS. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008; pp. 2199–2204. [Google Scholar]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Risk analysis in green supply chain using fuzzy AHP approach: A case study. Resour. Conserv. Recycl. 2015, 104, 375–390. [Google Scholar] [CrossRef]

- Boutkhoum, O.; Hanine, M.; Tikniouine, A.; Agouti, T. Multi-criteria Decisional Approach of the OLAP Analysis by Fuzzy Logic: Green Logistics as a Case Study. Arab. J. Sci. Eng. 2015, 40, 2345–2359. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hu, A.H. Green supply chain management in the electronic industry. Int. J. Environ. Sci. Technol. 2008, 5, 205–216. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. An integrated methodology of FTA and fuzzy AHP for risk assessment in green supply chain. Int. J. Oper. Res. 2016, 25, 77–99. [Google Scholar] [CrossRef]

- Thamsatitdej, P.; Jongpaiboon, M.; Samaranayake, P.; Laosirihongthong, T. Green supply chain management, triple bottom line, and organizational theory—Prioritization with fuzzy AHP method. In Proceedings of the 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 6–9 December 2015; pp. 1588–1592. [Google Scholar]

- Wu, K.-J.; Tseng, M.-L.; Vy, T. Evaluation the drivers of green supply chain management practices in uncertainty. Procedia Soc. Behav. Sci. 2011, 25, 384–397. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Sarkis, J.; Wang, X. Assessing green supply chain practices in the Ghanaian mining industry: A framework and evaluation. Int. J. Prod. Econ. 2016, 181, 325–341. [Google Scholar] [CrossRef]

- Wang, Z.; Mathiyazhagan, K.; Xu, L.; Diabat, A. A decision making trial and evaluation laboratory approach to analyze the barriers to Green Supply Chain Management adoption in a food packaging company. J. Clean. Prod. 2016, 117, 19–28. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K. A hierarchical fuzzy TOPSIS approach to assess improvement areas when implementing green supply chain initiatives. Int. J. Prod. Res. 2013, 51, 3117–3130. [Google Scholar] [CrossRef]

- Wang, H.-F.; Hsu, H.-W. Resolution of an uncertain closed-loop logistics model: An application to fuzzy linear programs with risk analysis. J. Environ. Manag. 2010, 91, 2148–2162. [Google Scholar] [CrossRef] [PubMed]

- Balaman, Ş.Y.; Selim, H. A decision model for cost effective design of biomass based green energy supply chains. Bioresour. Technol. 2015, 191, 97–109. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.C.; Tseng, M.L.; Lin, Y.H.; Lin, Z.S. Implementation of green supply chain management in uncertainty. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 7–10 December 2010; pp. 260–264. [Google Scholar]

- Mohammed, A.; Wang, Q. The fuzzy multi-objective distribution planner for a green meat supply chain. Int. J. Prod. Econ. 2017, 184, 47–58. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Lim, M.; Wu, K.-J.; Zhou, L.; Bui, D.T.D. A novel approach for enhancing green supply chain management using converged interval-valued triangular fuzzy numbers-grey relation analysis. Resour. Conserv. Recycl. 2017. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Flexible Decision Modeling for Evaluating the Risks in Green Supply Chain Using Fuzzy AHP and IRP Methodologies. Glob. J. Flex. Syst. Manag. 2015, 16, 19–35. [Google Scholar] [CrossRef]

- Sofyalıoğlu, Ç.; Kartal, B. The Selection of Global Supply Chain Risk Management Strategies by Using Fuzzy Analytical Hierarchy Process—A Case from Turkey. Procedia Soc. Behav. Sci. 2012, 58, 1448–1457. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Breun, P.; Schultmann, F. Assessing social risks of global supply chains: A quantitative analytical approach and its application to supplier selection in the German automotive industry. J. Clean. Prod. 2017, 149, 96–109. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Mohapatra, P.; Kumar, V.; Dey, P.K.; Brady, M.; Tiwari, M.K.; Nudurupati, S.S. Green supply chain performance measurement using fuzzy ANP-based balanced scorecard: A collaborative decision-making approach. Prod. Plan. Control 2014, 25, 698–714. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Z. Study of Green Supply Chain and its Performance Based on Fuzzy AHP and Measurement System. In Proceedings of the 2009 International Conference on E-Business and Information System Security, Wuhan, China, 23–24 May 2009; pp. 1–5. [Google Scholar]

- Rostamy, A.A.A.; Shaverdi, M.; Ramezani, I. Green supply chain management evaluation in publishing industry based on fuzzy AHP approach. J. Logist. Manag. 2013, 2, 9–14. [Google Scholar]

- Pishvaee, M.S.; Razmi, J. Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl. Math. Model. 2012, 36, 3433–3446. [Google Scholar] [CrossRef]

- Pinto-Varela, T.; Barbosa-Póvoa, A.P.F.D.; Novais, A.Q. Bi-objective optimization approach to the design and planning of supply chains: Economic versus environmental performances. Comput. Chem. Eng. 2011, 35, 1454–1468. [Google Scholar] [CrossRef]

- Mousazadeh, M.; Torabi, S.A.; Pishvaee, M.S. Green and Reverse Logistics Management Under Fuzziness. In Supply Chain Management Under Fuzziness: Recent Developments and Techniques; Kahraman, C., Öztayşi, B., Eds.; Springer: Berlin, Germany, 2014; pp. 607–637. [Google Scholar]

- Ćirović, G.; Pamučar, D.; Božanić, D. Green logistic vehicle routing problem: Routing light delivery vehicles in urban areas using a neuro-fuzzy model. Expert Syst. Appl. 2014, 41, 4245–4258. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Lin, R.-J.; Lin, Y.-H.; Chen, R.-H.; Tan, K. Close-loop or open hierarchical structures in green supply chain management under uncertainty. Expert Syst. Appl. 2014, 41, 3250–3260. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Teng, L.-W. Sustainable product and supply chain design decisions under uncertainties. Int. J. Precis. Eng. Manuf. 2013, 14, 1953–1960. [Google Scholar] [CrossRef]

- Tuzkaya, G.; Gülsün, B. Evaluating centralized return centers in a reverse logistics network: An integrated fuzzy multi-criteria decision approach. Int. J. Environ. Sci. Technol. 2008, 5, 339–352. [Google Scholar] [CrossRef]

- Qin, Z.; Ji, X. Logistics network design for product recovery in fuzzy environment. Eur. J. Oper. Res. 2010, 202, 479–490. [Google Scholar] [CrossRef]

- Subulan, K.; Baykasoğlu, A.; Özsoydan, F.B.; Taşan, A.S.; Selim, H. A case-oriented approach to a lead/acid battery closed-loop supply chain network design under risk and uncertainty. J. Manuf. Syst. 2015, 37, 340–361. [Google Scholar] [CrossRef]

- Jindal, A.; Sangwan, K.S.; Saxena, S. Network Design and Optimization for Multi-product, Multi-time, Multi-echelon Closed-loop Supply Chain under Uncertainty. Procedia CIRP 2015, 29, 656–661. [Google Scholar] [CrossRef]

- Alimoradi, A.; Yussuf, R.M.; Ismail, N.B.; Zulkifli, N. Developing a fuzzy linear programming model for locating recovery facility in a closed loop supply chain. Int. J. Sustain. Eng. 2015, 8, 122–137. [Google Scholar] [CrossRef]

- Demirel, N.; Özceylan, E.; Paksoy, T.; Gökçen, H. A genetic algorithm approach for optimising a closed-loop supply chain network with crisp and fuzzy objectives. Int. J. Prod. Res. 2014, 52, 3637–3664. [Google Scholar] [CrossRef]

- Ramezani, M.; Kimiagari, A.M.; Karimi, B.; Hejazi, T.H. Closed-loop supply chain network design under a fuzzy environment. Knowl. Based Syst. 2014, 59, 108–120. [Google Scholar] [CrossRef]

- Soleimani, H.; Govindan, K.; Saghafi, H.; Jafari, H. Fuzzy multi-objective sustainable and green closed-loop supply chain network design. Comput. Ind. Eng. 2017, 109, 191–203. [Google Scholar] [CrossRef]

- Govindan, K.; Paam, P.; Abtahi, A.-R. A fuzzy multi-objective optimization model for sustainable reverse logistics network design. Ecol. Indic. 2016, 67, 753–768. [Google Scholar] [CrossRef]

- Mirakhorli, A. Fuzzy multi-objective optimization for closed loop logistics network design in bread-producing industries. Int. J. Adv. Manuf. Technol. 2014, 70, 349–362. [Google Scholar] [CrossRef]

- Subulan, K.; Taşan, A.S.; Baykasoğlu, A. A fuzzy goal programming model to strategic planning problem of a lead/acid battery closed-loop supply chain. J. Manuf. Syst. 2015, 37, 243–264. [Google Scholar] [CrossRef]

- Mehrbod, M.; Tu, N.; Miao, L.; Wenjing, D. Interactive fuzzy goal programming for a multi-objective closed-loop logistics network. Ann. Oper. Res. 2012, 201, 367–381. [Google Scholar] [CrossRef]

- Talaei, M.; Moghaddam, B.F.; Pishvaee, M.S.; Bozorgi-Amiri, A.; Gholamnejad, S. A robust fuzzy optimization model for carbon-efficient closed-loop supply chain network design problem: A numerical illustration in electronics industry. J. Clean. Prod. 2016, 113, 662–673. [Google Scholar] [CrossRef]

- Farrokh, M.; Azar, A.; Jandaghi, G.; Ahmadi, E. A novel robust fuzzy stochastic programming for closed loop supply chain network design under hybrid uncertainty. Fuzzy Sets Syst. 2017. [Google Scholar] [CrossRef]

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T.; Campos, L.M.S. Identification and analysis of reverse logistics barriers using fuzzy Delphi method and AHP. Resour. Conserv. Recycl. 2016, 108, 182–197. [Google Scholar] [CrossRef]

- Tavana, M.; Zareinejad, M.; di Caprio, D.; Kaviani, M.A. An integrated intuitionistic fuzzy AHP and SWOT method for outsourcing reverse logistics. Appl. Soft Comput. 2016, 40, 544–557. [Google Scholar] [CrossRef]

- Malviya, R.K.; Kant, R. Hybrid decision making approach to predict and measure the success possibility of green supply chain management implementation. J. Clean. Prod. 2016, 135, 387–409. [Google Scholar] [CrossRef]

- Senthil, S.; Srirangacharyulu, B.; Ramesh, A. A Decision Making Methodology for the Selection of Reverse Logistics Operating Channels. Procedia Eng. 2012, 38, 418–428. [Google Scholar] [CrossRef]

- Niknejad, A.; Petrovic, D. Optimisation of integrated reverse logistics networks with different product recovery routes. Eur. J. Oper. Res. 2014, 238, 143–154. [Google Scholar] [CrossRef]

- Özceylan, E.; Paksoy, T. Fuzzy multi-objective linear programming approach for optimising a closed-loop supply chain network. Int. J. Prod. Res. 2013, 51, 2443–2461. [Google Scholar] [CrossRef]

- Phuc, P.N.K.; Yu, V.F.; Tsao, Y.-C. Optimizing fuzzy reverse supply chain for end-of-life vehicles. Comput. Ind. Eng. 2016. [Google Scholar] [CrossRef]

- Mohajeri, A.; Fallah, M. A carbon footprint-based closed-loop supply chain model under uncertainty with risk analysis: A case study. Transp. Res. Part D Transp. Environ. 2016, 48, 425–450. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Torabi, S.A. A possibilistic programming approach for closed-loop supply chain network design under uncertainty. Fuzzy Sets Syst. 2010, 161, 2668–2683. [Google Scholar] [CrossRef]

- Kannan, G.; Murugesan, P.; Senthil, P.; Haq, A.N. Multicriteria group decision making for the third party reverse logistics service provider in the supply chain model using fuzzy TOPSIS for transportation services. Int. J. Serv. Technol. Manag. 2009, 11, 162–181. [Google Scholar] [CrossRef]

- Meng, K.; Lou, P.; Peng, X.; Prybutok, V. A hybrid approach for performance evaluation and optimized selection of recoverable end-of-life products in the reverse supply chain. Comput. Ind. Eng. 2016, 98, 171–184. [Google Scholar] [CrossRef]

- Nukala, S.; Gupta, S.M. A fuzzy mathematical programming approach for supplier selection in a closed-loop supply chain network. In Proceedings of the 2007 POMS-Dallas Meeting, Dallas, TX, USA, 4–7 May 2007; pp. 4–7. [Google Scholar]

- Vahdani, B.; Razmi, J.; Tavakkoli-Moghaddam, R. Fuzzy Possibilistic Modeling for Closed Loop Recycling Collection Networks. Environ. Model. Assess. 2012, 17, 623–637. [Google Scholar] [CrossRef]

- Yeh, C.-H.; Xu, Y. Sustainable planning of e-waste recycling activities using fuzzy multicriteria decision making. J. Clean. Prod. 2013, 52, 194–204. [Google Scholar] [CrossRef]

- Azadeh, A.; Raoofi, Z.; Zarrin, M. A multi-objective fuzzy linear programming model for optimization of natural gas supply chain through a greenhouse gas reduction approach. J. Nat. Gas Sci. Eng. 2015, 26, 702–710. [Google Scholar] [CrossRef]

- Ignatius, J.; Ghasemi, M.R.; Zhang, F.; Emrouznejad, A.; Hatami-Marbini, A. Carbon efficiency evaluation: An analytical framework using fuzzy DEA. Eur. J. Oper. Res. 2016, 253, 428–440. [Google Scholar] [CrossRef]

- Aviso, K.B.; Tan, R.R.; Culaba, A.B.; Cruz, J.B., Jr. Fuzzy input–output model for optimizing eco-industrial supply chains under water footprint constraints. J. Clean. Prod. 2011, 19, 187–196. [Google Scholar] [CrossRef]

| Journal | JCLP | IJPE | EJOR | RCR | C&IE | Omega | ESWA | IJPR | TRE | SCM:IJ | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Year | |||||||||||

| 2017 | 18 | 2 | 0 | 1 | 4 | 4 | 1 | 0 | 0 | 0 | 8 |

| 2016 | 23 | 6 | 3 | 4 | 6 | 3 | 0 | 2 | 1 | 0 | 29 |

| 2015 | 15 | 16 | 1 | 4 | 2 | 3 | 2 | 1 | 1 | 0 | 49 |

| 2014 | 5 | 9 | 8 | 2 | 2 | 5 | 3 | 3 | 2 | 0 | 44 |

| 2013 | 20 | 3 | 2 | 3 | 2 | 0 | 1 | 2 | 1 | 0 | 32 |

| 2012 | 0 | 15 | 3 | 1 | 1 | 1 | 6 | 2 | 1 | 5 | 43 |

| 2011 | 3 | 5 | 0 | 7 | 1 | 1 | 4 | 0 | 3 | 0 | 33 |

| 2010 | 2 | 5 | 2 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 36 |

| 2009 | 2 | 0 | 2 | 3 | 2 | 0 | 1 | 2 | 2 | 2 | 26 |

| 2008 | 5 | 5 | 0 | 0 | 1 | 3 | 1 | 0 | 3 | 3 | 19 |

| 2007 | 2 | 2 | 2 | 0 | 0 | 0 | 0 | 3 | 0 | 1 | 15 |

| 2006 | 2 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 7 |

| 2005 | 2 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 2 | 10 |

| 2004 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 2003 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 |

| 2002 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 |

| 2001 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| 2000 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 3 |

| 1999 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 2 |

| 1998 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| 1997 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 1996 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 1995 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 1994 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Total | 101 | 70 | 29 | 26 | 25 | 23 | 20 | 18 | 16 | 14 | 365 |

| Authors | Title | Year | Journal | Citation |

|---|---|---|---|---|

| Fleischmann, Moritz; Bloemhof-Ruwaard, Jacqueline M.; Dekker, Rommert; van der Laan, Erwin; van Nunen, Jo A.E.E.; van Wassenhove, Luk N. | Quantitative models for reverse logistics: A review | 1997 | European Journal of Operations Research | 2492 |

| Seuring, Stefan; Müller, Martin | From a literature review to a conceptual framework for sustainable supply chain management | 2008 | Journal of Cleaner Production | 2468 |

| Srivastava, Samir K. | Green supply-chain management: A state-of-the-art literature review | 2007 | International Journal of Management Reviews | 2425 |

| Carter, Craig R.; Rogers Dale S. | A framework of sustainable supply chain management: moving toward new theory | 2008 | International Journal of Physical Distribution and Logistics Management | 1756 |

| Zhu, Qinghua; Sarkis, Joseph | Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises | 2004 | Journal of Operations Management | 1474 |

| Rao, Purba; Holt, Diane | Do Green Supply Chains Lead To Competitiveness And Economic Performance? | 2005 | International Journal of Operations and Production Management | 1402 |

| Sarkis, Joseph | A strategic decision framework for green supply chain management | 2003 | Journal of Cleaner Production | 1268 |

| Linton, Jonathan D.; Klassen, Robert; Jayaraman, Vaidyanathan | Sustainable Supply Chains: An introduction | 2007 | Journal of Operations Management | 1174 |

| Gungor, Askiner; Gupta, Surendra M. | Issues in environmentally conscious manufacturing and product recovery: a survey | 1999 | Computers and Industrial Engineering | 1137 |

| Fleischmann, Mortiz; Krikke, Hans Ronald; Dekker, Rommert; Flapper, Simme Douwe P. | A characterisation of logistics networks for product recovery | 2000 | Omega | 1012 |

| ECLO Dimension | Research Methodology | Modeling Approach | Sustainability | Sustainability Dimensions | Industry |

|---|---|---|---|---|---|

| SSCM/GSCM/CLSCM/Low-carbon logistics/Waste management | Conceptual model/Quantitative modeling/Empirical analysis/Case study/Literature review | Mathematical programming/MCDM/Fuzzy sets/Heuristics/Simulation/Game Theory/Hybrid methods | Yes/No | Economic/Environmental/Social | Food/Electronics/Construction etc. |

| Industry | No. of Papers | Industry | No. of Papers | Industry | No. of Papers |

|---|---|---|---|---|---|

| Electronics industry | 59 | Recycling industry | 7 | Furniture industry | 3 |

| Automotive industry | 25 | Plastic industry | 7 | Steel industry | 2 |

| Energy industry | 25 | Textile industry | 6 | Aluminum industry | 2 |

| Food industry | 25 | Paper industry | 5 | Packaging industry | 2 |

| Bioenergy industry | 18 | Apparel industry | 4 | Fashion industry | 2 |

| Manufacturing industry | 9 | Healthcare industry | 4 | Pharmaceuticals | 2 |

| Logistics industry | 9 | Mining industry | 4 | Miscellaneous * | 11 |

| Chemicals industry | 7 | Glass industry | 3 |

| Industry | No. of Papers | Industry | No. of Papers |

|---|---|---|---|

| Electronics industry | 24 | Bioenergy industry | 4 |

| Automotive industry | 12 | Food industry | 4 |

| Energy industry | 7 | Healthcare industry | 3 |

| Plastic industry | 5 | City logistics | 2 |

| Logistics industry | 4 | Mining industry | 2 |

| Manufacturing industry | 4 | Tire recovery | 2 |

| Miscellaneous * | 13 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tozanli, O.; Duman, G.M.; Kongar, E.; Gupta, S.M. Environmentally Concerned Logistics Operations in Fuzzy Environment: A Literature Survey. Logistics 2017, 1, 4. https://doi.org/10.3390/logistics1010004

Tozanli O, Duman GM, Kongar E, Gupta SM. Environmentally Concerned Logistics Operations in Fuzzy Environment: A Literature Survey. Logistics. 2017; 1(1):4. https://doi.org/10.3390/logistics1010004

Chicago/Turabian StyleTozanli, Ozden, Gazi Murat Duman, Elif Kongar, and Surendra M. Gupta. 2017. "Environmentally Concerned Logistics Operations in Fuzzy Environment: A Literature Survey" Logistics 1, no. 1: 4. https://doi.org/10.3390/logistics1010004

APA StyleTozanli, O., Duman, G. M., Kongar, E., & Gupta, S. M. (2017). Environmentally Concerned Logistics Operations in Fuzzy Environment: A Literature Survey. Logistics, 1(1), 4. https://doi.org/10.3390/logistics1010004