Porous Three-Dimensional Scaffold Generation for 3D Printing

Abstract

:1. Introduction

2. Mathematical Model and Numerical Method

3. Numerical Experiments

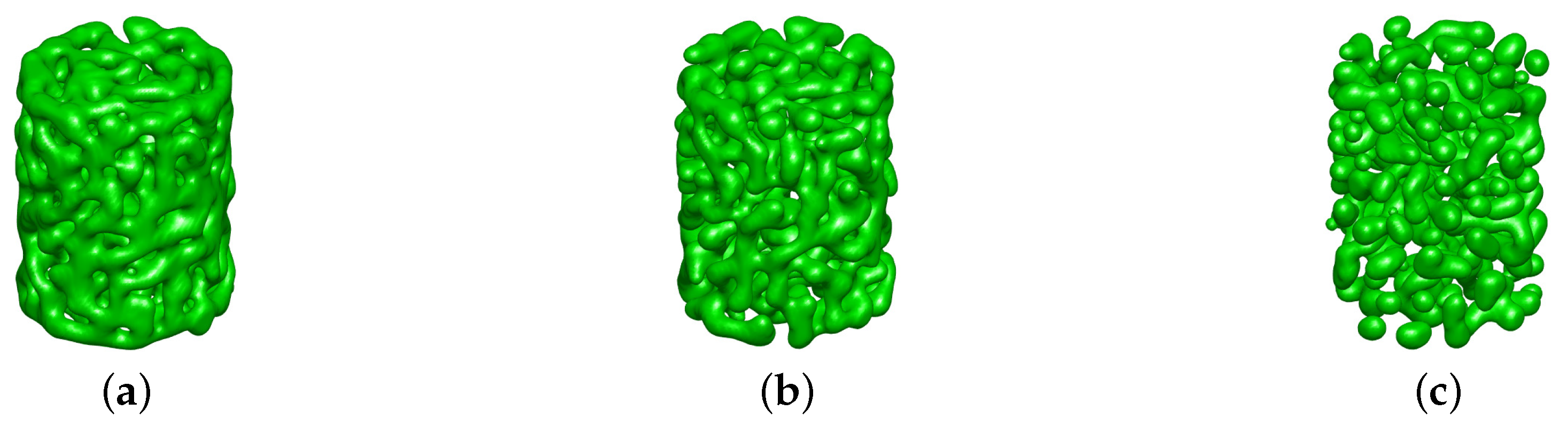

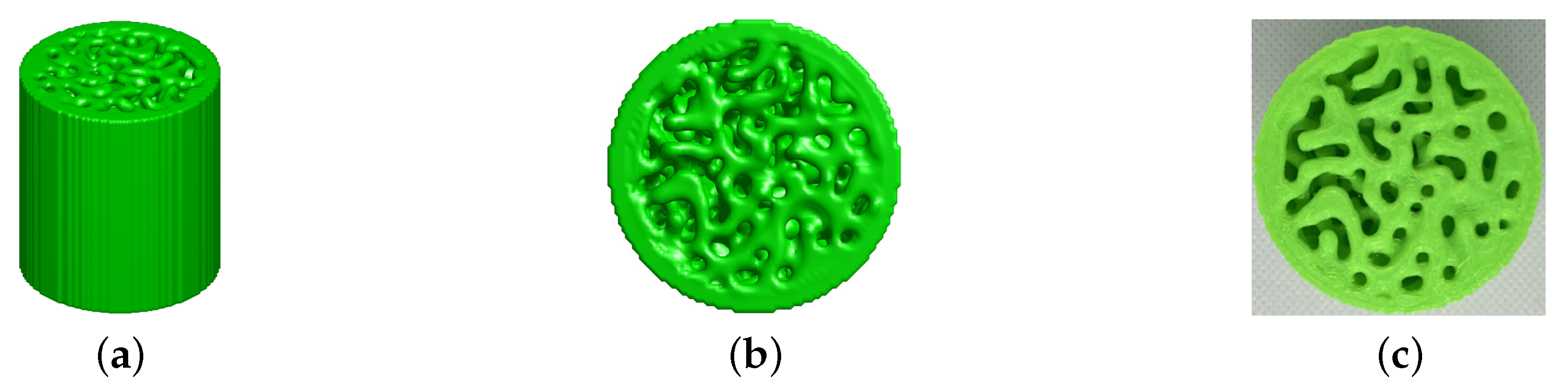

3.1. Simple Structures

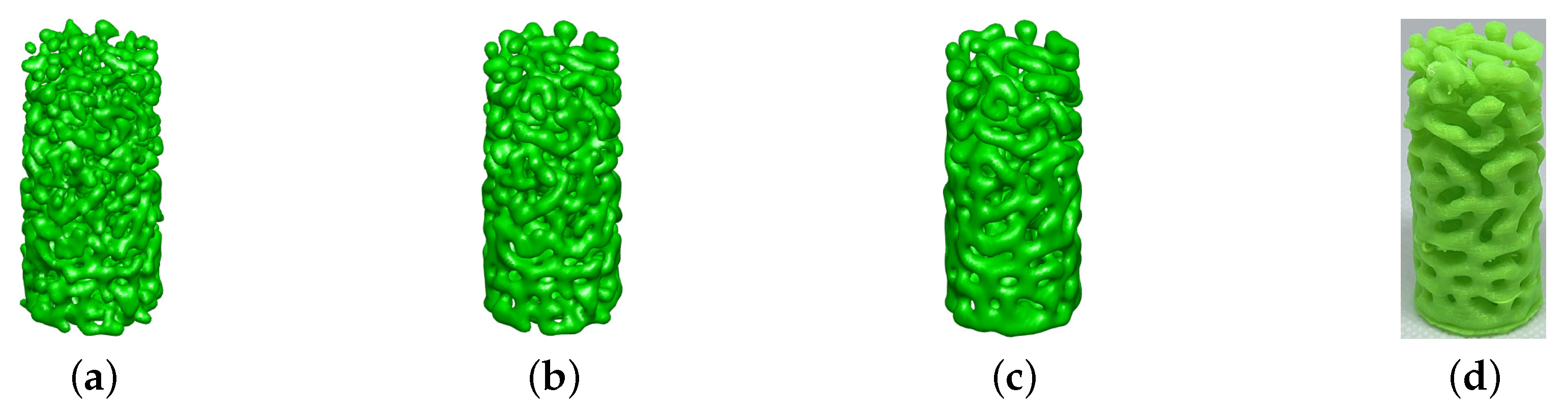

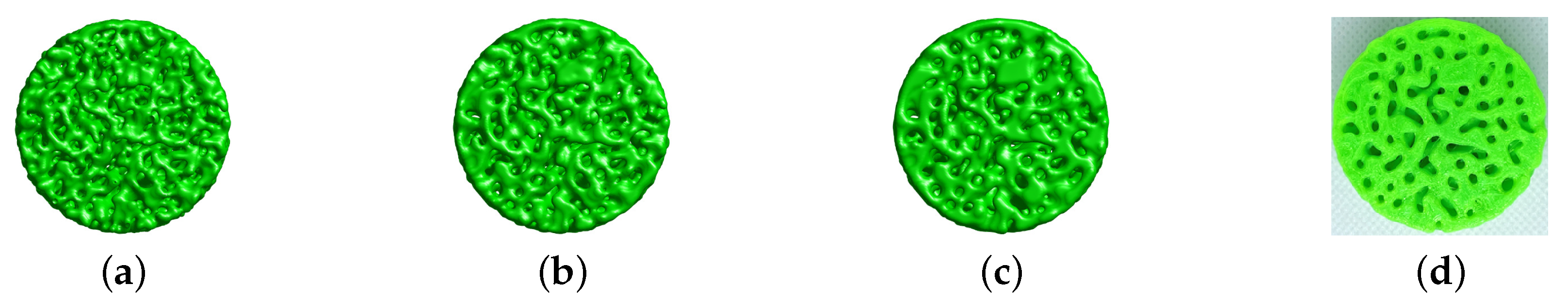

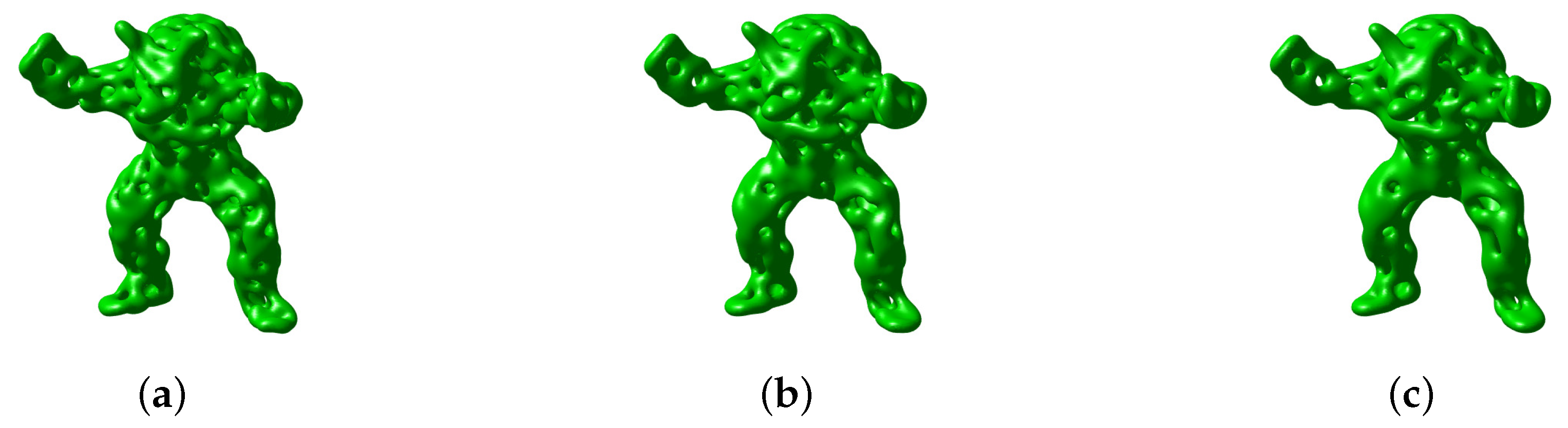

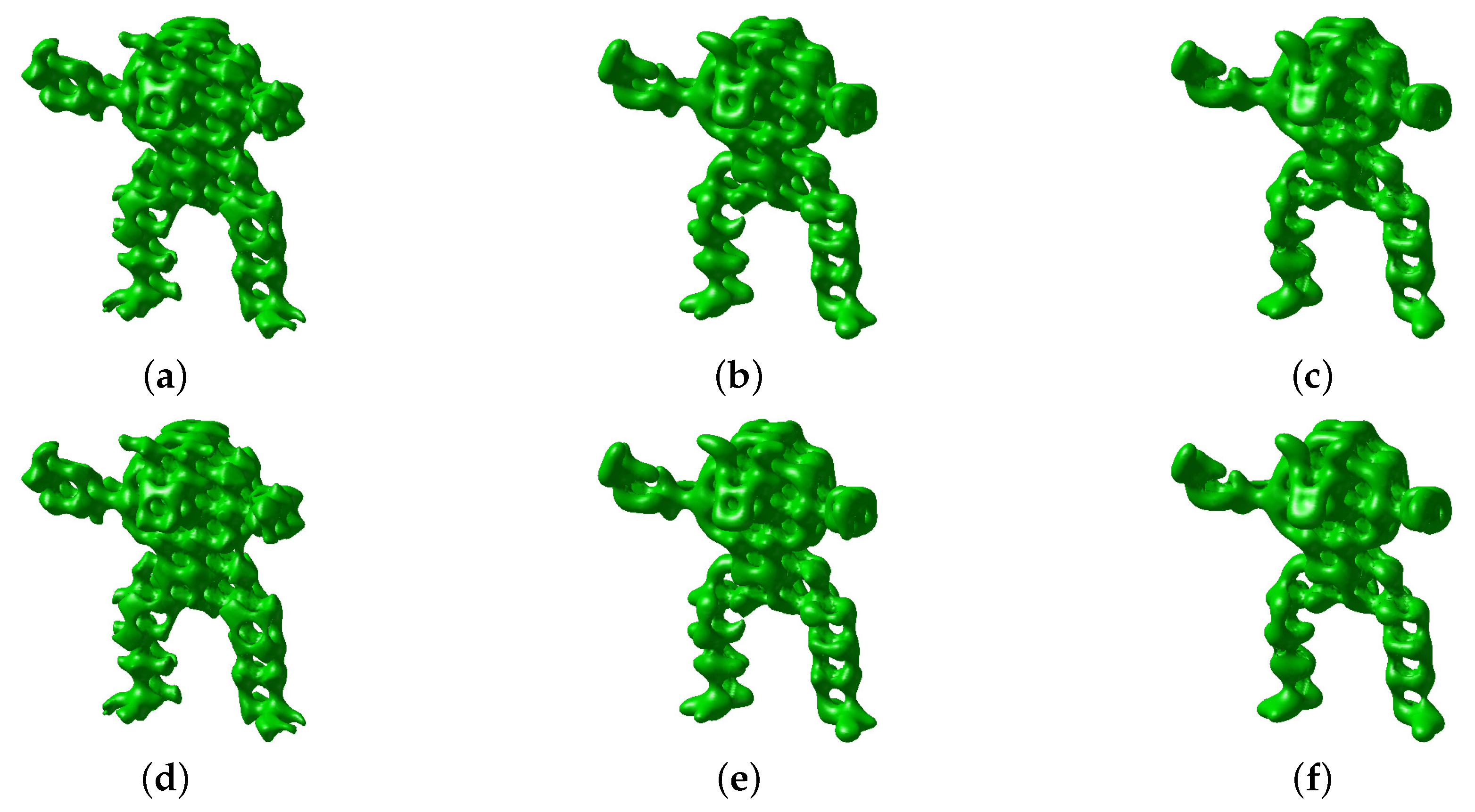

3.2. Complex Structures

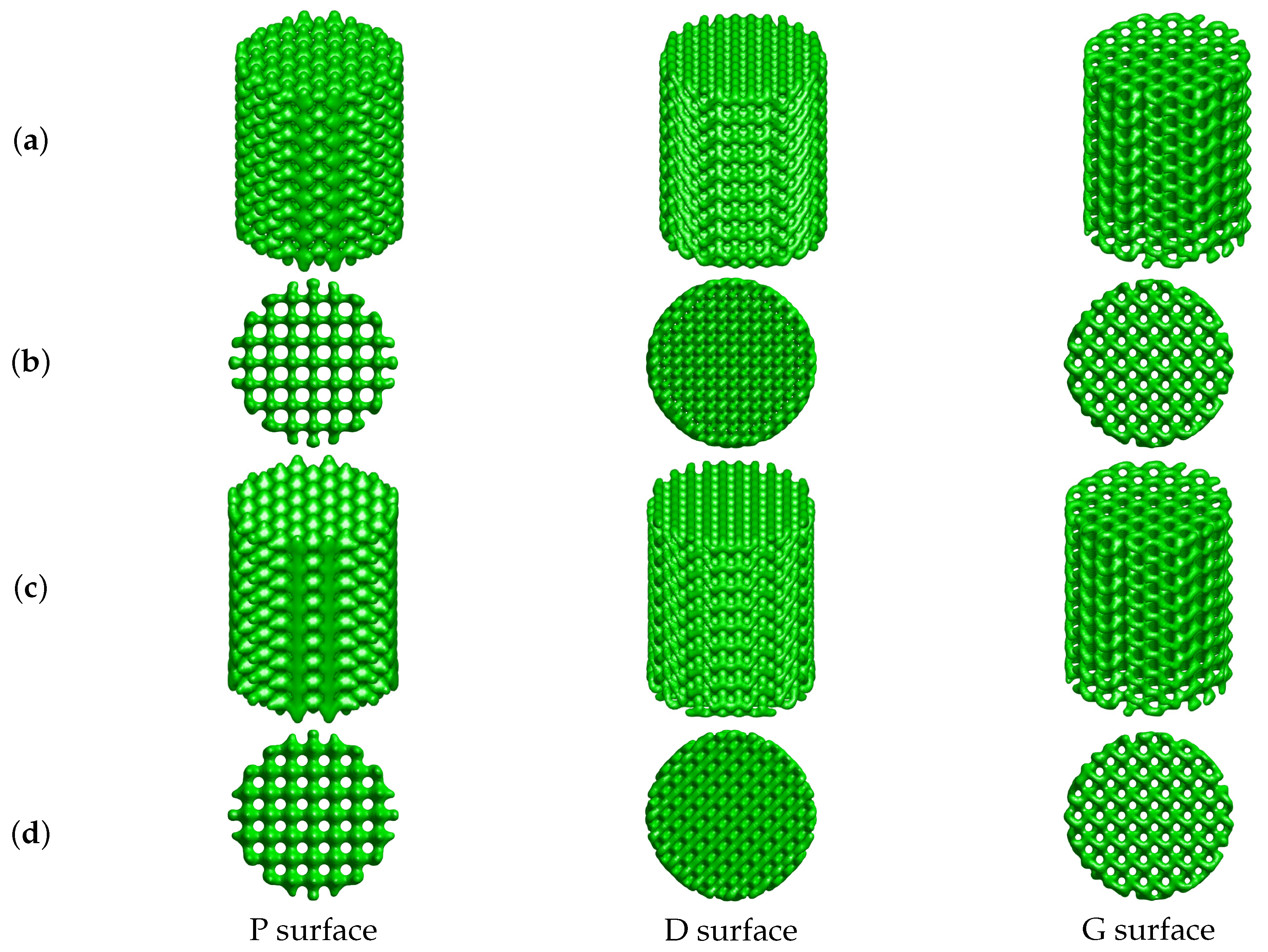

3.3. Porous Structure Generation Using TPMS

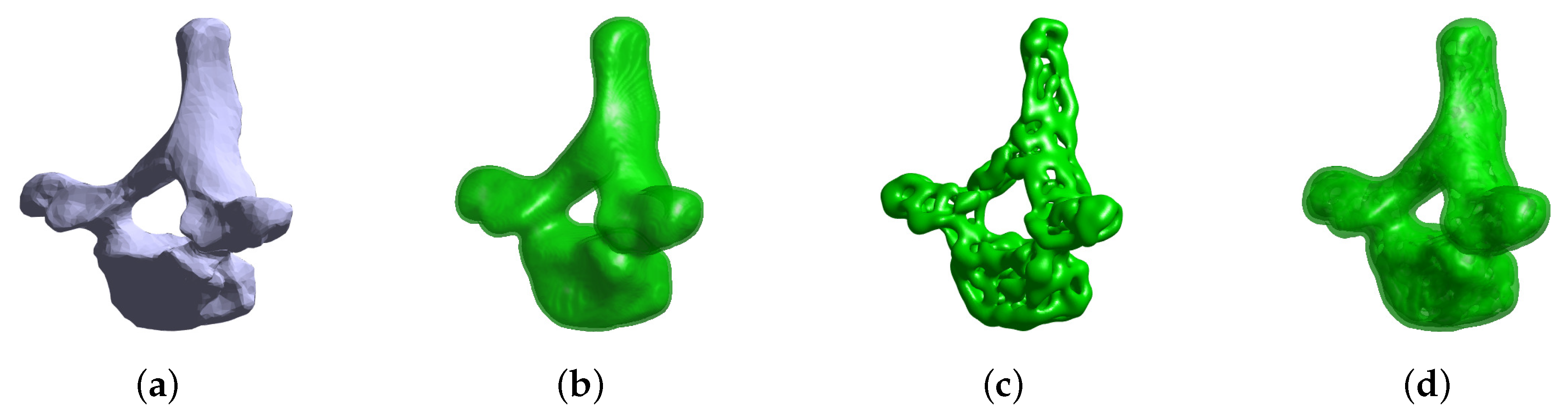

3.4. TPMS Scaffolds Inside Complex Surfaces

4. Conclusions

- •

- The proposed method can generate porous structures from a solid volume using a distance function.

- •

- The porous structure generating algorithm is simple and easy to implement.

- •

- The proposed algorithm can control pore shapes by the space-dependent average concentration function.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Neto, A.; Ferreira, J. Synthetic and marine-derived porous scaffolds for bone tissue engineering. Materials 2018, 11, 1702. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, T.; Kim, M.; Goh, T.; Lee, J.; Kim, Y.; Yoon, S.; Lee, C. Evaluation of Structural and Mechanical Properties of Porous Artificial Bone Scaffolds Fabricated via Advanced TBA-Based Freeze-Gel Casting Technique. Appl. Sci. 2019, 9, 1965. [Google Scholar] [CrossRef] [Green Version]

- Scheffler, M.; Colombo, P. Cellular Ceramics: Structure, Manufacturing, Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Gajendiran, M.; Choi, J.; Kim, S.J.; Kim, K.; Shin, H.; Koo, H.J.; Kim, K. Conductive biomaterials for tissue engineering applications. J. Ind. Eng. Chem. 2017, 51, 12–26. [Google Scholar] [CrossRef]

- Tang, W.; Lin, D.; Yu, Y.; Niu, H.; Guo, H.; Yuan, Y.; Liu, C. Bioinspired trimodal macro/micro/nano-porous scaffolds loading rhBMP-2 for complete regeneration of critical size bone defect. Acta Biomater. 2016, 32, 309–323. [Google Scholar] [CrossRef] [PubMed]

- Cipitria, A.; Lange, C.; Schell, H.; Wagermaier, W.; Reichert, J.C.; Hutmacher, D.W.; Fratzl, P.; Duda, G.N. Porous scaffold architecture guides tissue formation. J. Bone Miner. Res. 2012, 27, 1275–1288. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Toman, J.; Yu, Y.; Biyikli, E.; Kirca, M.; Chmielus, M.; To, A.C. Efficient design-optimization of variable-density hexagonal cellular structure by additive manufacturing: Theory and validation. J. Manuf. Sci. Eng. 2015, 137, 021004. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Badwal, P.S.; Gibson, I. Design and fabrication considerations for three dimensional scaffold structures. In Proceedings of the International Conference on Design and Technologyy, KEG, Geelong, Australia, 5–8 December 2016; pp. 120–126. [Google Scholar]

- Kou, X.; Tan, S. A simple and effective geometric representation for irregular porous structure modeling. Comput. Aided Des. 2010, 42, 930–941. [Google Scholar] [CrossRef] [Green Version]

- Hollister, S.J. Porous scaffold design for tissue engineering. Nat. Mater. 2005, 4, 518. [Google Scholar] [CrossRef]

- Castro, A.; Pires, T.; Santos, J.; Gouveia, B.; Fernandes, P. Permeability versus Design in TPMS Scaffolds. Materials 2019, 12, 1313. [Google Scholar] [CrossRef] [Green Version]

- Hu, J.; Wang, S.; Wang, Y.; Li, F.; Luo, Z. A lightweight methodology of 3D printed objects utilizing multi-scale porous structures. Vis. Comput. 2019, 35, 949–959. [Google Scholar] [CrossRef]

- Song, Y.; Yang, Z.; Liu, Y.; Deng, J. Function representation based slicer for 3d printing. Comput. Aided Geom. Des. 2018, 62, 276–293. [Google Scholar] [CrossRef]

- Mao, Y.; Wu, L.; Yan, D.M.; Guo, J.; Chen, C.W.; Chen, B. Generating hybrid interior structure for 3D printing. Comput. Aided Geom. Des. 2018, 62, 63–72. [Google Scholar] [CrossRef]

- Wang, X.; Ying, X.; Liu, Y.J.; Xin, S.Q.; Wang, W.; Gu, X.; Mueller-Wittig, W.; He, Y. Intrinsic computation of centroidal Voronoi tessellation (CVT) on meshes. Comput. Aided Des. 2015, 58, 51–61. [Google Scholar] [CrossRef]

- Corsini, M.; Cignoni, P.; Scopigno, R. Efficient and flexible sampling with blue noise properties of triangular meshes. IEEE Trans. Vis. Comput. Graph. 2012, 18, 914–924. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schumacher, C.; Thomaszewski, B.; Gross, M. Stenciling: Designing Structurally-Sound Surfaces with Decorative Patterns. Comput. Graph. Forum. 2016, 35, 101–110. [Google Scholar] [CrossRef]

- Turk, G. Generating textures on arbitrary surfaces using reaction-diffusion. In ACM SIGGRAPH Computer Graphics; ACM: New York, NY, USA, 1991; Volume 25, pp. 289–298. [Google Scholar]

- Jeong, D.; Kim, J. Microphase separation patterns in diblock copolymers on curved surfaces using a nonlocal Cahn–Hilliard equation. Eur. Phys. J. E 2015, 38, 117. [Google Scholar] [CrossRef]

- Bertozzi, A.L.; Esedoglu, S.; Gillette, A. Inpainting of binary images using the Cahn–Hilliard equation. IEEE Trans. Image Process. 2006, 16, 285–291. [Google Scholar] [CrossRef]

- Chalupeckỳ, V. Numerical studies of Cahn–Hilliard equation and applications in image processing. In Proceedings of the Czech–Japanese Seminar in Applied Mathematics, Praha, Czech Republic, 4–7 August 2004; pp. 10–22. [Google Scholar]

- Boyer, F.; Lapuerta, C.; Minjeaud, S.; Piar, B.; Quintard, M. Cahn–Hilliard/Navier–Stokes model for the simulation of three-phase flows. Transp. Porous Media 2010, 82, 463–483. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Lu, B.; Jeong, D.; Kim, J. Multicomponent volume reconstruction from slice data using a modified multicomponent Cahn–Hilliard system. Pattern Recognit. 2019, 93, 124–133. [Google Scholar] [CrossRef]

- Eyre, D.J. An unconditionally stable one-step scheme for gradient systems. 1998, 1–15, Unpublished article. [Google Scholar]

- Shen, J.; Tang, T.; Wang, L.L. Spectral Methods: Algorithms, Analysis and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011; Volume 41. [Google Scholar]

- Kim, J. Phase-field models for multi-component fluid flows. Commun. Comput. Phys. 2012, 12, 613–661. [Google Scholar] [CrossRef]

- Shin, J.; Jeong, D.; Kim, J. A conservative numerical method for the Cahn–Hilliard equation in complex domains. J. Comput. Phys. 2011, 230, 7441–7455. [Google Scholar] [CrossRef]

- Yoo, D.J. Computer-aided porous scaffold design for tissue engineering using triply periodic minimal surfaces. Int. J. Precis. Eng. Manuf. 2011, 12, 61–71. [Google Scholar] [CrossRef]

- Lee, H.G.; Park, J.; Yoon, S.; Lee, C.; Kim, J. Mathematical Model and Numerical Simulation for Tissue Growth on Bioscaffolds. Appl. Sci. 2019, 9, 4058. [Google Scholar] [CrossRef] [Green Version]

- Gong, T.; Xie, J.; Liao, J.; Zhang, T.; Lin, S.; Lin, Y. Nanomaterials and bone regeneration. Bone Res. 2015, 3, 15029. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.; Jeong, D.; Yoon, S.; Kim, J. Porous Three-Dimensional Scaffold Generation for 3D Printing. Mathematics 2020, 8, 946. https://doi.org/10.3390/math8060946

Lee C, Jeong D, Yoon S, Kim J. Porous Three-Dimensional Scaffold Generation for 3D Printing. Mathematics. 2020; 8(6):946. https://doi.org/10.3390/math8060946

Chicago/Turabian StyleLee, Chaeyoung, Darae Jeong, Sungha Yoon, and Junseok Kim. 2020. "Porous Three-Dimensional Scaffold Generation for 3D Printing" Mathematics 8, no. 6: 946. https://doi.org/10.3390/math8060946