1. Introduction

In soft robotics, the rigid structures of traditional “hard” robots are replaced with innovative, compliant designs fabricated using flexible materials. Typical “hard” robots can perform prescribed tasks repetitively and with extreme precision. However, it is challenging for traditional robots to safely interact with delicate objects or operate in unstructured environments. In contrast, flexible materials and large strain deformations make soft robotics ideal for applications, such as human-robot interaction or squeezing between obstacles [

1]. Examples of soft robots developed to date are grippers for fragile objects [

2], biomedical robots, such as hand rehabilitation devices [

3], and biomimetic systems, including crawling tetrapods [

4] and manipulators inspired by octopus arms [

5].

Realising the potential of soft robotics has required novel actuator designs. In a traditional robot, actuation occurs at joints connected by rigid members. In contrast, in soft robots, actuation is distributed throughout the flexible members of the system [

1]. Actuation mechanisms for soft robots include dielectric elastomers [

6], ionic polymer-metal composites [

7,

8] and soft pneumatic actuators, such as fibre-reinforced actuators [

9] or pneumatics networks (PneuNets) bending actuators [

10]. PneuNets bending actuators use controlled inflation of moulded expandable chambers to achieve large bending displacements and are a flexible design well suited to varied soft robotics applications.

Soft robotics presents special challenges for position sensing and control [

11]. Traditional “hard” robots are rigid, and typical operating loads only cause small deflections of the robot structure. In hard robots, a small number of sensors at the joints of the robot can be used to measure the robot position, and excellent positioning accuracy may be achieved even with open loop control. In contrast, soft robots have much higher compliance, and even small applied forces can cause significant deformation. Additionally, this deformation is distributed across the entire flexible structure of the soft robot. As such, for accurate control of soft robots, position sensing is both more necessary and more difficult.

Conventional rigid sensors, such as encoders and metal or silicon strain gauges, are ill suited to soft robotics applications [

11]. Instead, novel integrated sensors must be developed. In previous research, deformation sensing for soft robotics has been accomplished by techniques including optical measurement using light sources and light sensors mounted on the robot surface [

12], capacitive sensing using conductive layers on either side of a stretchable dielectric [

13] or resistive strain transducers exploiting the change in resistance that occurs when microfluidic channels containing liquid metals or conductive grease are deformed [

14,

15]. In order to avoid the need for external parts, a complex sensing circuit, or the fabrication of liquid-filled channels, an alternative design of an integrated sensor is desired.

Due to the mechanical and electrical properties of carbon nanotubes (CNT), electrically-conductive CNT networks on soft polymer substrates can be used to produce highly stretchable resistive strain sensors [

16]. Additionally, carbon nanotube resistive strain sensors can be fabricated using low-cost soft lithography techniques [

17]. In this work, a soft pneumatic bending actuator with an integrated carbon nanotube position sensor is demonstrated by integrating a carbon nanotube resistive large-strain sensor with a PneuNets-type soft pneumatic bending actuator. The carbon nanotube resistive sensor is easily integrated during the fabrication of the soft bending actuator by a simple soft lithography process and is able to measure the position of the soft bending actuator over a displacement range of 270. In comparison to current state of the art sensors using liquid metals or conductive grease, this sensor has the advantages of easier integration in the fabrication process, a thin 0.3-mm thickness (avoiding stiffening of the actuator structure) and, due to the moulding process used for fabrication, is expected to be ideally suited for manufacturing sensors at multiple locations at one time.

2. Concept

The soft pneumatic bending actuator used in this work followed the PneuNets design [

18] and was fabricated using Ecoflex

® 00-30, an addition curing silicone material with Shore hardness 00-30 [

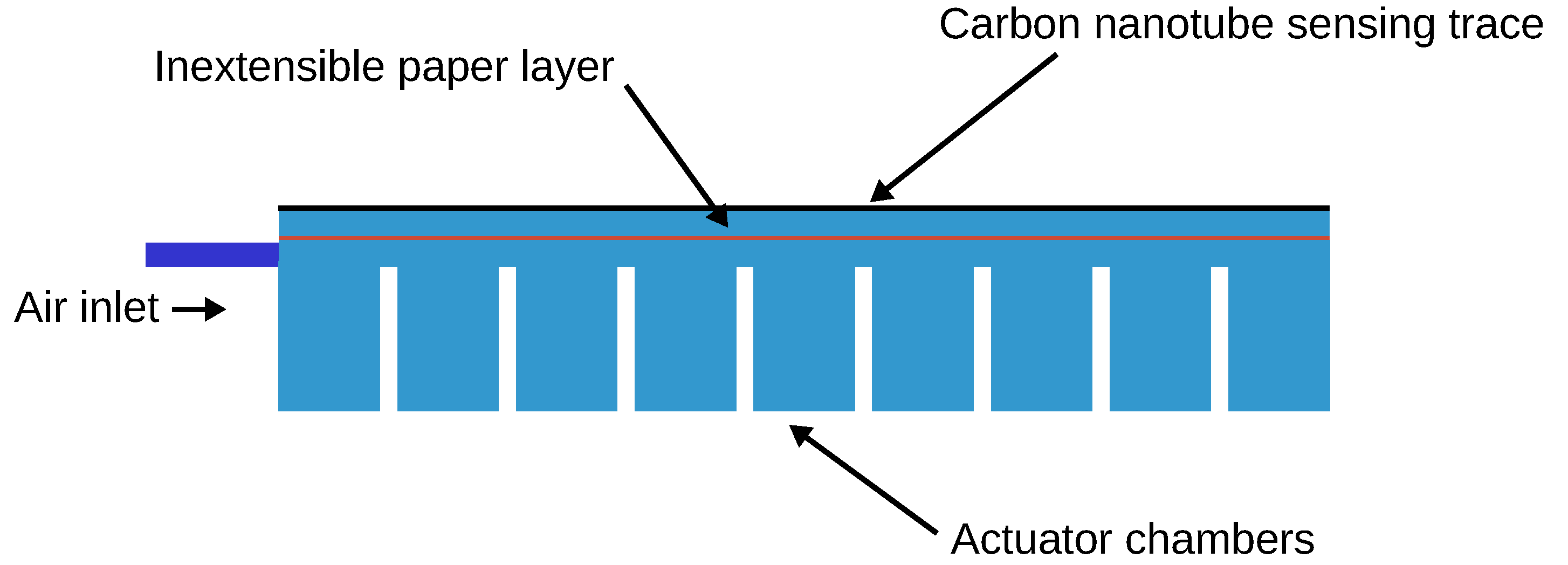

19]. The integrated carbon nanotube resistive sensor used multi-walled carbon nanotubes (MWCNT) purchased from Shenzhen Nanotech Port Co. Ltd. (Shenzhen, China), with a diameter in the range of 10–30 nm and a length >2 μm. The overall structure of the soft robotic actuator with integrated sensor is illustrated in

Figure 1. The key dimensions of the fabricated device are listed in

Table 1.

PneuNets bending actuators consist of a series of interconnected thin-walled air chambers moulded in silicone and bonded to a comparatively stiff upper layer [

10]. The upper layer itself consists of a relatively inextensible paper sheet coated on each side with silicone [

10]. When the air pressure inside the chambers is increased, the chambers inflate without significantly stretching the upper layer.

In our device, the carbon nanotube position sensor is fabricated on the top surface of the upper layer. As the applied pressure is increased and the actuator deflects upwards, the carbon nanotube traces are compressed, leading to a decrease in resistance. It is expected that this design, in which the sensing element is compressed rather than stretched during actuation, will avoid issues with the cracking of the carbon nanotube composite that can occur under excessive tensile strain.

3. Fabrication

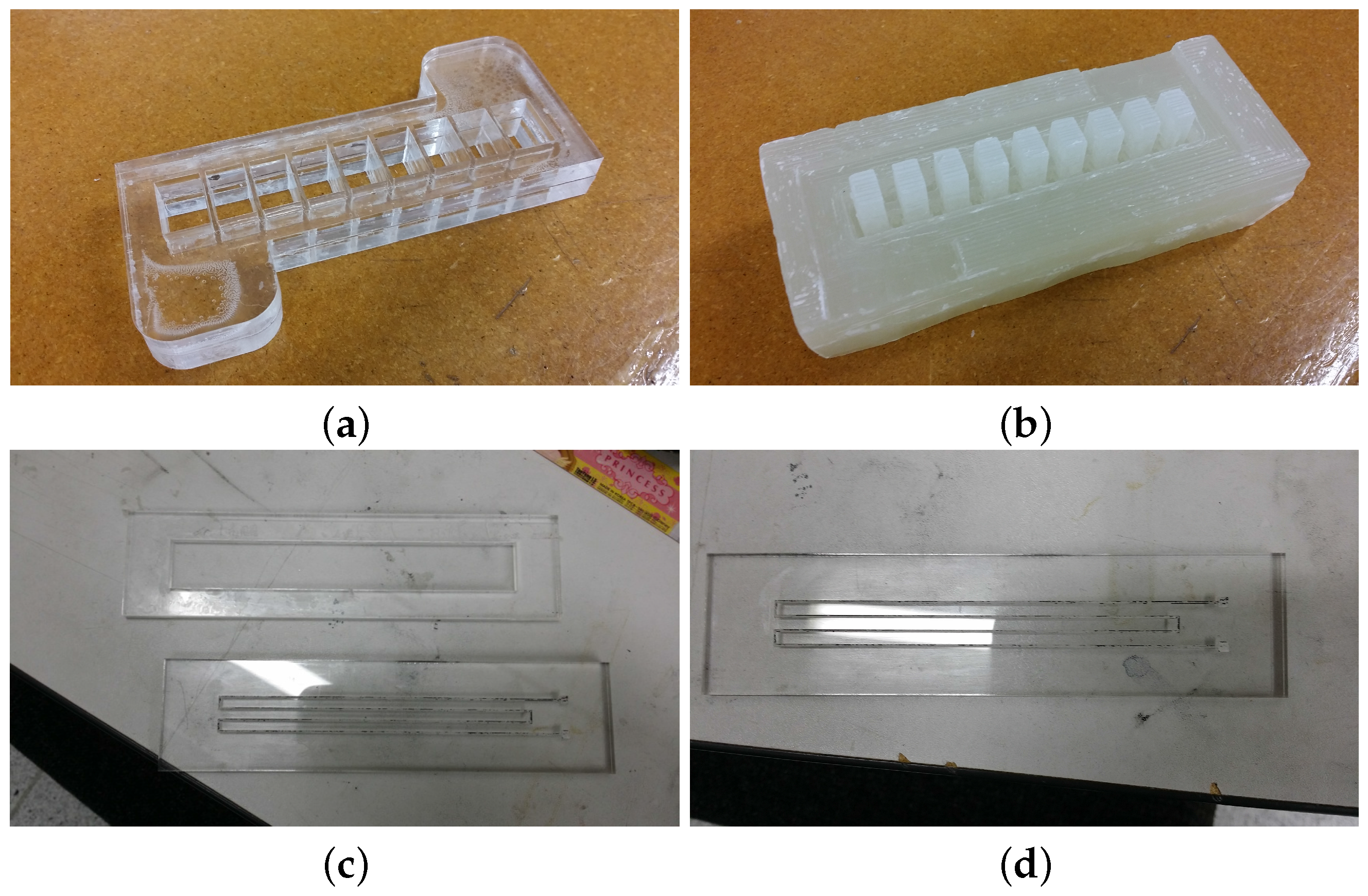

The soft pneumatic bending actuator and integrated carbon nanotube sensor were produced using a soft lithography process with the four moulds shown in

Figure 2. Where possible, the moulds were produced using a laser-cut and laser-engraved acrylic sheet, with CNCmachining of the wax material used for the more complex geometry of the outer chamber mould.

First, the air chambers of the PneuNets actuator were fabricated using the outer and inner chamber moulds. Next, the carbon nanotube sensor and actuator upper layer were fabricated using the upper layer and carbon nanotube moulds. Finally, the assemblies were bonded together using more Ecoflex® as the adhesive.

3.1. Chambers of the Soft Pneumatic Bending Actuator

The initial step in the fabrication was to form the chambers of the soft pneumatic actuator itself. The procedure for fabricating the PneuNets soft actuator followed that presented by the Harvard Biodesign Lab Soft Robotics Toolkit [

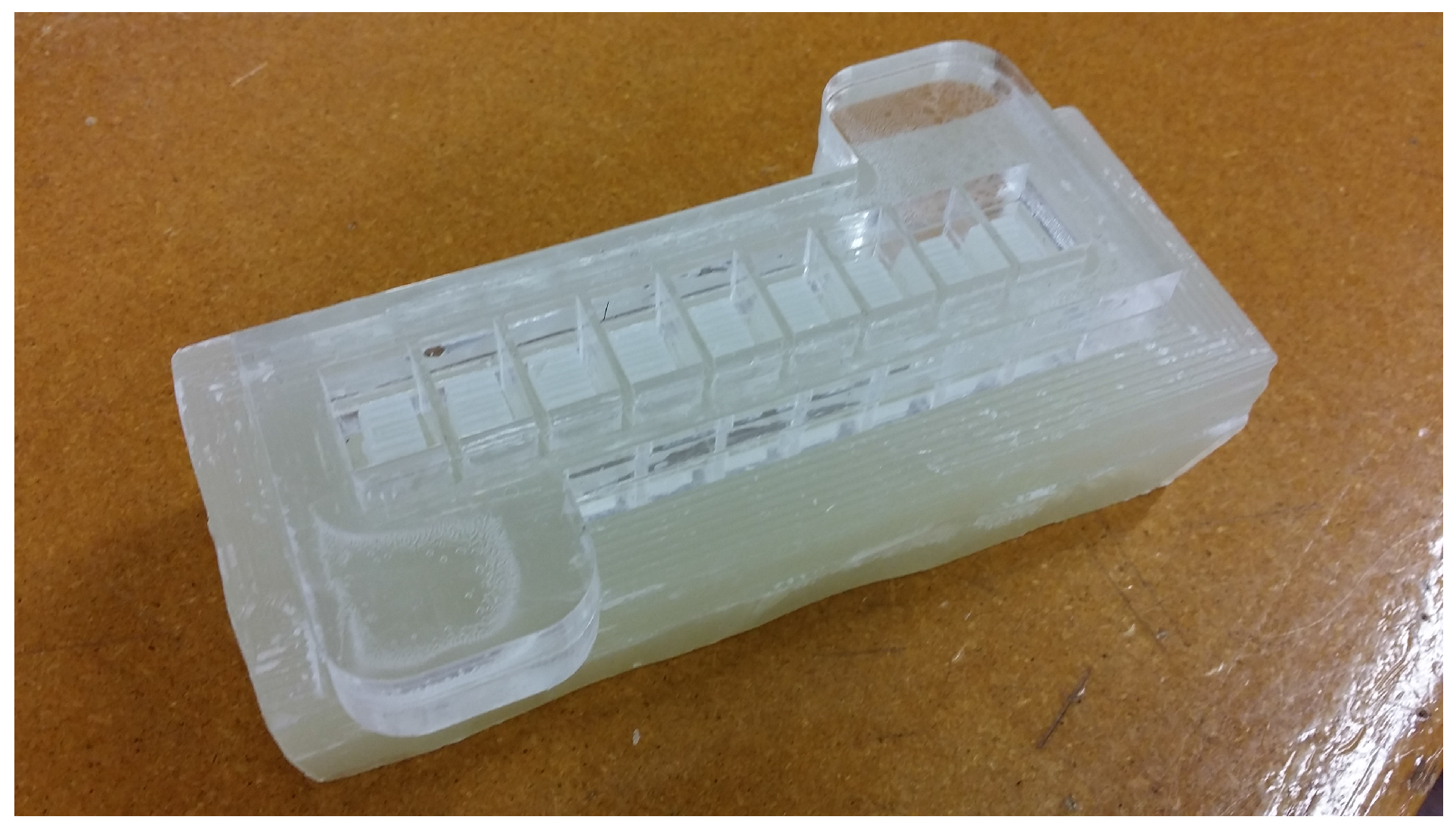

18]. In summary, Ecoflex

® 00-30 Part A and Part B were mixed in a 1:1 ratio and cast in the assembled inner and outer chamber moulds shown in

Figure 3. The assembly was left to cure for four hours at room temperature before removal from the mould.

3.2. Carbon Nanotube Sensor

The carbon nanotube resistive sensor was produced by a simple soft lithography process using the laser-engraved acrylic mould (shown in

Figure 2d) and a 0.5% dispersion of MWCNT in isopropanol (IPA) by weight.

First, the dispersion of MWCNT in IPA was prepared by the addition of 0.05 g MWCNT to 10 g of IPA, followed by sonication for 30 min in an Elmasonic ultrasound system to disperse the carbon nanotubes. An excess of the resulting MWCNT dispersion was then dispensed into the carbon nanotube mould, followed by spreading with a flat sheet to remove excess until there were no remaining gaps in the engraved track on the mould. The filled mould was then dried under vacuum to remove remaining IPA.

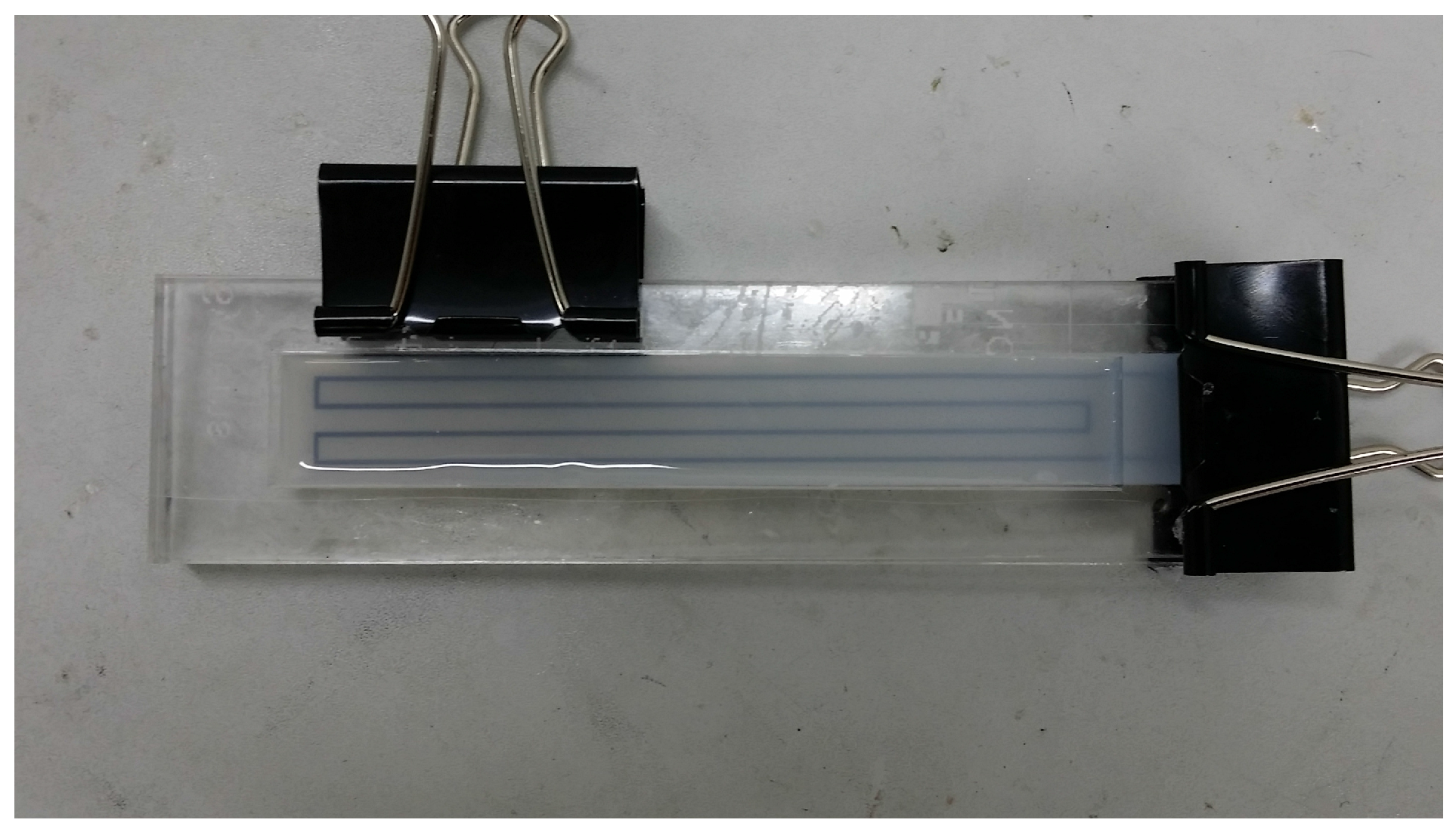

Finally, the Ecoflex

® mixture was poured into the mould to form the upper layer of the soft pneumatic actuator and bonded to the MWCNT, as shown in

Figure 4.

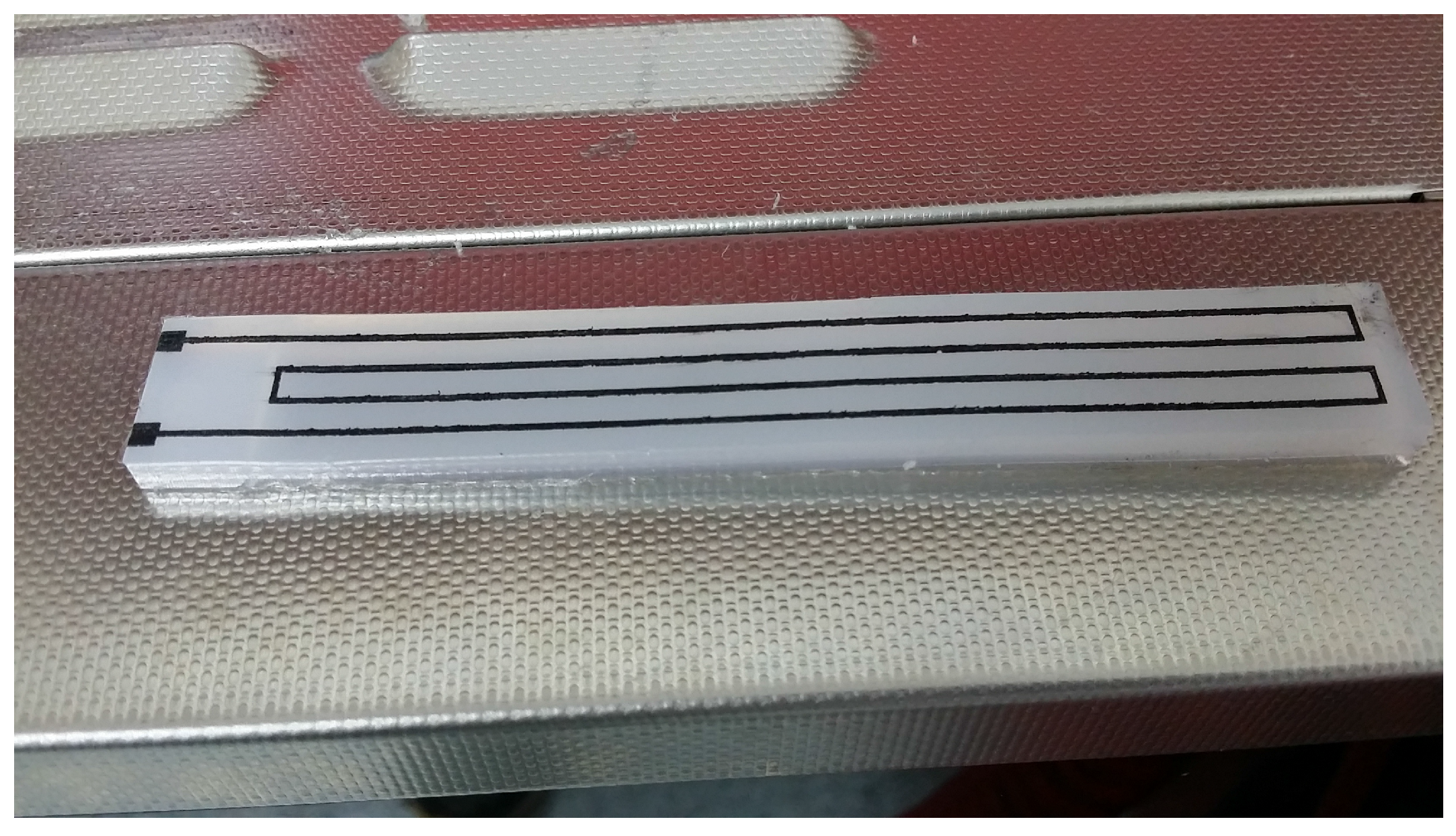

The completed upper layer with the MWCNT sensor is shown in

Figure 5. As shown in

Figure 5, the MWCNT layer has become adhered to the silicone material due to the penetration of Ecoflex

® into the MWCNT layer during curing.

3.3. Final Assembly

In the final stage of the assembly process, the cured chamber assembly and upper layer were joined using additional Ecoflex

® 00-30 mixture, which was spread on the top surface of the chamber assembly and the lower surface of the upper layer. To complete the fabrication process, after curing the final assembly for 4 h at room temperature, it was placed in an oven at 80 C for 2 h and 100 C for 1 h to fully cure the Ecoflex

®. The completed soft pneumatic actuator with integrated MWCNT sensor is shown in

Figure 6.

4. Characterization

After fabrication, the performance of the bending actuator with the integrated carbon nanotube position sensor was characterized using an experimental system controlled from a computer to pressurize the actuator and measure bending angle and resistance.

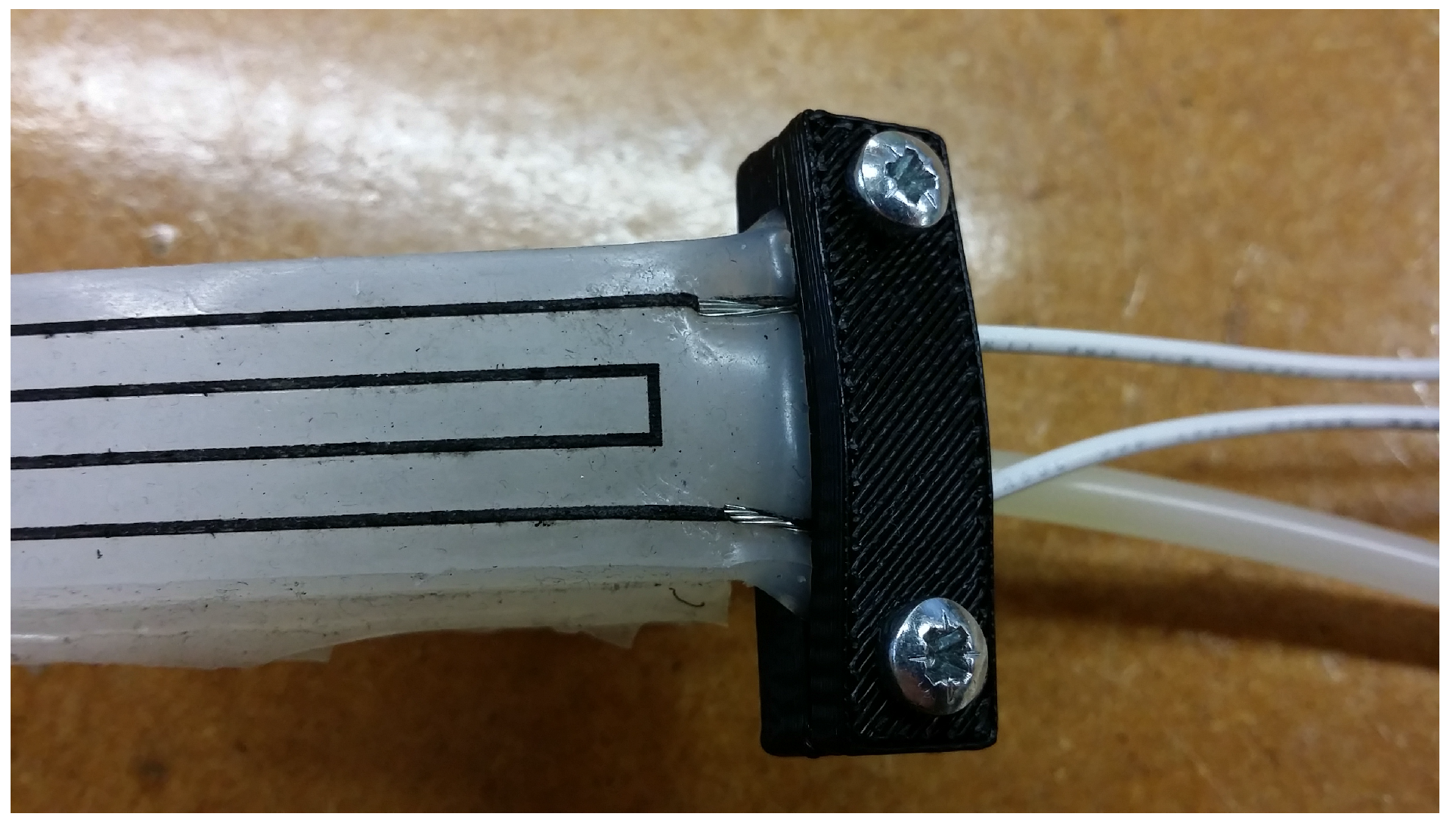

An electro-pneumatic regulator valve (SMC ITV0030-3BS) was used to supply the actuator with a controllable air pressure between 0 and 500 kPa. At the same time, the angular position of the tip of the actuator was measured using a fixed camera and image processing software using the OpenCV library [

20] to detect the rotation angle of a fiducial marker fixed to the end of the soft actuator. The resistance of the carbon nanotube large-strain sensor was measured using a Keithley 2602 source measure unit (SMU). In order to make a reliable connection to the carbon nanotube traces, the 3D printed mechanical clamp shown in

Figure 7 was used to hold the electrodes in place.

5. Results and Discussion

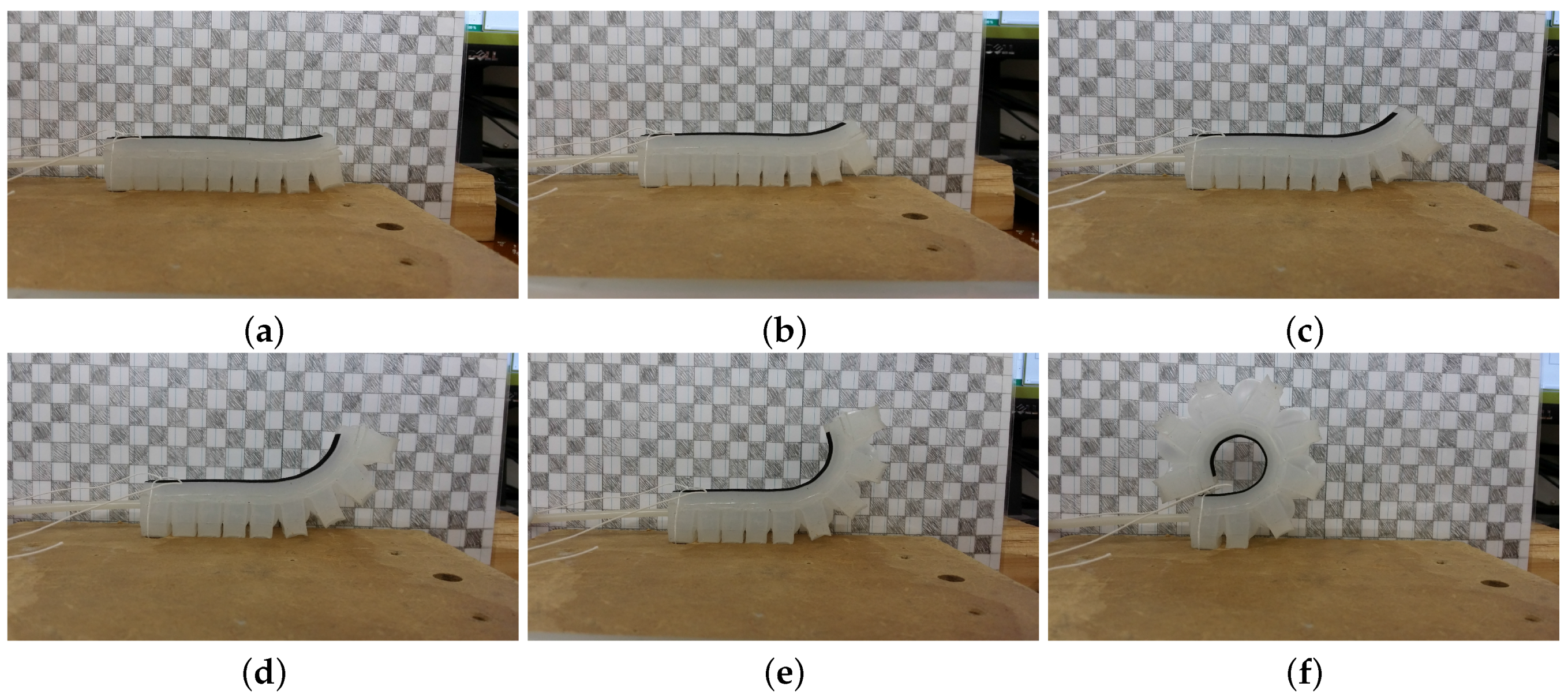

The bending of the soft pneumatic actuator when the applied pressure is increased is shown in

Figure 8. As shown in

Figure 8, the actuator is capable of bending by more than 180 degrees. Due to the gap between adjacent actuator chambers in the relaxed state and the hyperelastic nature of the Ecoflex

® material, the pneumatic pressure and the bending angle are not linearly related. As a result, very little actuator displacement occurs at low pressure, while at higher pressures, the angle of bending increases rapidly.

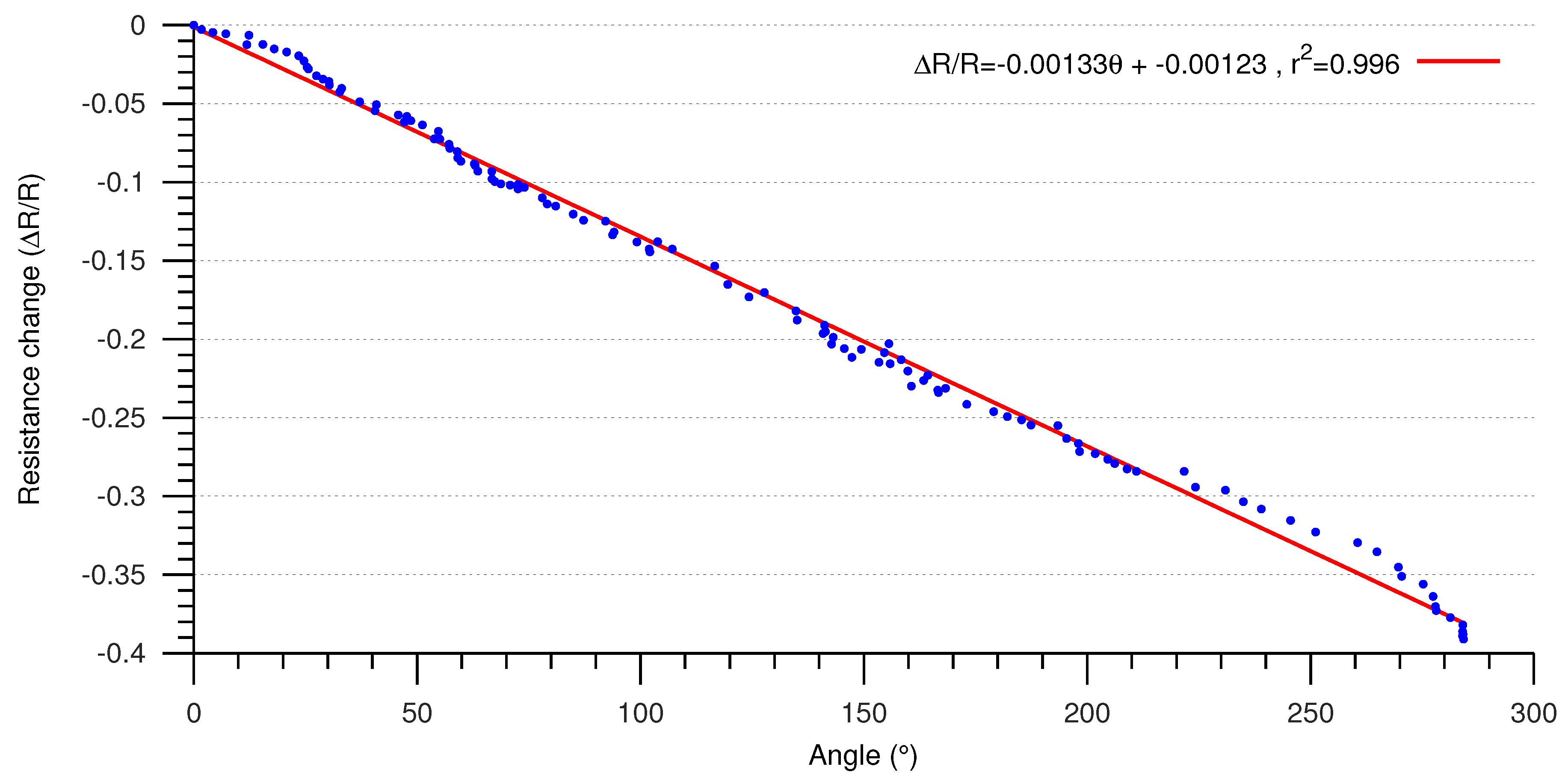

The change in resistance of the carbon nanotube sensor during bending is plotted against the bending angle in

Figure 9. The change in resistance of a strained CNT layer depends on the combined effects of geometry change, tunnelling and physical disconnection effects, such as cracking [

17]. From

Figure 9, the relationship between bending angle and CNT strain sensor voltage is approximately linear (

), as was also observed by other researchers at a similar strain level [

21]. There is a substantial 38% decrease in sensor resistance between the relaxed and fully bent state, confirming that the integrated carbon nanotube large strain sensor is well suited to measuring the displacement of a soft pneumatic actuator.

The hysteresis of the fabricated device is illustrated in

Figure 10. From

Figure 10, the largest difference between the measured resistance with increasing angle and decreasing angle was approximately 5% (occurring at θ = 150°). Due to limitations of the experimental setup (where only the pressure in the actuator was controlled), it was challenging to control the rate of change of angle while deflating the actuator. For this reason, there are fewer data points in the curve for decreasing θ than the curve for increasing θ. It is expected that some of the hysteresis may be explained by a different mechanical deflected shape during (faster) deflation than (slower) inflation.