Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting

Abstract

:1. Introduction

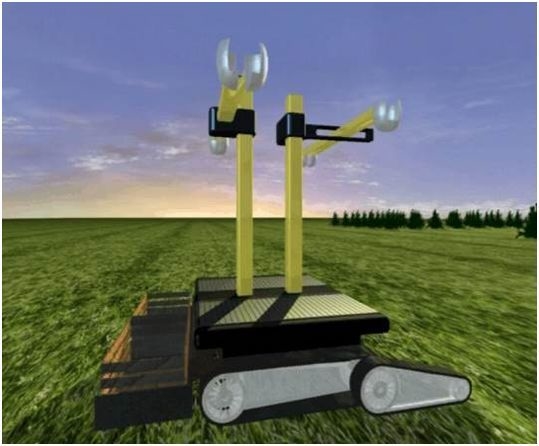

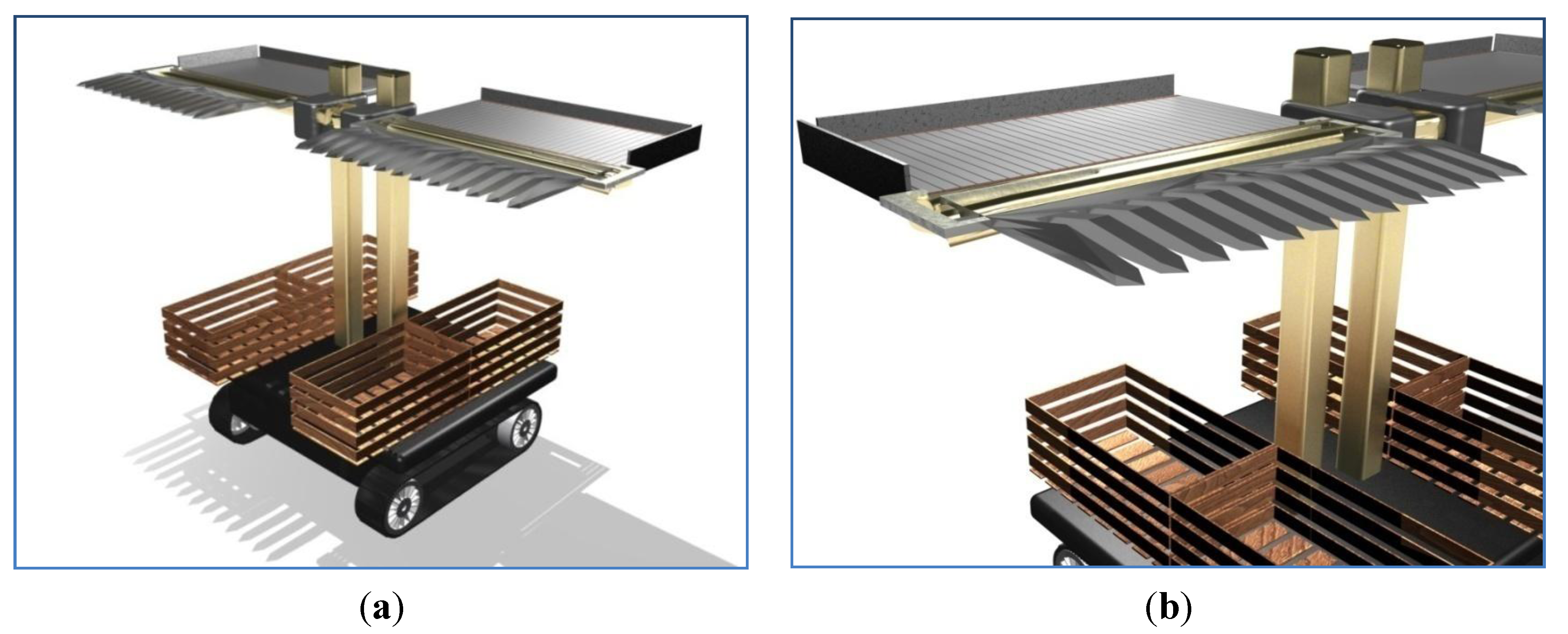

2. Investigation about Artichokes Field Design and Current Harvest Methodology

3. Machines Design and Simulations

4. Artificial Vision Algorithm

4.1. Details of the Image Processing Algorithm

| Parameter | Minimum value | Maximum value |

|---|---|---|

| Contrast | 0.0755 | 0.16 |

| Entropy | 0.2745 | 0.33 |

| Standard Deviation | 0.2045 | 0.24 |

4.2. Results of the Image Processing Algorithm

5. Results

| Selective Harvesting robot | Mass Harvesting robot | |

|---|---|---|

| Speed | 2 m/s (Arm)–0.2 m/s (Vehicle) | 0.2 m/s (Vehicle) |

| Productivity | 0.13 Artichokes/s | 1.2 Artichokes/s |

| Productivity per hour | 480 Artichokes/h | 4,320 Artichokes/h |

| TOTAL Productivity (Working day) | 3,840 Artichokes/8 h | 34,560 Artichokes/8 h |

| Weight harvested (Unit weight of typical artichoke 200 g) | 96 kg/h | 864 kg/h |

6. Conclusions

Acknowledgements

Conflicts of Interest

References

- Longo, D.; Pennisi, A.; Bonsignore, R.; Schillaci, G.; Muscato, G. A small autonomous electrical vehicle as partner for heroic viticulture. Acta Hort. 2013, 978, 391–398. [Google Scholar]

- Longo, D.; Muscato, G.; Caruso, L.; Conti, A.; Schillaci, G. Design of a Remotely Operable Sprayer for Precision Farming Application. In Proceedings of International Conference Ragusa SHWA2012, Ragusa Ibla, Italy, 3–6 September 2012; pp. 238–242.

- Tillet, N.D. Robotic manipulators in horticulture: A review. J. Agric. Eng. Res. 1993, 55, 89–105. [Google Scholar] [CrossRef]

- Sarig, Y. Robotics for fruit harvesting: A state-of-the-art review. J. Agric. Eng. Res. 1993, 54, 265–280. [Google Scholar] [CrossRef]

- Sanders, K.F. Orange harvesting systems review. Biosyst. Eng. 2005, 90, 115–125. [Google Scholar] [CrossRef]

- Li, P.; Lee, S.; Hsu, H.-Y. Review on fruit harvesting method for potential use of automatic fruit harvesting systems. Proc. Eng. 2011, 23, 351–366. [Google Scholar] [CrossRef]

- Muscato, G.; Prestifilippo, M.; Abbate, N.; Rizzuto, I. A prototype of an orange picking robot: Past history, the new robot and experimental results. Ind. Robot. Int. J. 2005, 32, 128–138. [Google Scholar] [CrossRef]

- Kapach, K.; Barnea, E.; Mairon, R.; Edan, Y.; Ben-Shahar, O. Computer vision for fruit harvesting robots—State of the art and challenges ahead. Int. J. Comput. Vis. Robot. 2012, 3, 4–34. [Google Scholar] [CrossRef]

- Jimenez, A.R.; Ceres, R.; Pons, J.L. A survey of computer vision methods for locating fruit on trees. Trans. Am. Soc. Agric. Eng. 2000, 43, 1911–1920. [Google Scholar]

- Schillaci, G.; Pennisi, A.; Franco, F.; Longo, D. Detecting Tomato Crops in Greenhouses Using a Vision Based Method. In Proceedings of International Conference Ragusa SHWA2010, Ragusa Ibla, Italy, 3–6 September 2012; pp. 252–258.

- Van Henten, E.J.; Hemming, J.; van Tuijl, B.A.J.; Kornet, J.G.; Meuleman, J.; Bontsema, J.; van Os, E.A. An autonomous robot for harvesting cucumbers in greenhouses. Auton. Robots 2002, 13, 241–258. [Google Scholar] [CrossRef]

- Hayashi, S.; Ota, T.; Kubota, K.; Ganno, K.; Kondo, N. Robotic Harvesting Technology for Fruit Vegetables in Protected Horticultural Production. In Proceedings of the Information and Technology for Sustainable Fruit and Vegetable Production, FRUITIC 05, Montpellier, France, 12–16 September 2005.

- Foglia, M.M.; Reina, G. Agricultural robot for radicchio harvesting. J. Field Robot. 2006, 23, 363–377. [Google Scholar]

- Belforte, G.; Deboli, R.; Gay, P.; Piccarolo, P.; Ricauda Aimonino, D. Robot design and testing for green house applications. Biosyst. Eng. 2006, 95, 309–321. [Google Scholar] [CrossRef]

- Acaccia, G.M.; Michelini, R.C.; Molfino, R.M.; Razzoli, R.P. Mobile Robots in Greenhouse Cultivation: Inspection and Treatment of Plants. In Proceedings of ASER 2003, 1st International Workshop on Advances in Service Robotics, Bardolino, Italy, 13–15 March 2003.

- Lee, W.S.; Slaughter, D.C.; Giles, D.K. Robotic weed control system for tomatoes. Precis. Agric. 1999, 1, 95–113. [Google Scholar] [CrossRef]

- Pari, L.; Sissot, F.; Giannini, E. European Union Research Project Biocard: Mechanization Activities Results. In Proceedings of the Technology and Management to Increase the Efficiency in Sustainable Agricultural System Conference, Rosario, Argentina, 1–4 September 2009.

- Pari, L.; Civitarese, V.; Assirelli, A.; del Giudice, A. Prototype for Cynara Cardunculus Capitula Threshing and Biomass Windrowing. In Proceedings of the 17th European Biomass Conference & Exibition—From Research to Industry and Markets, Hamburg, Germany, 29 June–3 July 2009; Volume 1, pp. 262–267.

- Haralick, R.M.; Shanmugan, K.; Dinstein, I. Textural features for image classification. IEEE Trans. Syst. Man Cybern. 1973, 3, 610–621. [Google Scholar] [CrossRef]

- Mallat, S. A theory for multiresolution signal decomposition: The wavelet representation. IEEE Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Archontoulis, S.V.; Struik, P.C.; Vos, J.; Danalatos, N.G. Phenological growth stages of Cynara cardunculus: Codification and description according to the BBCH scale. Ann. Appl. Biol. 2010, 156, 253–270. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Longo, D.; Muscato, G. Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting. Robotics 2013, 2, 217-230. https://doi.org/10.3390/robotics2040217

Longo D, Muscato G. Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting. Robotics. 2013; 2(4):217-230. https://doi.org/10.3390/robotics2040217

Chicago/Turabian StyleLongo, Domenico, and Giovanni Muscato. 2013. "Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting" Robotics 2, no. 4: 217-230. https://doi.org/10.3390/robotics2040217

APA StyleLongo, D., & Muscato, G. (2013). Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting. Robotics, 2(4), 217-230. https://doi.org/10.3390/robotics2040217