Damage Analysis and Evaluation of Light Steel Structures Exposed to Wind Hazards

Abstract

:1. Introduction

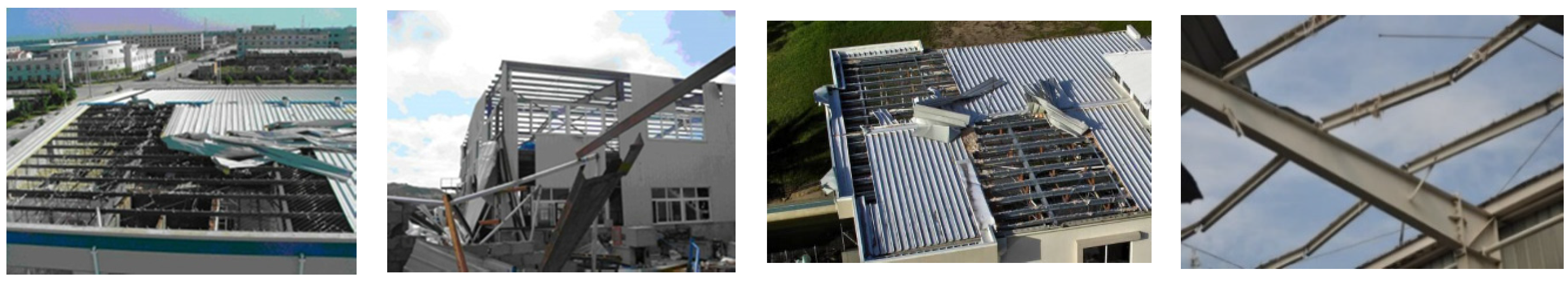

2. Cladding

3. Purlin-Sheeting System (Roof/Wall Systems)

4. Main Resisting System

5. Performance Evaluation of Light Steel Systems Exposed to Wind Hazards

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, S.; Shi, Y.Z.; Geng, X.Q. Damage analysis of light steel industrial building under 0414 Typhoon of Taizhou, Zhejiang. Steel Struct. 2005, 20, 52–57. (In Chinese) [Google Scholar]

- Jin, Y.; Yang, Q.; Li, Q. Typhoon damage investigation of claddings of light steel buildings. J. Build. Struct. 2010, 2, S197–S201. (In Chinese) [Google Scholar]

- Song, F.F. Typhoon Damage Estimation and Prediction of Wind Vulnerable Stuctures; Harbin Institute of Technology: Harbin, China, 2010. (In Chinese) [Google Scholar]

- Boughton, G.N.; Henderson, D.J.; Ginger, J.D.; Holmes, J.D.; Walker, G.R.; Leitch, G.J.; Somerville, L.R.; Frye, U.; Jayasinghe, N.C.; Kim, P.Y. Tropical Cyclone Yasi Structural Damage to Buildings; CTS Technical Report No. 57; James Cook University: Townsville City, Australia, 2011; Volume 4. [Google Scholar]

- Henderson, D.; Ginger, J.; Leitch, C.; Boughton, G.; Falck, D. Tropical Cyclone Larry Damage to Buildings in the Innisfail Area; Technical Report No. 51; James Cook University: Townsville City, Australia, 2006; Volume 9. [Google Scholar]

- Fan, B.Y.; Tamura, S.Y.; Cao, Q.S.; Yang, N. Investigation and Analysis of Public and Industrial Building Damage Caused by Typhoon “Mujigae”. In Zhanjiang Guangdong Yearbook of Disaster Prevention; Zhanjiang Municipal People’s Government: Zhanjiang, China, 2016. (In Chinese) [Google Scholar]

- Lovisa, A.C.; Henderson, D.J.; Ginger, J.D.; Walker, G. Characterizing fatigue microcrack initiation in profiled steel roof cladding. Eng. Struct. 2016, 125, 364–373. [Google Scholar] [CrossRef]

- Xu, Y.L. Fatigue performance of screw-fastened light-gauge-steel roofing sheets. Eng. Struct. 1995, 121, 389–398. [Google Scholar] [CrossRef]

- Xu, Y.L.; Teng, J.D. Local plastic failure of light gauge steel roofing sheets: Finite element analysis versus experiment. J. Constr. Steel Res. 1994, 30, 125–150. [Google Scholar] [CrossRef]

- Mahendran, M. Behaviour and design of crest-fixed profiled steel roof claddings under wind uplift. Eng. Struct. 1994, 16, 368–376. [Google Scholar] [CrossRef] [Green Version]

- Mahendran, M. Test method for determination of pull-through strength of screwed connections in profiled steel claddings. Civ. Eng. Trans. 1995, 37, 219–227. [Google Scholar]

- Mahendran, M. Wind-resistance low-rise buildings in the Tropics. J. Perform. Constr. Facil. 1995, 9, 330–345. [Google Scholar] [CrossRef]

- Mahaarachchi, D.; Mahendran, M. Strength of screwed connections in crest-fixed trapezoidal steel claddings. Aust. J. Struct. Eng. 2005, 6, 11–23. [Google Scholar]

- Lovisa, A.C.; Wang, V.Z.; Henderson, D.J.; Ginger, J.D. Development and validation of a numerical model for steel roof cladding subject to static uplift loads. Wind Struct. 2013, 17, 495–513. [Google Scholar] [CrossRef]

- Mahaarachchi, D.; Mahendran, M. Wind uplift strength of trapezoidal steel cladding with closely spaced ribs. J. Wind Eng. Ind. Aerodyn. 2009, 97, 140–150. [Google Scholar] [CrossRef] [Green Version]

- Mahaarachchi, D.; Mahendran, M. A strain criterion for pull-through failures in crest-fixed steel claddings. Eng. Struct. 2009, 31, 498–506. [Google Scholar] [CrossRef] [Green Version]

- Stephan, H.C. Investigation of a Testing Approach for Trapezoidal Crest Fastened Metal Cladding; Stellenbosch University: Stllenbosch, South Africa, 2013. [Google Scholar]

- Morgan, J.; Beck, V. Failure of sheet metal roofing under repeated wind loading. Civ. Eng. Trans. 1977, 138, 290–294. [Google Scholar]

- Beck, V.; Stevens, L. Wind loading failures of corrugated roof cladding. Civ. Eng. Trans. 1979, 19, 1–5. [Google Scholar]

- Lynn, B.A.; Stathopoulos, T. Wind-induced fatigue on low metal buildings. J. Struct. Eng. 1985, 111, 826–839. [Google Scholar] [CrossRef]

- Mahendran, M. Fatigue behavior of corrugated roofing under cyclic wind loading. Civ. Eng. Trans. 1990, 32, 219–226. [Google Scholar]

- Mahendran, M. Effect of Overload Cycles on Thin steel roof claddings during cyclonic winds. J. Test. Eval. Am. Soc. Test. Mater. 1994, 22, 451–457. [Google Scholar]

- Mahendran, M. Steel roof claddings under simulated cyclonic wind forces. Aust. Civ. Eng. Trans. 1994, 36, 1–10. [Google Scholar]

- Mahendran, M. Towards an appropriate fatigue loading sequence for roof claddings in cyclone prone areas. Eng. Struct. 1995, 17, 476–484. [Google Scholar] [CrossRef] [Green Version]

- Ellifrit, D.; Burnette, R. Pull-over strength of screws in simulated building tests. In Proceedings of the Tenth International Speciality Conference on Cold-formed Steel Structures, St. Louis, MI, USA, 23–24 October 1990.

- Xu, Y.L. Determination of wind-induced fatigue loading on roof cladding. J. Eng. Mech. 1995, 121, 956–963. [Google Scholar] [CrossRef]

- Xu, Y.L. Wind-induced fatigue loading and damage to hip and gable roof claddings. J. Struct. Eng. 1996, 122, 1475–1483. [Google Scholar] [CrossRef]

- Henderson, D.J. Response of Pierced Fixed Metal Roof Cladding to Fluctuating Wind Loads; School of James Cook University: Townsville, Australia, 2010. [Google Scholar]

- Hancock, G.J.; Trahair, N.S. Finite element analysis of the lateral buckling of continuously restrained beam-columns. Civ. Eng. Trans. 1978, 20, 120–127. [Google Scholar]

- Hancock, G.J.; Trahair, N.S. Lateral buckling of roof purlins with diaphragm restraints. Civ. Eng. Trans. 1979, 21, 10–15. [Google Scholar]

- Hancock, G.J.; Celeban, M.; Healy, C.; Geogiou, P.N.; Ings, N.L. Tests of purlins with screw fastened sheeting under wind uplift. In Proceedings of the Tenth International Speciality Conference on Cold-formed Steel Structures, St. Louis, MI, USA, 23–24 October 1990.

- Rousch, C.J.; Hancock, G.J. Comparison of tests of bridged and unbridged purlins with a nonlinear analysis model. J. Constr. Steel Res. 1997, 41, 197–220. [Google Scholar] [CrossRef]

- Lucas, R.M. Modeling of cold-formed purlin-sheeting systems—Part 1: Full model. Thin-Walled Struct. 1997, 27, 223–243. [Google Scholar] [CrossRef]

- Lucas, R.M. Modeling of cold-formed purlin-sheeting systems—Part 2: Simplified model. Thin-Walled Struct. 1997, 27, 263–286. [Google Scholar] [CrossRef]

- Katnam, K.B.; van Impe, R.; Lagae, G.; de Strycker, M. A theoretical numerical study of the rotational restraint in cold-formed steel single purlin-sheeting systems. Comput. Struct. 2007, 85, 1185–1193. [Google Scholar] [CrossRef]

- Vrany, T. Effect of loading on the rotational restraint of cold-formed purlins. Thin-Wall Struct. 2007, 44, 1287–1292. [Google Scholar] [CrossRef]

- European Committee for Standardization. Eurocode3: Design of Steel Structures Part 1–3, General Rules for Cold-Formed Thin Gauge Members and Sheeting; European Committee for Standardization (CEN): Brussels, Belgium, 2003. [Google Scholar]

- Gao, T.; Moen, C. Predicting rotational restraint provided to wall girts and roof purlins by through-fastened metal panels. Thin-Walled Struct. 2012, 61, 145–153. [Google Scholar] [CrossRef]

- Zhao, C.X.; Yang, J.; Wang, F.; Chan, A.H.C. Rotational stiffness of cold-formed steel roof purlin-sheeting connections. Eng. Struct. 2014, 59, 284–297. [Google Scholar] [CrossRef]

- Ye, Z.M.; Kettle, R.; Li, L.; Schafer, B.W. Buckling behavior of cold-formed zed-purlins partially restrained by steel sheeting. Thin-Walled Struct. 2002, 20, 853–864. [Google Scholar] [CrossRef]

- Ye, Z.M.; Kettle, R.; Li, L. Analysis of cold-formed zed-purlins partially restrained by steel sheeting. Comput. Struct. 2004, 82, 731–739. [Google Scholar] [CrossRef]

- Chu, X.T.; Ye, Z.M.; Kettle, R.; Li, L.Y. Buckling behavior of cold-formed channel sections under uniformly distributed loads. Thin-Walled Struct. 2005, 43, 531–542. [Google Scholar] [CrossRef]

- Li, L.Y. Lateral-torsional buckling of cold-formed zed-purlins partial-laterally restrained by metal sheeting. Thin-Walled Struct. 2004, 42, 995–1011. [Google Scholar] [CrossRef]

- Yuan, W.B.; Cheng, S.S.; Li, L.Y.; Kim, B. Web-flange distortional buckling of partially restrained cold-formed steel purlins under uplift loading. Int. J. Mech. Sci. 2014, 89, 476–481. [Google Scholar] [CrossRef]

- Li, L.Y. Analyses of distortional buckling of cold-formed sigma purlins using EN 19930103. J. Constr. Steel Res. 2009, 65, 2099–2102. [Google Scholar] [CrossRef]

- Chen, J.-K.; Li, L.Y. Distortional buckling of cold-formed steel sections subjected to uniformly distributed transverse loading. Int. J. Struct. Stab. Dyn. 2010, 10, 1017–1030. [Google Scholar] [CrossRef]

- Basaglia, C.; Camotim, D.; Goncalves, R.; Graca, A. GBT-based assessment of the buckling behavior of cold-formed steel purlins restrained by sheeting. Thin-Walled Struct. 2013, 72, 217–229. [Google Scholar] [CrossRef]

- Basaglia, C. On the structural behavior of steel purlin-sheeting systems. Master’s Thesis, University of Sao Paulo, Sao Calos, Brazil, 2004. [Google Scholar]

- Dubina, D.; Ungureanu, V. Behaviour of multi-span cold-formed Z-purlins with bolted lapped connections. Thin-Walled Struct. 2010, 48, 866–871. [Google Scholar] [CrossRef]

- Polyzois, D. Sagrods as lateral supports for girts and purlins. J. Struct. Eng. 1987, 113, 1521–1531. [Google Scholar] [CrossRef]

- Zhang, L.; Tong, G. Moment resistance and flexural rigidity of lapped connections in multi-span cold-formed Z-purlin systems. Thin-Walled Struct. 2008, 46, 551–560. [Google Scholar] [CrossRef]

- Zhang, L.; Tong, G.S. Stress analysis on cold-formed C-purlins subjected to wind suction load considering the effective stiffness of anti-sag bar. Thin-Walled Struct. 2015, 90, 107–118. [Google Scholar] [CrossRef]

- Zhang, L.; Tong, G.S. Lateral buckling of simply supported C- and Z-section purlins with top flange horizontally restrained. Thin-Walled Struct. 2016, 99, 155–167. [Google Scholar] [CrossRef]

- Zhang, L.; Tong, G.S. Lateral buckling of C-section purlins with one anti-sag bar at middle span section. Thin-Walled Struct. 2016, 102, 246–257. [Google Scholar] [CrossRef]

- Sun, K.Q.; Tong, G.S.; Zhang, L. Twisting about constrained line of parallel purlins inter braced by sagrods under wind suctions. Thin-Walled Struct. 2016, 108, 30–40. [Google Scholar] [CrossRef]

- Pham, C.H.; Hancock, G.J. Direct strength design of cold-formed purlins. J. Struct. Eng. 2009, 135, 229–238. [Google Scholar] [CrossRef]

- Gaorgescu, M.; Ungureanu, V. Stabilisation of continuous Z-purlins by sandwich panels: Full scale experimental approach. Thin-Walled Struct. 2014, 81, 242–249. [Google Scholar] [CrossRef]

- Ren, C.; Li, L.Y.; Yang, J. Bending analysis of partially restrained channel-section purlins subjected to up-lift loadings. J. Constr. Steel Res. 2012, 72, 254–260. [Google Scholar] [CrossRef]

- Li, L.Y.; Ren, C.; Yang, J. Theoretical analysis of partially restrained zed-purlin beam subjected to up-lift loads. J. Constr. Steel Res. 2012, 70, 273–279. [Google Scholar] [CrossRef]

- Gosowski, B.; Kubica, E.; Rykaluk, K. Analysis of laterally restrained cold-formed C-shaped purlins according to Vlasov theory. Arch. Civ. Mech. Eng. 2015, 15, 456–468. [Google Scholar] [CrossRef]

- Vieira, L.C.M., Jr.; Malite, M.; Schafer, B.W. Simplified models for cross-section stress demands on C-section purlins in uplift. Thin-Walled Struct. 2010, 48, 33–41. [Google Scholar] [CrossRef]

- Gao, T.; Moen, C.D. Extending the direct strength method for cold-formed steel design to through-fastened simple span girts and purlins with laterally unbraced compression flanges. J. Struct. Eng. 2014, 104, 1299–1328. [Google Scholar] [CrossRef]

- Ren, C.; Zhao, X.Z.; Chen, Y.Y. Buckling behavior of partially restrained cold-formed steel zed purlins subjected to transverse distributed uplift loading. Eng. Struct. 2016, 114, 14–24. [Google Scholar] [CrossRef]

- Davies, J.M.; Bryan, E.R. Manual of Stresses Skin Diaphragm Design; Granada Publishing: Great Britain, UK, 1982. [Google Scholar]

- Mahendran, M.; Moor, C. Three-dimensional modeling of steel portal frame buildings. J. Struct. Eng. 1999, 125, 870–878. [Google Scholar] [CrossRef]

- Jang, S. Evaluation of Ultimate Strength of Low-Rise Steel Building Frames and Components Using Wind Tunnel Data; Lehigh University: Bethlehem, PA, USA, 2004. [Google Scholar]

- Duthinh, D.; William, P.F. Safety evaluation of low-rise steel structures under wind loads by nonlinear database-assisted technique. J. Struct. Eng. 2007, 133, 587–594. [Google Scholar] [CrossRef]

- Duthinh, D.; Main, J.A.; Wright, A.P.; Simiu, E. Low-rise steel structures under directional winds: Mean recurrence interval of failure. J. Struct. Eng. 2008, 134, 1383–1388. [Google Scholar] [CrossRef]

- Li, X.; Chen, S.F. Wind-resistant safety analysis of light-weight steel portal frame structures. J. Zhejiang Univ. 2013, 47, 2141–2145. [Google Scholar]

- Ellingwood, B.R. Structural reliability and performance-based engineering. Struct. Build. 2008, 161, 199–208. [Google Scholar] [CrossRef]

- Garcia, P.A. Estimacion de Danos Producidos Por Viento en Edificaciones Industrials; Department of Civil Engineering, University of Puerto Rico: Mayaguez, Puerto Rico, 2008; pp. 44–48. [Google Scholar]

- Ellingwood, B.R.; Rosowsky, D.V.; Li, Y.; Kim, J.H. Fragility assessment of light-frame wood construction subjected to wind and earthquake hazards. J. Struct. Eng. 2004, 130, 1921–1930. [Google Scholar] [CrossRef]

- Ellingwood, B.R.; Tekie, P.B. Wind load statistics for probability-based structural design. J. Struct. Eng. 1999, 125, 453–463. [Google Scholar] [CrossRef]

- Li, Y.; Ellingwood, B.R. Hurricane damage to residential construction in the US: Importance of uncertainty modeling in risk assessment. Eng. Struct. 2006, 28, 1009–1018. [Google Scholar] [CrossRef]

- Li, Y.; Ellingwood, B.R. Framework for multihazard risk assessment and mitigation for wood-frame residential construction. J. Struct. Eng. 2009, 135, 159–168. [Google Scholar] [CrossRef]

- Henderson, D.J.; Ginger, J.D. Vulnerability model of an Australian high-set house subjected to cyclonic wind loading. Wind Struct. 2007, 10, 269–285. [Google Scholar] [CrossRef]

- Konthesingha, K.M.C.; Stewart, M.G.; Ryan, P.; Ginger, J.; Henderson, D. Reliability based vulnerability modeling of metal-clad industrial buildings to extreme wind loading for cyclonic regions. J. Wind Eng. Ind. Aerodyn. 2015, 147, 176–185. [Google Scholar] [CrossRef]

- Lee, K.H.; Rosowsky, D.V. Fragility assessment for roof sheathing failure in high wind regions. Eng. Struct. 2005, 27, 857–868. [Google Scholar] [CrossRef]

- Zhao, M.W.; Gu, M. Probabilistic wind vulnerability analysis of light-weight steel buildings. J. Cent. South Univ. 2012, 43, 3609–3618. [Google Scholar]

- Xiao, Y.F. Typhoon Wind Hazard Analysis Based on Numerical Simulation and Fragility of Light-Gauge Steel Structure in Southeast China Costal Regions; Harbin Institute of Technology: Harbin, China, 2011. (In Chinese) [Google Scholar]

- Goyal, P.K.; Datta, T.K. Effect of wind directionality on the vulnerability of rural houses due to cyclonic wind. Nat. Hazards Rev. 2013, 14, 258–267. [Google Scholar] [CrossRef]

- Sivapathasundaram, M.; Mahendran, M. Development of fragility curves for localized pull-through failures of thin steel roof battens. Eng. Struct. 2016, 124, 64–84. [Google Scholar] [CrossRef]

- Zhang, S.; Nishijima, K.; Maruyama, T. Reliability-based modeling of typhoon induced wind vulnerability for residential buildings in Japan. J. Wind Eng. Ind. Aerodyn. 2014, 124, 68–81. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, N.; Bai, F. Damage Analysis and Evaluation of Light Steel Structures Exposed to Wind Hazards. Appl. Sci. 2017, 7, 239. https://doi.org/10.3390/app7030239

Yang N, Bai F. Damage Analysis and Evaluation of Light Steel Structures Exposed to Wind Hazards. Applied Sciences. 2017; 7(3):239. https://doi.org/10.3390/app7030239

Chicago/Turabian StyleYang, Na, and Fan Bai. 2017. "Damage Analysis and Evaluation of Light Steel Structures Exposed to Wind Hazards" Applied Sciences 7, no. 3: 239. https://doi.org/10.3390/app7030239