Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Charactarisation

2.2. Semi-Continuous Trials

2.2.1. Co-Digestion Trials

2.2.2. Mono-Digestion Trials

2.3. Analytical Methods

3. Results and Discussions

3.1. Substrate Characterization

3.2. Semi-Continuous Co-Digestion Trials Fed with Different Mixing Ratios of Organic Fraction of Municipal Solid Waste (OFMSW) and Primary Sludge (PS)

3.2.1. Trace Metal Analyses

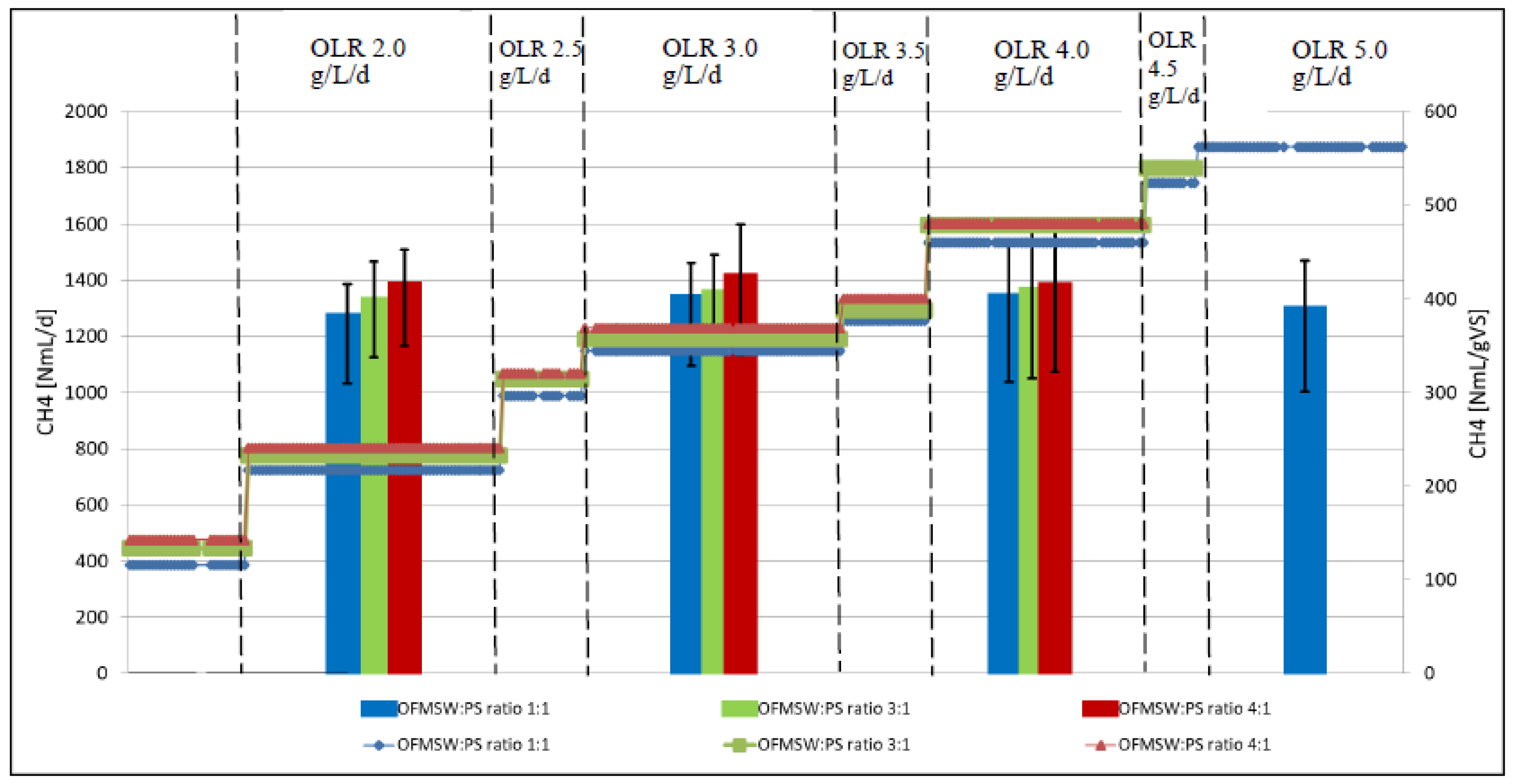

3.2.2. Process Stability and Biogas Production, Anaerobic Co-Digestion (AcoD) Trials

3.3. Semi-Continuous Mono-Digestion Trials with OFMSW as the Only Feedstock

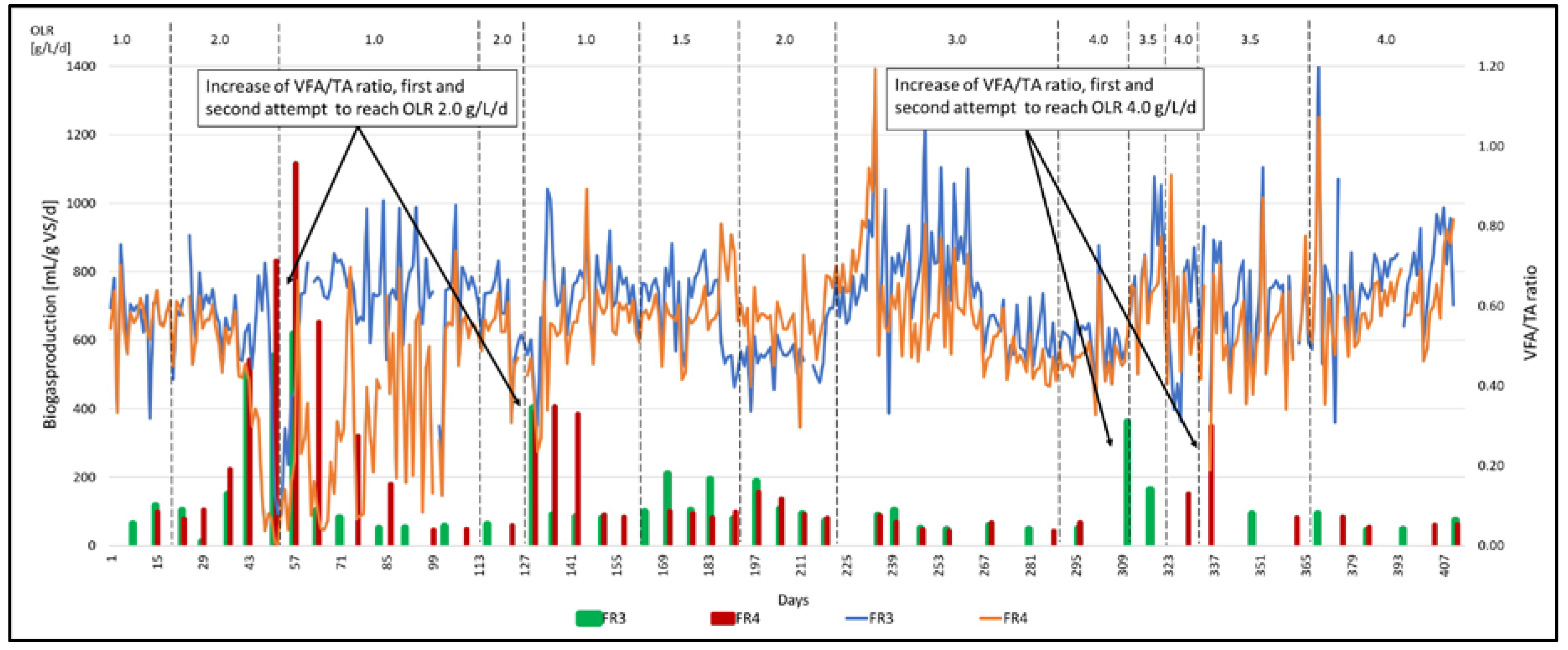

3.3.1. Anaerobic Digestion (AD) trials of OFMSW Digestion Prior to the Addition of Commercial Trace Element Solutions (CTES)

3.3.2. Trace Metal Analyses

3.3.3. AD Trials of OFMSW Digestion along with CTES Addition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Bioreactions. In Biogas from Waste and Renewable Resources: An Introduction, 2nd ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010; pp. 101–108. [Google Scholar]

- Gerardi, M. Substrates, Products, and Biogas. Anaerobic digestion stages. In The Microbiology of Anaerobic Digesters; WILEY-INTERSCIENCE; A John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 51–117. [Google Scholar]

- Schattauer, A.; Abdoun, E.; Weiland, P.; Plöchl, M.; Heiermann, M. Abundance of trace elements in demonstration biogas plants. Biosyst. Eng. 2011, 108, 57–65. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, M.; Wu, C.; Wang, Q.; Gao, M.; Huang, Q. A comprehensive review on food waste anaerobic digestion: Research updates and tendencies. Bioresour. Technol. 2018, 247, 1069–1076. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Chen, J.; Wang, T. Effects of Nitrilotriacetic Acid on Anaerobic Co-Digestion of Food Waste and Sludge. Waste Biomass Valorization 2018, 9, 1731–1734. [Google Scholar] [CrossRef]

- Fermoso, F.G.; Bartacek, J.; Jansen, S.; Lens, P.N.L. Metal supplementation to UASB bioreactors: From cell-metal interactions to full-scale application. Sci. Total Environ. 2009, 407, 3652–3667. [Google Scholar] [CrossRef] [PubMed]

- Banks, C.J.; Zhang, Y.; Jiang, Y.; Heaven, S. Trace element requirements for stable food waste digestion at elevated ammonia concentrations. Bioresour. Technol. 2012, 104, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Osuna, M.B.; Iza, J.M.; Zandvoort, M.H.; Lens, P.N.L. Essential metal depletion in an anaerobic reactor. Water Sci. Technol. 2003, 48, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Romero-Güiza, M.S.; Vila, J.; Mata-Alvarez, J.; Chimenos, J.M.; Astals, S. The role of additives on anaerobic digestion: A review. Renew. Sustain. Energy Rev. 2016, 58, 1486–1499. [Google Scholar] [CrossRef]

- Feng, X.M.; Karlsson, A.; Svensson, B.H.; Bertilsson, S. Impact of trace element addition on biogas production from food industrial waste—Linking process to microbial communities. FEMS Microbiol. Ecol. 2010, 74, 226–240. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Peng, X.; Wang, X.; Wu, D. Anaerobic digestion of food waste: A review focusing on process stability. Bioresour. Technol. 2018, 248, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Girotto, F.; Alibardi, L.; Cossu, R. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jahng, D. Long-term anaerobic digestion of food waste stabilized by trace elements. Waste Manag. 2012, 32, 1509–1515. [Google Scholar] [CrossRef] [PubMed]

- Thyberg, K.L.; Tonjes, D.J. Drivers of food waste and their implications for sustainable policy development. Resour. Conserv. Recycl. 2016, 106, 110–123. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L.; Li, A. Enhanced anaerobic digestion of food waste by trace metal elements supplementation and reduced metals dosage by green chelating agent [S, S]-EDDS via improving metals bioavailability. Water Res. 2015, 84, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Demirel, B.; Scherer, P. Trace element requirements of agricultural biogas digesters during biological conversion of renewable biomass to methane. Biomass Bioenergy 2011, 35, 992–998. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Effects of Co and Ni nanoparticles on biogas and methane production from anaerobic digestion of slurry. Energy Convers. Manag. 2017, 141, 108–119. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Steyer, J.P.; Delgenès, J.P.; Escudié, R. Food waste valorization via anaerobic processes: A review. Rev. Environ. Sci. Bio/Technol. 2016, 15, 499–547. [Google Scholar] [CrossRef]

- Wang, P.; Wang, H.; Qiu, Y.; Ren, L.; Jiang, B. Microbial characteristics in anaerobic digestion process of food waste for methane production—A review. Bioresour. Technol. 2018, 248, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Keucken, A.; Habagil, M.; Batstone, D.; Jeppsson, U.; Arnell, M. Anaerobic co-digestion of sludge and organic food waste-performance, inhibition, and impact on the microbial community. Energies 2018, 11, 2325. [Google Scholar] [CrossRef]

- Pongthornpruek, S.; Watmuang, S. Biogas Production from Anaerobic Co-Digestion of Food Waste Mixed with Domestic Wastewater. Appl. Mech. Mater. 2016, 855, 103–107. [Google Scholar] [CrossRef]

- Bioprocess Control. BIOREACTOR SIMULATOR—Continuous Fermentation Made Easy. Available online: https://www.bioprocesscontrol.com/products/bioreactor-simulator (accessed on 30 April 2020).

- Forgács, G.; Pourbafrani, M.; Niklasson, C.; Taherzadeh, M.J.; Hováth, I.S. Methane production from citrus wastes: Process development and cost estimation. J. Chem. Technol. Biotechnol. 2012, 87, 250–255. [Google Scholar] [CrossRef]

- Bioprocess Control. Microfow Gasflow Meter, Operation & Maintainance Manual. Available online: https://www.bioprocesscontrol.com/media/1376/bioprocess-control-uflow.pdf (accessed on 30 April 2020).

- Geotech. Biogas Check Operating Manual 2010, Geotechnical Instruments England. Available online: http://www.keison.co.uk/products/geotechnical/BiogasCheckManual.pdf (accessed on 30 April 2020).

- Carlsson, M.; Uldal, M. Substrathandbok för Biogasproduktion. Rapport SGC 200 •1102-7371 • ISRN SGC-R-200-SE. vol. nr 200. Available online: https://www.osti.gov/etdeweb/servlets/purl/948934 (accessed on 30 April 2020).

- Switzenbaum, M.S.; Giraldo-Gomez, M.; Eugenio Hickey, F.R. Monitoring of the anaerobic methane fermentation process. Enzym. Microb. Technol. 1990, 12, 722–730. [Google Scholar] [CrossRef]

- Jarvis, Å.; Schnurer, A. Mikrobiologisk Handbook för Biogasanläggningar Sc Rapport SGC 207•1102-7371 • ISRN SGC 207. Available online: http://www.sgc.se/ckfinder/userfiles/files/SGC207.pdf (accessed on 30 April 2020).

- Andersson, A. Effekten av Kemiras Processhjälpmedel BDP866 i Hulesjöns Avloppsreningsverks Rötgaskammare för Matavfall. Master’s Thesis, Chalmers Tkniska Högskola, Gothenburg, Sweden, June 2014. [Google Scholar]

- Kayhanian, M.; Rich, D. Pilot-scale high solids thermophilic anaerobic digestion of municipal solid waste with an emphasis on nutrient requirements. Biomass Bioenergy 1995, 8, 433–444. [Google Scholar] [CrossRef]

- Hornung, A. Anaerobic Digestion. In Transformation of Biomass Theory to Practice, 1st ed.; Hornung, A., Ed.; John Wiley & Sons Ltd.: Birmingham, UK, 2014; pp. 31–55. [Google Scholar] [CrossRef]

- Chellapandi, P. In silico description of cobalt and nickel assimilation systems in the genomes of methanogens. Syst. Synth. Biol. 2011, 5, 105–114. [Google Scholar] [CrossRef] [PubMed]

| Trace Elements | |||

|---|---|---|---|

| OFMSW | Primary Sludge | ||

| Average | Average | ||

| Total solids (TS) | % | 24.7 ± 4.6 | 5.55 ± 0.65 |

| Volatile Solids | % VS | 94.9 ± 0.9 | 84.05 ± 0.45 |

| Iron-Fe | mg/kg TS | 160 ± 14.1 | 4750 ± 350 |

| Cobalt-Co | mg/kg TS | <2.5 | <2.5 |

| Nickel-Ni | mg/kg TS | <4.8 | 6.8 ± 0.3 |

| Molybdenum-Mo | mg/kg TS | <0.95 | 2.4 ± 0.1 |

| Selenium-Se | mg/kg TS | <0.95 | <0.99 |

| Tungsten-W | mg/kg TS | <1.1 | 1.15 ± 0.1 |

| Boron-B | mg/kg TS | <24 | <25 |

| Nitrogen-(Kjeldahl) | mg/kg | 34,713 ± 6665 | 2200 ± 100 |

| Ammonium-(NH4–N) | mg/kg | 1045 ± 77.8 | 385 ± 25 |

| Total COD | mg/kg | 182,025 ± 2652 | 48,390 ± 810 |

| CODSol | mg/kg | 57,850 ± 1131 | 11,985 ± 495 |

| Fats | % of TS | 14.6 ± 2.8 | 16.7 ± 2.5 |

| Proteins | g/100 g | 3.6 ± 0.1 | 2.8 ± 0.4 |

| Uncertainty (%) | Initial Values | OFMSW:PS Ratio 1:1 (OLR 5.0 gVS/L/d) | OFMSW:PS Ratio 3:1 (OLR 4.0 gVS/L/d) | OFMSW:PS Ratio 4:1 (OLR 4.0 gVS/L/d) | ||||

|---|---|---|---|---|---|---|---|---|

| Inoculum * | First Trial | Repeated Trial | First Trial | Repeated Trial | ||||

| Total solids-(TS) | % | +/− 10 | 3.1 | 4.7 | 4.0 | 4.0 | 4.0 | 4.3 |

| Volatile Solids | % of TS | +/− 10 | 69.1 | 71.4 | 76.7 | 73.7 | 67.3 | 71.8 |

| Nitrogen-(Kjeldhal) | mg/kg ** | +/− 10 | 2900 | 3900 | 3600 | 2400 | 2700 | 3900 |

| Nitrogen-(Kjeldhal) | % of TS | +/− 10 | 9.3 | 6.9 | 9.0 | 9.2 | 6.7 | 9.1 |

| Ammonium-Nitrogen | mg/kg ** | +/− 10 | 1300 | 1900 | 1500 | 920 | 1300 | 1500 |

| Ammonium-Nitrogen | % of TS | +/− 10 | 4.2 | 3.4 | 3.8 | 4.2 | 3.2 | 3.5 |

| Iron-Fe | mg/kg TS | +/− 15 | 11,000 | 5900 | 4400 | 6500 | 7500 | 3300 |

| Cobalt-Co | mg/kg TS | +/− 20 | 2.6 | 2.1 | 1.2 | 1.6 | 6.4 | 1.0 |

| Nickel-Ni | mg/kg TS | +/− 15 | 15 | 10 | 7.9 | 9.4 | 11 | 6.7 |

| Molybdenum-Mo | mg/kg TS | +/− 20 | 5.4 | 3.4 | 2.8 | 3.9 | 3.2 | 2.0 |

| Selenium-Se | mg/kg TS | +/− 20 | 1.8 | <0.97 | <0.97 | 1.5 | 1.4 | <0.97 |

| Tungsten-W | mg/kg TS | +/− 25 | 2.0 | 4 | <1.1 | 2.0 | 1.5 | <1.1 |

| Boron-B | mg/kg TS | +/− 15 | <25 | 20 | 38 | 26 | 28 | 27 |

| AD Reactors | Literature | |||||

|---|---|---|---|---|---|---|

| Uncertainty (%) | Initial Values | OFMSW without CTES Addition (OLR 1.0 g/L/d) | OFMSW with CTES Addition (OLR 4.0 g/L/d) | Recommended Concentrations of TEs [4] | ||

| Parameter | Unit | 1 Inoculum | Average values (from three trial repetitions) | |||

| Total solids | % | +/− 10 | 3.1 | 1.25 ± 0.18 | 2 | |

| Volatile Solids | % of TS | +/− 10 | 69.1 | 80.9 ± 4.18 | 75.7 | |

| Nitrogen-(Kjeldhal) | mg/L | +/− 10 | 2900 | 1717 ± 202 | 2800 | |

| Ammonium-Nitrogen | mg/L | +/− 10 | 1300 | 881.7 ± 34.47 | 1300 | |

| Iron, Fe | mg/L | +/− 15 | 341 | 24.17 ± 3.25 | 32 | >0.28–200 |

| Cobalt-Co | mg/L | +/− 20 | 0.08 | 0.003 ± 0.00 | 0.03 | >0.00059–20 |

| Nickel-Ni | mg/L | +/− 15 | 0.47 | 0.04 ± 0.04 | 0.07 | 0.005–30 |

| Molybdenum-Mo | mg/L | +/− 20 | 0.17 | 0.02 ± 0.00 | 0.04 | >0.00096–50 |

| Selenium-Se | mg/L | +/− 20 | 0.06 | 0.01 ± 0.00 | <0.02 | 0.079–0.79 |

| Tungsten-W | mg/L | +/− 25 | 0.06 | 0.005 ± 0.00 | n.d. | 0.018–18.3 |

| Boron-B | mg/L | +/− 15 | <0.78 | 0.25 ± 0.02 | n.d. | 0.001–11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habagil, M.; Keucken, A.; Sárvári Horváth, I. Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge. Environments 2020, 7, 42. https://doi.org/10.3390/environments7060042

Habagil M, Keucken A, Sárvári Horváth I. Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge. Environments. 2020; 7(6):42. https://doi.org/10.3390/environments7060042

Chicago/Turabian StyleHabagil, Moshe, Alexander Keucken, and Ilona Sárvári Horváth. 2020. "Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge" Environments 7, no. 6: 42. https://doi.org/10.3390/environments7060042

APA StyleHabagil, M., Keucken, A., & Sárvári Horváth, I. (2020). Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge. Environments, 7(6), 42. https://doi.org/10.3390/environments7060042