1. Introduction

Smart materials represent an ideology that the materials themselves, which are the building blocks of current mechanical and electrical structures, can react to presented stimuli, thereby improving safety and efficiency. Smart materials as a class represent a wide range of materials and applications including piezoelectrics, shape-memory alloys, ferroelectrics, thermoelectric materials, and dielectric elastomers. This research focuses on one sub-group: electroactive polymers. Electroactive polymers are categorized under the subclass of soft sensors and actuators. Electroactive polymer materials are a unique class, capable of responding mechanically to an electric stimulus or of storing electrical energy from mechanical deformation in the same way as a capacitor. This makes these materials optimal for sensing, as well as actuation. The field of electroactive polymers can be further divided into two subsets: ionic and electric. Electric electroactive polymers generally require large electric fields for stimulation (between 80 V/µm and 180 V/µm) [

1,

2,

3]. However, electric electroactive polymers have the ability to retain their activated state under a DC field, exhibit fast response times (microsecond range), and have no general environmental limitations excluding those that are polymer based [

4]. Ionic gels, ionic polymer metal composites, conductive polymers, and specific nanotube based constructions comprise the ionic class. Ionic electroactive polymers require a smaller activation field—generally 1–5 V for conductive polymers—but due to their operating mechanism, an aqueous environment must be maintained [

5]. While possible, a DC field maintained strain is more challenging to achieve in ionic polymers, but it can be achieved with certain subsets, such as conductive polymers. The focus of this research is on dielectric electroactive polymers which fall under the electric category, and more specifically, the utilization of these materials in industrial environments.

Dielectric elastomers were discovered in 1880 when Wilhelm Roentgen observed the movement of a mass by a 16 cm × 100 cm rubber band when an electric field was introduced to the rubber band. The rubber band had a fixed boundary at one end, with the mass remaining at the alternate end of the polymer. Roentgen studied the change in length of the rubber band [

6,

7]. In 1899, Sacerdote formulated that the strain response was due to an electric field [

4,

7]. In 1925, the first electroactive polymer was discovered and donned with the name “Electret.” Eguchi discovered this material which was a mixture of carnauba, wax, beeswax, and rosin, and documented the material’s piezoelectric characteristics [

8]. In the 1970’s, Zhang and Bar-Cohen began research on poly(vinylidene fluoride), and noted its piezoelectric responses [

4,

9,

10]. As a result of these observations, scientists began developing of a novel class of electroactive polymer materials. Then in the 1990s and the early 2000s, significant developments occurred through enhanced strains and the development of actuation strain enhancement through addition of mechanical pre-strain to the polymer matrix [

11,

12]. Goshkoderia and Rudykh [

13] studied the effect of mechanical deformation on the stability of the dielectric material and proposed a model for predicting the electrostatic moduli of the dielectric material subjected to mechanical deformation. Furthermore, this work explored the effect of adding embedded inclusions on the dielectric matrix to improve the electrostatic properties of these materials. Other interesting uses of these materials include the study and use of spherically shaped objects made of EAP’s to model and produce micro-fluidic pumps [

14].

Flouroelastomers are often used in EAP applications thanks to their ability to work as acceptable ferroelectric materials while maintaining a high resistance to high temperature, and good chemical resistance to degradation when exposed to a wide variety of solvents, acids, and bases. According to ASTM D1418 [

15] Flouroelastomers are generally available in three specific compositions of the M class, which represents Rubbers having a saturated chain of the polymethylene type: (a) Non-substituted alkene monomers, (b) Partially substituted alkene monomers, and (c) fully substituted alkene monomers. Flouroelastomers are further classified into six different types based on their chemical composition, of which PMVE (Perflouromethilvinylether), a type 3, M rubber, is the preferred material for use in EAP applications thanks to its dielectric properties. Although the electrical properties of Flouroelastomers are less favorable than those of some acrylates, silicones, or urethanes, these materials are preferred for their high resistance to chemical degradation, high flexibility, and manufacturability [

16]. Various researchers have attempted to improve the electric and mechanical properties of PDVF by synthesizing or combining it with diverse materials. Rat et al. [

3] proposed and used P(VDF-TrFE) 70–30% mol as a dielectric material for EAP actuators and energy harvesting applications. In their work, they were able to homogenously disperse spin-crossover nanoparticles to enhance the mechanical flexibility and electric permittivity of the base P(VDF-TrFE) copolymer. Thakur et al. [

17] investigated the use of aqueous functionalization of PVDF through bio-inspired proteins. They investigated the dielectric properties of regular PVDF and PDOPA@PVDF (dopamine-modified PVDF) films at various frequencies and temperatures. The PDOPA@PVDF resulted in a dielectric constant of 2.67 times higher than PVDF. According to Li et al. [

15] conductive and strengthening particles of Silicon Dioxide SiO

2, (nanofillers) can be used to facilitate crystallization of the polymer and have better control of the polymerization process. The addition of such particles resulted in an improved dielectric constant, low dielectric loss, excellent mechanical strength, toughness, and optical transparency. In this research, commercially available industrial grade fluoropolymer materials were adapted through the addition of graphite particles to adjust their electrical properties, and were used to produce dielectric EAPs through a one-step chemical pre-strain process.

2. Theoretical Background

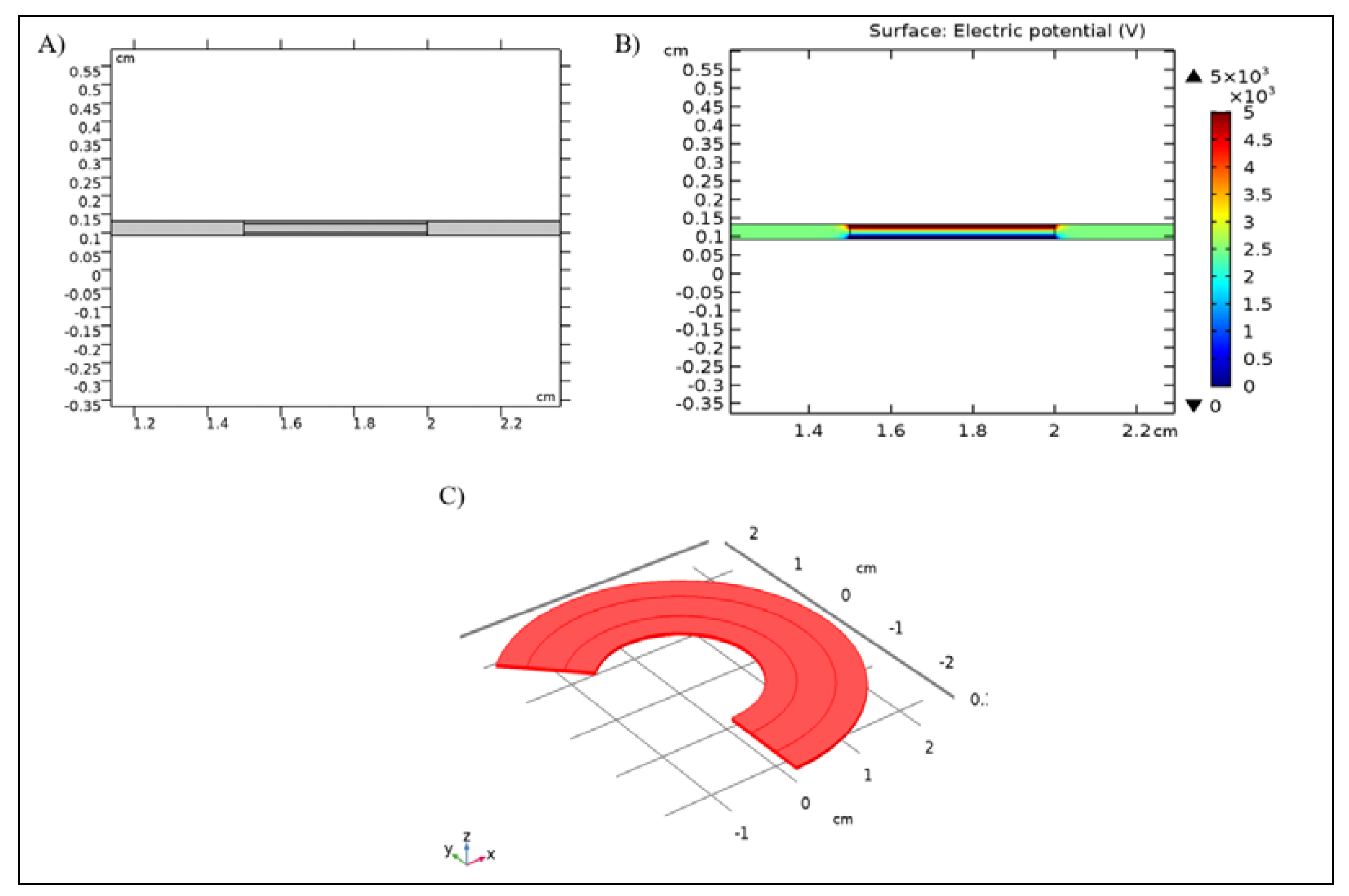

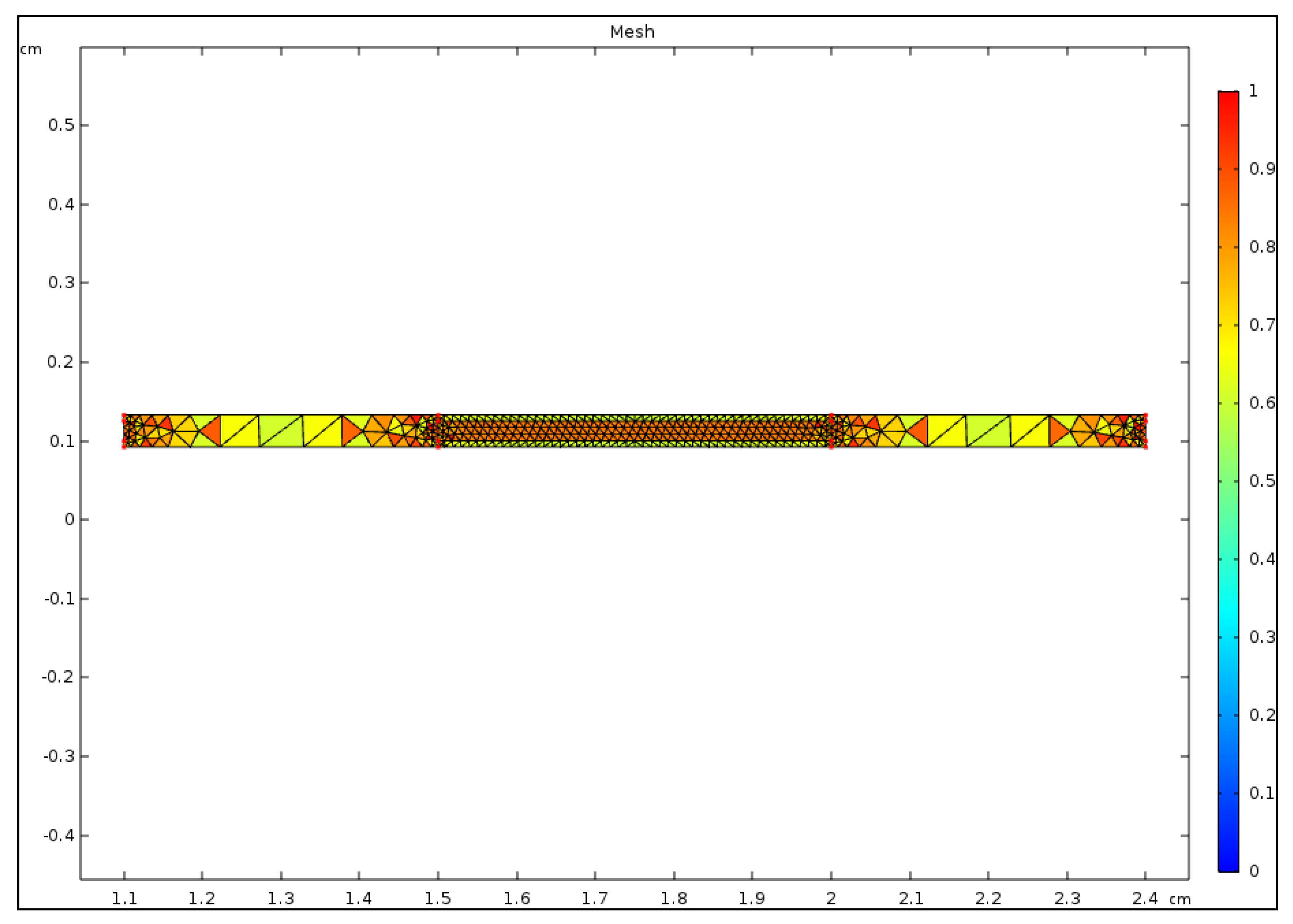

Dielectric elastomers are built as a parallel plate capacitor, comprised of a dielectric layer placed between two conductive layers. These materials actuate based on two primary mechanisms (1) Maxwell stress and (2) electrostriction [

18]. As the capacitor which makes up the electroactive polymer circuit charges, a Maxwell stress is generated from changes in the electric field distribution as the dielectric is strained. This is also called Coulombic charge interaction. The second mechanism is electrostriction, wherein the dielectric material changes over time with strain, and often change can be seen in the materials permittivity [

19]. The full relation to stress in the

x and

z directions can be seen in Equations (1) and (2). In these equations, σ represents mechanical stress, ε is the dielectric constant of the insulator,

εo is the permittivity of free space, 8.85 × 10

−12 F/m, V represents the applied electrical potential,

a1 is an electrostrictive coefficient which is the change in relative permittivity when shape is changed assuming constant volume, and

a2 represents a density dependent permittivity [

19]. However, the electrostriction effects are small in comparison to the Coulombic charge interaction response [

18,

19,

20]. Therefore, for simplification, the following equations can be used to define the anticipated actuation and corresponding pressures seen by the electroactive material. The corresponding stresses can be seen in Equations (3) and (4).

The pressure to achieve and maintain the designated strain can be found from calculating the differences between

and

as seen in Equation (5). In this equation

represents the change in normal stress,

ε is the dielectric constant of the insulator material,

εo is the permittivity of free space which is 8.85 × 10

−12 F/m, and V represents the applied electrical potential.

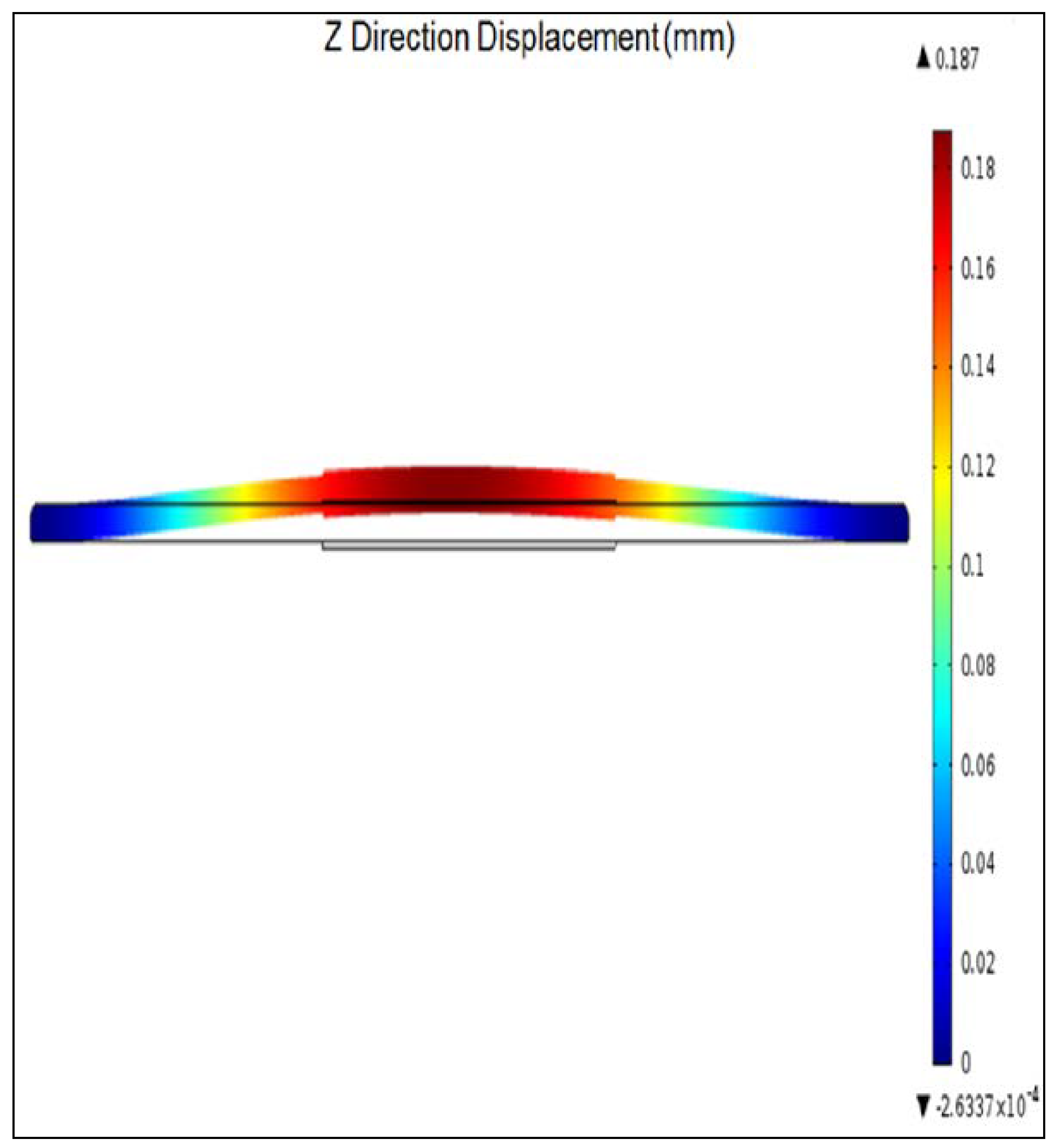

Equation (6) shows the compressive pressure from the perspective of the dielectric polymer film in the

z-axis through dividing the force by the square of the thickness [

18,

19,

20,

21]. In this equation, P represents electrostatic pressure,

ε is the dielectric constant of the insulator material,

εo is the permittivity of free space which is 8.85 × 10

−12 F/m, V represents the applied electrical potential, and

D is the dielectric thickness.

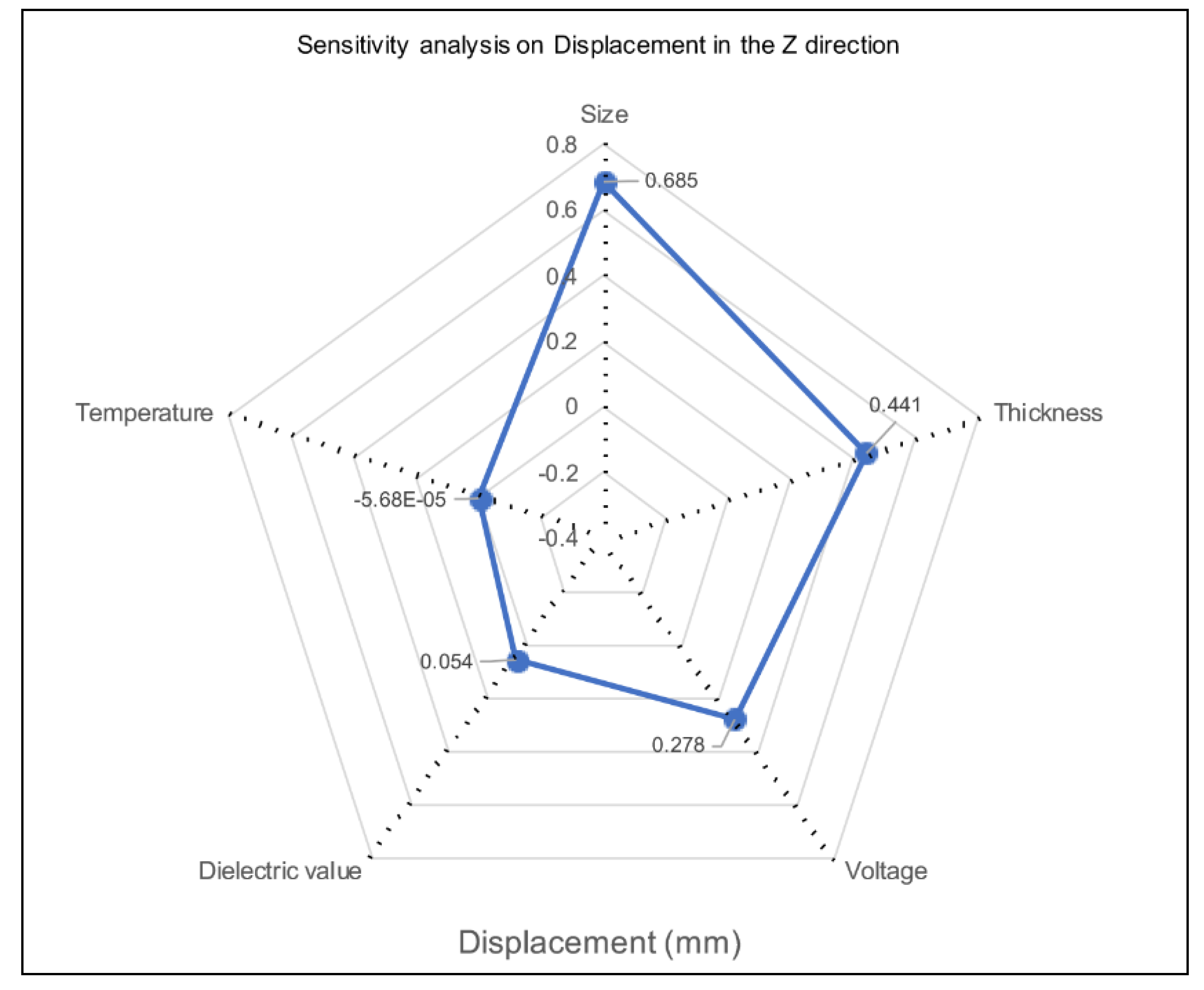

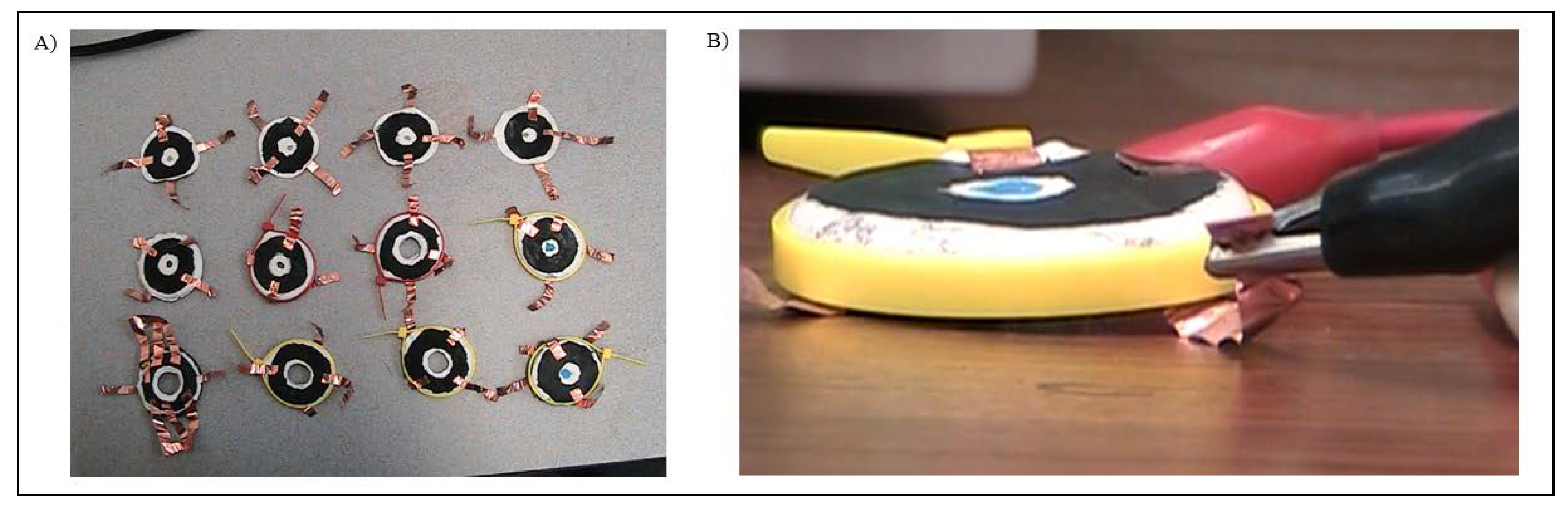

This formulated pressure is the foundation for actuation seen in the finite element model presented in this research and the correlating experimental data. This research expands upon this foundational knowledge to predict and test how a commonly used fluoropolymer industrial material can be manufactured and enhanced for use as a dielectric electroactive polymer in real world applications. This research produces a novel method of chemical pre-strain and uses an industrial polymer as the dielectric material, while also simplifying manufacturing through a single step process for pre-strain and electrode applications. Actuators produced using this method are evaluated for actuation response.