Near Net Shape Manufacture of Titanium Alloy Components from Powder and Wire: A Review of State-of-the-Art Process Routes

Abstract

:1. Introduction

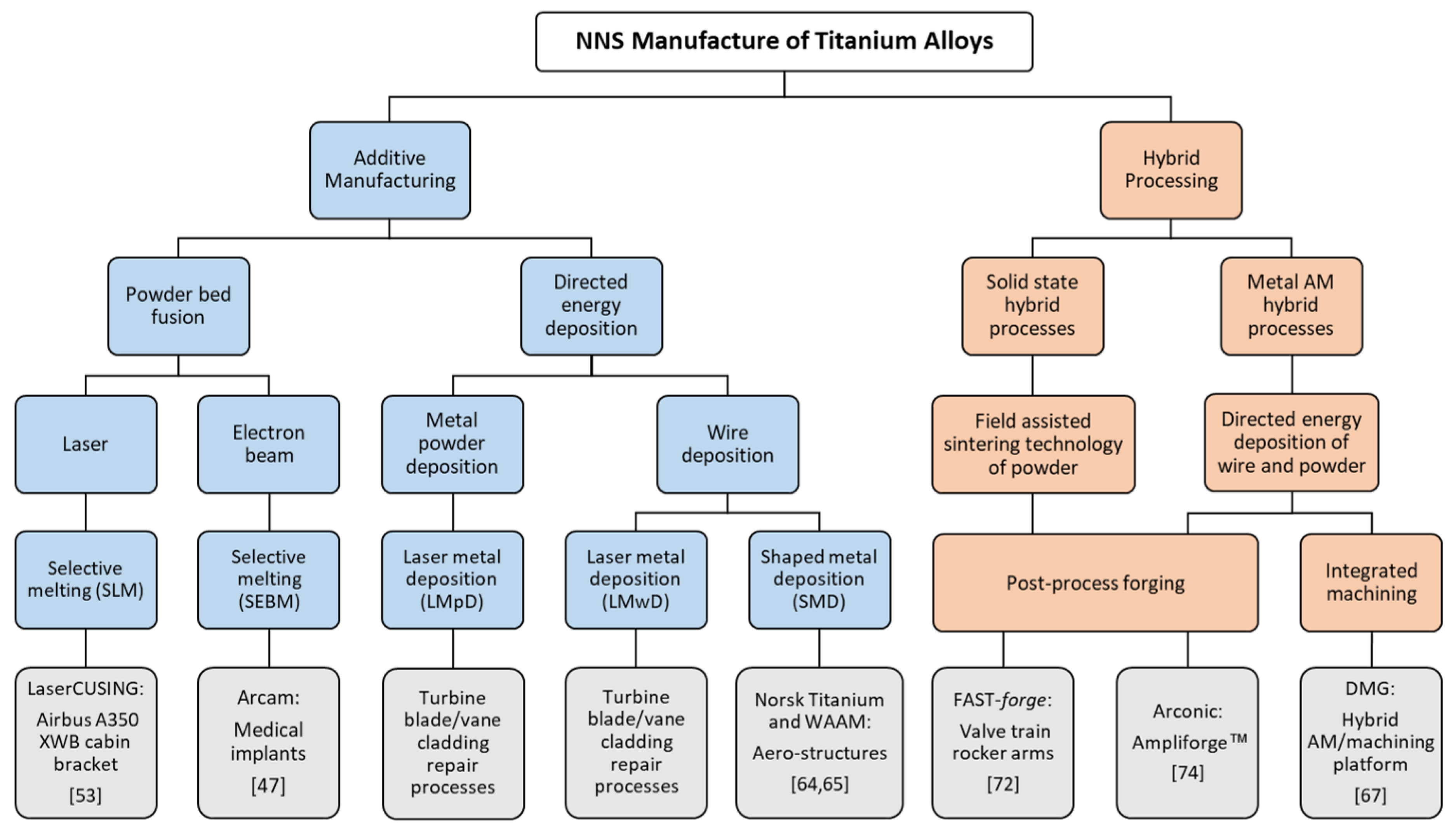

2. Additive Manufacturing Processes

2.1. Limitations of Metal AM for Titanium Alloy Components

2.2. Selective Laser Melting

2.3. Selective Electron Beam Melting

2.4. Directed Energy Deposition

2.5. Blown Powder Directed Energy Deposition

2.6. Wire Fed Directed Energy Deposition

2.7. Consolidation of Powder into Wire

3. Hybrid Processing Routes

3.1. FAST-forge

3.2. Hybrid AM Technology for Forging

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Jackson, M.; Boyer, R.R. Titanium and its Alloys: Processing, Fabrication and Mechanical Performance. Encycl. Aerosp. Eng. 2010. [Google Scholar] [CrossRef]

- Klocke, F.; Arntz, K.; Klingbeil, N.; Schulz, M. Wire-based laser metal deposition for additive manufacturing of TiAl6V4: Basic investigations of microstructure and mechanical properties from build up parts. Proc. SPIE Laser 3D Manuf. IV 2017, 10095, 100950U. [Google Scholar] [CrossRef]

- Jackson, M.; Dring, K. A review of advances in processing and metallurgy of titanium alloys. Mater. Sci. Technol. 2006, 22, 881–887. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.S.; Zhang, Y.; Xia, Y.; Cao, F.; Koopman, M.; Free, M. Powder metallurgy of titanium—Past, present, and future. Int. Mater. Rev. 2018, 63, 407–459. [Google Scholar] [CrossRef]

- Nazari, K.A.; Rahman Rashid, R.A.; Palanisamy, S.; Xia, K.; Dargusch, M.S. A novel Ti-Fe composite coating deposited using laser cladding of low cost recycled nano-crystalline titanium powder. Mater. Lett. 2018, 229, 301–304. [Google Scholar] [CrossRef]

- Qi, Y.; Timokhina, I.B.; Shekhter, A.; Sharp, K.; Lapovok, R. Optimization of upcycling of Ti-6Al-4V swarf. J. Mater. Process. Technol. 2018, 255, 853–864. [Google Scholar] [CrossRef]

- Shi, Q.; Tse, Y.Y.; Higginson, R.L. Microstructure and texture development during solid consolidation recycling of Ti-6Al-4V. Mater. Charact. 2019, 147, 223–232. [Google Scholar] [CrossRef]

- Peter, W.H.; Yamamoto, Y. Near Net Shape Manufacturing of New, Low Cost Titanium Powders for Industry; Technical Report; Oak Ridge National Laboratory: Oak Ridge, YN, USA, 2013.

- Agapovichev, A.; Sotov, A.; Kokareva, V.; Smelov, V. Possibilities and limitations of titanium alloy additive manufacturing. Matec Web Conf. 2018, 224, 01064. [Google Scholar] [CrossRef]

- Bolzoni, L.; Ruiz-Navas, E.; Zhang, D.L.; Gordo, E. Modification of Sintered Titanium Alloys by Hot Isostatic Pressing. Key Eng. Mater. 2012, 520, 63–69. [Google Scholar] [CrossRef] [Green Version]

- Kelto, C.; Kosmal, B.; Eylon, D.; Froes, F. Titan. Powder Metall. A Perspect. JOM 1980, 32, 17–25. [Google Scholar] [CrossRef]

- German, R.M. Progress in titanium metal powder injection molding. Materials 2013, 6, 3641–3662. [Google Scholar] [CrossRef] [PubMed]

- Eylon, D.; Froes, F.; Gardiner, R. Developments in Titanium Alloy Casting Technology. JOM 1983, 35, 35–47. [Google Scholar] [CrossRef]

- Jackson, M. Superplastic forming and diffusion bonding of titanium alloys. In Superplastic Forminf of Advanced Metaillic Materials: Methods and Applications; Giuliano, G., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2011. [Google Scholar]

- Javaid, M.; Haleem, A. Additive manufacturing applications in medical cases: A literature based review. Alex. J. Med. 2018, 54, 411–422. [Google Scholar] [CrossRef] [Green Version]

- Popov, V.V.; Gary, J.; Kovalevsky, M.k.A.; Dzhenzhera, G.; Strokin, E.; Kolomiets, A.; Ramon, J.; Muller-kamskii, G. Design and 3D-printing of titanium bone implants: Brief review of approach and clinical cases. Biomed. Eng. Lett. 2018, 8, 337–344. [Google Scholar] [CrossRef] [PubMed]

- Nickels, L. AM and aerospace: An ideal combination. Met. Powder Rep. 2015, 70, 300–303. [Google Scholar] [CrossRef]

- Neikter, M.; Åkerfeldt, P.; Pederson, R.; Antti, M.L. Microstructure characterisation of Ti-6Al-4V from different additive manufacturing processes. IOP Conf. Ser. Mater. Sci. Eng. 2017, 258. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. Machining of Additively Manufactured Parts: Implications for Surface Integrity. Procedia CIRP 2016, 45, 119–122. [Google Scholar] [CrossRef]

- Miura, H. Direct laser forming of titanium alloy powders for medical and aerospace applications. KONA Powder Part. J. 2015, 32, 253–263. [Google Scholar] [CrossRef]

- Yilmaz, O.; Ugla, A.A. Shaped metal deposition technique in additive manufacturing: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1781–1798. [Google Scholar] [CrossRef]

- Gorsse, S.; Hutchinson, C.; Gouné, M. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–783. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Zhao, H.; Léonard, F.; Derguti, F.; Todd, I.; Prangnell, P.B. XCT analysis of the influence of melt strategies on defect population in Ti-6Al-4V components manufactured by Selective Electron Beam Melting. Mater. Charact. 2015, 102, 47–61. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Arias-González, F.; del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Gil, F.J.; Pou, J. Microstructure and crystallographic texture of pure titanium parts generated by laser additive manufacturing. Met. Mater. Int. 2018, 24, 231–239. [Google Scholar] [CrossRef]

- Gong, X.; Lydon, J.; Cooper, K.; Chou, K. Beam speed effects on Ti-6Al-4V microstructures in electron beam additive manufacturing. J. Mater. Res. 2014, 29, 1951–1959. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Zheng, H.; Tang, K.; Ding, L.; Li, H.; Gong, S. Microstructure and mechanical properties of LMD-SLM hybrid forming Ti6Al4V alloy. Mater. Sci. Eng. A 2016, 660, 24–33. [Google Scholar] [CrossRef]

- Neikter, M.; Åkerfeldt, P.; Pederson, R.; Antti, M.L.; Sandell, V. Microstructural characterization and comparison of Ti-6Al-4V manufactured with different additive manufacturing processes. Mater. Charact. 2018, 143, 68–75. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the texture formation of selective laser melted Ti-6Al-4V. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Cunningham, R.; Narra, S.P.; Ozturk, T.; Beuth, J.; Rollett, A.D. Evaluating the Effect of Processing Parameters on Porosity in Electron Beam Melted Ti-6Al-4V via Synchrotron X-ray Microtomography. JOM 2016, 68, 765–771. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Brandl, E.; Palm, F.; Michailov, V.; Viehweger, B.; Leyens, C. Mechanical properties of additive manufactured titanium (Ti-6Al-4V) blocks deposited by a solid-state laser and wire. Mater. Des. 2011, 32, 4665–4675. [Google Scholar] [CrossRef]

- Bian, L.; Thompson, S.M.; Shamsaei, N. Mechanical Properties and Microstructural Features of Direct Laser-Deposited Ti-6Al-4V. JOM 2015, 67, 629–638. [Google Scholar] [CrossRef]

- Baufeld, B.; Van Der Biest, O.; Gault, R. Microstructure of Ti-6Al-4V specimens produced by shaped metal deposition. Int. J. Mater. Res. 2009, 100, 1536–1542. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Towrie, M.; Atwood, R.C.; Withers, P.J.; Lee, P.D. The effect of powder oxidation on defect formation in laser additive manufacturing. Acta Mater. 2019, 166, 294–305. [Google Scholar] [CrossRef]

- Caballero, A.; Ding, J.; Bandari, Y.; Williams, S. Oxidation of Ti-6Al-4V During Wire and Arc Additive Manufacture. 3D Print. Addit. Manuf. 2019, 6, 29–37. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Thomson-Larkins, J.; St John, D.H.; Dargusch, M.S. Sensitivity of Ti-6Al-4V components to oxidation during out of chamber Wire and Arc Additive Manufacturing. J. Mater. Process. Technol. 2018, 258, 29–37. [Google Scholar] [CrossRef]

- Na, T.W.; Kim, W.R.; Yang, S.M.; Kwon, O.; Park, J.M.; Kim, G.H.; Jung, K.H.; Lee, C.W.; Park, H.K.; Kim, H.G. Effect of laser power on oxygen and nitrogen concentration of commercially pure titanium manufactured by selective laser melting. Mater. Charact. 2018, 143, 110–117. [Google Scholar] [CrossRef]

- Karlsson, J.; Norell, M.; Ackelid, U.; Engqvist, H.; Lausmaa, J. Surface oxidation behavior of Ti-6Al-4V manufactured by Electron Beam Melting (EBM®). J. Manuf. Process. 2015, 17, 120–126. [Google Scholar] [CrossRef]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Sun, Y.; Aindow, M.; Hebert, R.J. The effect of recycling on the oxygen distribution in Ti-6Al-4V powder for additive manufacturing. Mater. High Temp. 2018, 35, 217–224. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive Manufacturing of Titanium Alloy for Aircraft Components. Procedia CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Caiazzo, F.; Cardaropoli, F.; Alfieri, V.; Sergi, V.; Cuccaro, L. Experimental analysis of selective laser melting process for Ti-6Al-4V turbine blade manufacturing. In Proceedings of the XIX International Symposium on High-Power Laser Systems and Applications 2012, Istanbul, Turkey, 30 January 2013; Volume 8677, p. 86771H. [Google Scholar] [CrossRef]

- Harun, W.; Manam, N.; Kamariah, M.; Sharif, S.; Zulkifly, A.; Ahmad, I.; Miura, H. A review of powdered additive manufacturing techniques for Ti-6Al-4V biomedical applications. Powder Technol. 2018, 331, 74–97. [Google Scholar] [CrossRef]

- Schulze, C.; Weinmann, M.; Schweigel, C.; Keßler, O.; Bader, R. Mechanical Properties of a Newly Additive Manufactured Implant Material Based on Ti-42Nb. Materials 2018, 11, 124. [Google Scholar] [CrossRef] [PubMed]

- Fousová, M.; Vojt, D.; Jablonská, E.; Fojt, J. Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process. J. Mech. Behav. Biomed. Mater. 2017, 69, 368–376. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Nomani, J.; Goldberg, M.; Littlefair, G. Metallurgical and Machinability Characteristics of Wrought and Selective Laser Melted Ti-6Al-4V. J. Metall. 2016, 2016, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Milton, S.; Morandeau, A.; Chalon, F.; Leroy, R. Influence of Finish Machining on the Surface Integrity of Ti6Al4V Produced by Selective Laser Melting. Procedia CIRP 2016, 45, 127–130. [Google Scholar] [CrossRef] [Green Version]

- Khorasani, A.M.; Gibson, I.; Goldberg, M.; Littlefair, G. A comprehensive study on surface quality in 5-axis milling of SLM Ti-6Al-4V spherical components. Int. J. Adv. Manuf. Technol. 2018, 94, 3765–3784. [Google Scholar] [CrossRef]

- In-situ Quality Assurance with QMmeltpool 3D from Concept Laser. Available online: https://www.concept-laser.de/contact_usa/in-situ-quality-assurance-with-qmmeltpool-3d-from-concept-laser/ (accessed on 14 May 2019).

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting a review. Int. Mater. Rev. 2016, 6608. [Google Scholar] [CrossRef]

- Zhang, L.c.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Rawal, S.; Brantley, J.; Karabudak, N. Additive manufacturing of Ti-6Al-4V alloy components for spacecraft applications. In Proceedings of the 6th International Conference on Recent Advances in Space Technologies (RAST 2013), Istanbul, Turkey, 12–14 June 2013; pp. 5–11. [Google Scholar] [CrossRef]

- Sartori, S.; Moro, L.; Ghiotti, A.; Bruschi, S. On the tool wear mechanisms in dry and cryogenic turning Additive Manufactured titanium alloys. Tribiol. Int. 2017, 105, 264–273. [Google Scholar] [CrossRef]

- Palanisamy, C. A review of additive manufacturing of α - β Ti alloy components through selective laser melting and laser metal deposition. J. Eng. Sci. Technol. 2018, 13, 790–812. [Google Scholar]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. Machining of functionally graded Ti6Al4V/ WC produced by Directed Energy Deposition. Addit. Manuf. 2018, 24, 20–29. [Google Scholar] [CrossRef]

- Baufeld, B.; Van Der Biest, O.; Gault, R.; Ridgway, K. Manufacturing Ti-6Al-4V components by Shaped Metal Deposition: Microstructure and mechanical properties. IOP Conf. Ser. Mater. Sci. Eng. 2011, 26, S106–S111. [Google Scholar] [CrossRef]

- Bermingham, M.; Nicastro, L.; Kent, D.; Chen, Y.; Dargusch, M. Optimising the mechanical properties of Ti-6Al-4V components produced by wire and arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 2018. [Google Scholar] [CrossRef]

- Clark, D.; Whittaker, M.T.; Bache, M.R. Microstructural characterization of a prototype titanium alloy structure processed via direct laser deposition (DLD). Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2012, 43, 388–396. [Google Scholar] [CrossRef]

- Norsk Titanium. Available online: https://www.norsktitanium.com/ (accessed on 15 May 2019).

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2015, 32, 641–647. [Google Scholar] [CrossRef]

- WAAM Demo Parts. Available online: https://waammat.com/about/demo-parts (accessed on 14 May 2019).

- Flynn, J.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid Additive and Subtractive Machine Tools- Research and Industrial Developments. Int. Mach. Tools Manuf. 2015. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. On the machinability of directed energy deposited Ti6Al4V. Addit. Manuf. 2018, 19, 39–50. [Google Scholar] [CrossRef]

- Hoye, N.; Cuiuri, D.; Rashid, R.A.R.; Palanisamy, S. Machining of GTAW additively manufactured Ti-6Al-4V structures. Int. J. Adv. Manuf. Technol. 2018, 99, 313–326. [Google Scholar] [CrossRef]

- Pardoe, J.A. ‘Conform’ Continuous Extrusion of Metal Powders into Products for Electrical Industry: Development Experience. Powder Metall. 1979, 22, 22–28. [Google Scholar] [CrossRef]

- Thomas, B.M.; Derguti, F.; Jackson, M. Continuous extrusion of a commercially pure titanium powder via the Conform process. Mater. Sci. Technol. 2017, 33, 899–903. [Google Scholar] [CrossRef]

- Weston, N.S.; Jackson, M. FAST-forge—A new cost-effective hybrid processing route for consolidating titanium powder into near net shape forged components. J. Mater. Process. Technol. 2017, 243, 335–346. [Google Scholar] [CrossRef]

- Calvert, E.; Wynne, B.; Weston, N.; Tudball, A.; Jackson, M. Thermomechanical processing of a high strength metastable beta titanium alloy powder, consolidated using the low-cost FAST-forge process. J. Mater. Process. Technol. 2018, 254, 158–170. [Google Scholar] [CrossRef]

- Arconic Announces Airbus 3D Printing Research Agreement. Available online: https://www.aero-mag.com/arconic-announces-airbus-3d-printing-research-agreement/ (accessed on 14 May 2019).

- Chastka, M.; Alman, E.; Satoh, G.; Bodily, B. Arconic WDED Additive Manufacturing and the Ampliforge Process. In Proceedings of the Forging Industry Technical Conference, Long Beach, CA, USA, 11–12 September 2018. [Google Scholar]

| Process Route | Condition | Yield Strength (MPa) | UTS a (MPa) | Elongation (%) |

|---|---|---|---|---|

| SLM | As built | 736–1166 | 1035–1407 | 1.6–12 |

| Heat treated | 862–1145 | 936–1228 | 7–12 | |

| HIP b | 835–973 | 910–1088 | 5–19 | |

| SEBM | As built | 782–1150 | 775–1237 | 2.3–17 |

| Heat treated | 869 | 965 | 6 | |

| HIP | 795–876 | 870–978 | 13–20 | |

| LMD | As built | 908–1105 | 1025–1163 | 3.8–14 |

| Heat treated | 832–1066 | 832–1112 | 0.8–16 | |

| HIP | 850–952 | 920–1007 | 11.8–17 | |

| SMD [35] | As built | NA | 936-1014 | 5.1–19 |

| ASTM | Wrought | >860 | >960 | >10 |

| Requirement c | Cast | >758 | >860 | >8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Childerhouse, T.; Jackson, M. Near Net Shape Manufacture of Titanium Alloy Components from Powder and Wire: A Review of State-of-the-Art Process Routes. Metals 2019, 9, 689. https://doi.org/10.3390/met9060689

Childerhouse T, Jackson M. Near Net Shape Manufacture of Titanium Alloy Components from Powder and Wire: A Review of State-of-the-Art Process Routes. Metals. 2019; 9(6):689. https://doi.org/10.3390/met9060689

Chicago/Turabian StyleChilderhouse, Thomas, and Martin Jackson. 2019. "Near Net Shape Manufacture of Titanium Alloy Components from Powder and Wire: A Review of State-of-the-Art Process Routes" Metals 9, no. 6: 689. https://doi.org/10.3390/met9060689