Mechanical Properties and Application of Right-Hand Rolling-Thread Steel Bolt in Deep and High-Stress Roadway

Abstract

:1. Introduction

2. Background

3. Experiments on Rolling-Thread and Full-Thread Steel Bolt

3.1. Pretightening Force Transformation Efficiency

- (1)

- The thread structure has the most important effect on the conversion of the torque on the nut to the pretightening force on the bolt rod. Applying the same torque to the nut of bolts with different thread sizes can result in different pretightening forces on the bolt rod. The rise angles of different sizes of threads are different, resulting in different thread friction forces [34,35,36,37]. The greater the thread friction force, the smaller the pretightening force transformation efficiency.

- (2)

- The materials of the bolt rod and nut are the second important factor affecting the pretightening force transformation efficiency. The material of the bolt rod is generally steel. The friction coefficients for the nuts and the bolt rod are different, depending on the materials with which they are made. The smaller the friction coefficient between the nut and the bolt rod, the more advantageous it is to convert the torque on the nut to the pretightening force on the bolt. In order to maximize the pretightening force transformation efficiency, the material with the minimum friction coefficient with steel should be selected to make the nut. The friction coefficients between the different materials for the nuts and the steel bolt rod are shown in Table 2. Table 2 shows that the friction coefficient between steel and ductile iron is the lowest, which is about 60% of the friction coefficient between steel and steel. Under the same thread structure and frictional reduction structure, the thread friction force of the bolt matching the ductile iron nut is 0.6 times that of the bolt matching the steel nut. Therefore, the pretightening force transformation efficiency of the bolt matching the ductile iron nut is the highest. At present, the nuts of the bolts used in mine roadways are mostly steel nuts [38,39,40,41], which is obviously disadvantageous for the high preload of bolts. Therefore, the bolt used in mine roadways should be matched with ductile iron nuts.

- (3)

- Frictional reduction structureThe tail structure of the bolt for mining service mainly includes a tray, spherical washer, frictional reduction gasket, and nut. The frictional reduction structure is mainly a frictional reduction gasket. The frictional reduction gasket can reduce the frictional torque between the nut and spherical washer, thereby improving the pretightening force transformation efficiency of the bolt. At present, the material of the frictional reduction gasket mainly includes four kinds, namely PTFE, nylon 1010, modified nylon 1010, and high-density polyethylene [42,43,44,45,46]. The nylon 1010 gasket has the best frictional reduction effect.

3.2. Test on Torque-Pretightening Force of Rolling-Thread and Full-Thread Steel Bolt

4. Experiments on Left and Right-Hand Threaded Steel Bolts

4.1. Tensile Test of Left and Right-Hand Threaded Steel Bolt

4.2. Anchorage Test of Left-Hand and Right-Hand Threaded Steel Bolts

5. Pull-Out Test in the Field

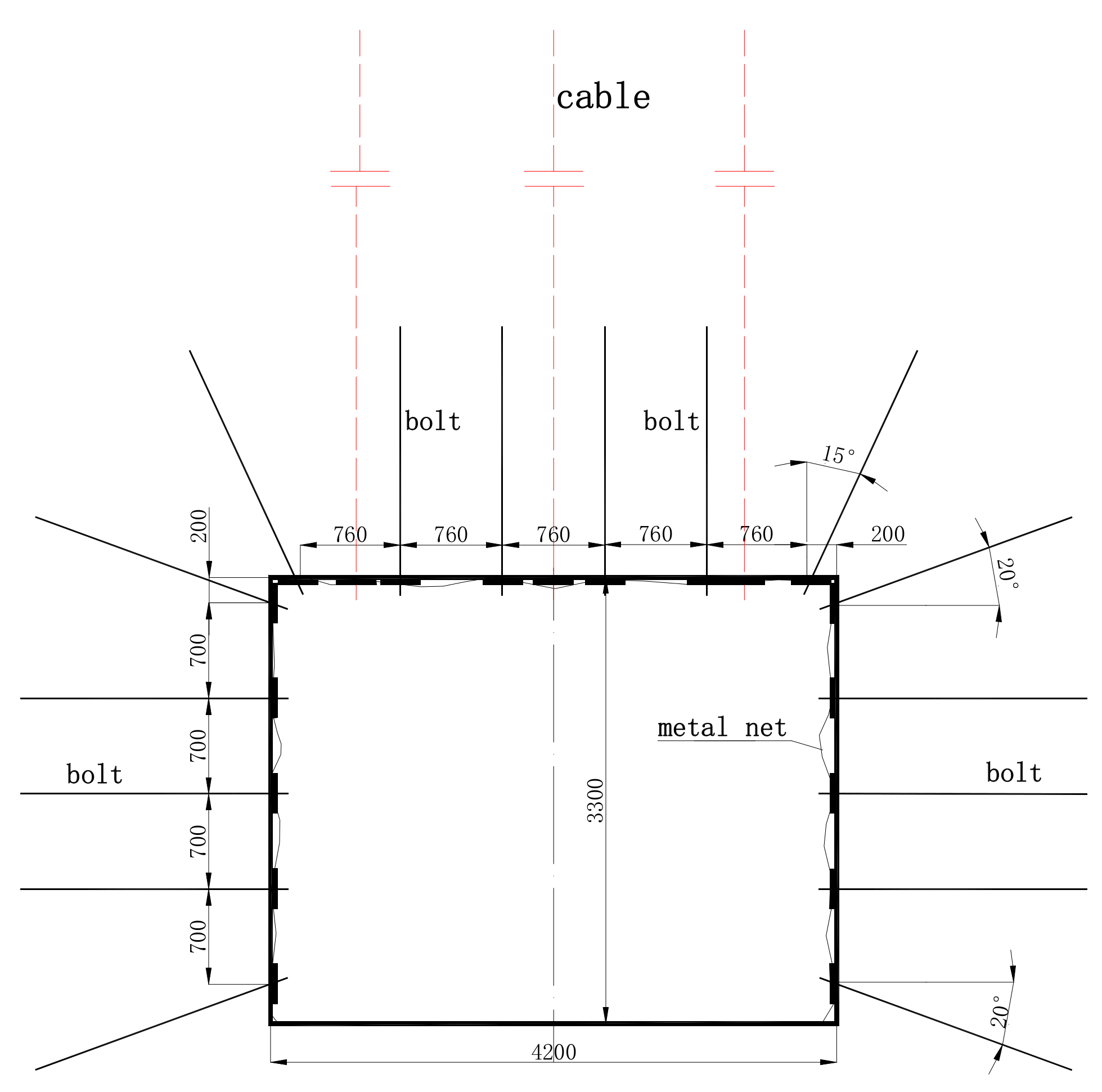

6. Application

7. Conclusions

- (1)

- The pretightening force transformation efficiency is the ratio between the pretightening force on the bolt and the torque on the nut. The factors affecting the pretightening force transformation efficiency of the bolts include the thread structure, the bolt rod and nut materials, and the frictional reduction structure. It is easier to apply a high pretightening force to the rolling-thread steel bolt than to the full-thread steel bolt.

- (2)

- Due to the different thread shape and thread height, the effective tensile section area of the left-hand threaded steel bolt with the same diameter is more than 10% larger than that of the right-hand threaded steel bolt. So, the yield strength and tensile strength of the left-hand threaded steel bolt with the same material and diameter are more than 10% higher than those of the right-hand threaded steel bolt.

- (3)

- The anchoring forces of the Φ18 and Φ20 left-hand threaded steel bolt were 46.2% and 33.3% greater than those of the right-hand threaded steel bolt, respectively. Due to the different screw thread directions, the anchoring forces of the left-hand threaded steel bolts with the same material and diameter are significantly greater than those of the right-hand threaded steel bolts.

- (4)

- In the 1301 haulage roadway, the maximum pull-out force of the left-hand threaded steel bolt with the same diameter was obviously greater than that of the right-hand threaded steel bolt.

- (5)

- The surrounding rock control effect of the test roadway supported by left-hand threaded steel bolts was obviously better than that of the roadway supported by the normal right-hand threaded steel bolts. The left-hand threaded steel bolts can can effectively control the stability of the surrounding rock in the 1301 haulage roadway of the Daxing Coal Mine.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tan, X.; Chen, W.Z.; Liu, H.Y.; Andrew, H.C.; Tian, H.M.; Meng, X.J.; Wang, F.Q.; Deng, X.L. A combined supporting system based on foamed concrete and U-shaped steel for underground coal mine roadways undergoing large deformations. Tunn. Undergr. Space Technol. 2017, 68, 196–210. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Liu, N.; Zheng, X.G.; Zhang, N. Mechanical model for controlling floor heave in deep roadways with U-shaped steel closed support. Int. J. Min. Sci. Technol. 2015, 25, 713–720. [Google Scholar] [CrossRef]

- Jiao, Y.Y.; Song, L.; Wang, X.Z.; Coffi, A.A. Improvement of the U-shaped steel sets for supporting the roadways in loose thick coal seam. Int. J. Rock Mech. Min. Sci. 2013, 60, 19–25. [Google Scholar] [CrossRef]

- Zhang, J.P.; Liu, L.M.; Cao, J.Z.; Yan, X.; Zhang, F.T. Mechanism and application of concrete-filled steel tubular support in deep and high stress roadway. Constr. Build. Mater. 2018, 163, 233–246. [Google Scholar] [CrossRef]

- Huang, W.P.; Yuan, Q.; Tan, Y.L.; Wang, J.; Liu, G.L.; Qu, G.L.; Li, C. An innovative support technology employing a concrete- filled steel tubular structure for a 1000-m-deep roadway in a high in situ stress field. Tunn. Undergr. Space Technol. 2018, 73, 26–36. [Google Scholar] [CrossRef]

- Zhang, J.P.; Liu, L.M.; Li, Q.H.; Peng, W.; Zhang, F.T.; Cao, J.Z.; Wang, H. Development of cement- based self-stress composite grouting material for reinforcing rock mass and engineering application. Constr. Build. Mater. 2019, 201, 314–327. [Google Scholar] [CrossRef]

- Zhang, J.P.; Liu, L.M.; Zhang, F.T.; Cao, J.Z. Development and application of new composite grouting material for sealing groundwater inflow and reinforcing wall rock in deep mine. Sci. Rep. 2018, 8, 1–11. [Google Scholar]

- Hatzor, Y.H.; Wainshtein, I.; Mazor, D.B. Stability of shallow karstic caverns in blocky rock masses. Int. J. Rock Mech. Min. Sci. 2010, 47, 1289–1303. [Google Scholar] [CrossRef]

- Hsu, S.C.; Chiang, S.S.; Lai, J.R. Failure mechanisms of tunnels in weak rock with interbedded structures. Int. J. Rock Mech. Min. Sci. 2004, 41, 670–675. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Pan, R.; Li, S.C.; He, M.C.; Sun, H.B.; Qin, Q.; Yu, H.C.; Luan, Y.C. Failure mechanism of surrounding rock with high stress and confined concrete support system. Int. J. Rock Mech. Min. Sci. 2018, 102, 89–100. [Google Scholar] [CrossRef]

- Jansseune, A.; Wouter, D.C.; Jan, B. Elastic failure of locally supported silos with U-shaped longitudinal stiffeners. KSCE J. Civ. Eng. 2015, 19, 1041–1049. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, S.C.; Wang, D.C.; Wang, F.Q.; Li, W.T.; Ren, Y.X.; Guo, N.B.; Shao, X. Experimental studies on the mechanical properties and deformation & failure mechanism of U-type confined concrete arch centering. Tunn. Undergr. Space Technol. 2016, 51, 20–29. [Google Scholar]

- Suorineni, F.T.; Kaiser, P.K.; Henning, J.G. Safe rapid drifting-support selection. Tunn. Undergr. Space Technol. 2008, 23, 682–699. [Google Scholar] [CrossRef]

- Shchetinin, V.V. Investigation of different types of flexible anchor tendons (rock bolts) for stabilization of rock masses. Hydrotech. Constr. 1974, 8, 315–320. [Google Scholar] [CrossRef]

- Manh, H.T.; Sulem, J.; Subrin, D.; Billaux, D. Anisotropic timedependent modeling of tunnel excavation in squeezing ground. Rock Mech. Rock Eng. 2015, 48, 2301–2317. [Google Scholar] [CrossRef]

- Panarace, M.; Garnil, C.; Cane, L.; Rodr, G.E.; Medina, M. Identification, remediation, and analysis of karst sinkholes in the longest railroad tunnel in South Korea. Eng. Geol. 2012, 135, 92–105. [Google Scholar]

- Zhang, G.H.; Jiao, Y.Y.; Wang, H. Outstanding issues in excavation of deep and long rock tunnels: A case study. Can. Geotech. J. 2014, 51, 984–994. [Google Scholar] [CrossRef]

- Villaescusa, E.; Varden, R.; Hassell, R. Quantifying the performance of resin anchored rock bolts in the Australian underground hard rock mining industry. Int. J. Rock Mech. Sand Min. Sci. 2008, 30, 94–102. [Google Scholar] [CrossRef]

- Campbell, R.; Mould, R.J. Impacts of gloving and un-mixed resin in fully encapsulated roof bolts on geotechnical design assumption sand strata control. Int. J. Coal Geol. 2005, 64, 116–125. [Google Scholar] [CrossRef]

- Ivanovi, A.; Neilson, R.D. Modelling of debonding along the fixed anchor length. Int. J. Rock Mech. Min. Sci. 2009, 46, 699–707. [Google Scholar] [CrossRef]

- Ivanovic, A.; Neilson, R.D. Influence of geometry and material properties on the axial vibration of a rock bolt. Int. J. Rock Mech. Min. Sci. 2008, 45, 941–951. [Google Scholar] [CrossRef]

- Inácio, M.M.G.; Ramos, A.P.; Faria, D.M.V. Strengthening of flat slabs with transverse reinforcement by introduction of steel bolts using different anchorage approaches. Eng. Struct. 2012, 44, 63–77. [Google Scholar]

- Pedersen, N.L.; Pedersen, P. Bolt-plate contact assemblies with prestress and external loads: Solved with super element technique. Comput. Struct. 2009, 87, 1374–1383. [Google Scholar] [CrossRef]

- Ana, I.; Richard, D.N. Non-destructive testing of rock bolts for estimating total bolt length. Int. J. Rock Mech. Min. Sci. 2013, 64, 36–43. [Google Scholar]

- Ding, X.L.; Weng, Y.H.; Zhang, Y.T.; Xu, T.J.; Wang, T.L.; Rao, Z.W.; Qi, Z.F. Stability of Large Parallel Tunnels Excavated in Weak Rocks: A Case Study. Rock Mech. Rock Eng. 2017, 50, 2443–2464. [Google Scholar] [CrossRef]

- Li, Q.F.; Zhu, C.Q.; Duan, Y. Theoretical and experimental research on characteristics of lateral vibration for a pre-stress bolt supporting system. J. Coal Sci. Eng. 2009, 15, 33–37. [Google Scholar] [CrossRef]

- Isabelle, T.; Laura, B.M.; Faouzi, H.H.; Jacques, S.; Zbigniew, L.; Aleksander, W. Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar]

- Li, C.C. Performance of D-bolts Under Static Loading. Rock Mech. Rock Eng. 2012, 45, 183–192. [Google Scholar]

- Korane, K.; Sauer, S. The nuts and bolts of specifying fastener torque. Mach. Des. 1998, 70, 81–83. [Google Scholar]

- Ibrahim, R.A.; Pettit, C. Uncertainties and dynamic problems of bolted joints and other fasteners. J. Sound Vib. 2005, 279, 857–936. [Google Scholar] [CrossRef]

- Anders, J.; Cismoski, D.; Pattillo, P.; Fox, A.; Pitts, D. Analysis of Thread Engagement Requirements for Studs and Nuts. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Shigeru, Y.; Amiya, K.; Yasunori, S. Effects of residual stress on elastic plastic behavior of metallic glass bolts formed by cold thread rolling. J. Mater. Process. Technol. 2014, 214, 2593–2599. [Google Scholar]

- Zhang, M.G. Roadway Support Technology in Goaf of Ultra-close Distance Coal Seams. J. Shandong Univ. Sci. Technol. 2018, 37, 35–41. [Google Scholar]

- Ahmad, R.Z.; Oyadiji, S.O. Clamping of fine Kirschner wires in external fixators. Proc. Inst. Mech. Eng. Part H 2016, 230, 1036–1042. [Google Scholar]

- Lambert, T.H. Effects of variations in the screw thread coefficient of friction on the clamping force of bolted connections. ARCHIVE J. Mech. Eng. Sci. 1962, 4, 401–406. [Google Scholar] [CrossRef]

- Abhijit, B.; Barnik, S.R.; John, D.B.; Subhash, C.S. An experimental investigation of torque and force generation for varying tool tilt angles and their effects on microstructure and mechanical properties: Friction stir welding of AA 6061-T6. J. Manuf. Process. 2018, 31, 395–404. [Google Scholar]

- Philipp, K.; Peter, G. Defect detection in thread rolling processes—Experimental study and numerical investigation of driving parameters. Int. J. Mach. Tools Manuf. 2018, 129, 27–36. [Google Scholar]

- Kang, H.; Wu, Y.; Gao, F.; Jiang, P.; Cheng, P.; Meng, X.; Li, Z. Mechanical performances and stress states of rock bolts under varying loading conditions. Tunn. Undergr. Space Technol. 2016, 52, 138–146. [Google Scholar] [CrossRef]

- Tao, Z.G.; Zhao, F.; Wang, H.J.; Zhang, H.J.; Peng, Y.Y. Innovative constant resistance large deformation bolt for rock support in high stressed rock mass. Arabian J. Geosci. 2017, 10, 341. [Google Scholar]

- Lip, H.T.; Mehmet, E.U. Ultimate Tilt-Bearing Capacity of Bolted Connections in Cold-Reduced Steel Sheets. J. Struct. Eng. 2017, 143, 04016206. [Google Scholar]

- Segarra, P.; Sanchidrián, J.A.; Castedo, R.; Castillo, I.D. Coupling of blasting seismographs to rock and its effectiveness for horizontal ground motion. Int. J. Rock Mech. Min. Sci. 2017, 92, 81–90. [Google Scholar] [CrossRef]

- Yan, Y.F.; Shen, Y.F.; Hou, W.T.; Li, J.P. Friction stir spot welding thin acrylonitrile butadiene styrene sheets using pinless tool. Int. J. Adv. Manuf. Technol. 2018, 97, 2749–2755. [Google Scholar] [CrossRef]

- Osmolovsky, D.S. Efficiency of vibration-damping gaskets with dry friction for reduction noise of circular woodworking machines. Polythematic Online Sci. J. Kuban State Agrar. Univ. 2011, 70, 533–548. [Google Scholar]

- Yu, Q.G.; Zhang, H.X.; Deng, W.N.; Zou, Y.P. The Non- symmetric Shape of Surface Subsidence Caused by Mining. J. Shandong Univ. Sci. Technol. 2018, 37, 42–48. [Google Scholar]

- Liu, X.S.; Tan, Y.L.; Ning, J.G.; Lu, Y.W.; Gu, Q.H. Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int. J. Rock Mech. Min. Sci. 2018, 110, 140–150. [Google Scholar] [CrossRef]

- Yin, D.W.; Chen, S.J.; Liu, X.Q.; Ma, H.F. Effect of joint angle in coal on failure mechanical behavior of roof rock-coal combined body. Q. J. Eng. Geol. Hydroge. 2018, 51, 202–209. [Google Scholar] [CrossRef]

| Name | Buried Depth (m) | Vertical Stress (MPa) | Maximum Horizontal Principal Stress (MPa) | Direction of Principal Stress |

|---|---|---|---|---|

| In situ stress | 800 | 31.2 | 22.6 | N6°E |

| Materials | Steel and Wear-Resisting Cast Iron | Steel and Gray Cast Iron | Steel and Steel | Steel and Ductile Iron |

|---|---|---|---|---|

| Friction coefficient | 0.10–0.12 | 0.12–0.15 | 0.11–0.17 | 0.07–0.10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, L.; Shao, J.; Li, Q. Mechanical Properties and Application of Right-Hand Rolling-Thread Steel Bolt in Deep and High-Stress Roadway. Metals 2019, 9, 346. https://doi.org/10.3390/met9030346

Zhang J, Liu L, Shao J, Li Q. Mechanical Properties and Application of Right-Hand Rolling-Thread Steel Bolt in Deep and High-Stress Roadway. Metals. 2019; 9(3):346. https://doi.org/10.3390/met9030346

Chicago/Turabian StyleZhang, Jinpeng, Limin Liu, Jun Shao, and Qinghai Li. 2019. "Mechanical Properties and Application of Right-Hand Rolling-Thread Steel Bolt in Deep and High-Stress Roadway" Metals 9, no. 3: 346. https://doi.org/10.3390/met9030346