Joining Aluminium Alloy 5A06 to Stainless Steel 321 by Vaporizing Foil Actuators Welding with an Interlayer

Abstract

:1. Introduction

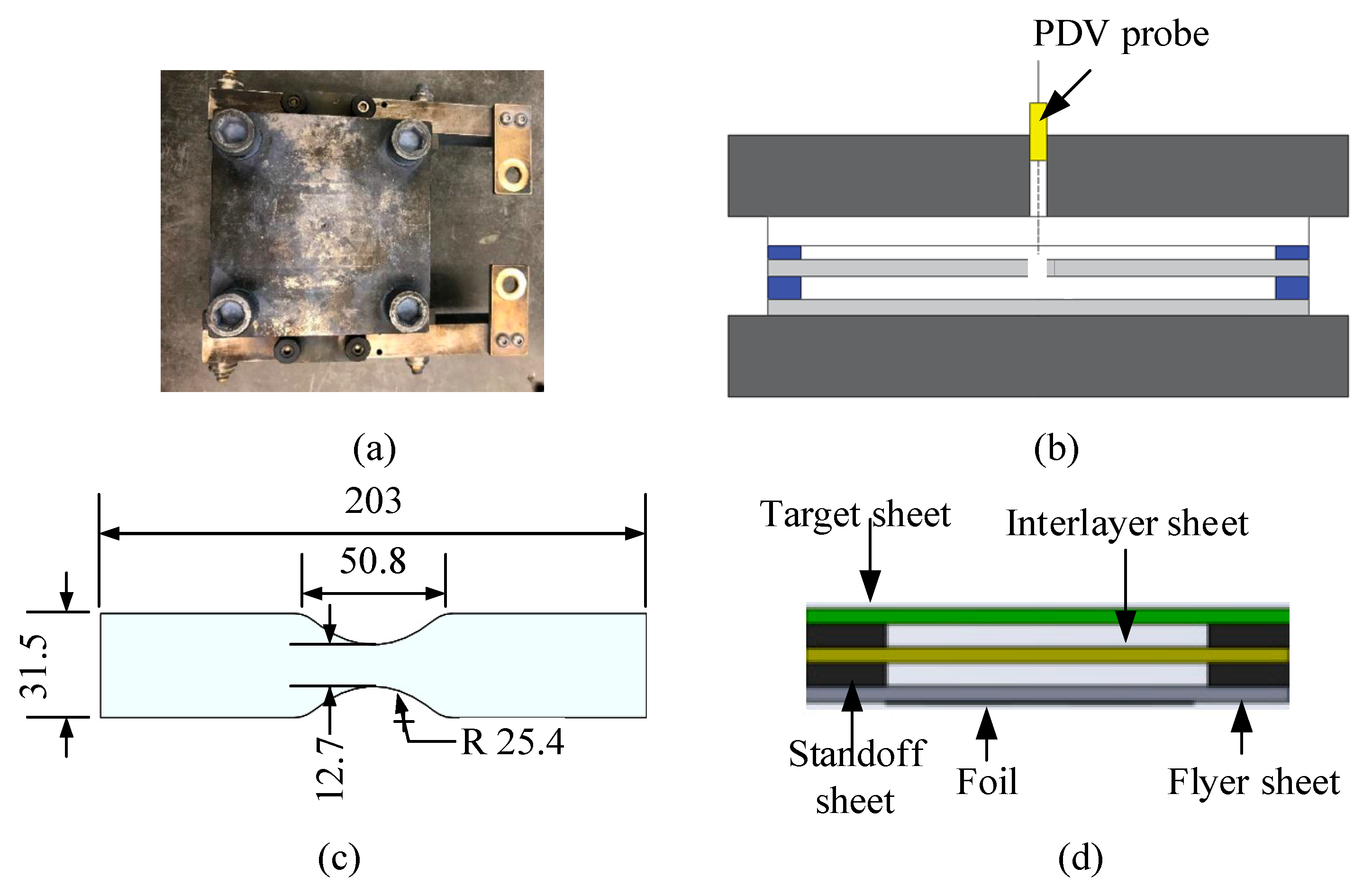

2. Experimental Procedure

2.1. Materials and Methods

2.2. Velocity Measurement

2.3. Strength Testing

3. Results and Discussion

3.1. Velocity, Current, and Voltage Traces

3.2. Mechanical Testing

3.3. Interfacial Morphologies

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Disclaimer

References

- Sahin, M. Joining of stainless-steel and aluminium materials by friction welding. Int. J. Adv. Manuf. Technol. 2009, 41, 487–497. [Google Scholar] [CrossRef]

- Sun, Z.; Karppi, R. The application of electron beam welding for the joining of dissimilar metals: An overview. J. Mater. Process. Technol. 1996, 59, 257–267. [Google Scholar] [CrossRef]

- Jafarian, M.; Khodabandeh, A.; Manafi, S. Evaluation of diffusion welding of 6061 aluminum and AZ31 magnesium alloys without using an interlayer. Mater. Des. 2015, 65, 160–164. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, D.; Han, L.; Liu, D. Interfacial microstructure and mechanical property of resistance spot welded joint of high strength steel and aluminium alloy with 4047 AlSi12 interlayer. Mater. Des. 2014, 57, 186–194. [Google Scholar] [CrossRef]

- Song, J.L.; Lin, S.B.; Yang, C.L.; Fan, C.L. Effects of Si additions on intermetallic compound layer of aluminum–steel tig welding–brazing joint. J. Alloys Compd. 2009, 488, 217–222. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zhang, Z.D.; Liu, L.M. The effect of galvanized iron interlayer on the intermetallics in the Laser weld bonding of Mg to Al fusion zone. J. Mater. Eng. Perform. 2013, 22, 351–357. [Google Scholar] [CrossRef]

- Wang, H.; Liu, L.; Liu, F. The characterization investigation of laser-arc-adhesive hybrid welding of Mg to Al joint using Ni interlayer. Mater. Des. 2013, 50, 463–466. [Google Scholar] [CrossRef]

- Balakrishnan, M.; Balasubramanian, V.; Madhusudhan Reddy, G. Effect of hardfaced interlayer thickness on ballistic performance of armour steel welds. Mater. Des. 2013, 44, 59–68. [Google Scholar] [CrossRef]

- Date, H.; Kobayakawa, S.; Naka, M. Microstructure and bonding strength of impact-welded aluminium–stainless steel joints. J. Mater. Process. Technol. 1999, 85, 166–170. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Guglielmino, E.; Mariano Sili, A. Full-field analysis of Al/Fe explosive welded joints for shipbuilding applications. Mar. Struct. 2018, 57, 207–218. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Guglielmino, E. Non linear finite element simulation of explosive welded joints of dissimilar metals for shipbuilding applications. Ocean Eng. 2018, 160, 346–353. [Google Scholar] [CrossRef]

- Topolski, K.; Szulc, Z.; Garbacz, H. Microstructure and properties of the Ti6Al4V/Inconel 625 bimetal obtained by explosive joining. J. Mater. Eng. Perform. 2016, 25, 3231–3237. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Xie, M.; Shang, X.; Zhang, L.; Bai, Q.; Xu, T. Interface characteristic of explosive-welded and hot-rolled Ta1/X65 bimetallic plate. Metals 2018, 8, 159. [Google Scholar] [CrossRef]

- Kaya, Y. Microstructural, mechanical and corrosion investigations of ship steel-aluminum bimetal composites produced by explosive welding. Metals 2018, 8, 544. [Google Scholar] [CrossRef]

- Balasundaram, R.; Patel, V.K.; Bhole, S.D.; Chen, D.L. Effect of zinc interlayer on ultrasonic spot welded aluminum-to-copper joints. Mater. Sci. Eng. A 2014, 607, 277–286. [Google Scholar] [CrossRef]

- Berlin, A.; Nguyen, T.C.; Worswick, M.J.; Zhou, Y. Metallurgical analysis of magnetic pulse welds of AZ31 magnesium alloy. Sci. Technol. Weld. Join. 2013, 16, 728–734. [Google Scholar] [CrossRef]

- Zhang, Y.; Babu, S.S.; Prothe, C.; Blakely, M.; Kwasegroch, J.; LaHa, M.; Daehn, G.S. Application of high velocity impact welding at varied different length scales. J. Mater. Process. Technol. 2011, 211, 944–952. [Google Scholar] [CrossRef]

- Yılmaz, M.; Çöl, M.; Acet, M. Interface properties of aluminum/steel friction-welded components. Mater. Charact. 2002, 49, 421–429. [Google Scholar] [CrossRef]

- Madhusudhan Reddy, G.; Venkata Ramana, P. Role of nickel as an interlayer in dissimilar metal friction welding of maraging steel to low alloy steel. J. Mater. Process. Technol. 2012, 212, 66–77. [Google Scholar] [CrossRef]

- Han, J.H.; Ahn, J.P.; Shin, M.C. Effect of interlayer thickness on shear deformation behavior of AA5083 aluminum alloy/SS41 steel plates manufactured by explosive welding. J. Mater. Sci. 2003, 38, 13–18. [Google Scholar] [CrossRef]

- Manikandan, P.; Hokamoto, K.; Fujita, M.; Raghukandan, K.; Tomoshige, R. Control of energetic conditions by employing interlayer of different thickness for explosive welding of titanium/304 stainless steel. J. Mater. Process. Technol. 2008, 195, 232–240. [Google Scholar] [CrossRef]

- Vivek, A.; Hansen, S.R.; Liu, B.C.; Daehn, G. Vaporizing foil actuator: A tool for collision welding. J. Mater. Process. Technol. 2013, 213, 2304–2311. [Google Scholar] [CrossRef]

- Vivek, A.; Hansen, S.; Benzing, J.; He, M.; Daehn, G. Impact welding of aluminum to copper and stainless steel by vaporizing foil actuator: Effect of heat treatment cycles on mechanical properties and microstructure. Metall. Mater. Trans. A 2015, 46, 4548–4558. [Google Scholar] [CrossRef]

- Liu, B.; Vivek, A.; Presley, M.; Daehn, G. Dissimilar impact welding of 6111-T4, 5052-H32 aluminum alloys to 22MnB5, Dp980 steels and the structure–property relationship of a strongly bonded interface. Metall. Mater. Trans. A 2018, 49, 899–907. [Google Scholar] [CrossRef]

- Liu, B.; Vivek, A.; Daehn, G.S. Joining sheet aluminum AA6061-T4 to cast magnesium AM60B by vaporizing foil actuator welding: Input energy, interface, and strength. J. Manuf. Process. 2017, 30, 75–82. [Google Scholar] [CrossRef]

- Nassiri, A.; Zhang, S.; Lee, T.; Abke, T.; Vivek, A.; Kinsey, B.; Daehn, G. Numerical investigation of Cp-Ti & Cu110 impact welding using smoothed particle hydrodynamics and arbitrary lagrangian-eulerian methods. J. Manuf. Process. 2017, 28, 558–564. [Google Scholar]

- Chen, S.; Huo, X.; Guo, C.; Wei, X.; Huang, J.; Yang, J.; Lin, S. Interfacial characteristics of Ti/Al joint by vaporizing foil actuator welding. J. Mater. Process. Technol. 2019, 263, 73–81. [Google Scholar] [CrossRef]

- Johnson, J.R.; Taber, G.; Vivek, A.; Zhang, Y.; Golowin, S.; Banik, K.; Fenton, G.K.; Daehn, G. Coupling experiment and simulation in electromagnetic forming using photon doppler velocimetry. Metal Form. 2009, 80, 359–365. [Google Scholar]

- Vivek, A.; Hansen, S.R.; Daehn, G. High strain rate metalworking with vaporizing foil actuator: Control of flyer velocity by varying input energy and foil thickness. Rev. Sci. Instrum. 2014, 85, 75101. [Google Scholar] [CrossRef] [PubMed]

| Capacitance | Inductance | Resistance | Maximum Charging Energy | Short Circuit Current Rise Time |

|---|---|---|---|---|

| 426 μF | 100 nH | 10 mΩ | 16 kJ at 8.66 kV | 12 μs |

| Energy Input | Lap-Shear Average | Test 1 | Test 2 | Test 3 | Peel Average | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|---|

| (kJ) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) |

| 6 | 29.9 | 28.8 | 31.9 | 28.9 | 1.62 | 1.59 | 1.61 | 1.66 |

| 8 | 35 | 34.2 | 36.2 | 34.7 | 1.65 | 1.69 | 1.65 | 1.62 |

| 10 | 44 | 43.5 | 45.4 | 43.1 | 2.15 | 2.12 | 2.18 | 2.16 |

| 12 | 42.6 | 42.9 | 42.2 | 42.6 | 2.03 | 2.01 | 2.04 | 2.03 |

| EDS | EDS | EDS | EDS | EDS | EDS | EDS | |

|---|---|---|---|---|---|---|---|

| Spot 1 | Spot 2 | Spot 3 | Spot 4 | Spot 5 | Spot 6 | Spot7 | |

| Al | 42.3 | 0.77 | 42.49 | 62.99 | 67.16 | 66.79 | 67.17 |

| Fe | 42.56 | 69.79 | 42.47 | 21.61 | 22.84 | 22.54 | 22.25 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, S.; Chen, S.; Mao, Y.; Xiao, J.; Vivek, A.; Daehn, G. Joining Aluminium Alloy 5A06 to Stainless Steel 321 by Vaporizing Foil Actuators Welding with an Interlayer. Metals 2019, 9, 43. https://doi.org/10.3390/met9010043

Su S, Chen S, Mao Y, Xiao J, Vivek A, Daehn G. Joining Aluminium Alloy 5A06 to Stainless Steel 321 by Vaporizing Foil Actuators Welding with an Interlayer. Metals. 2019; 9(1):43. https://doi.org/10.3390/met9010043

Chicago/Turabian StyleSu, Shan, Shujun Chen, Yu Mao, Jun Xiao, Anupam Vivek, and Glenn Daehn. 2019. "Joining Aluminium Alloy 5A06 to Stainless Steel 321 by Vaporizing Foil Actuators Welding with an Interlayer" Metals 9, no. 1: 43. https://doi.org/10.3390/met9010043