Effect of Surface Roughness on the Bonding Strength and Spring-Back of a CFRP/CR980 Hybrid Composite

Abstract

:1. Introduction

2. Experiments

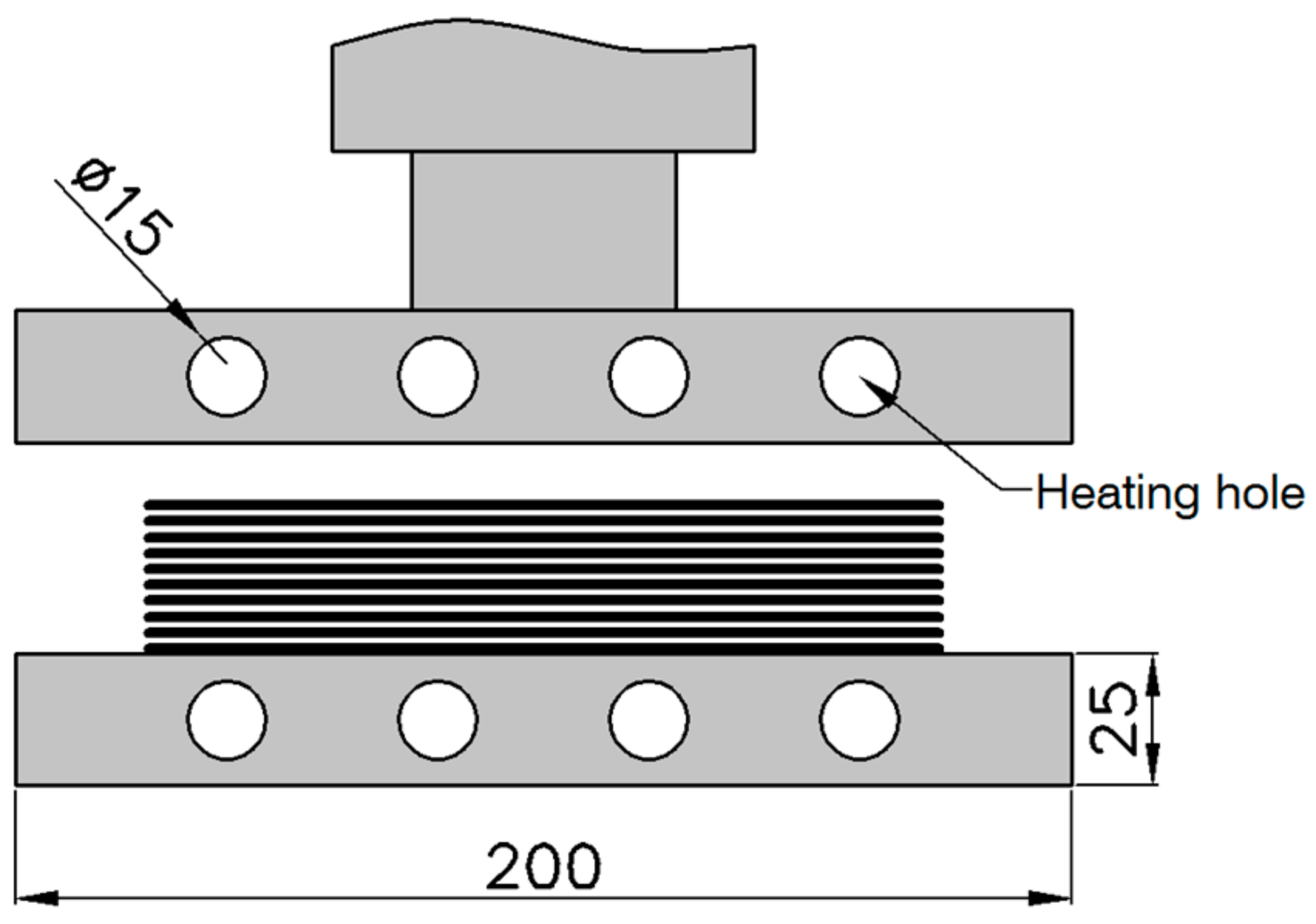

2.1. Shear Lap Adhesion Test of the CFRP/CR980 Hybrid Composite

2.1.1. Preparation of Specimen

2.1.2. Production of Specimen

2.2. V-Bending Test of CFRP/CR980 Hybrid Composite

3. Results

3.1. CFRP/CR980 Hybrid Composite by Shear Lap Adhesion Test

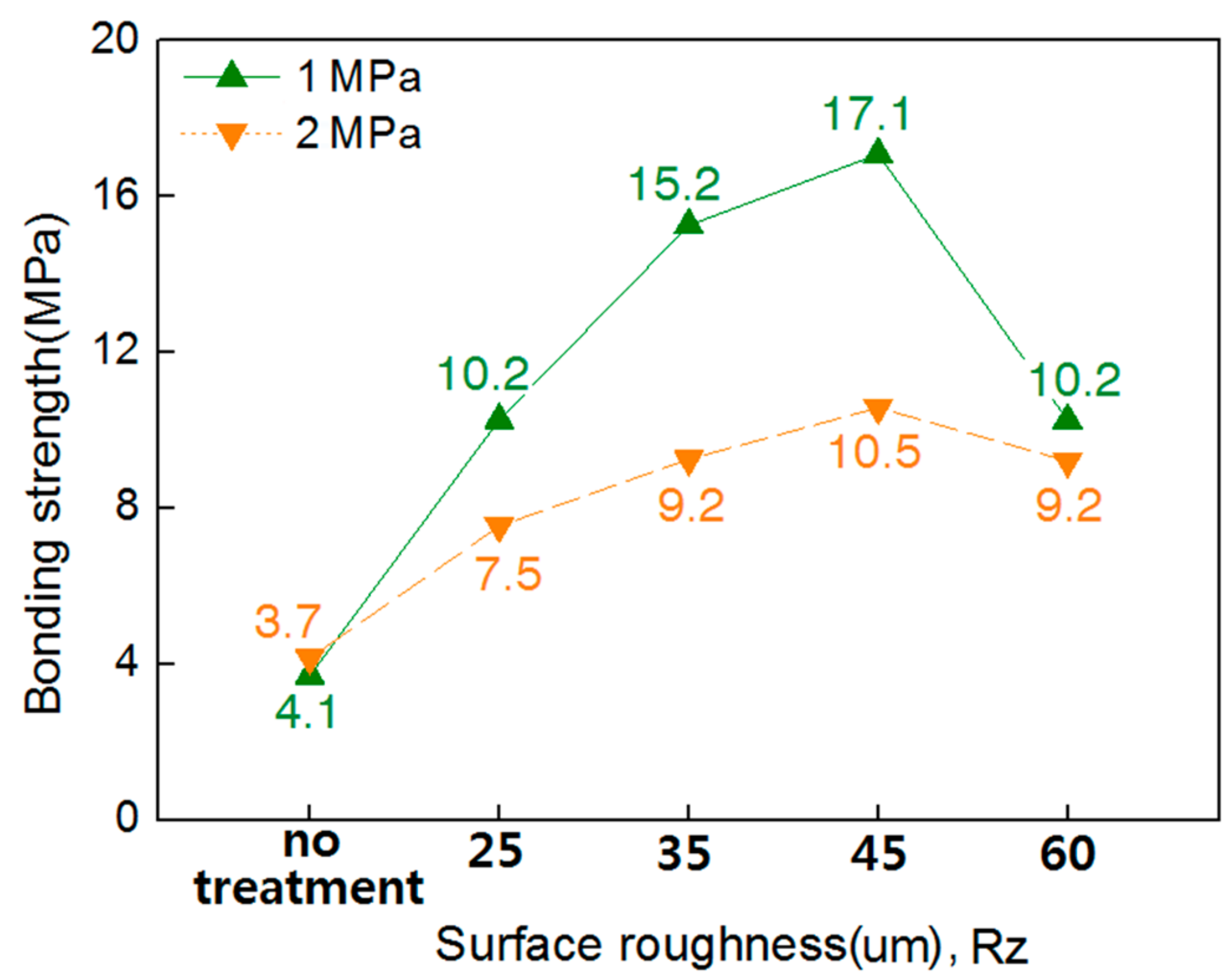

3.1.1. Bonding Strength

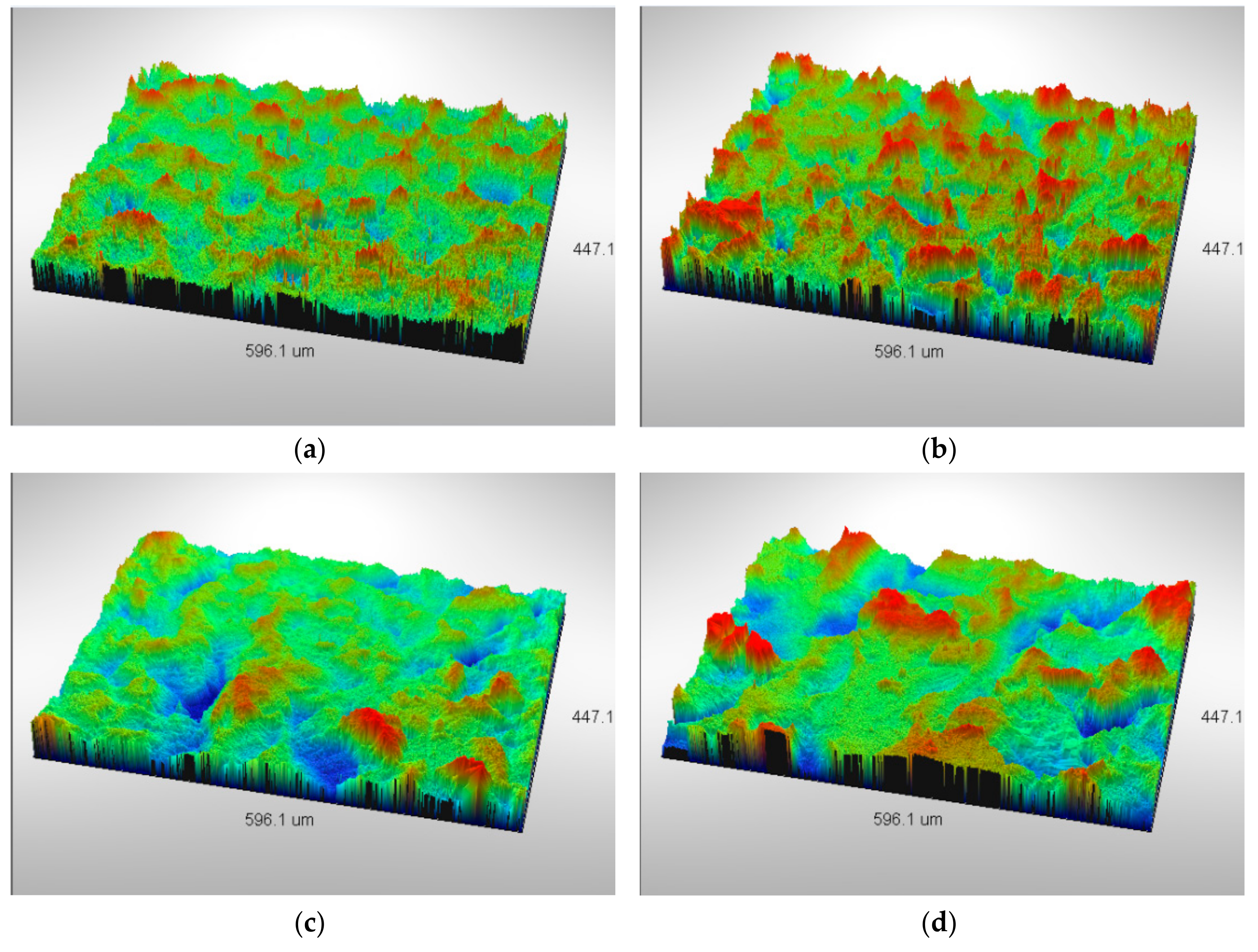

3.1.2. Microstructures

3.2. CFRP/CR980 Hybrid Composite by V-Bending Test

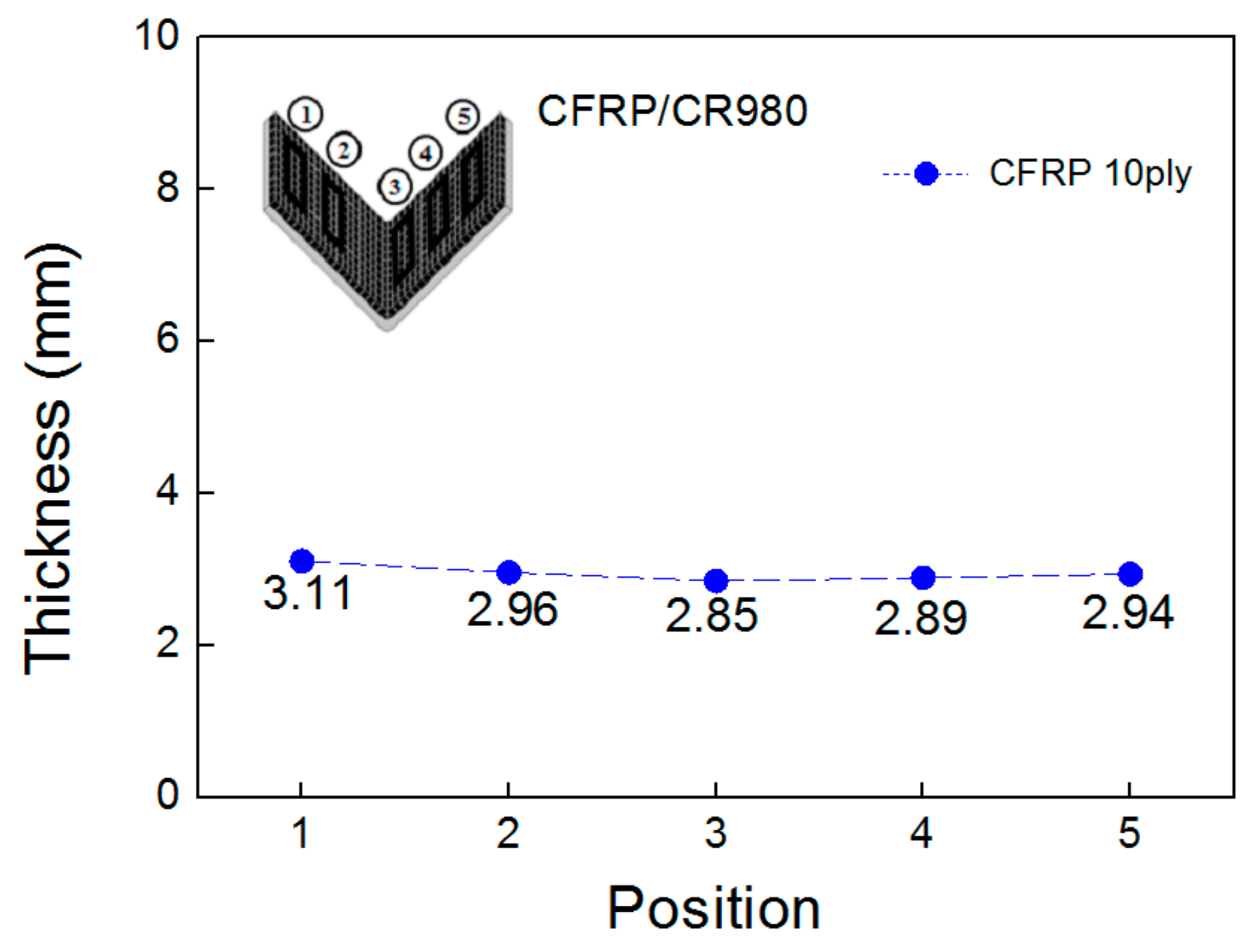

3.2.1. Thickness

3.2.2. Spring-Back Angle

3.2.3. Microstructures

4. Conclusions

- (1)

- The bonding strength between the surface-treated CR980 and CFRP generally increased depending on the degree of surface treatment. In the condition of Rz = 60 μm or more, the bonding strength was reduced.

- (2)

- The bonding strength of specimens pressurized at 2 MPa was lower than that at 1 MPa, when pressure was applied during the production of shear test specimen to measure the bond strength.

- (3)

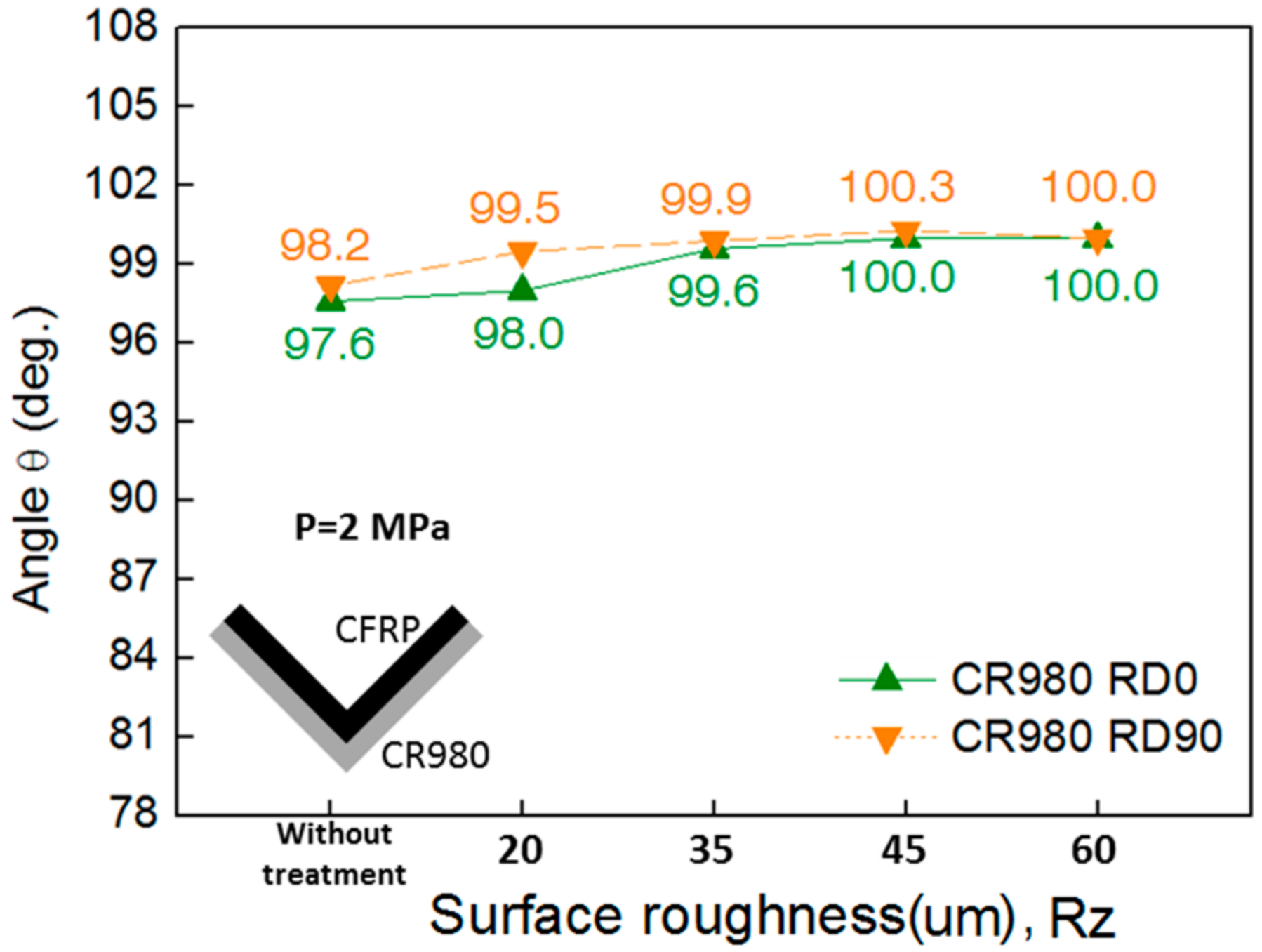

- The spring-back angle tended to increase with an increase in the surface roughness. There is a little bit of difference in spring-back angles between 1 MPa and 2 MPa of the pressure.

- (4)

- Delamination occurred at the bonding interface near the punch contact area of the CFRP/CR980 hybrid composite without treatment under 1 MPa of the pressure.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Lightweighting-Wikipedia. Available online: https://en.wikipedia.org/wiki/Lightweighting (accessed on 1 September 2018).

- Lightweight-Materials-Cars-and-Trucks/Department of Energy. Available online: https://www.energy.gov/eere/vehicles/lightweight-materials-cars-and-trucks (accessed on 1 September 2018).

- Al-Zubaidy, H.; Zhao, X.L.; Al-Mihaidi, R. Mechanical Behaviour of Normal Modulus Carbon Fibre Reinforced Polymer (CFRP) and Epoxy under Impact Tensile Loads. Procedia Eng. 2011, 10, 2453–2458. [Google Scholar] [CrossRef]

- Van-Paepegem, W.; De-Geyter, K.; Vanhooymissen, P.; Degrieck, J. Effect of friction on the hysteresis loops from three-point bending fatigue tests of fibre-reinforced composites. Compos. Struct. 2006, 72, 212–217. [Google Scholar] [CrossRef]

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of Lightweight Components by Metal Forming. CIRP Ann.-Manuf. Technol. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Fuwa, M.; Bunsell, A.R.; Harris, B. Tensile failure mechanisms in carbon fibre reinforced plastics. J. Mater. Sci. 1975, 10, 2062–2070. [Google Scholar] [CrossRef]

- Paiva, J.M.F.; Mayer, S.; Rezende, M.C. Comparison of Tensile Strength of Different Carbon Fabric Reinforced Epoxy Composites. Mater. Res. 2006, 9, 83–89. [Google Scholar] [CrossRef]

- Yu, T.; Fernando, D.; Teng, J.G.; Zhao, X.L. Experimental study on CFRP-to-steel bonded interfaces. Compos. Part B Eng. 2012, 43, 2279–2289. [Google Scholar] [CrossRef]

- Lee, M.S.; Kim, S.J.; Lim, O.D.; Kang, C.G. Effect of process parameters on epoxy flow behavior and formability with CR340/CFRP composites by different laminating in deep drawing process. Procedia Eng. 2014, 81, 1627–1632. [Google Scholar] [CrossRef]

- Lee, M.S.; Kim, S.J.; Kim, H.H.; Lim, O.D.; Kang, C.G. Effects of process parameters on epoxy flow behavior and formability in deep drawing process with CR340/carbon fiber–reinforced plastic composites. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2014, 229, 86–99. [Google Scholar] [CrossRef]

- High Performance Carbon Fibers—National Historic Chemical Landmark. Available online: https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/carbonfibers.html (accessed on 1 September 2018).

- Fan, L.-T.; Gharpuray, M.M.; Lee, Y.H. Nature of Cellulosic Material. Cellul. Hydrolys. 1987, 3, 5–20. [Google Scholar]

- Via, B.K.; So, C.L.; Shupe, T.F.; Groom, L.H.; Wikaira, J. Mechanical response of longleaf pine to variation in microfibril angle, chemistry associated wavelengths, density, and radial position. Compos. Part A Appl. Sci. Manuf. 2009, 40, 60–66. [Google Scholar] [CrossRef]

- Wei, P.; Rao, X.; Yang, J.; Guo, Y.; Chen, H.; Zhang, Y.; Wang, Z. Hot pressing of wood-based composites: A review. For. Prod. J. 2016, 66, 419–427. [Google Scholar] [CrossRef]

- Lee, M.S.; Kim, S.J.; Lim, O.D.; Kang, C.G. A study on mechanical properties of Al5052/CFRP/Al5052 composite through three-point bending tests and shear lap tests according to surface roughness. J. Compos. Mater. 2016, 10, 1–11. [Google Scholar] [CrossRef]

- Korea Carbon. Available online: https://www.hcarbon.com/product/overview.asp (accessed on 1 September 2018).

- Toray. Available online: https://www.toray.com/products/prod_001.html (accessed on 1 September 2018).

- Hyundai Steel. Available online: https://www.hyundai-steel.com/kr/products-technology/products/hotrolledsteel.hds (accessed on 1 September 2018).

- Korean Agency for Technology and Standard. Methods of Making Samples of Carbon Fiber Reinforced Plastics; KS M 3713; KATS: Seoul, Korea, 2012. [Google Scholar]

- Standard Guide for Testing Polymer Matrix Composite Materials; ASTM D4762-16; ASTM International: West Conshohocken, PA, USA, 2011.

- Choi, S.W.; Lee, M.S.; Kang, C.G. Effect of process parameters and laminating methods on spring-back in V-bending of CFRP/CR340 hybrid composites. Int. J. Precis. Eng. Manuf. 2016, 17, 395–400. [Google Scholar] [CrossRef]

| Construction | Weight of Carbon Fiber | Weight of Resin | Resin Content | Total Weight | Fabric Thickness |

|---|---|---|---|---|---|

| Plain | 205 g/m2 | 150 gr/m2 | 42 ± 2% | 352 gr/m2 | 0.27 ± 0.05 mm |

| Construction | Yield Strength | Tensile Strength | Elongation | Elastic Modulus | |

|---|---|---|---|---|---|

| 3K Carbon fiber | 3530 MPa | 1.5% | E1 = 135 GPa, E2 = 10 GPa | ||

| SPFC980Y | (RD0°) | 568 MPa | 900 MPa | 18.8% | 200 GPa |

| (RD90°) | 619 MPa | 1043 MPa | 18.0% | ||

| Surface Roughness (Rz) between CFRP and CR980 | Pressure | Temperature of Mold | Curring Time |

|---|---|---|---|

| 20, 35, 45, 60 μm | 1, 2 MPa | 160 °C | 30 min |

| Pressure | Temperature of Mold | Curring Time | Direction of CR980 Sheet |

|---|---|---|---|

| 1, 2 MPa | 160 °C | 30 min | RD0°, RD90° |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, J.H.; Jin, C.K.; Lee, M.S.; Choi, S.W.; Kang, C.G. Effect of Surface Roughness on the Bonding Strength and Spring-Back of a CFRP/CR980 Hybrid Composite. Metals 2018, 8, 716. https://doi.org/10.3390/met8090716

Hwang JH, Jin CK, Lee MS, Choi SW, Kang CG. Effect of Surface Roughness on the Bonding Strength and Spring-Back of a CFRP/CR980 Hybrid Composite. Metals. 2018; 8(9):716. https://doi.org/10.3390/met8090716

Chicago/Turabian StyleHwang, Ji Hoon, Chul Kyu Jin, Min Sik Lee, Su Won Choi, and Chung Gil Kang. 2018. "Effect of Surface Roughness on the Bonding Strength and Spring-Back of a CFRP/CR980 Hybrid Composite" Metals 8, no. 9: 716. https://doi.org/10.3390/met8090716