Microstructure and Mechanical Properties of Mg/Al Clad Bars with Ni Interlayer Processed by Compound Castings and Multi-Pass Caliber Rolling

Abstract

:1. Introduction

2. Materials and Methods

3. Results

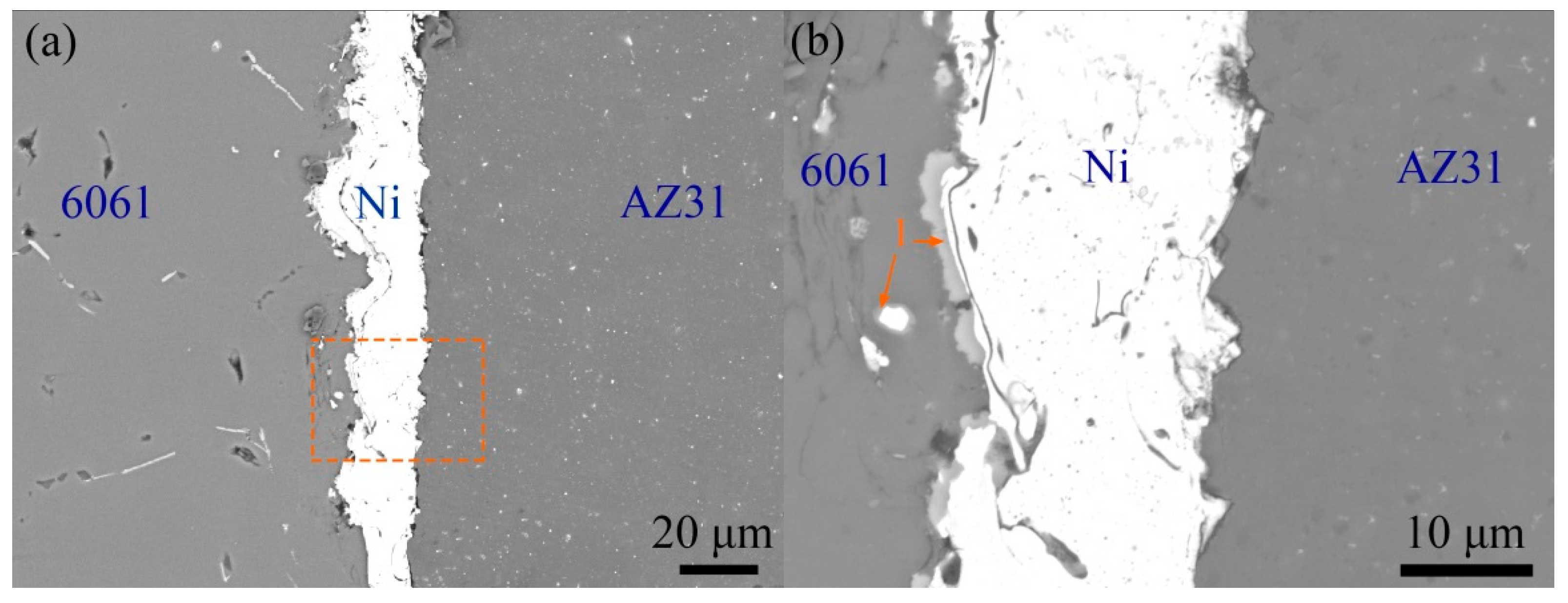

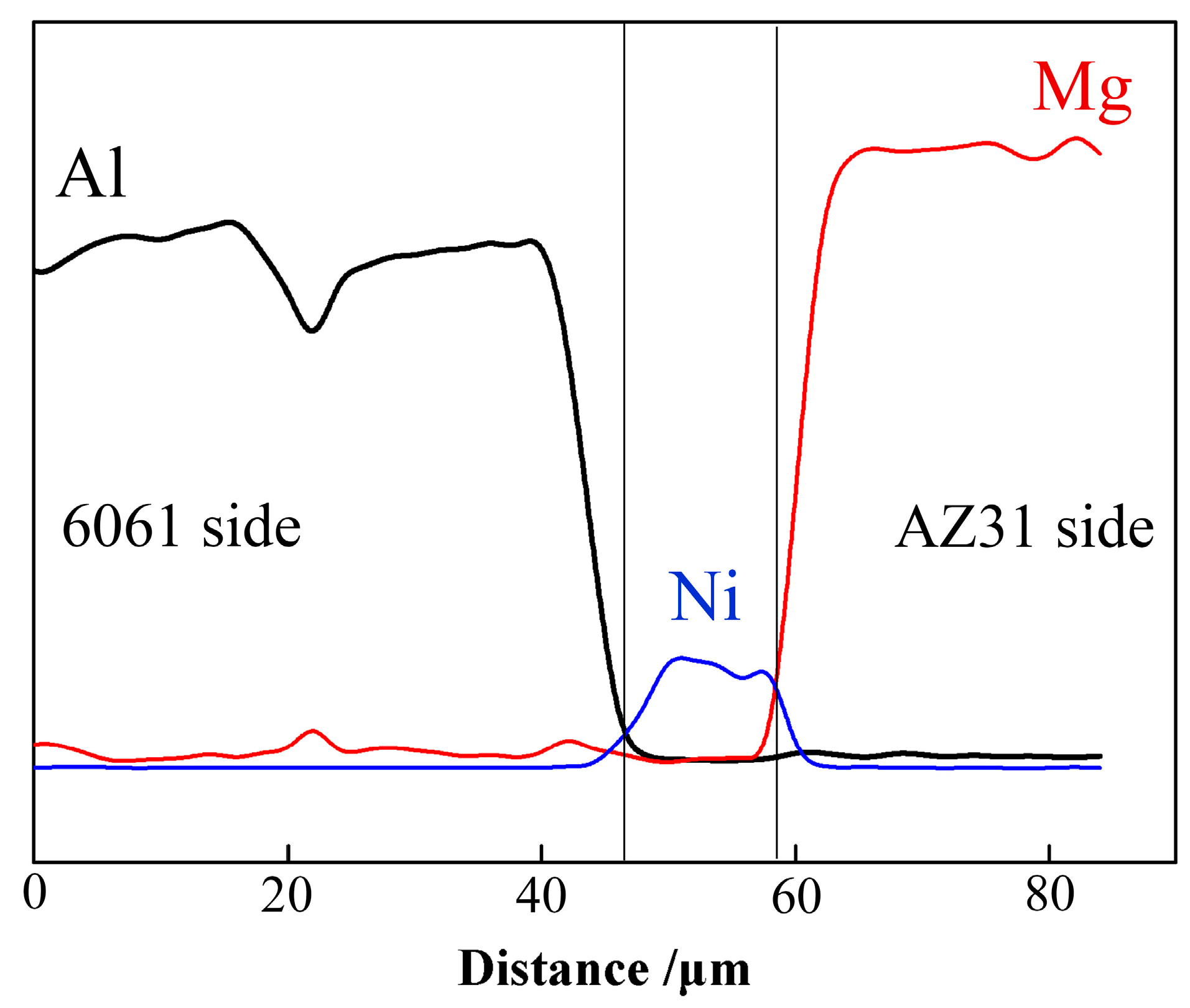

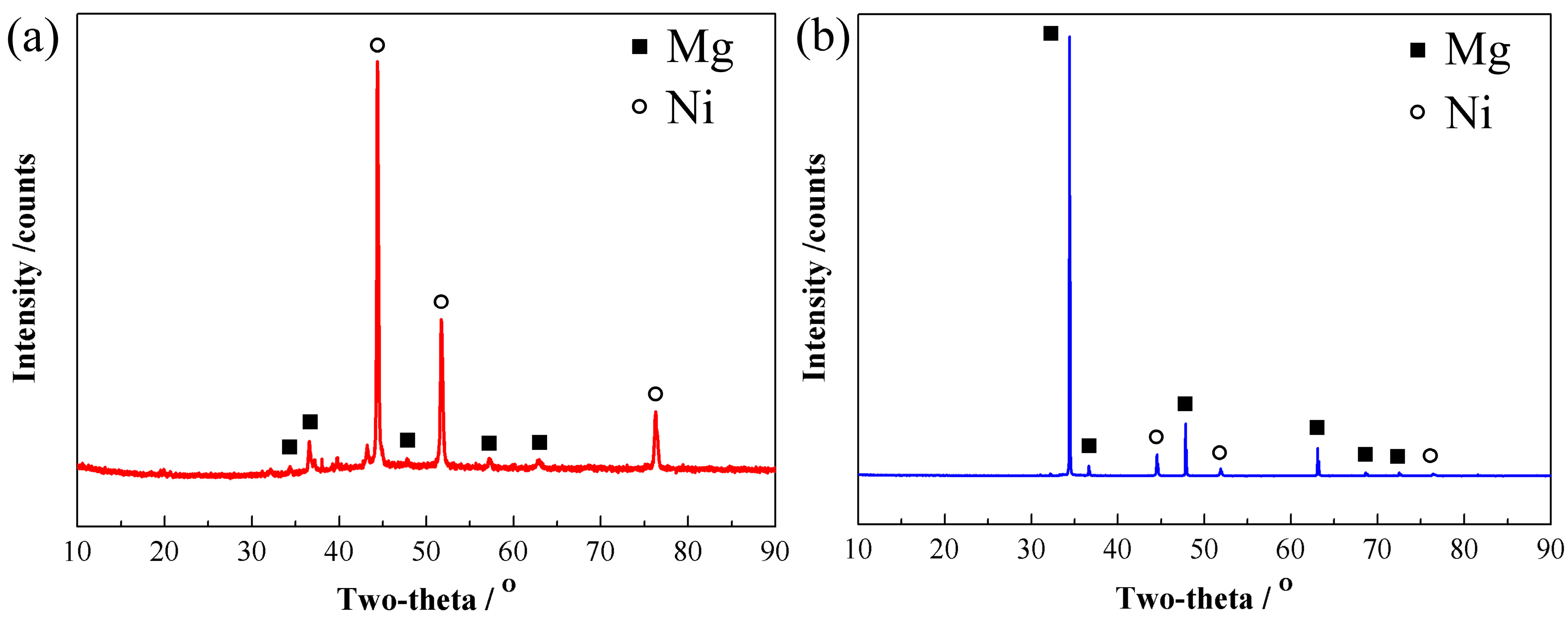

3.1. Microstructure and Microhardness of the As-Cast Composites

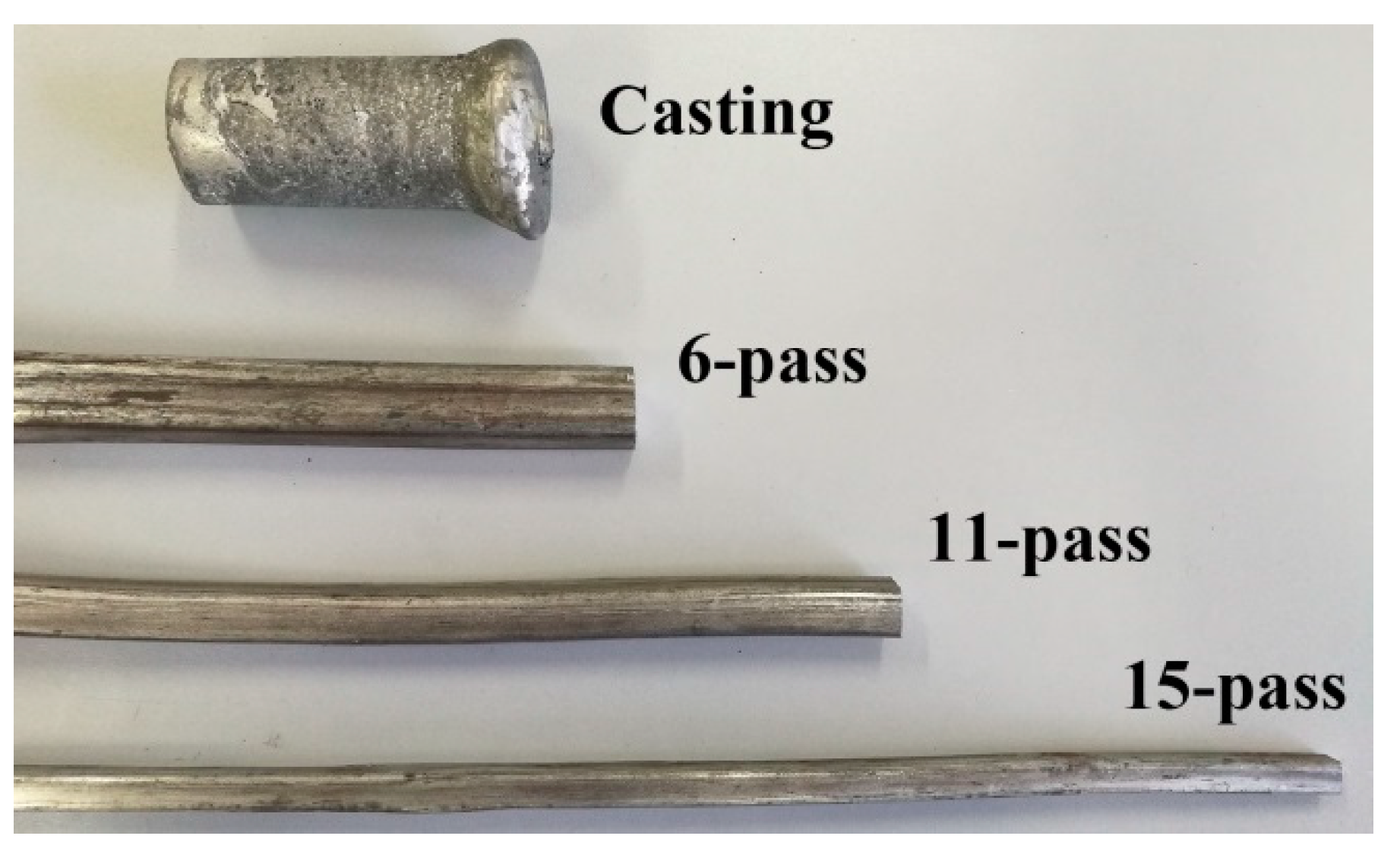

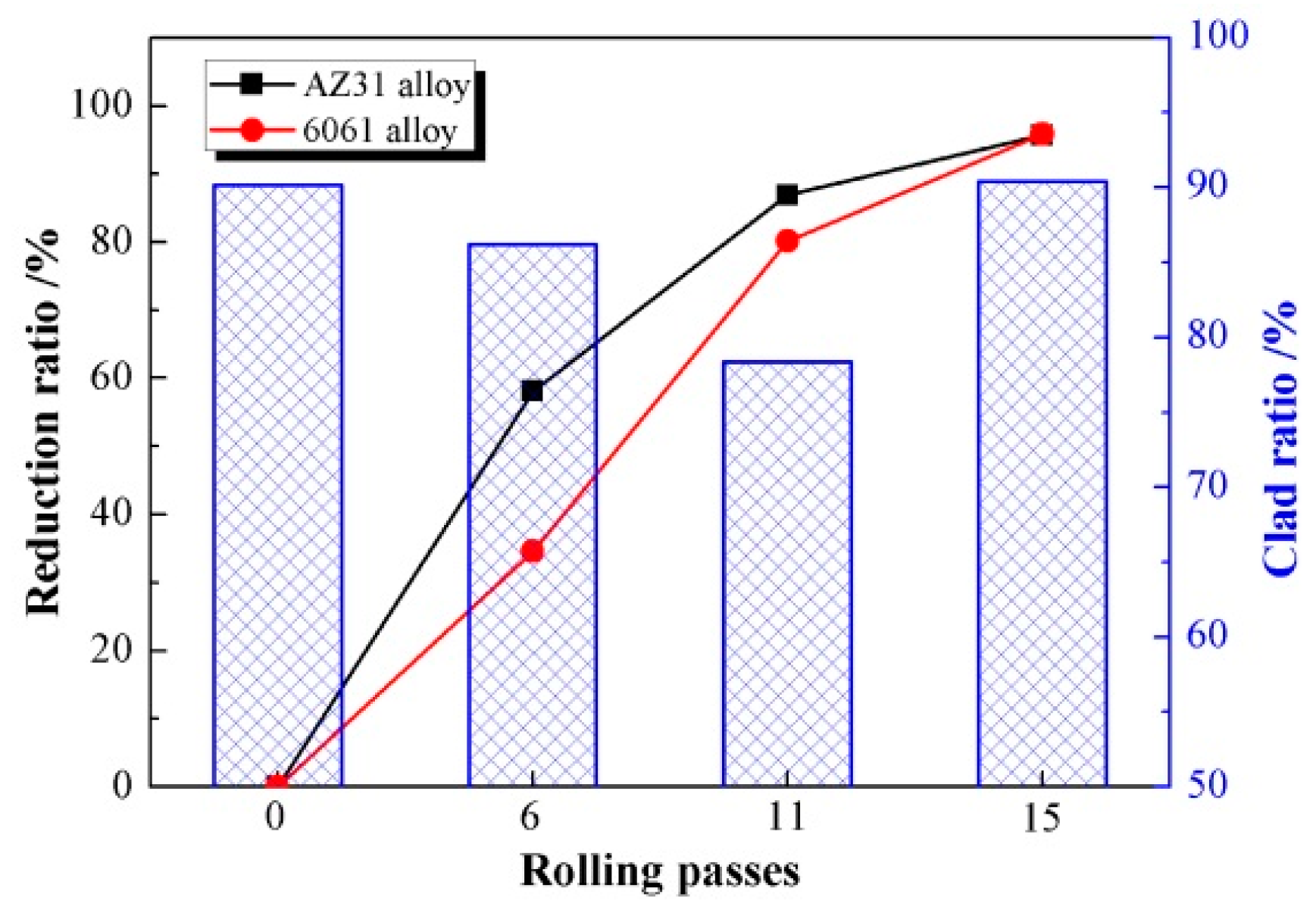

3.2. Characterization after Warm Caliber Rolling

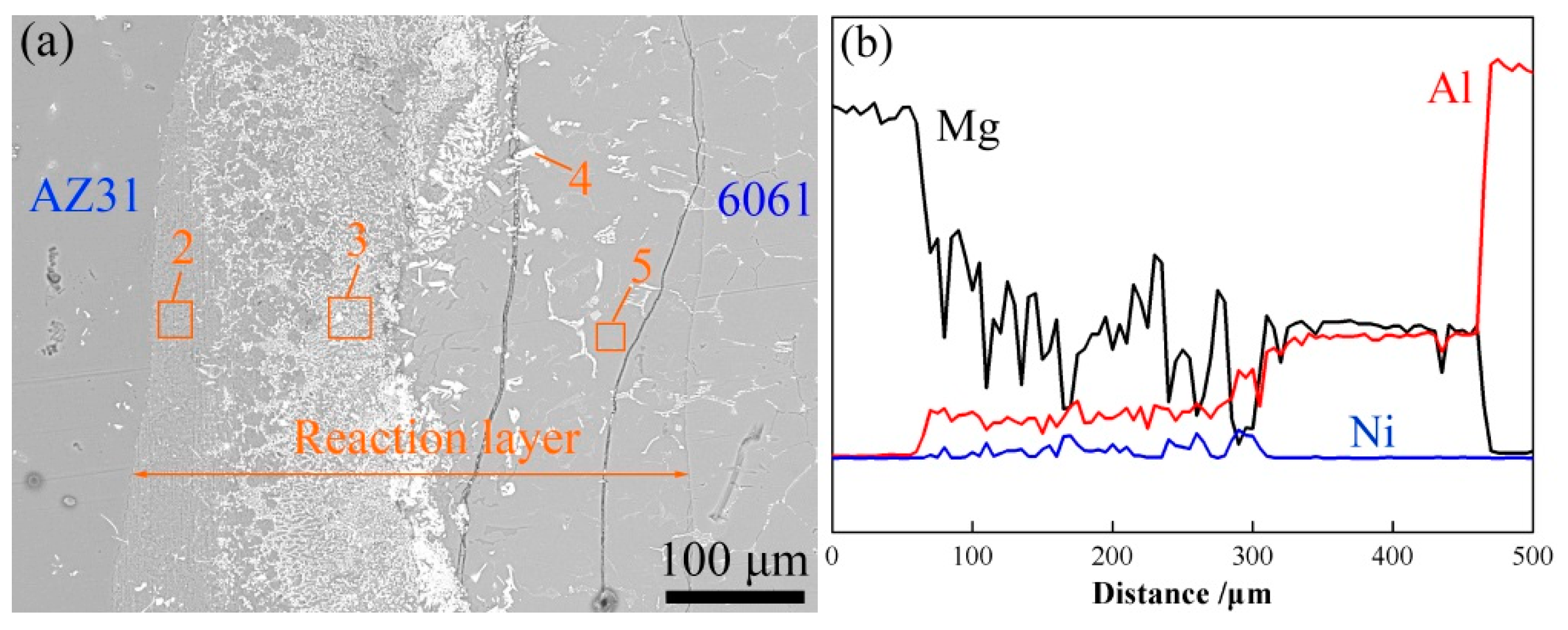

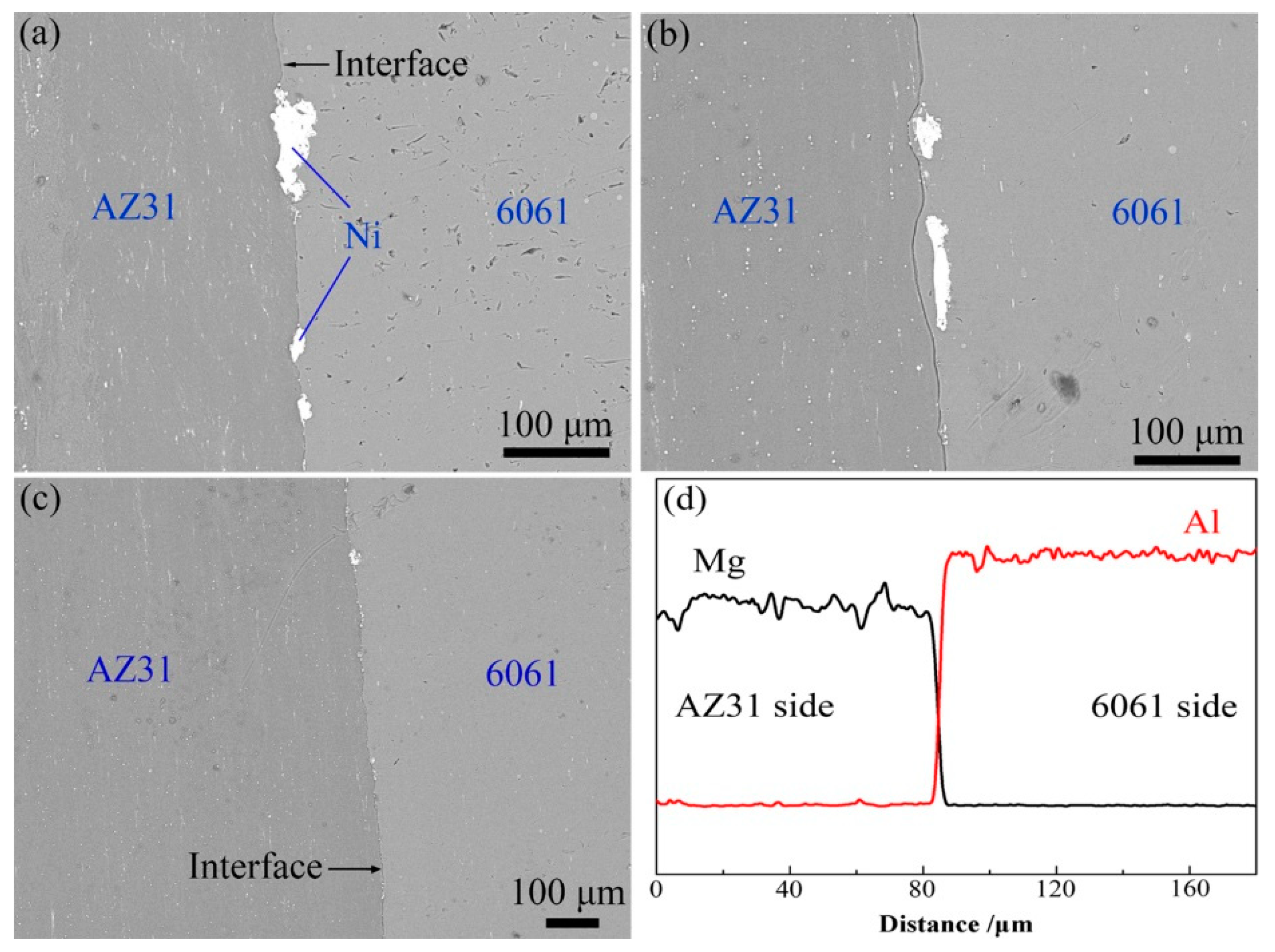

3.3. Microstructural Evolution of Interface

3.4. Microhardness Evolution of Caliber Rolled Composites

4. Discussion

5. Conclusions

- (1)

- The formation of Mg-Al intermetallic phases was impeded effectively by the Ni interlayer, and a well bonded AZ31/Ni/6061 multilayer structure was formed at the interface during the compound casting process. Increasing the pouring temperature resulted in the reaction between Ni and base alloys and the formation of a thick reaction layer composing of complex Mg-Al-Ni intermetallic compounds.

- (2)

- The strain in the AZ31 and 6061 base alloys was inhomogeneous during the caliber rolling process, mainly being concentrated on and around the clad AZ31 alloy during the initial passes, and subsequently introduced into the center with increasing number of passes. The deformation of the AZ31 and 6061 alloys tended to be equivalent after 15-pass rolling.

- (3)

- The continuous Ni interlayer fabricated by plasma spraying was fragmented in the subsequent rolling process. With increasing strain, the Ni particle fragments became smaller and uniform. Meanwhile, the fresh AZ31 and 6061 base alloys squeezed out and bonded together under the rolling force. After 15-pass rolling, the hard Ni interlayer transformed into the dispersed particles at the interface and a well-bonded interface with no visible defects was formed.

Author Contributions

Funding

Conflicts of Interest

References

- Ashby, M.F.; Broechet, Y.J.M. Designing hybrid materials. Acta Mater. 2003, 51, 5801–5821. [Google Scholar] [CrossRef]

- Zheng, H.; Yang, J.; Wu, R.; Wang, T.; Ma, X.; Hou, L.; Zhang, M.; Betsofen, S.; Krit, B.L. Influence of annealing temperature on the microstructure and mechanical properties of Al/Mg/Al composite sheets fabricated by roll bonding. Adv. Eng. Mater. 2016, 18, 1792–1798. [Google Scholar] [CrossRef]

- Nie, J.; Liu, M.; Wang, F.; Zhao, Y.; Li, Y.; Cao, Y.; Zhu, Y. Fabrication of Al/Mg/Al Composites via accumulative roll bonding and their mechanical properties. Materials 2016, 9, 951. [Google Scholar] [CrossRef] [PubMed]

- Anne, G.; Ramesh, M.R.; Nayaka, H.S.; Arya, S.B.; Sahu, S. Development and characteristics of accumulative roll bonded Mg-Zn/Ce/Al hybrid composite. J. Alloy. Compd. 2017, 724, 146–154. [Google Scholar] [CrossRef]

- Priel, E.; Ungarish, Z.; Navi, N.U. Co-extrusion of a Mg/Al composite billet: A computational study validated by experiments. J. Mater. Process. Technol. 2016, 236, 103–113. [Google Scholar] [CrossRef]

- Jafarian, M.; Rizi, M.S.; Jafarian, M.; Honarmand, M.; Javadinejad, H.R.; Ghaheri, A.; Bahramipour, M.T.; Ebrahimian, M. Effect of thermal tempering on microstructure and mechanical properties of Mg-AZ31/Al-6061diffusion bonding. Mater. Sci. Eng. A 2016, 666, 372–379. [Google Scholar] [CrossRef]

- Fu, B.; Qin, G.; Li, F.; Meng, X.; Zhang, J.; Wu, C. Friction stir welding process of dissimilar metals of 6061-T6 aluminum alloy to AZ31B magnesium alloy. J. Mater. Process. Technol. 2015, 218, 38–47. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, W.; Cao, X.; Wu, J. The effect of annealing on the interface microstructure and mechanical characteristics of AZ31B/AA6061 composite plates fabricated by explosive welding. Mater. Des. 2015, 65, 1100–1109. [Google Scholar] [CrossRef]

- Qiao, X.; Li, X.; Zhang, X.; Chen, Y.; Zheng, M.; Golovin, I.S.; Gao, N.; Starink, M.J. Intermetallics formed at interface of ultrafine grained Al/Mg bi-layered disks processed by high pressure torsion at room temperature. Mater. Lett. 2016, 181, 187–190. [Google Scholar] [CrossRef] [Green Version]

- Papis, K.J.M.; Hallstedt, B.; Loffler, J.F.; Uggowitzer, P.J. Interface formation in aluminium–aluminium compound casting. Acta Mater. 2008, 56, 3036–3043. [Google Scholar] [CrossRef]

- Liu, N.; Jie, J.; Lu, Y.; Wu, L.; Fu, Y.; Li, T. Characteristics of clad aluminum hollow billet prepared by horizontal continuous casting. J. Mater. Process. Technol. 2014, 214, 60–66. [Google Scholar] [CrossRef]

- He, K.; Zhao, J.; Li, P.; He, J.; Tang, Q. Investigation on microstructures and properties of arc-sprayed-Al/AZ91D bimetallic material by solid-liquid compound casting. Mater. Des. 2016, 112, 553–564. [Google Scholar] [CrossRef]

- Liu, J.C.; Hua, J.; Nie, X.Y.; Li, H.X.; Du, Q.; Zhang, J.S.; Zhuang, L.Z. The interface bonding mechanism and related mechanical properties of Mg/Al compound materials fabricated by insert molding. Mater. Sci. Eng. A 2015, 635, 70–76. [Google Scholar] [CrossRef]

- Park, J.; Song, H.; Kim, J.S.; Sohn, S.S.; Lee, S. Three-ply Al/Mg/Al clad sheets fabricated by twin-Roll casting and post-treatments (homogenization, warm rolling, and annealing). Metall. Mater. Trans. A 2017, 48, 57–62. [Google Scholar] [CrossRef]

- Jiang, W.; Li, G.; Fan, Z.; Wang, L.; Liu, F. Investigation on the interface characteristics of Al/Mg bimetallic castings processed by lost foam casting. Metall. Mater. Trans. A 2016, 47, 2462–2470. [Google Scholar] [CrossRef]

- Paramsothy, M.; Srikanth, N.; Gupta, M. Solidification processed Mg/Al bimetal macrocomposite: Microstructure and mechanical properties. J. Alloy. Compd. 2008, 461, 200–208. [Google Scholar] [CrossRef]

- Wang, D.; Cao, X.; Wang, L.; Cao, M.; Wang, W. Influence of hot rolling on the interface microstructure and mechanical properties of explosive welded Mg/Al composite plates. J. Mater. Res. 2017, 32, 863–873. [Google Scholar] [CrossRef]

- Jiang, W.; Jiang, Z.; Li, G.; Wu, Y.; Fan, Z. Microstructure of Al/Al bimetallic composites by lost foam casting with Zn interlayer. Mater. Sci. Technol. 2017, 34, 1–6. [Google Scholar] [CrossRef]

- Xu, G.; Luo, A.; Chen, Y.; Sachdev, A.K. Interfacial phenomena in magnesium/aluminum bi-metallic castings. Mater. Sci. Eng. A 2014, 595, 154–158. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Chen, Y.; Luo, A.; Liu, L. Interface formation in magnesium/aluminium bimetallic castings with a nickel interlayer. Int. J. Cast Metal. Res. 2016, 29, 338–343. [Google Scholar] [CrossRef]

- Yin, F.; Liu, C.; Zhang, Y.; Qin, Y.; Liu, N. Effect of Ni interlayer on characteristics of diffusion bonded Mg/Al joints. Mater. Sci. Technol. 2018, 34, 1104–1111. [Google Scholar] [CrossRef]

- Liu, N.; Liu, C.; Liang, C.; Zhang, Y. Influence of Ni interlayer on microstructure and mechanical properties of Mg/Al bimetallic castings. Metall. Mater. Trans. A 2018, 49, 3556–3564. [Google Scholar] [CrossRef]

- Nayan, N.; Singh, G.; Prabhu, T.; Svs, N.M.; Ramamurty, U. Cryogenic mechanical properties of warm multi-pass caliber-rolled fine-grained titanium alloys: Ti-6Al-4V (normal and ELI grades) and VT14. Metall. Mater. Trans. A 2018, 49, 128–146. [Google Scholar] [CrossRef]

- Krállics, G.; Gubicza, J.; Bezi, Z.; Barkai, I. Manufacturing of ultrafine-grained titanium by caliber rolling in the laboratory and in industry. J. Mater. Process. Technol. 2014, 214, 1307–1315. [Google Scholar] [CrossRef]

- Inoue, T.; Yin, F.; Kimura, Y.; Tsuzaki, K.; Ochiai, S. Delamination effect on impact properties of ultrafine-grained low-carbon steel processed by warm caliber rolling. Metall. Mater. Trans. A 2010, 41, 341–355. [Google Scholar] [CrossRef]

- Konieczny, M. Microstructural characterisation and mechanical response of laminated Ni-intermetallic composites synthesised using Ni sheets and Al foils. Mater. Charact. 2012, 70, 117–124. [Google Scholar] [CrossRef]

- Hajjari, E.; Divandari, M.; Razavi, S.H.; Homma, T.; Kamado, S. Intermetallic compounds and antiphase domains in Al/Mg compound casting. Intermetallics 2012, 23, 182–186. [Google Scholar] [CrossRef]

- Mezbahul-Islam, M.; Medraj, M. A critical thermodynamic assessment of the Mg–Ni, Ni–Y binary and Mg–Ni–Y ternary systems. Calphad 2009, 33, 478–486. [Google Scholar] [CrossRef]

- Liu, W.; Long, L.; Ma, Y.; Wu, L. Microstructure evolution and mechanical properties of Mg/Al diffusion bonded joints. J. Alloy. Compd. 2015, 643, 34–39. [Google Scholar] [CrossRef]

- Hajjari, E.; Divandari, M.; Razavi, S.H.; Emami, S.M.; Homma, T.; Kamado, S. Dissimilar joining of Al/Mg light metals by compound casting process. J. Mater. Sci. 2011, 46, 6491–6499. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Fan, Z.; Jiang, Z.; Liu, X.; Liu, F. Effects of pouring temperature on microstructure, mechanical properties, and fracture behavior of Al/Mg bimetallic composites produced by lost foam casting process. Int. J. Adv. Manuf. Technol. 2017, 91, 1355–1368. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Y.; Luo, A.A. A novel aluminum surface treatment for improved bonding in magnesium/aluminum bimetallic castings. Scr. Mater. 2014, 86, 52–55. [Google Scholar] [CrossRef]

- Inoue, T.; Yin, F.; Kimura, Y. Strain distribution and microstructural evolution in multi-pass warm caliber rolling. Mater. Sci. Eng. A 2007, 466, 114–122. [Google Scholar] [CrossRef]

- Chang, H.; Zheng, M.; Gan, W.; Wu, K.; Maawad, E.; Brokmeier, H. Texture evolution of the Mg/Al laminated composite fabricated by the accumulative roll bonding. Scr. Mater. 2009, 61, 717–720. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Z. Effect of Zn alloy interlayer on interface microstructure and strength of diffusion-bonded Mg-Al joints. Scr. Mater. 2008, 58, 283–286. [Google Scholar] [CrossRef]

| Alloys | Element Content (wt. %) | ||||||

|---|---|---|---|---|---|---|---|

| Al | Zn | Mn | Si | Cu | Fe | Mg | |

| AZ31 | 2.91 | 0.88 | 0.42 | 0.01 | 0.01 | 0.02 | Bal. |

| 6061 | Bal. | 0.2 | 0.13 | 0.48 | 0.15 | 0.58 | 0.92 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Fu, Y.; Yin, F.; Liu, N.; Liang, C. Microstructure and Mechanical Properties of Mg/Al Clad Bars with Ni Interlayer Processed by Compound Castings and Multi-Pass Caliber Rolling. Metals 2018, 8, 704. https://doi.org/10.3390/met8090704

Chen L, Fu Y, Yin F, Liu N, Liang C. Microstructure and Mechanical Properties of Mg/Al Clad Bars with Ni Interlayer Processed by Compound Castings and Multi-Pass Caliber Rolling. Metals. 2018; 8(9):704. https://doi.org/10.3390/met8090704

Chicago/Turabian StyleChen, Lu, Ying Fu, Fuxing Yin, Ning Liu, and Chunyong Liang. 2018. "Microstructure and Mechanical Properties of Mg/Al Clad Bars with Ni Interlayer Processed by Compound Castings and Multi-Pass Caliber Rolling" Metals 8, no. 9: 704. https://doi.org/10.3390/met8090704

APA StyleChen, L., Fu, Y., Yin, F., Liu, N., & Liang, C. (2018). Microstructure and Mechanical Properties of Mg/Al Clad Bars with Ni Interlayer Processed by Compound Castings and Multi-Pass Caliber Rolling. Metals, 8(9), 704. https://doi.org/10.3390/met8090704