Effect of Calcium on the Hot Working Behavior of AZ31-1.5 vol.% Nano-Alumina Composite Prepared by Disintegrated Melt Deposition (DMD) Processing

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

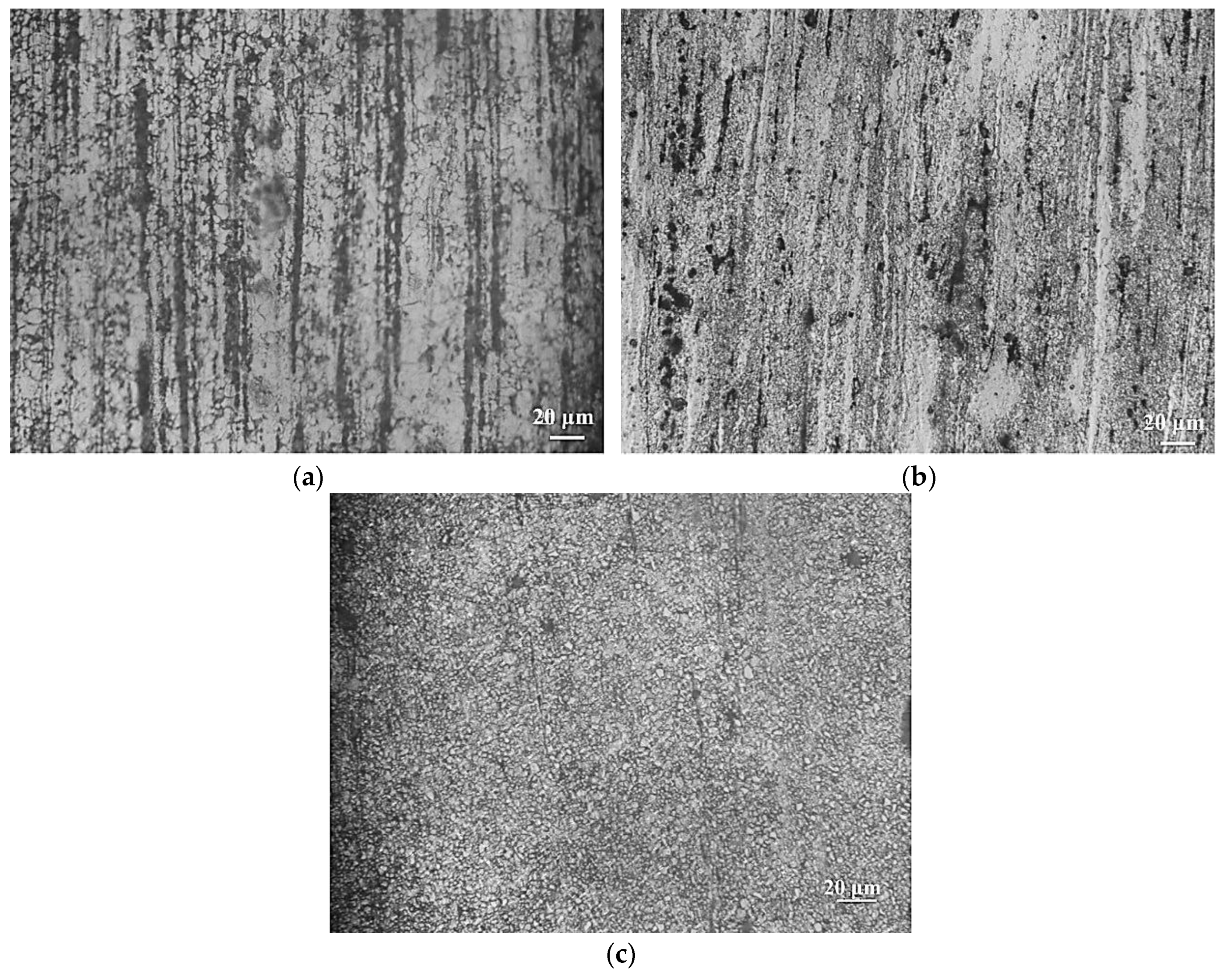

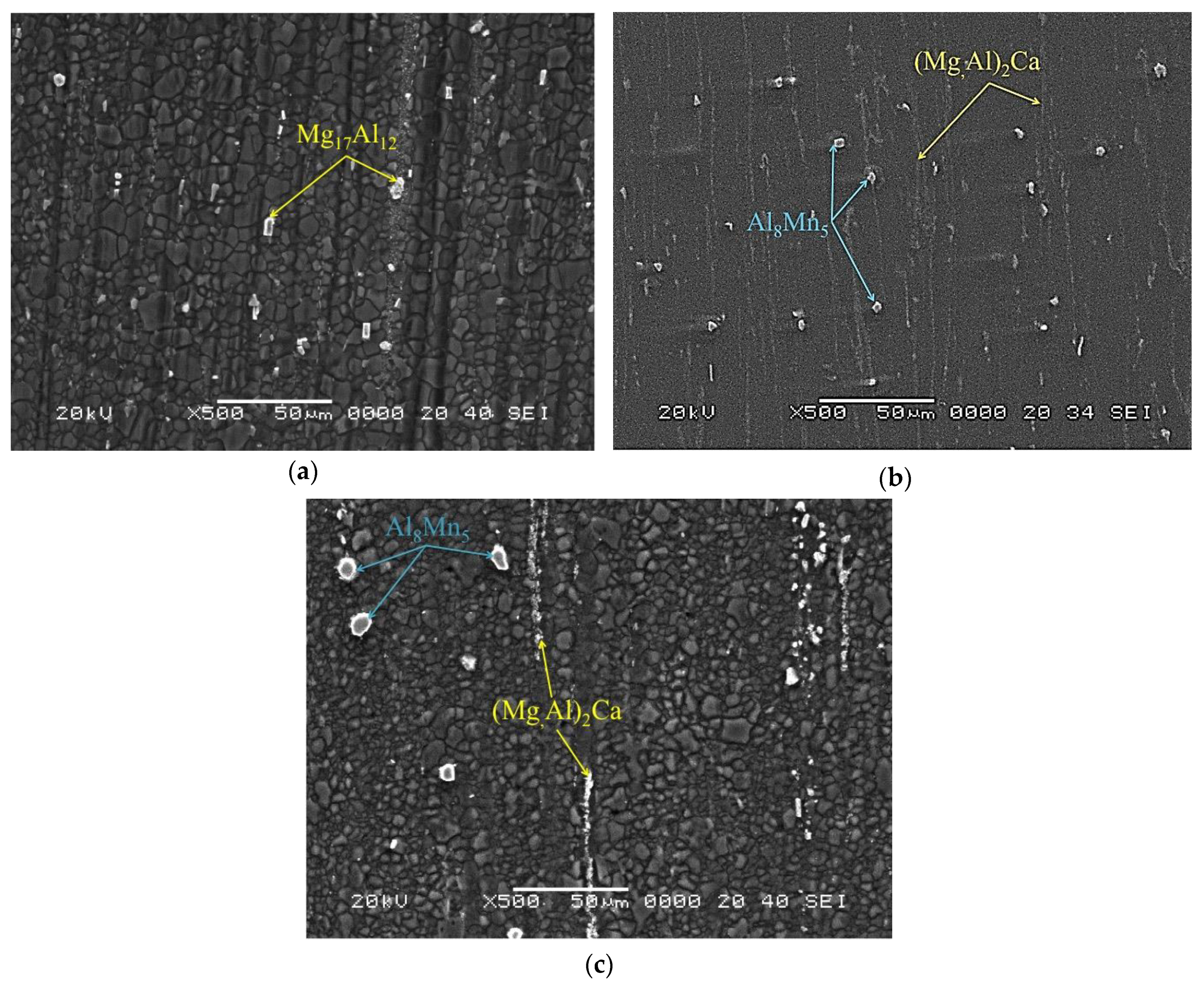

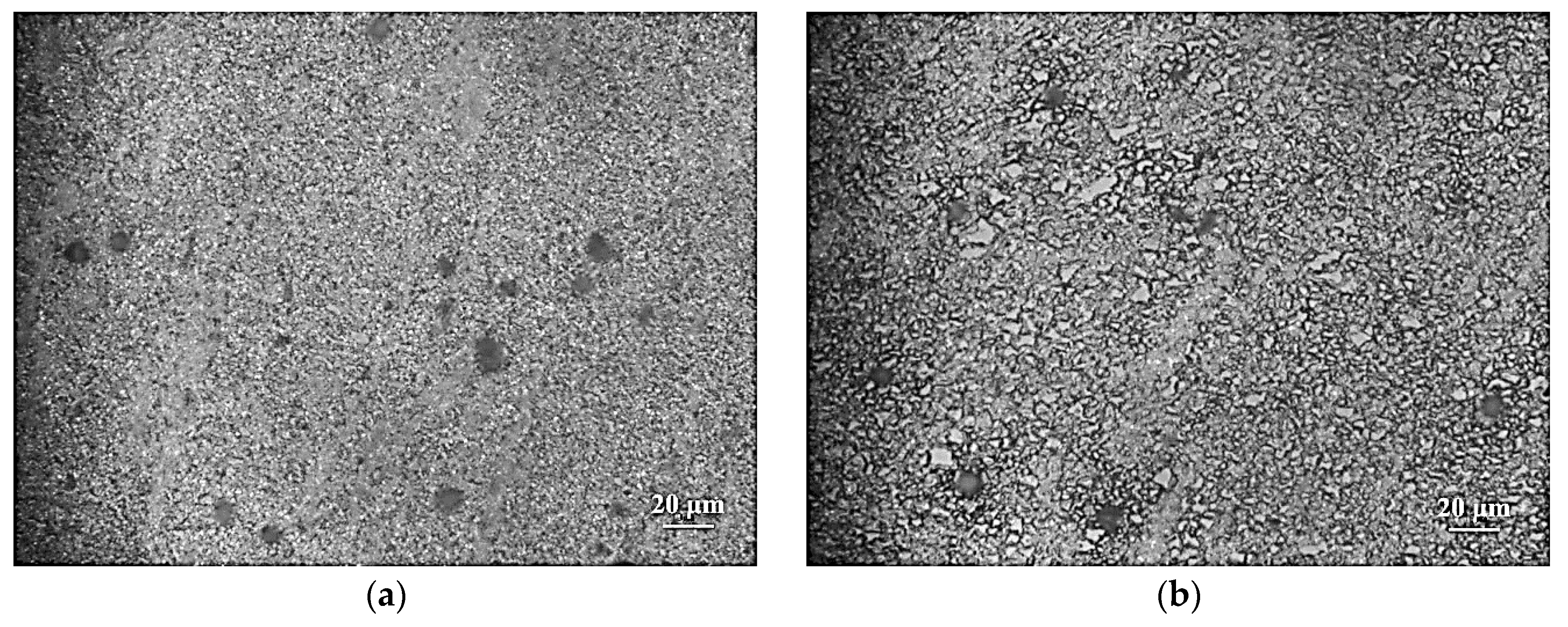

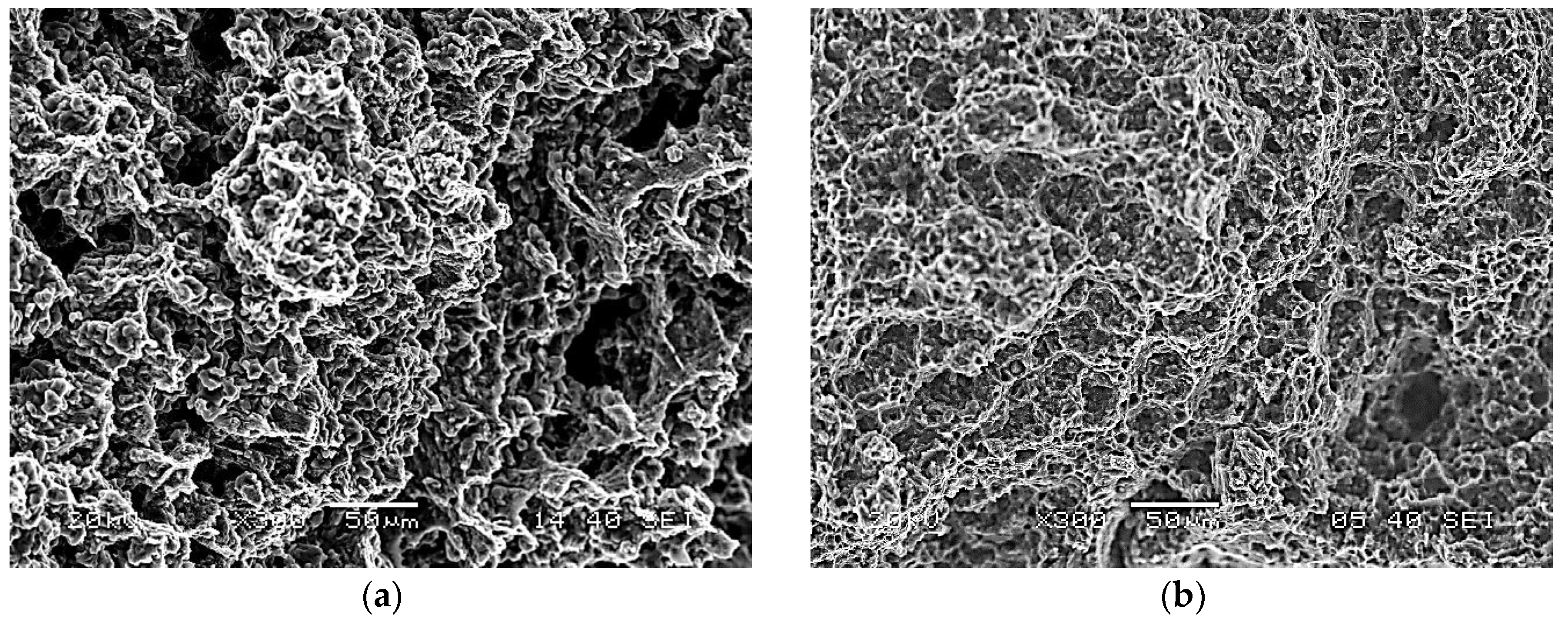

3.1. Initial Microstructure of the Composites

3.2. Processing Maps for Hot Working

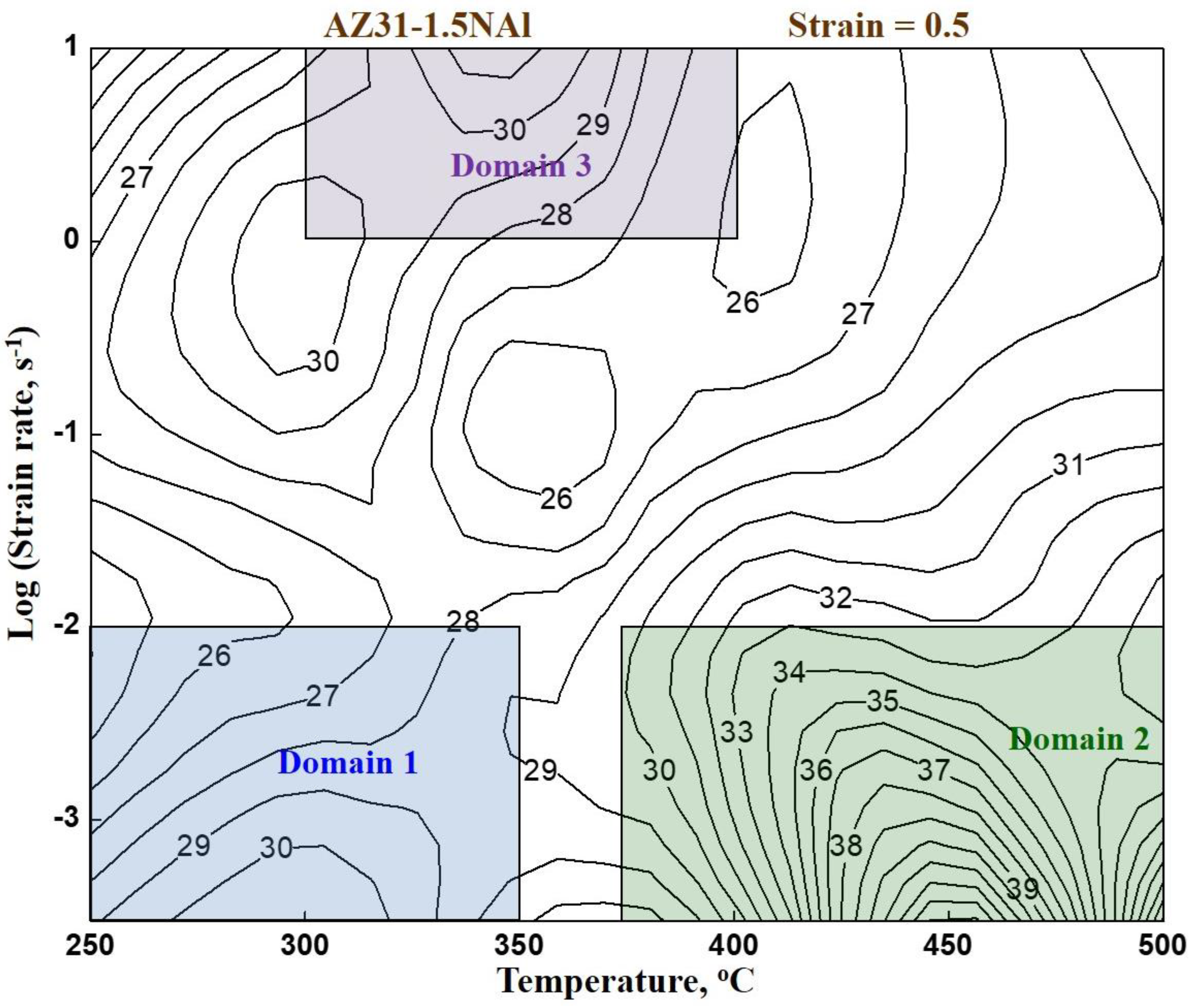

3.2.1. AZ31-1.5NAl Base Composite

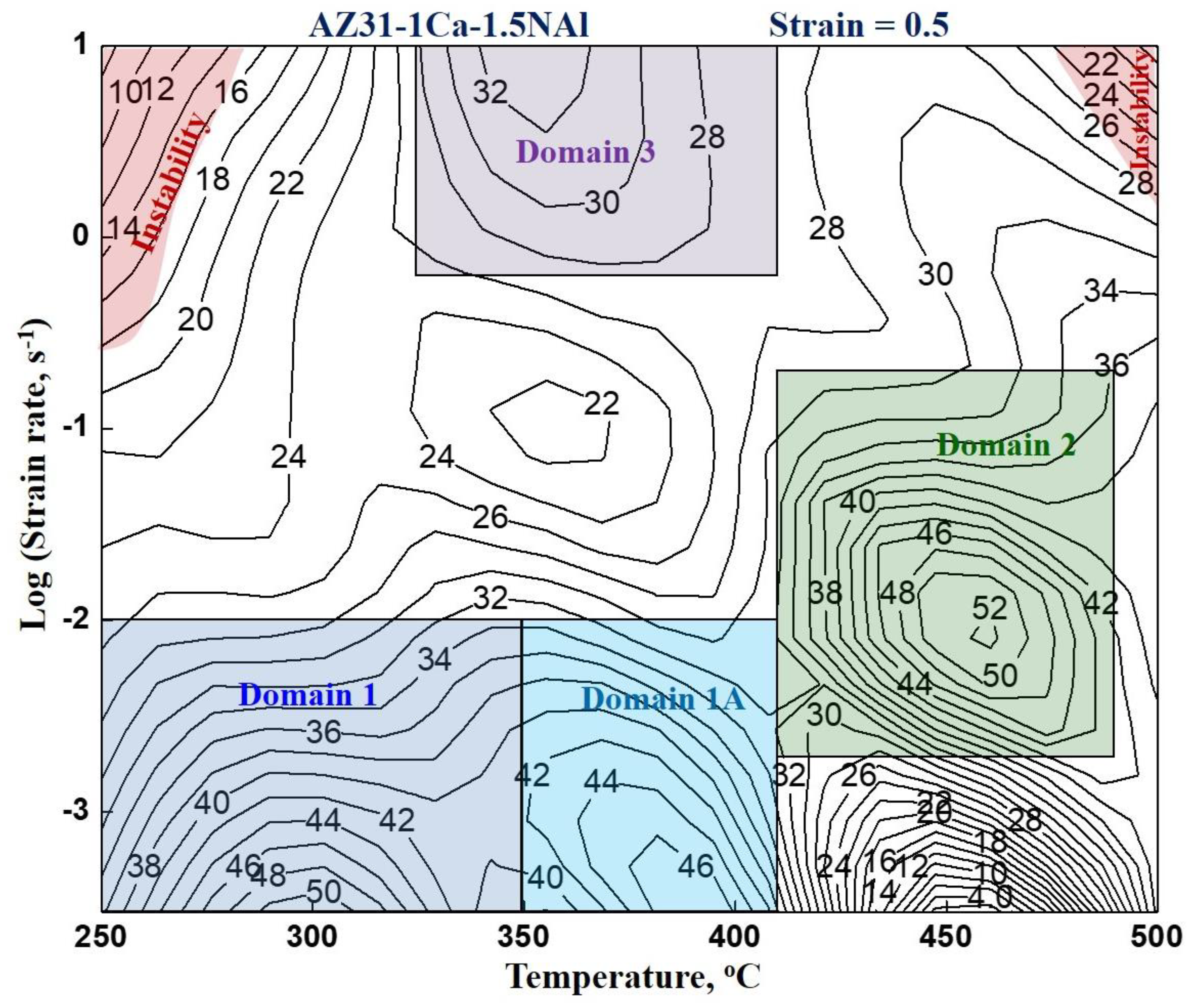

3.2.2. AZ31-1Ca-1.5NAl Composite

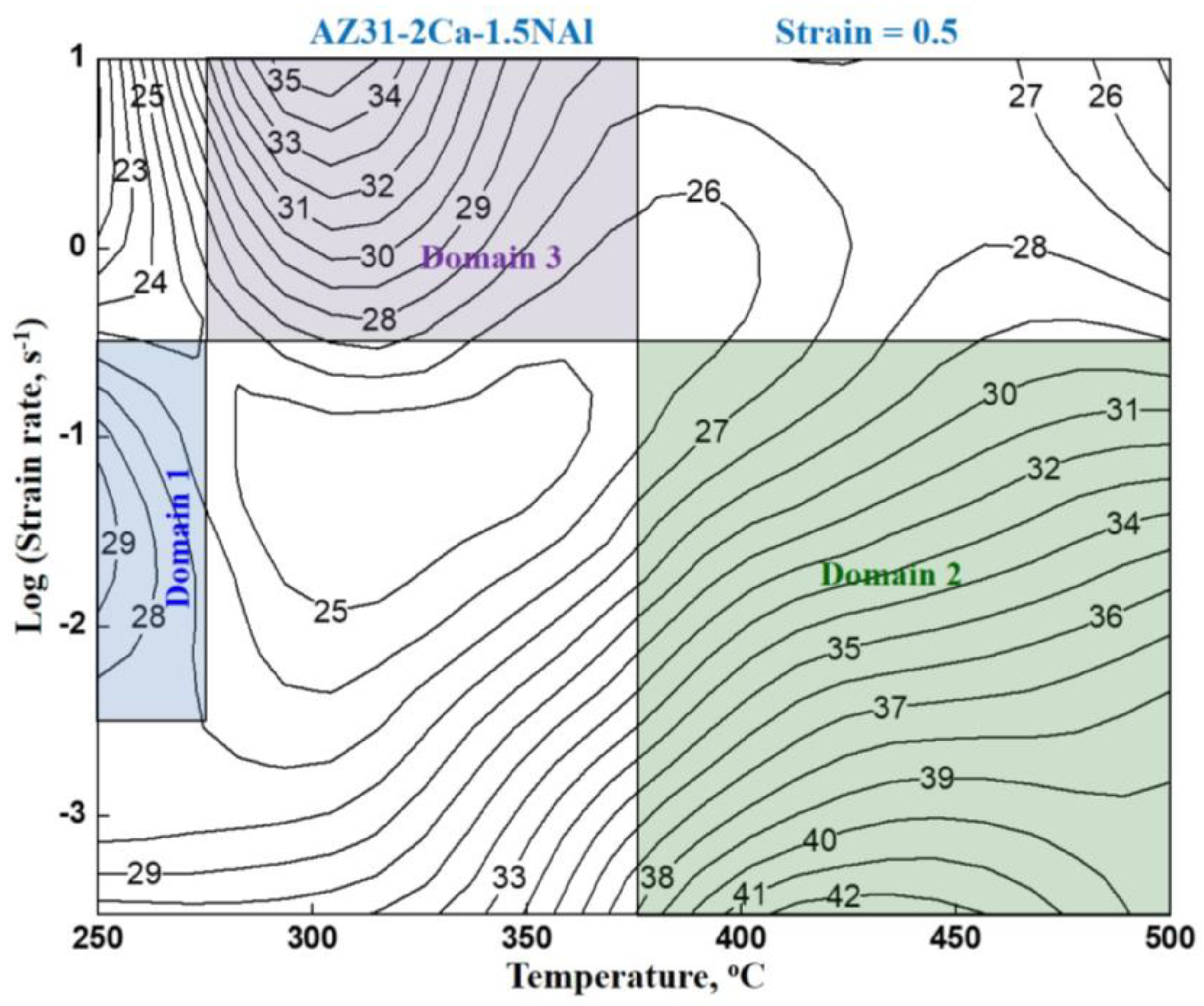

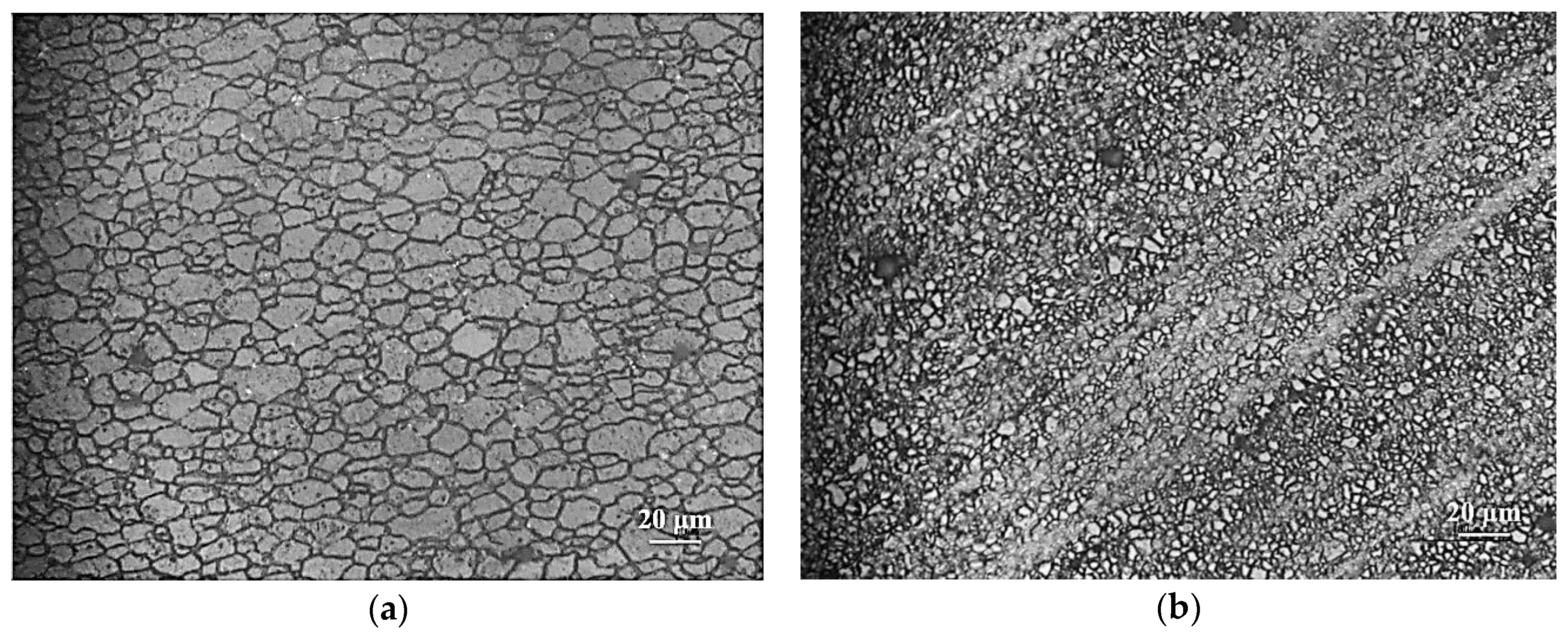

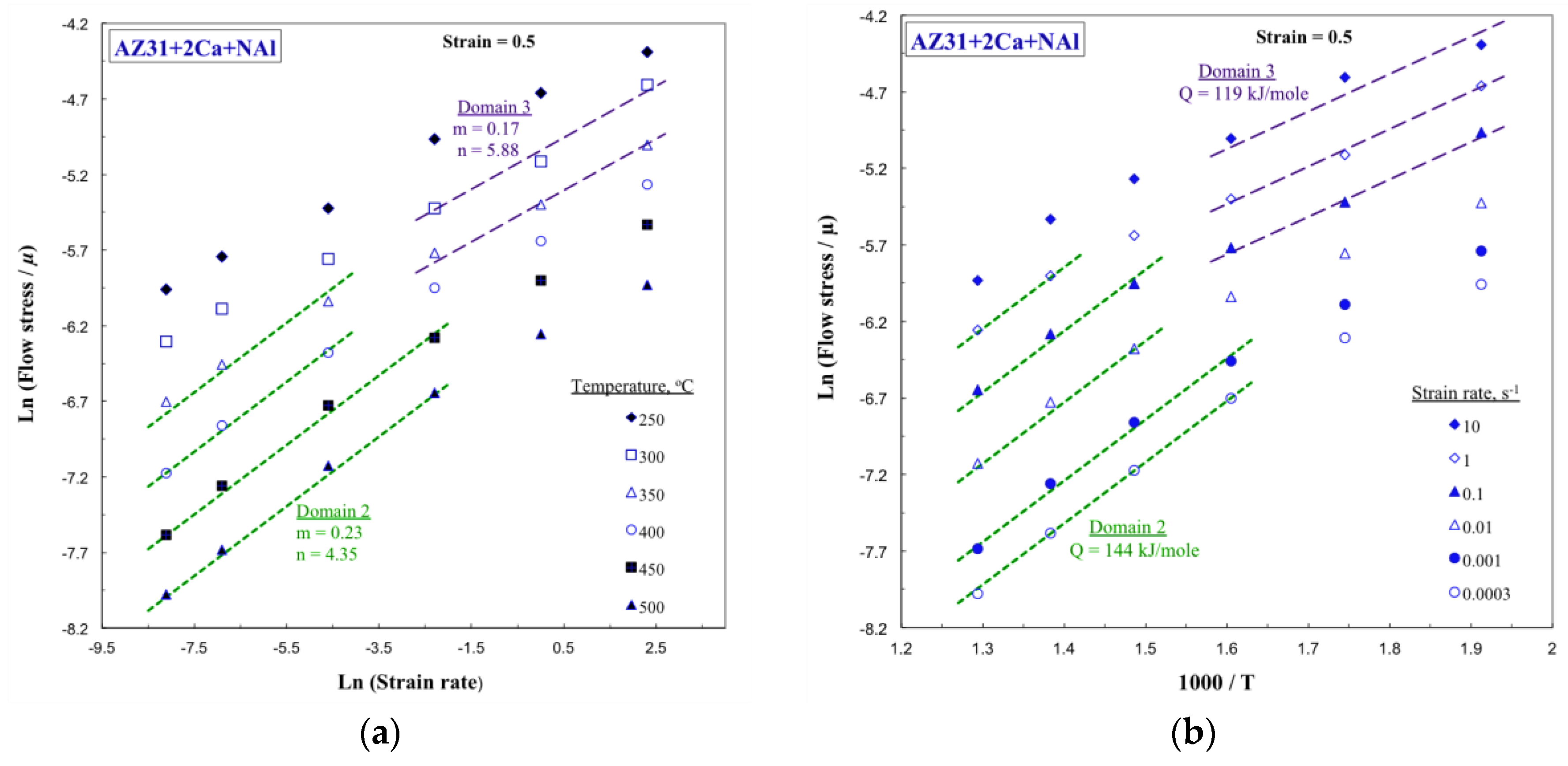

3.2.3. AZ31-2Ca-1.5NAl Composite

4. Conclusions

- The addition of calcium to AZ31-1.5NAl composite refines the grain size and increases the <100> texture in the rod.

- All the three nanocomposites exhibit three DRX domains in the approximate temperature–strain rate ranges of (1) 250–300 °C/0.0003 –0.01 s−1, (2) 400–500 °C/0.0003–0.03 s−1, and (3) 300–400 °C/1–10 s−1.

- With 1% Ca addition to AZ31 nano-alumina composite, Domain 1 is split into two: in one part, basal slip dominates, and prismatic slip dominates in the other part, with climb as the recovery mechanism. Domain 2 moves to higher strain rates and Domain 3 has become wider.

- Addition of Ca avoids wedge cracking that occurs in AZ31-1.5NAl composite at higher temperatures and lower strain rates (Domain 2). This is because the Ca-containing intermetallic particles pin down the grain boundary and prevent sliding, thereby avoiding formation of wedge cracks at grain boundary triple junctions.

- Addition of 1% Ca to AZ31-1.5NAl composite widens all the three workability windows and enhances the hot workability. This composition may be considered to be optimum from hot workability viewpoint.

- Increase of Ca addition to 2% prevents DRX at lower temperatures and strain rates (Domain 1) of base composite and causes only dynamic recovery. This is due to high back stress, caused by Ca-containing particles, that slows down recovery by climb and reducing rate of DRX nucleation.

- Domain 3 occurring at lower temperatures and higher strain rates is common to all the three composites and is widened by Ca addition. DRX in this domain occurs by basal + prismatic slip along with recovery via climb controlled by grain boundary self-diffusion due to very fine grain size in the composite.

- All the three composites may be processed under conditions corresponding to Domain 3 since the strain rates are high enough to ensure productivity, and the grain size resulting in the component will be fine, giving superior product properties.

Author Contributions

Funding

Conflicts of Interest

References

- Kainer, K.U.; Dieringa, H.; Dietzel, W.; Hort, N.; Blawert, C. The use of magnesium alloys: Past, present and future. In Magnesium Technology in Global Age; Pekguleryuz, M.O., Mackenzie, L.W.F., Eds.; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 2006; pp. 3–19. [Google Scholar]

- Rao, K.P.; Prasad, Y.V.R.K.; Dharmendra, C.; Suresh, K.; Hort, N.; Dieringa, H. Review on hot working behavior and strength of calcium-containing magnesium alloys. Adv. Eng. Mater. 2018. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of nano-Y2O3 containing magnesium nano-composites using solidification processing. J. Alloys Compd. 2007, 429, 176–183. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nanoparticles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Paramsothy, M.; Hassan, S.F.; Srikanth, N.; Gupta, M. Enhancing tensile/compressive response of magnesium alloy AZ31 by integrating with Al2O3 nanoparticles. Mater. Sci. Eng. A 2009, 527, 162–168. [Google Scholar] [CrossRef]

- Ezatpour, H.R.; Chaichi, A.; Sajjadi, S.A. The effect of Al2O3-nanoparticles as the reinforcement additive on the hot deformation behavior of 7075 aluminum alloy. Mater. Des. 2015, 88, 1049–1056. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Hu, X.; Wu, K.; Zheng, M. Effects of hot rolling on microstructure, macrotexture and mechanical properties of pre-extruded AZ31/SiC nanocomposite sheets. Mater. Sci. Eng. A 2017, 683, 15–23. [Google Scholar] [CrossRef]

- Wang, T.; Nie, K.; Deng, K.; Liang, W. Analysis of hot deformation behavior and microstructure evolution of as-cast SiC nanoparticles reinforced magnesium matrix composite. J. Mater. Res. 2016, 31, 3437–3447. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Gupta, M. Improving compressive strength and oxidation resistance of AZ31B magnesium alloy by addition of nano-Al2O3 particulates and Ca. J. Compos. Mater. 2010, 44, 883–896. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Gupta, M. Enhancing mechanical response of AZ31B using Cu+nano-Al2O3 addition. Mater. Sci. Eng. A 2010, 527, 1411–1416. [Google Scholar] [CrossRef]

- Paramsothy, M.; Chan, J.; Kwok, R.; Gupta, M. Enhanced mechanical response of hybrid AZ31/AZ91 based on the addition of Si3N4 nanoparticles. Mater. Sci. Eng. A 2011, 528, 6545–6551. [Google Scholar] [CrossRef]

- Suresh, K.; Dharmendra, C.; Rao, K.P.; Prasad, Y.V.R.K.; Gupta, M. Processing Map of AZ31-1Ca-1.5vol.% Nano-Alumina Composite for Hot Working. Mater. Manuf. Process. 2015, 30, 1161–1167. [Google Scholar] [CrossRef]

- Zhong, T.; Rao, K.P.; Prasad, Y.V.R.K.; Zhao, F.; Gupta, M. Hot deformation mechanisms, microstructure and texture evolution in extruded AZ31-Nano Alumina composite. Mater. Sci. Eng. A 2014, 589, 41–49. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps, 2nd ed.; ASM International: Materials Park, OH, USA, 2015; ISBN 978-1-62708-091-0. [Google Scholar]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K. Processing maps: A status report. J. Mater. Eng. Perform. 2003, 12, 638–645. [Google Scholar] [CrossRef]

- Hilborn, R.C. Chaos and Non-Linear Dynamics; Oxford University Press: Oxford, UK, 1994. [Google Scholar]

- Ziegler, H. Some extremum principles in irreversible thermodynamics with applications to continuum mechanics. In Progress in Solid Mechanics; Sneddon, I.N., Hill, R., Eds.; John Wiley: New York, NY, USA, 1965; Volume 4, pp. 91–193. [Google Scholar]

- Prasad, Y.V.R.K.; Rao, K.P. Hot deformation mechanisms and microstructural control in high temperature extruded AZ31 magnesium alloy. Adv. Eng. Mater. 2007, 9, 558–565. [Google Scholar] [CrossRef]

- Jonas, J.J.; Sellars, C.M.; Tegart, W.J.M. Strength and structure under hot working conditions. Metall. Rev. 1969, 14, 1–24. [Google Scholar]

- Prasad, Y.V.R.K.; Rao, K.P. Processing maps and rate controlling mechanisms of hot deformation of electrolytic tough pitch copper in the temperature range 300–950 °C. Mater. Sci. Eng. A 2005, 391, 141–150. [Google Scholar] [CrossRef]

- Morris, J.R.; Scharff, J.; Ho, K.M.; Turner, D.E.; Ye, Y.Y.; Yoo, M.H. Prediction of a {1122} hcp stacking fault using a modified generalized stacking-fault calculation. Philos. Mag. A 1997, 76, 1065–1077. [Google Scholar] [CrossRef]

- Frost, H.J.; Ashby, M.F. Deformation-Mechanism Maps; Pergamon Press: Oxford, UK, 1982; p. 44. [Google Scholar]

- Alloy Phase Diagrams. ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 3, p. 556. [Google Scholar]

| Parameter | AZ31-1.5 NAl [13] | AZ31-1Ca-1.5NAl [12] | AZ31-2Ca-1.5NAl (Current Research) | |

|---|---|---|---|---|

| Initial grain size, μm | (1) | 7 | 2–3 | 2–3 |

| Initial texture | (2) | 2–3 R | 4–5 R | – |

| Phases in the microstructure | (3) | Nano-alumina; Al8Mn5 | Nano-alumina; (Mg,Al)2Ca; Al8Mn5 | Nano-alumina; (Mg,Al)2Ca; Al8Mn5 |

| Domain 1 | (4) | 250–350 °C 0.0003–0.01 s−1 | 250–350 °C 0.0003–0.01 s−1 | 250– 75 °C 0.003–0.3 s−1 |

| (5) | 300 °C/0.0003 s−1; peak η: 30% | 300 °C/0.0003 s−1; peak η: 50% | 250 °C/0.03 s−1 peak η: 29% | |

| (6) | 116 kJ/mole | 96 kJ/mole | – | |

| (7) | – | 30% | – | |

| (8) | DRX: Basal slip + climb by Lattice self-diffusion | DRX: Basal slip + climb by lattice self-diffusion | Dynamic recovery | |

| Domain 1A | (4) | – | 350–410 °C 0.0003–0.01 s−1 | – |

| (5) | – | 400 °C/0.0003 s−1; peak η: 46% | – | |

| (8) | – | DRX: Prismatic slip + climb by lattice self-diffusion | – | |

| Domain 2 | (4) | 375–500 °C 0.0003–0.01 s−1 | 410–490 °C 0.002–0.2 s−1 | 375–500 °C 0.0003–0.3 s−1 |

| (5) | 450 oC/0.0003 s−1; peak η: 43% | 450 °C/0.01 s−1; peak η: 52% | 425 °C/0.0003 s−1; peak η: 42% | |

| (6) | 152 kJ/mole | 276 kJ/mole | 144 kJ/mole | |

| (7) | 42% | 24% | 49% (at 400 °C) | |

| (8) | DRX: Pyramidal slip + cross slip | DRX: Pyramidal slip + cross slip | DRX: Pyramidal slip + cross slip | |

| Domain 3 | (4) | 300–400 °C 1–10 s−1 | 325–410 °C 0.6–10 s−1 | 275–375 °C 0.3–10 s−1 |

| (5) | 350 °C /10 s−1; peak η: 31% | 350 °C/10 s−1; peak η: 33% | 300 °C/10 s−1; peak η: 35% | |

| (6) | 119 kJ/mole | 103 kJ/mole | 119 kJ/mole | |

| (7) | – | 18% (at 3 s−1) | 42% (at 2.3 s−1) | |

| (8) | DRX: Basal slip + climb by grain boundary self-diffusion | DRX: Basal slip + climb by grain boundary self-diffusion | DRX: Basal slip + climb by grain boundary self-diffusion |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, K.P.; Dharmendra, C.; Suresh, K.; Prasad, Y.V.R.K.; Gupta, M. Effect of Calcium on the Hot Working Behavior of AZ31-1.5 vol.% Nano-Alumina Composite Prepared by Disintegrated Melt Deposition (DMD) Processing. Metals 2018, 8, 699. https://doi.org/10.3390/met8090699

Rao KP, Dharmendra C, Suresh K, Prasad YVRK, Gupta M. Effect of Calcium on the Hot Working Behavior of AZ31-1.5 vol.% Nano-Alumina Composite Prepared by Disintegrated Melt Deposition (DMD) Processing. Metals. 2018; 8(9):699. https://doi.org/10.3390/met8090699

Chicago/Turabian StyleRao, Kamineni Pitcheswara, Chalasani Dharmendra, Kalidass Suresh, Yellapregada Venkata Rama Krishna Prasad, and Manoj Gupta. 2018. "Effect of Calcium on the Hot Working Behavior of AZ31-1.5 vol.% Nano-Alumina Composite Prepared by Disintegrated Melt Deposition (DMD) Processing" Metals 8, no. 9: 699. https://doi.org/10.3390/met8090699