Effect of Martensite–Austenite Constituent on Low-Temperature Toughness in YS 500 MPa Grade Steel Welds

Abstract

:1. Introduction

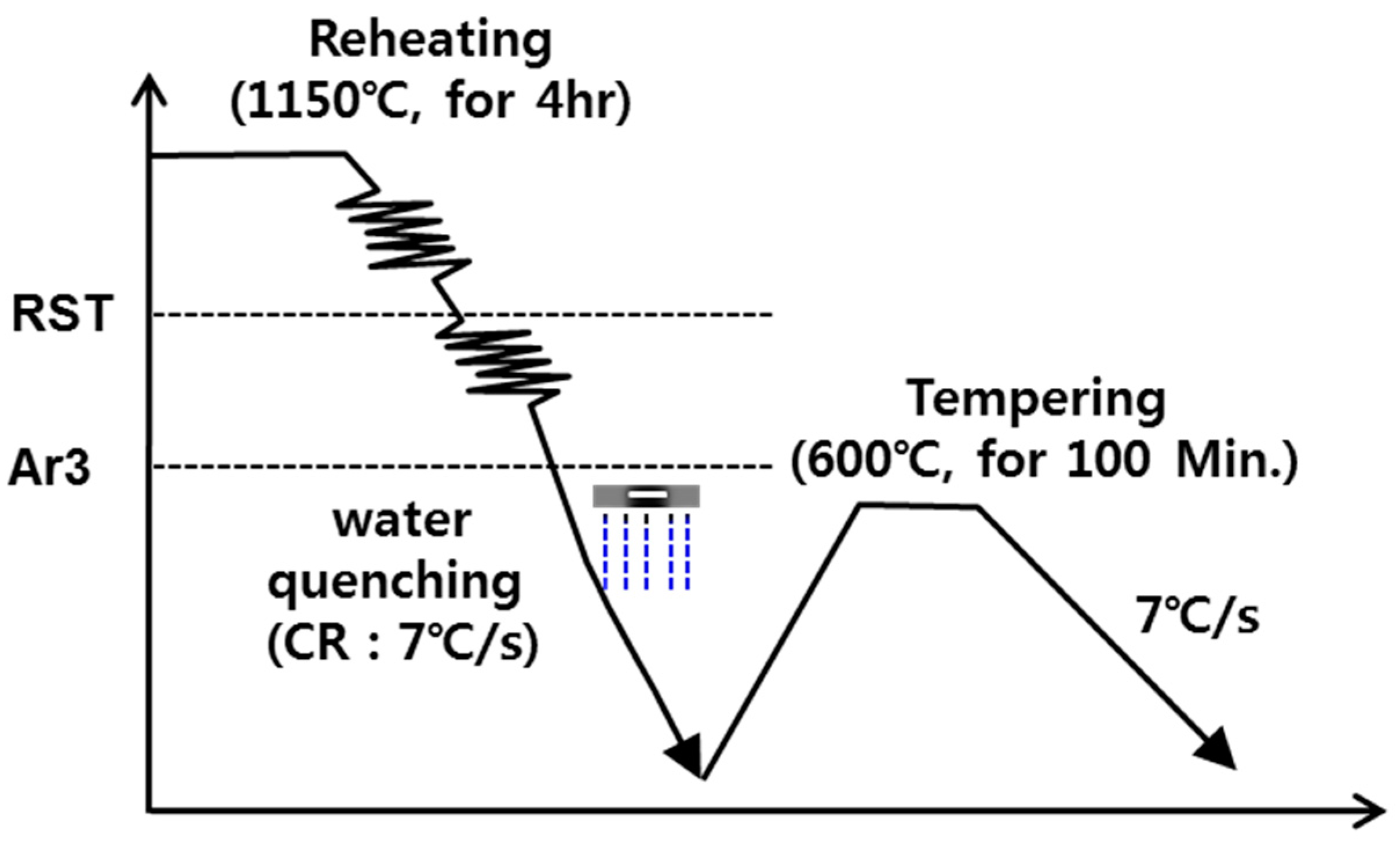

2. Experimental Details

3. Results and Discussion

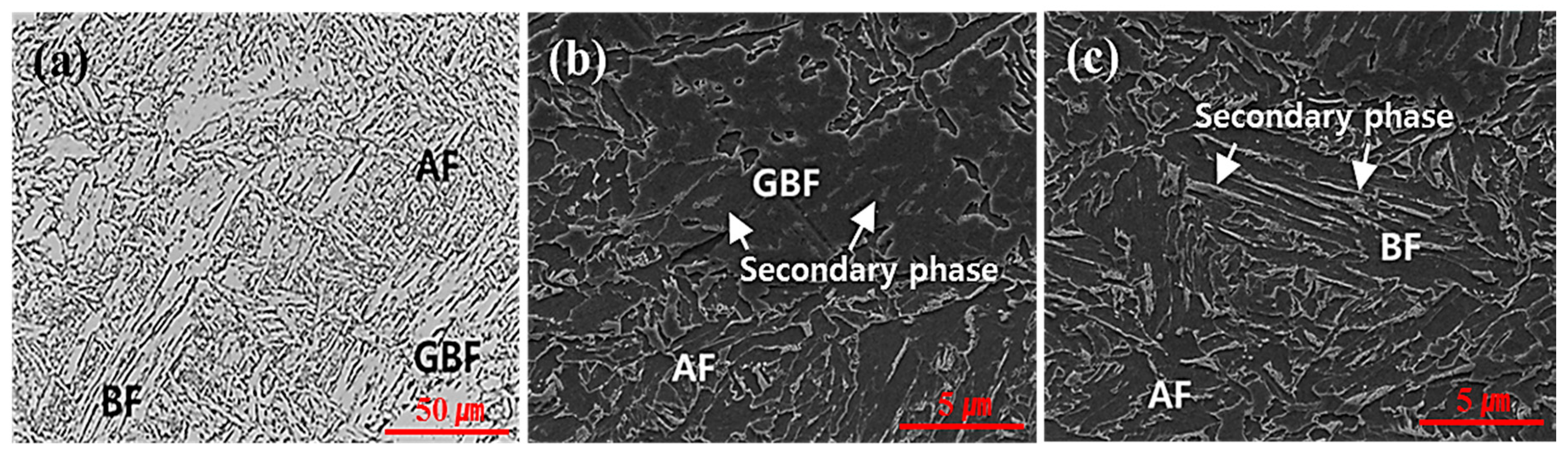

3.1. Microstructure and Mechanical Properties of the Base Metal

3.2. Microstructure and Mechanical Properties of Simulated HAZ

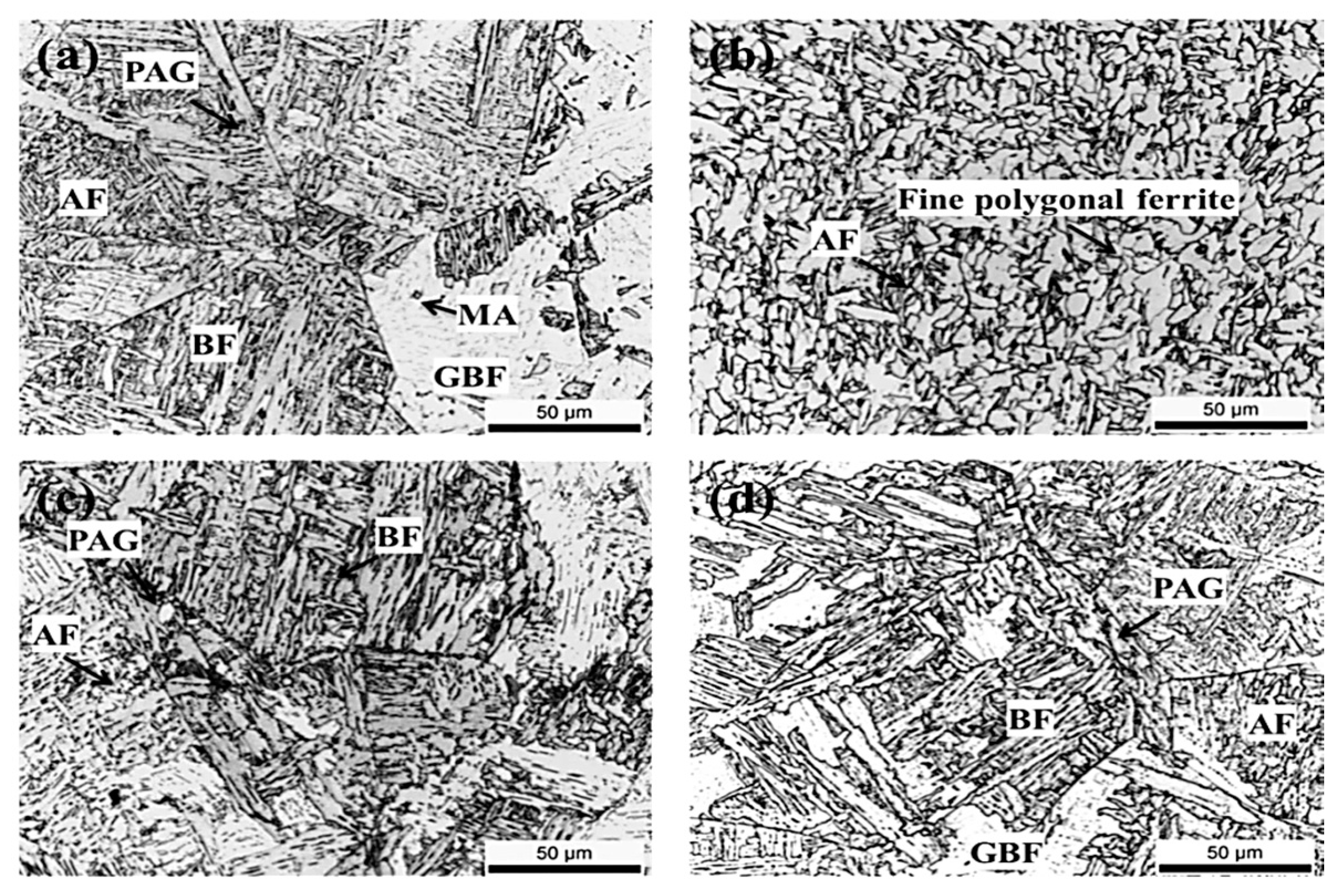

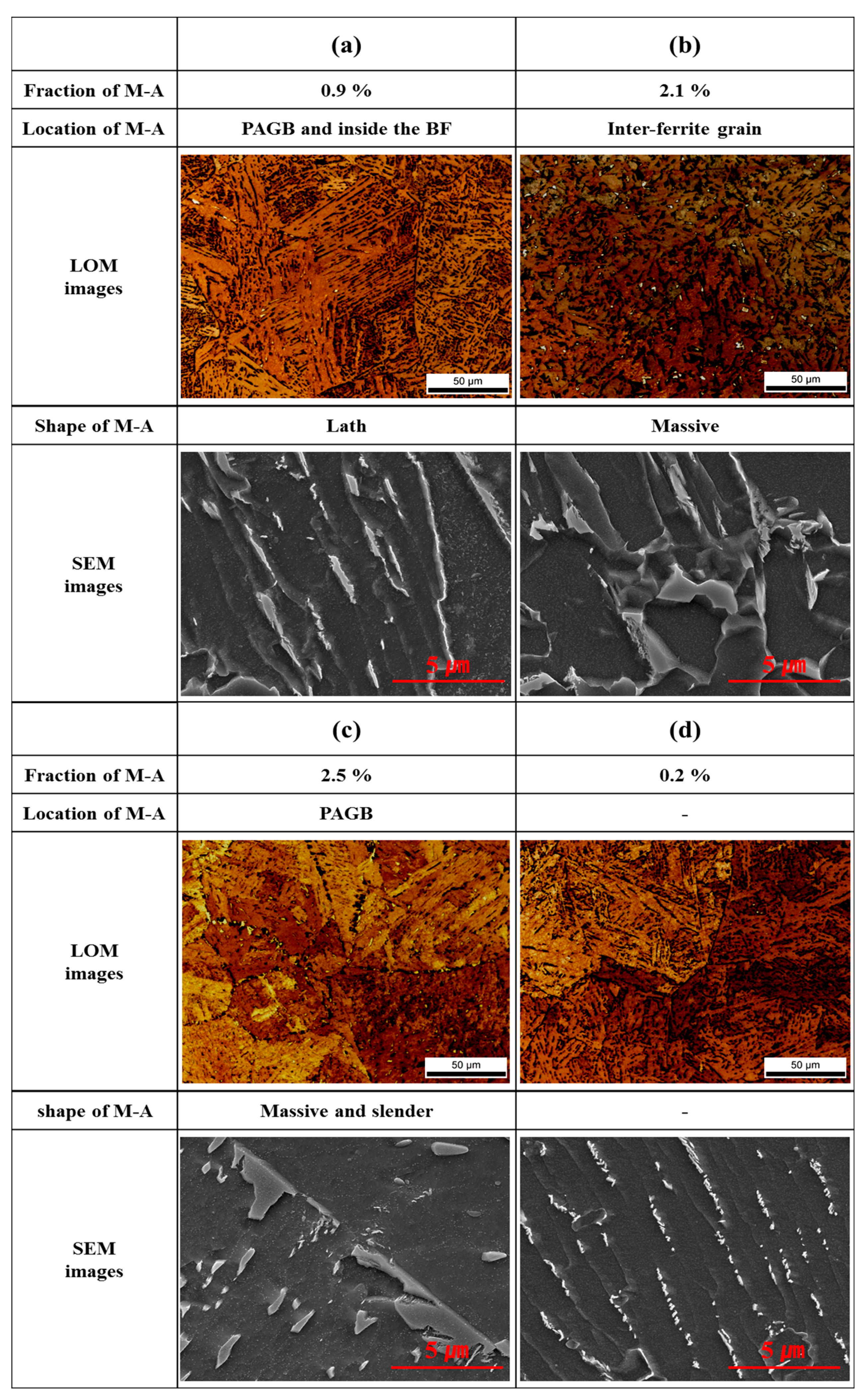

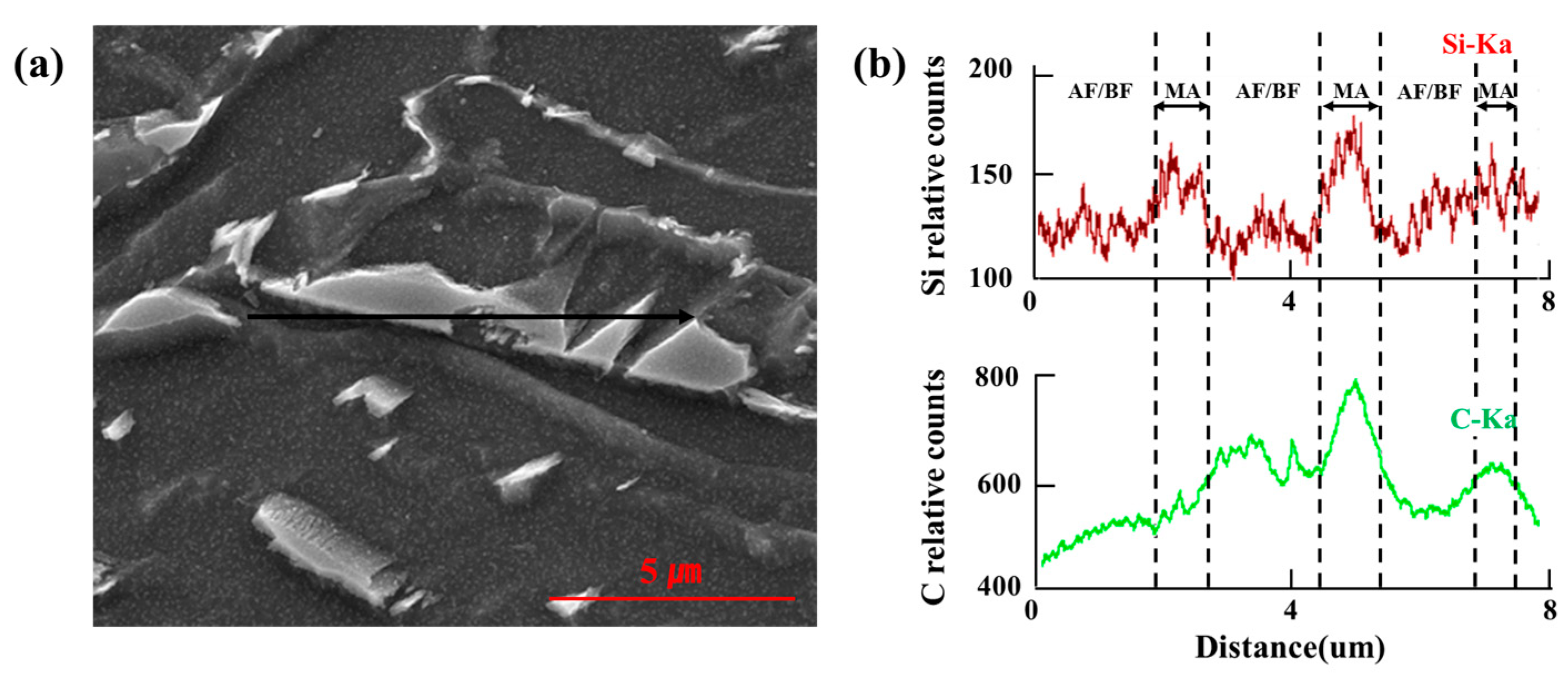

3.2.1. Microstructural Behaviour for Various HAZs

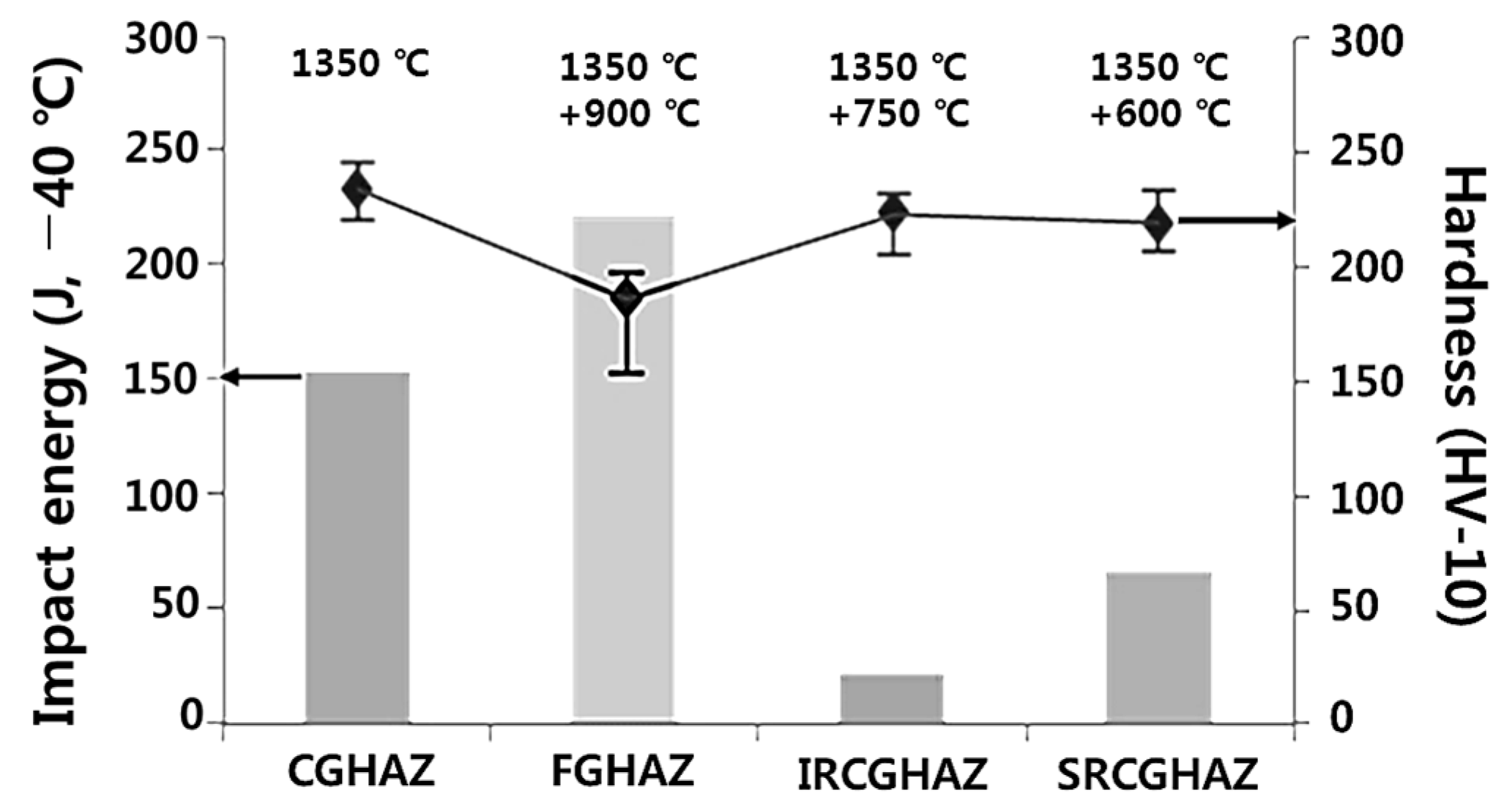

3.2.2. Mechanical Properties of the Various HAZs

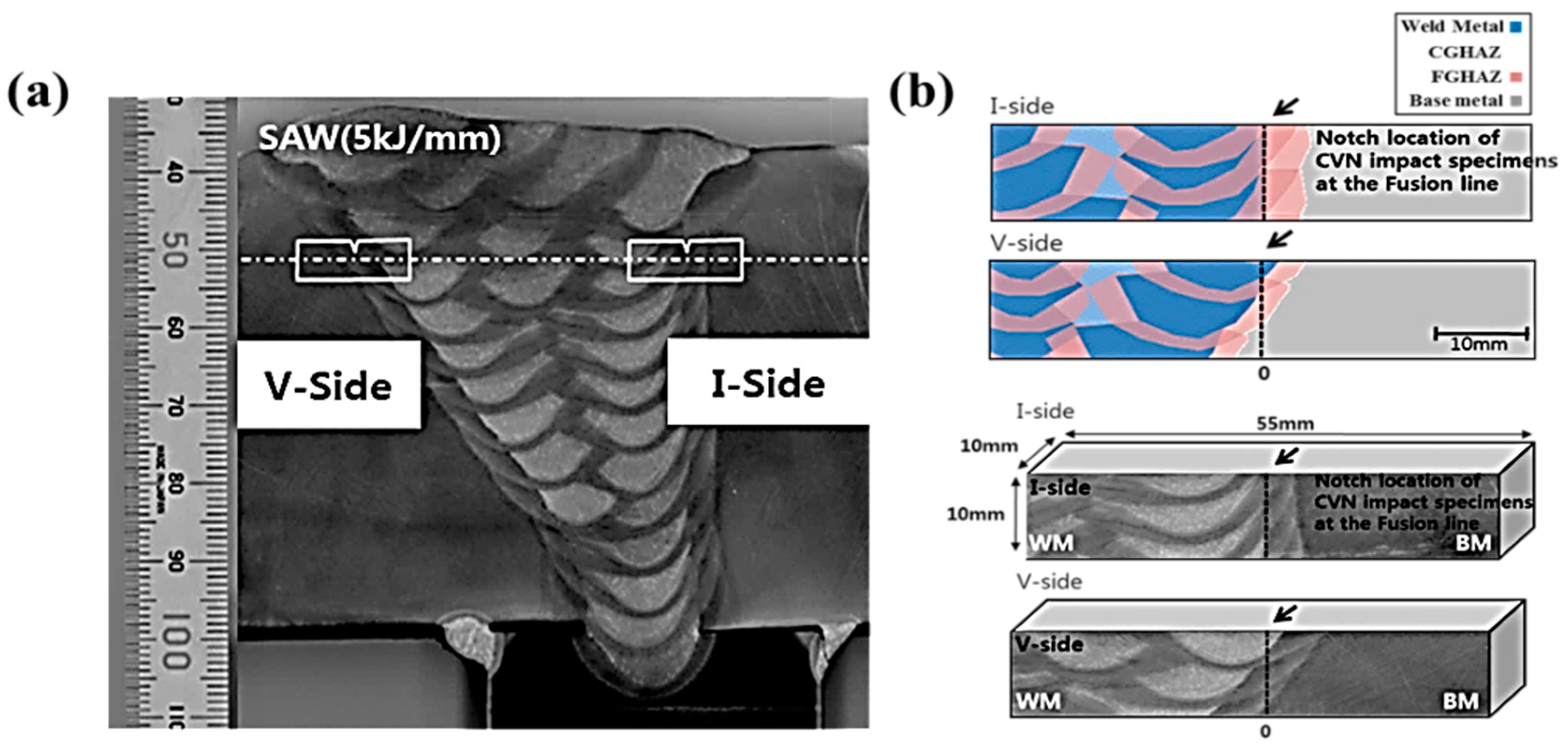

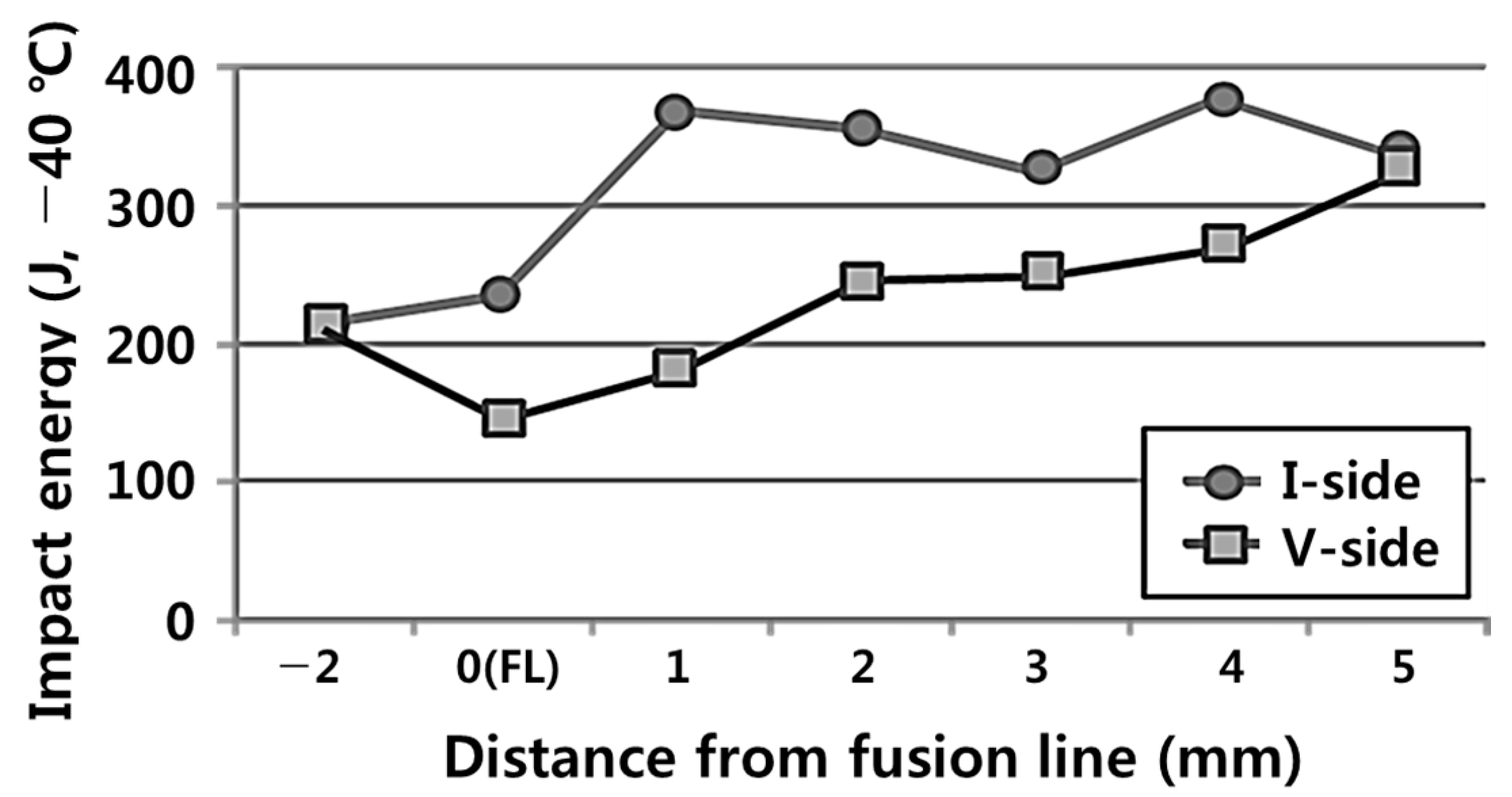

3.3. Properties of a Real Welded Joint Formed Using the Fabricated Steel Plate

4. Conclusions

- (1)

- The Gleeble simulator produced various HAZs including CGHAZ, FGHAZ, IRCGHAZ, and SRCGHAZ in the real welded joint. IRCGHAZ contained AF and BF microstructures, and FGHAZ contained mostly fine polygonal ferrite and AF. The microstructure of CGHAZ mainly consisted of AF, BF, and a small fraction of GBF. SRCGHAZ had the same type of microstructure as CGHAZ except for the small grain size. Therefore, various HAZs produced mostly same type of microstructure, i.e., AF, BF, and GBF.

- (2)

- The volume fractions of the M–A constituents in FGHAZ and IRCGHAZ were similar and greater than 2%. Unlike FGHAZ with massive-shaped M–A constituents that were randomly distributed in the inter-ferrite grain, both massive- and slender-shaped constituents coexisted in the IRCGHAZ primarily along the PAGB. The M–A constituent was hardly observed in SRCGHAZ. The CGHAZ contained a small amount (~0.9%) of lath-shaped M–A constituent on the PAGB and inside the BF microstructure.

- (3)

- The morphology and distribution of the M–A influenced the low-temperature impact toughness of the simulated HAZs. The FGHAZ exhibited superior toughness and showed mixed dimples and cleavage fractures due to the randomly distributed massive M–A in the inter-ferrite grain. However, the IRCGHAZ exhibited inferior toughness and typical cleavage fractures because its slender M–A located primarily along the PAGB. As a result, the low-temperature impact toughness was deteriorated as the volume fraction of M–A constituents increased and the distribution of the slender-shaped M–A constituents concentrated in the PAGB.

- (4)

- During the real submerged arc welding process, the I-side groove produced a smaller amount of the IRCGHAZ than that of the V-side groove. Therefore, the I-side of the welded groove was superior to the V-side in terms of CVN-absorbed energy tested at –40 °C. The design of multi-pass weld joints with less IRCGHAZ is recommended and can be achieved by applying optimized groove design to improve the toughness of the welds for the structure used in extreme environments.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, J.H.; Choi, S.W.; Park, D.H.; Lee, J.M. Charpy impact properties of stainless steel weldment in liquefied natural gas pipelines: Effect of low temperatures. Mater. Des. 2015, 65, 914–922. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Nathani, H.; Hartmann, J.E.; Siciliano, F. Microstructural evolution in a new 770 MPa hot rolled Nb-Ti microalloyed steel. Mater. Sci. Eng. A 2005, 394, 339–352. [Google Scholar] [CrossRef]

- Nishioka, K.; Ichikawa, K. Progress in thermomechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 2012, 13, 023001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, C.; Kang, N.; Liu, S. Effect of grain size on the resistance to hydrogen embrittlement of API 2W Grade 60 steels using in situ slow-strain-rate testing. Corros. Sci. 2017, 128, 33–41. [Google Scholar] [CrossRef]

- Amer, A.E.; Koo, M.Y.; Lee, K.H.; Kim, S.H.; Hong, S.H. Effect of welding heat input on microstructure and mechanical properties of simulated HAZ in Cu containing microalloyed steel. J. Mater. Sci. 2010, 45, 1248–1254. [Google Scholar] [CrossRef]

- Moon, J.; Kim, S.J.; Lee, C. Effect of thermo-mechanical cycling on the microstructure and strength of lath martensite in the weld CGHAZ of HSLA steel. Mater. Sci. Eng. A 2011, 528, 7658–7662. [Google Scholar] [CrossRef]

- Li, X.; Fan, Y.; Ma, X.; Subramanian, S.V.; Shang, C. Influence of Martensite-Austenite constituents formed at different intercritical temperatures on toughness. Mater. Des. 2015, 67, 457–463. [Google Scholar] [CrossRef]

- You, Y.; Shang, C.; Chen, L.; Subramanian, S. Investigation on the crystallography of the transformation products of reverted austenite in intercritically reheated coarse grained heat affected zone. Mater. Des. 2013, 43, 485–491. [Google Scholar] [CrossRef]

- Haugen, V.G.; Rogne, B.R.S.; Akselsen, O.M.; Thaulow, C.; Østby, E. Local mechanical properties of intercritically reheated coarse grained heat affected zone in low alloy steel. Mater. Des. 2014, 59, 135–140. [Google Scholar] [CrossRef]

- Chen, J.H.; Kikuta, Y.; Araki, T.; Yoneda, M.; Matsuda, Y. Micro-fracture behaviour induced by M–A constituent (Island Martensite) in simulated welding heat affected zone of HT80 high strength low alloyed steel. Acta. Metall. 1984, 32, 1779–1788. [Google Scholar] [CrossRef]

- Bonnevie, E.; Ferrière, G.; Ikhlef, A.; Kaplan, D.; Orain, J.M. Morphological aspects of martensite-austenite constituents in intercritical and coarse grain heat affected zones of structural steels. Mater. Sci. Eng. A 2004, 385, 352–358. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Gourgues, A.F.; Besson, J.; Sturel, T.; Pineau, A. Mechanisms and modelling of cleavage fractures in simulated heat affected zone microstructures in HSLA steel. Metall. Mater. Trans. A 2004, 35, 1039–1053. [Google Scholar] [CrossRef]

- Davis, C.L.; King, J.E. Cleavage initiation in the intercritically reheated coarse-grained heat-affected zone: Part I. Fractographic evidence. Metall. Mater. Trans. A 1994, 25, 563–573. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Analysis of microstructural variation and mechanical behaviors in submerged arc welded joint of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2012, 558, 592–601. [Google Scholar] [CrossRef]

- Qiu, C.; Lan, L.; Zhao, D.; Gao, X.; Du, L. Microstructural evolution and toughness in the HAZ of submerged arc welded low welding crack susceptibility steel. Acta. Metall. Sin. 2013, 26, 49–55. [Google Scholar] [CrossRef]

- Lan, H.F.; Du, L.X.; Misra, R.D.K. Effect of microstructural constituents on strength-toughness combination in a low carbon bainitic steel. Mater. Sci. Eng. A 2014, 611, 194–200. [Google Scholar] [CrossRef]

- Di, X.J.; An, X.; Cheng, F.J.; Wang, D.P.; Guo, X.J.; Xue, Z.K. Effect of martensite–austenite constituent on toughness of simulated inter-critically reheated coarse-grained heat-affected zone in X70 pipeline steel. Sci. Technol. Weld. Join. 2016, 21, 366–373. [Google Scholar] [CrossRef]

- Standard Specification for Weldable Structural Steels for Fixed Offshore Structures-Technical Delivery Conditions. BS EN 10225. 2009. Available online: https://www.din.de/en/getting-involved/standards-committees/fes/wdc-beuth: din21:119761806 (accessed on 5 December 2017).

- Information Technology-Calculating Program, Japan Welding Engineering Society Standards. Available online: http://www-it.jwes.or.jp (accessed on 5 December 2017).

- Standard Specification for Notched Bar Impact Testing of Metallic Materials1; ASTM E23-07: 2007; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2007; Available online: http://mhriau.ac.ir/_DouranPortal/Documents/ASTM%20E23%20%28impact%20test%29_20160406_233024.pdf (accessed on 5 December 2017).

- Recommended Practice for Preproduction Qualification for Steel Plates for Offshore Structures, Fourth Edition Standard; American Petroleum Institute (API): Washington, DC, USA, 2005; Available online: http://starglobal.com.vn/upload/files/Standard/206015667-API-RP-2Z-4th-Ed.pdf (accessed on 5 December 2017).

- Kim, I.; Lee, M.; Choi, Y.; Kang, N. Effects of Mo content on low-angle misorientation microstructure and mechanical properties of YS 550 MPa-Grade steels for offshore structures. Steel Res. Int. 2018, 89, 1700278. [Google Scholar] [CrossRef]

- South African Standard for Structural Steel, SANS 50025: 2009/EN 10025: 2004; SABS Standards Division: Cape Town, South Africa, 2004; Available online: https://store.sabs.co.za/pdfpreview.php?hash=5f3dfdb0e5ecf68792de91b64be6363c551259d8&preview=yes (accessed on 5 December 2017).

- Material Data Sheets for Structural Steel, NORSOK STANDARD M–120: 2000. Available online: http://www.standard.no/pagefiles/1170/m-120.pdf (accessed on 5 December 2017).

- Meester, B.D. The Weldability of Modern Structural TMCP Steels. ISIJ Int. 1997, 37, 537–551. [Google Scholar] [CrossRef]

- Terasaki, H.; Komizo, Y.I. Correlation between the microstructural development of bainitic ferrite and the characteristics of martensite-austenite constituent. Metall. Mater. Trans. A 2013, 44, 5289–5293. [Google Scholar] [CrossRef]

- Lee, S.; Kim, B.C.; Kwon, D. Fracture toughness analysis of heat-affected zones in high-strength low-alloy steel welds. Metall. Mater. Trans. A 1993, 24, 1133–1141. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.X.; Wang, J.J.; Xie, H.; Gao, H.C.R.; Misra, R.D.K. High toughness in the intercritically reheated coarse-grained (ICRCG) heat-affected zone (HAZ) of low carbon microalloyed steel. Mater. Sci. Eng. A 2014, 590, 323–328. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Analysis of martensite-austenite constituent and its effect on toughness in submerged arc welded joint of low carbon bainitic steel. J. Mater. Sci. 2012, 47, 4732–4742. [Google Scholar] [CrossRef]

- Taillard, R.; Verrier, P.; Maurickx, T.; Foct, J. Effect of silicon on CGHAZ toughness and microstructure of microalloyed steels. Metall. Mater. Trans. A 1995, 26, 447–457. [Google Scholar] [CrossRef]

- Han, C.; Li, K.; Liu, X.; Cao, R.; Cai, Z. Effect of Ti content and martensite-austenite constituents on microstructure and mechanical property. Sci. Technol. Weld. Join. 2018, 23, 410–419. [Google Scholar] [CrossRef]

- Lee, M.; Kang, N.; Liu, S.; Cho, K. Effects of inclusion size and acicular ferrite on cold cracking for high-strength steel welds of YS 600 MPa grade. Sci. Technol. Weld. Join. 2016, 21, 711–719. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | Cr | Cu | Mo | Ti | Nb | Ceq | |

|---|---|---|---|---|---|---|---|---|---|---|

| Base metal | 0.07 | 0.15 | 1.55 | 0.6 | - | 0.25 | 0.15 | 0.012 | 0.02 | 0.41 |

| Filler metal | 0.08 | 0.25 | 1.55 | 0.8 | 0.03 | 0.09 | 0.46 | - | - | - |

| Main Parameter | Current (A) | Voltage (V) | Travel Speed (cm/min) | Heat Input (kJ/cm) | InterpassTemperature (°C) |

|---|---|---|---|---|---|

| Range | 680–720 | 32–36 | 25–30 | 46–55 | ≤250 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, I.; Nam, H.; Lee, M.; Nam, D.; Park, Y.; Kang, N. Effect of Martensite–Austenite Constituent on Low-Temperature Toughness in YS 500 MPa Grade Steel Welds. Metals 2018, 8, 638. https://doi.org/10.3390/met8080638

Kim I, Nam H, Lee M, Nam D, Park Y, Kang N. Effect of Martensite–Austenite Constituent on Low-Temperature Toughness in YS 500 MPa Grade Steel Welds. Metals. 2018; 8(8):638. https://doi.org/10.3390/met8080638

Chicago/Turabian StyleKim, In, Hyunbin Nam, Myungjin Lee, Daegeun Nam, Yeongdo Park, and Namhyun Kang. 2018. "Effect of Martensite–Austenite Constituent on Low-Temperature Toughness in YS 500 MPa Grade Steel Welds" Metals 8, no. 8: 638. https://doi.org/10.3390/met8080638