An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties

Abstract

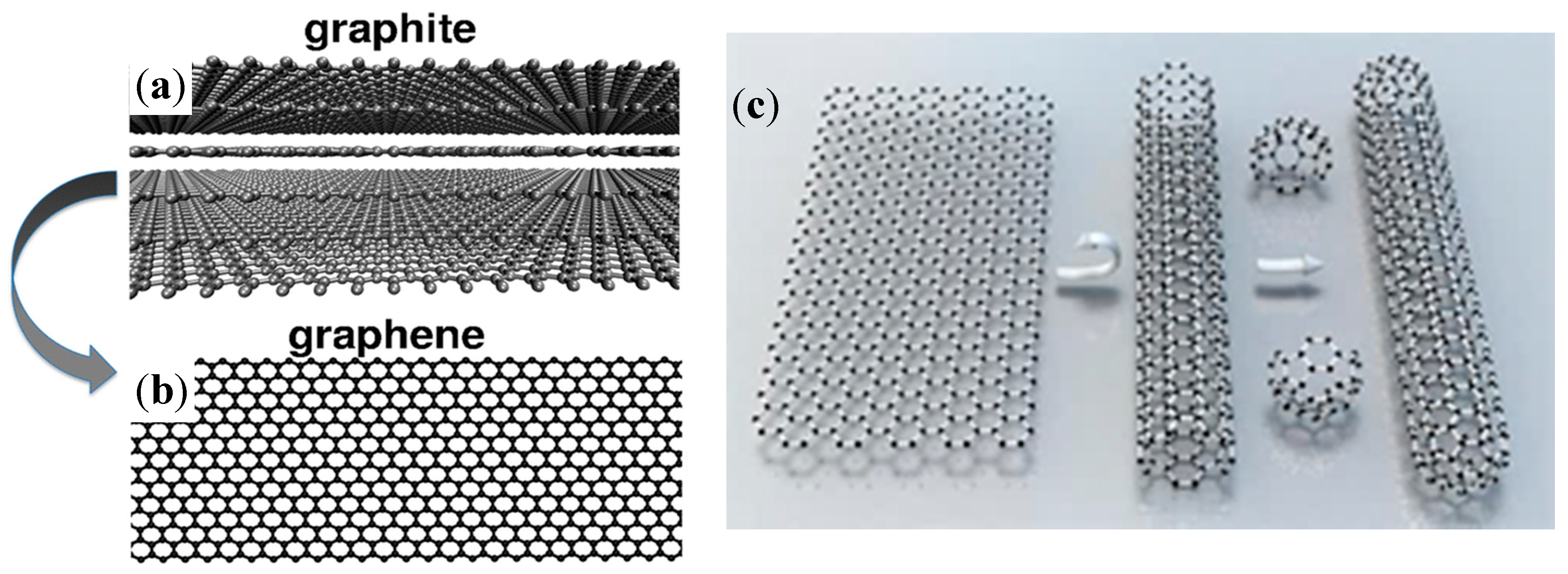

1. Introduction

2. Materials

2.1. Metal Matrix Nanocomposites (MMNCs)

- Higher mechanical properties;

- Lower specific gravity;

- Improved elevated temperature properties;

- The better thermal expansion coefficient;

- Higher thermal conductivity;

- Higher wear resistance;

- Improved damping capabilities.

2.2. Reinforcement

3. Properties of MMNCs

3.1. Density

3.2. Thermal Properties

3.2.1. The Coefficient of Thermal Expansion (CTE)

3.2.2. Thermal Conductivity

3.3. Mechanical Properties

3.3.1. Load Transfer Mechanism

3.3.2. Orowan Looping Mechanism

3.3.3. CTE-Mismatch Mechanism

3.3.4. Hall-Petch Effect

4. Al Matrix Composites (AMCs)

5. Copper Matrix Composites (CuMCs)

6. Magnesium Matrix Composites (MgMCs)

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rashad, M.; Pan, F.; Asif, M.; Tang, A. Powder metallurgy of Mg–1% Al–1% Sn alloy reinforced with low content of graphene nanoplatelets (GNPs). J. Ind. Eng. Chem. 2014, 20, 4250–4255. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Wang, Y. Improved high temperature strength of copper-graphene composite material. Mater. Lett. 2016, 181, 309–312. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Fan, G.; Pan, H.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Sci. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Jeong, Y.-H.; Seo, J.-J.; Tien, H.N.; Hong, S.-T.; Yum, Y.-J.; Hur, S.-H.; Lee, K.-J. Material properties of graphene/aluminum metal matrix composites fabricated by friction stir processing. Int. J. Precis. Eng. Manuf. 2014, 15, 1235–1239. [Google Scholar] [CrossRef]

- Perez-Bustamante, R.; Bolanos-Morales, D.; Bonilla-Maetinez, J.; Estrada-Guel, I. Microstructural and hardness behavior of graphene-nanoplatelets aluminum composites synthesized by mechanical alloying. J. Alloys Compd. 2014, 615, S578–S582. [Google Scholar] [CrossRef]

- Saboori, A.; Padovano, E.; Pavese, M.; Badini, C. Novel magnesium Elektron21-AlN nanocomposites produced by ultrasound-assisted casting; microstructure, thermal and electrical conductivity. Materials 2018, 11, 27. [Google Scholar] [CrossRef] [PubMed]

- Saboori, A.; Dadkhah, M.; Pavese, M.; Manfredi, D.; Biamino, S.; Fino, P. Hot deformation behavior of Zr-1% Nb alloy: Flow curve analysis and microstructure observations. Mater. Sci. Eng. A 2017, 696, 366–373. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Tribological performance of self-lubricating aluminum matrix nanocomposites: Role of graphene nanoplatelets. Eng. Sci. Technol. Int. J. 2016, 19, 463–469. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Biamino, S.; Fino, P.; Lombardi, M. Determination of critical condition for initiation of dynamic recrystallisation in Zr-1% Nb alloy. J. Alloys Compd. 2018, 757, 1–7. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Approach to enhance the mechanical strength and electrical and thermal conductivity of Cu-GNP nanocomposites. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Saboori, A.; Padovano, E.; Pavese, M.; Dieringa, H.; Badini, C. Effect of solution treatment on precipitation behaviors, age hardening response and creep properties of Elektron21 alloy reinforced by AlN nanoparticles. Materials 2017, 10, 1380. [Google Scholar] [CrossRef] [PubMed]

- Neubauer, E.; Kitzmantel, M.; Hulman, M.; Angerer, P. Potential and challenges of metal-matrix-composites reinforced with carbon nanofibers and carbon nanotubes. Compos. Sci. Technol. 2010, 70, 2228–2236. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Development of Al- and Cu-based nanocomposites reinforced by graphene nanoplatelets: Fabrication and characterization. Front. Mater. Sci. 2017, 11, 171–181. [Google Scholar] [CrossRef]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An overview of additive manufacturing of titanium components by directed energy deposition: Microstructure and mechanical properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, C.; Xiao, W.; Ameyama, K.; Ma, C. Enhanced mechanical properties of Al5083 alloy with graphene nanoplates prepared by ball milling and hot extrusion. Mater. Sci. Eng. A 2016, 658, 8–15. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Ben-hamu, G.; Eliezer, D.; Shin, K.S.; Cohen, S. The relation between microstructure and corrosion behavior of Mg–Y–RE–Zr alloys. J. Alloys Compd. 2007, 431, 269–276. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Liu, E.; He, C.; Han, Y.; Li, Q.; Nash, P.; Zhao, N. Fabrication of three-dimensional graphene/Cu composite by in-situ CVD and its strengthening mechanism. J. Alloys Compd. 2016, 688, 69–76. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Muradymov, R.V.; Korsun, I.V.; Yakovlev, G.A.; Smirnov, S.V. Novel aluminum-graphene and aluminum-graphite metallic composite materials: Synthesis and properties. J. Alloys Compd. 2016, 663, 449–459. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.; Wang, Y.; Du, S.; Liu, Z.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon N. Y. 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Yue, H.; Yao, L.; Gao, X.; Zhang, S.; Guo, E.; Zhang, H.; Lin, X.; Wang, B. Effect of ball-milling and graphene contents on the mechanical properties and fracture mechanisms of graphene nanosheets reinforced copper matrix composites. J. Alloys Compd. 2017, 691, 755–762. [Google Scholar] [CrossRef]

- Xue, C.; Bai, H.; Tao, P.F.; Wang, J.W.; Jiang, N. Thermal conductivity and mechanical properties of flake graphite/Al composite with a SiC nano-layer on graphite surface. Mater. Des. 2016, 108, 250–258. [Google Scholar] [CrossRef]

- Gao, X.; Yue, H.; Guo, E.; Zhang, H.; Lin, X.; Yao, L.; Wang, B. Preparation and tensile properties of homogeneously dispersed graphene reinforced aluminum matrix composites. Mater. Des. 2016, 94, 54–60. [Google Scholar] [CrossRef]

- Tian, W.; Li, S.; Wang, B.; Chen, X.; Liu, J.; Yu, M. Graphene-reinforced aluminum matrix composites prepared by spark plasma sintering. Int. J. Miner. Met. Mater. 2016, 23, 723–729. [Google Scholar] [CrossRef]

- Lavagna, L.; Massella, D.; Pavese, M. Preparation of hierarchical material by chemical grafting of carbon nanotubes onto carbon fibers. Diam. Relat. Mater. 2017, 80, 118–124. [Google Scholar] [CrossRef]

- Prasad, S.V.; Asthana, R. Aluminum metal–matrix composites for automotive applications: Tribological considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Musfirah, A.H.; Jaharah, A.G. Magnesium and aluminum alloys in automotive industry. J. Appl. Sci. Res. 2012, 8, 4865–4875. [Google Scholar]

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Hu, H.; Yu, A.; Li, N.; Allison, J.E. Potential magnesium alloys for high temperature die cast automotive applications: A review. Mater. Manuf. Process. 2003, 18, 687–717. [Google Scholar] [CrossRef]

- Macke, A.; Schultz, B.F. Metal matrix composites offer the automotive industry and opportunity to reduce vehicle weight, improve performance. Adv. Mater. Process. 2012, 45, 19–23. [Google Scholar]

- Saboori, A.; Pavese, M.; Badini, C.; Eivani, A.R. Studying the age hardening kinetics of A357 aluminum alloys through the Johnson–Mehl–Avrami theory. Met. Powder Rep. 2017, 72, 420–424. [Google Scholar] [CrossRef]

- Saboori, A.; Moheimani, S.K.; Dadkhah, M.; Pavese, M.; Badini, C.; Fino, P. An overview of key challenges in the fabrication of metal matrix nanocomposites reinforced by graphene nanoplatelets. Metals 2018, 8, 172. [Google Scholar] [CrossRef]

- Metal Matrix Composite. Available online: https://en.wikipedia.org/wiki/Metal_matrix_composite (accessed on 15 January 2018).

- Kopeliovich, D. Metal Matrix Composites (Introduction). Available online: http://www.substech.com/ dokuwiki/doku.php?id=metal_matrix_composites_introduction, (accessed on 15 January 2018).

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Chen, Z.-C.; Takeda, T.; Ikeda, K. Microstructural evolution of reactive-sintered aluminum matrix composites. Compos. Sci. Technol. 2008, 68, 2245–2253. [Google Scholar] [CrossRef]

- Kopeliovich, D. Polymer Matrix Composites (Introduction). Available online: http://www.substech.com/ dokuwiki/doku.php?id=polymer_matrix_composites_introduction (accessed on 15 January 2018).

- Kopeliovich, D. Ceramic Matrix Composites (Introduction). Available online: http://www.substech.com/ dokuwiki/doku.php?id=ceramic_matrix_composites_introduction (accessed on 15 January 2018).

- Callister, W.D. Materials Science and Engineering—An Introduction; John Wiley & Sons, Inc.: New York, NY, USA, 2007; ISBN 9780471736967. [Google Scholar]

- Tang, Y.; Liu, L.; Li, W.; Shen, B.; Hu, W. Interface characteristics and mechanical properties of short carbon fibers/Al composites with different coatings. Appl. Surf. Sci. 2009, 255, 4393–4400. [Google Scholar] [CrossRef]

- Włodarczyk-Fligier, A.; Dobrzański, L.A.; Kremzer, M.; Adamiak, M. Manufacturing of aluminium matrix composite materials reinforced by Al2O3 particles. J. Achiev. Mater. Manuf. Eng. 2008, 27, 99–102. [Google Scholar]

- Huber, T.; Degischer, H.P.; Lefrance, G.; Schmitt, T. Thermal expansion studies on aluminium-matrix composites with different reinforcement architecture of SiC particles. Compos. Sci. Technol. 2006, 66, 2206–2217. [Google Scholar] [CrossRef]

- Huu, T.; Requena, G.; Degischer, P. Thermal expansion behaviour of aluminum matrix composites with densely packed SiC particles. Compos. Part A 2008, 39, 856–865. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Sivaprasad, K.; Sivasankaran, S.; Narayanasamy, R. Fabrication and consolidation behavior of Al 6061 nanocomposite powders reinforced by multi-walled carbon nanotubes. Powder Technol. 2014, 258, 189–197. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Aamir, M. Synergetic effect of graphene nanoplatelets (GNPs) and multi-walled carbon nanotube (MW-CNTs) on mechanical properties of pure magnesium. J. Alloys Compd. 2014, 603, 111–118. [Google Scholar] [CrossRef]

- Nie, K.B.; Wang, X.J.; Xu, L.; Wu, K.; Hu, X.S.; Zheng, M.Y. Influence of extrusion temperature and process parameter on microstructures and tensile properties of a particulate reinforced magnesium matrix nanocomposite. Mater. Des. 2012, 36, 199–205. [Google Scholar] [CrossRef]

- Gaspera, E.D.; Tucker, R.; Star, K.; Lan, E.H.; Ju, Y.S.; Dunn, B. Copper-based conductive composites with tailored thermal expansion. ACS Appl. Mater. Interfaces 2013, 5, 10966–10974. [Google Scholar] [CrossRef] [PubMed]

- Varol, T.; Canakci, A. The effect of type and ratio of reinforcement on the synthesis and characterization Cu-based nanocomposites by flake powder metallurgy. J. Alloys Compd. 2015, 649, 1066–1074. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, X.; Wang, R.; Li, M. Enhancement of the mechanical properties of graphene–copper composites with graphene–nickel hybrids. Mater. Sci. Eng. A 2014, 599, 247–254. [Google Scholar] [CrossRef]

- Rana, R.S.; Purohit, R.; Das, S. Review of recent Studies in Al matrix composites. Int. J. Sci. Eng. Res. 2012, 3, 1–16. [Google Scholar]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Effect of sample preparation on the microstructural evaluation of Al–GNPs nanocomposites. Met. Microstruct. Anal. 2017, 6, 619–622. [Google Scholar] [CrossRef]

- Hu, H.; Kong, J. Improved thermal performance of diamond-copper composites with boron carbide coating. J. Mater. Eng. Perform. 2014, 23, 651–657. [Google Scholar] [CrossRef]

- Zhang, D.; Zhan, Z. Preparation of graphene nanoplatelets-copper composites by a modified semi-powder method and their mechanical properties. J. Alloys Compd. 2016, 658, 663–671. [Google Scholar] [CrossRef]

- Kielbus, A.; Rzychon, T.; Przeliorz, R. DSC and microstructural investigations of the Elektron21 magnesium alloy. Mater. Sci. Forum 2010, 642, 1447–1452. [Google Scholar] [CrossRef]

- Katsarou, L.; Mounib, M.; Lefebvre, W.; Vorozhtsov, S.; Pavese, M.; Badini, C.; Molina-aldareguia, J.M.; Cepeda, C.; MariaTeresa, P.P.; Dieringa, H. Microstructure, mechanical properties and creep of magnesium alloy Elektron21 reinforced with AlN nanoparticles by ultrasound-assisted stirring. Mater. Sci. Eng. A 2016, 659, 84–92. [Google Scholar] [CrossRef]

- Chen, X. Fabrication and Properties of Particulate Reinforced Aluminum Matrix Composites by Spontaneous Infiltration. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2013. [Google Scholar]

- Zhu, J.; Wang, F.; Wang, Y.; Zhang, B.; Wang, L. Interfacial structure and stability of a co-continuous SiC/Al composite prepared by vacuum-pressure infiltration. Ceram. Int. 2017, 43, 6563–6570. [Google Scholar] [CrossRef]

- Dorfman, S.; Fuks, D. Carbon diffusion in copper-based metal matrix composites. Sens. Actuators A Phys. 1995, 51, 13–16. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C.; Guo, H.; Li, W. On the thermal conductivity of Cu–Zr/diamond composites. Mater. Des. 2013, 45, 36–42. [Google Scholar] [CrossRef]

- Lide, D.R. Handbook of Chemistry and Physics, 84th ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Nishida, Y. Introduction to Metal Matrix Composites: Fabrication and Recycling; Springer: Heidelberg, Germany, 2013. [Google Scholar]

- Cardarelli, F. Materials Handbook: A Coincise Desktop Reference; Springer: London, UK, 2008. [Google Scholar]

- Srinivasan, M. Non-Oxide Materials: Applications and Engineering; Springer: Dordrecht, The Netherlands, 1996; pp. 3–42. [Google Scholar]

- Safdari, M. A Computational and Experimental Study on the Electrical and Thermal Properties of Hybrid Nanocomposites Based on Carbon Nanotubes and Graphite Nanoplatelets. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2012. [Google Scholar]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Al, E. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Rollings, E.; Gweon, G.-H.; Zhou, S.Y.; Mun, B.S.; McChesney, J.L.; Hussain, B.S.; Fedorov, A.V.; First, P.N.; de Heer, W.A.; Lanzara, A. Synthesis and characterization of atomically thin graphite films on a silicon carbide substrate. J. Phys. Chem. Solids 2006, 67, 2172–2177. [Google Scholar] [CrossRef]

- Wang, X.; You, H.; Liu, F.; Li, M.; Wan, L.; Li, S.; Li, Q.; Xu, Y.; Tian, R.; Yu, Z.; et al. Large-scale synthesis of few-layered graphene using CVD. Chem. Vap. Depos. 2009, 15, 5356. [Google Scholar] [CrossRef]

- Kosynkin, D.V.; Higginbotham, A.L.; Sinitskii, A.; Lomeda, J.R.; Dimiev, A.; Price, B.K.; Tour, J.M. Longitudinal unzipping of carbon nanotubes to form graphene Nanoribbons. Nature 2009, 458, 872–876. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Hu, Y.; Li, C.; Qin, C.; Shi, M.; Ye, M. Layer-by-Layer Self-Assembly of Graphene Nanoplatelets. Langmuir 2009, 25, 6122–6128. [Google Scholar] [CrossRef] [PubMed]

- Jang, B.; Zhamu, A. Processing of nanographene platelets (NGPs) and NGP nanocomposites: A review. J. Mater. Sci. 2008, 43, 5092–5101. [Google Scholar] [CrossRef]

- Fukushima, H.; Drzal, L.; Rook, B.; Rich, M. Thermal conductivity of exfoliated graphite nanocomposites. J. Therm. Anal. Calorim. 2006, 85, 235–238. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Solis-Fernandez, P.; Bissett, M.; Ago, H. Synthesis, structure and applications of graphene-based 2D heterostructures. Chem. Soc. Rev. 2017, 46, 4572–4613. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Ji, H.; Cheng, H.-M.; Ruoff, R.S. Mass production and industrial applications of graphene materials. Natl. Sci. Rev. 2018, 5, 90–101. [Google Scholar] [CrossRef]

- Tung, T.T.; Nine, M.J.; Krebsz, M.; Pasinszki, T.; Coghlan, C.J.; Tran, D.N.; Losic, D. Recent advances in sensing applications of graphene assemblies and their composites. Adv. Funct. Mater. 2017, 27, 1702891. [Google Scholar] [CrossRef]

- Kováčik, J.; Emmer, Š. Thermal expansion of Cu/graphite composites: Effect of copper coating. Kov. Mater. 2011, 49, 411–416. [Google Scholar]

- Hale, D.K. The physical properties of composite materials. J. Mater. Sci. 1976, 11, 2105–2141. [Google Scholar] [CrossRef]

- Turner, P.S. Thermal-expansion stresses in reinforced plastics. J. Res. NBS 1946, 37, 239–250. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–150. [Google Scholar] [CrossRef]

- Schapery, R.A. Thermal expansion coefficients of composite materials based on energy principles. J. Compos. Mater. 1968, 2, 380–404. [Google Scholar] [CrossRef]

- Thermal Conductivity 2016. Available online: https://en.wikipedia.org/wiki/Thermal conductivity (accessed on 10 January 2018).

- Kittel, C. Introduction to Solid State Physics; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Völklein, F.; Reith, H.; Cornelius, T.W.; Rauber, M.; Neumann, R. The experimental investigation of thermal conductivity and the Wiedemann–Franz law for single metallic nanowires. Nanotechnology 2009, 20, 325706. [Google Scholar] [CrossRef] [PubMed]

- Davis, J.R. Copper and Copper Alloys; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Boden, A. Copper Graphite Composite Materials—A Novel Way to Engineer Thermal. Ph.D. Thesis, Freien Universität Berlin, Berlin, Germany, 2015. [Google Scholar]

- Klemens, P.G.; Pedraza, D.F. Thermal conductivity of graphite in the basal plane. Carbon N. Y. 1994, 32, 735–741. [Google Scholar] [CrossRef]

- Jacimovski, S.; Bukurov, M.; Setrajcic, J.; Al, E. Phonon thermal conductivity of graphene. Superlattices Microstruct. 2015, 88, 330–337. [Google Scholar] [CrossRef]

- Progelhof, R.C.; Throne, J.L.; Ruetsch, R.R. Methods for predicting the thermal conductivity of composite systems: A review. Polym. Eng. Sci. 1976, 16, 615–625. [Google Scholar] [CrossRef]

- Davis, L.C.; Artz, B.E. Thermal conductivity of metal-matrix composites Thermal conductivity of metal-matrix composites. J. Appl. Phys. 1995, 77, 849–855. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Grybczuk, M.; Chmielewski, M.; Pietrzak, K.; Kurzydlowski, K.J.; Strojny-nedza, A. Thermal conductivity of metal-graphene composites. Mater. Des. 2016, 99, 163–173. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Parizi, M.T. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Erman, A.; Groza, J.; Li, X.; Choi, H.; Cao, G. Nanoparticle effects in cast Mg-1 wt % SiC nano-composites. Mater. Sci. Eng. A 2012, 558, 39–43. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Gómez-Esparza, C.D.; Estrada-Guel, I.; Miki-Yoshida, M.; Licea-Jiménez, L.; Pérez-García, S.A.; Martínez-Sánchez, R. Microstructural and mechanical characterization of Al–MWCNT composites produced by mechanical milling. Mater. Sci. Eng. A 2009, 502, 159–163. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng. A 2008, 483–484, 148–152. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Saboori, A. Metal Matrix Nanocomposites—Potentials, Challenges and Feasible Solutions. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2017. [Google Scholar]

- Arsenault, R.J.; Shi, N. Dislocation generation due to differences between the coefficients of thermal expansion. Mater. Sci. Eng. 1986, 81, 175–187. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Landry, K.; Kalogeropoulou, S.; Eustathopoulos, N. Wettability of carbon by aluminum and aluminum alloys. Mater. Sci. Eng. A 1998, 254, 99–111. [Google Scholar] [CrossRef]

- Rodriuez-Reyes, M.; Pech-Canul, M.I.; Rendon-Angeles, J.C.; Lopez-Cuevas, J. Limiting the development of Al4C3 to prevent degradation of Al/SiC p composites processed by pressureless infiltration. Compos. Sci. Technol. 2006, 66, 1056–1062. [Google Scholar] [CrossRef]

- Maqbool, A.; Hussain, M.A.; Khalid, F.A.; Bakhsh, N.; Hussain, A.; Ho, M. Mechanical characterization of copper coated carbon nanotubes reinforced aluminum matrix composites. Mater. Charact. 2013, 86, 39–48. [Google Scholar] [CrossRef]

- Singh, B.B.; Balasubramanian, M. Processing and properties of copper-coated carbon fibre reinforced aluminum alloy composites. J. Mater. Process. Technol. 2009, 209, 2104–2110. [Google Scholar] [CrossRef]

- Wang, C.; Chen, G.; Wang, X.U.; Zhang, Y. Effect of Mg Content on the thermodynamics of interface reaction in Cf/Al composite. Met. Mater. Trans. A 2012, 43, 2514–2519. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, H.; Zhang, Y.; Li, J.; Wang, X. Effect of copper content on the thermal conductivity and thermal expansion of Al–Cu/diamond composites. Mater. Des. 2012, 39, 87–92. [Google Scholar] [CrossRef]

- Fan, T.; Yang, G.; Zhang, D. Prediction of chemical stability in SiC p/Al composites with alloying element addition using Wilson equation and an extended Miedema model. Mater. Sci. Eng. A 2005, 394, 327–338. [Google Scholar] [CrossRef]

- Liu, J.; Khan, U.; Coleman, J.; Fernandez, B.; Rodriguez, P.; Naher, S.; Brabazon, D. Graphene oxide and graphene nanosheet reinforced aluminium matrix composites: Powder synthesis and prepared composite characteristics. Mater. Des. 2016, 94, 87–94. [Google Scholar] [CrossRef]

- Bhadauria, A.; Singh, L.K.; Laha, T. Effect of Physio-chemically functionalized graphene nanoplatelets reinforcement on tensile properties of aluminum nanocomposite synthesized via spark plasma sintering. J. Alloys Compd. 2018, 748, 783–793. [Google Scholar] [CrossRef]

- Garbiec, D.; Jurczyk, M.; Levintant-zayonts, N.; Mo, T. Properties of Al–Al2O3 composites synthesized by spark plasma sintering method. Arch. Civ. Mech. Eng. 2015, 15, 933–939. [Google Scholar] [CrossRef]

- Arsalan, G.; Kara, F.; Turan, S. Quantitative X-ray diffraction analysis of reactive infiltrated boron carbide–aluminium composites. J. Eur. Ceram. Soc. 2003, 23, 1243–1255. [Google Scholar] [CrossRef]

- Ghasali, E.; Alizadeh, M.; Ebadzadeh, T. Mechanical and microstructure comparison between microwave and spark plasma sintering of Al-B4C composite. J. Alloys Compd. 2016, 655, 93–98. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ebrahimifard, R.; Baghchesara, M.A. Composites: Part B Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: A comparative study. Compos. Part B 2014, 56, 217–221. [Google Scholar] [CrossRef]

- Chawla, N.; Deng, X.; Schnell, D.R.M. Thermal expansion anisotropy in extruded SiC particle reinforced 2080 aluminum alloy matrix composites. Mater. Sci. Eng. A 2006, 426, 314–322. [Google Scholar] [CrossRef]

- Boostani, A.F.; Tahamtan, S.; Jiang, Z.Y.; Wei, D.; Yazdani, S.; Khosroshahi, R.A.; Mousavian, R.T.; Xu, J.; Zhang, X.; Gong, D. Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos. Part A 2015, 68, 155–163. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, X.; Wu, G. Interfacial microstructure of SiCp/Al composite produced by the pressureless infiltration technique. Ceram. Int. 2013, 39, 4893–4897. [Google Scholar] [CrossRef]

- Bartolucci, S.F.; Paras, J.; Rafiee, M.A.; Rafiee, J.; Lee, S.; Kapoor, D.; Koratkar, N. Graphene–aluminum nanocomposites. Mater. Sci. Eng. A 2011, 528, 7933–7937. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, Y.C.; Wang, X.D.; Yan, S.J.; Yang, C.; He, W.W.; Chen, J.Z.; Wang, S.Q.; Zhang, X.Y.; Dai, S.L. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater. Sci. Eng. A 2015, 626, 400–405. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, F.; Xu, J.; Nian, Q.; Lin, D.; Chen, C.; Zhu, X.; Chen, Y.; Zhang, M. 3D printing graphene-aluminum nanocomposites. J. Alloys Compd. 2018, 746, 269–276. [Google Scholar] [CrossRef]

- Zhao, R.; Xu, R.; Fan, G.; Chen, K.; Tan, Z.; Xiong, D.; Li, Z.; Dmitrievich, S.; Zhang, D. Reinforcement with in-situ synthesized carbon nano-onions in aluminum composites fabricated by flake powder metallurgy. J. Alloys Compd. 2015, 650, 217–223. [Google Scholar] [CrossRef]

- Cao, L.; Li, Z.; Kim, Y.; Fan, G.; Jiang, L.; Zhang, D.; Moon, W. The growth of carbon nanotubes in aluminum powders by the catalytic pyrolysis of polyethylene glycol. Carbon N. Y. 2011, 50, 1057–1062. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Shin, J.H.; Bae, D.H. Strengthening behavior of few-layered graphene/aluminum composites. Carbon N. Y. 2014, 82, 143–151. [Google Scholar] [CrossRef]

- Yan, S.J.; Dai, S.L.; Zhang, X.Y.; Yang, C.; Hong, Q.H.; Chen, J.Z.; Lin, Z.M. Investigating aluminum alloy reinforced by graphene nano flakes. Mater. Sci. Eng. A 2014, 612, 440–444. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Yu, Z.; Asif, M. Investigation on microstructural, mechanical and electrochemical properties of aluminum composites reinforced with graphene nanoplatelets. Prog. Nat. Sci. Mater. Int. 2015, 25, 460–470. [Google Scholar] [CrossRef]

- Reddy, K.S.; Sreedhar, D.; Kumar, K.D.; Kumar, G.P. Role of reduced graphene oxide on mechanical-thermal properties of aluminum metal matrix nano composites. Mater. Today Proc. 2015, 2, 1270–1275. [Google Scholar] [CrossRef]

- Bastwros, M.; Kim, G.; Zhu, C.; Zhang, K.; Wang, S.; Tang, X.; Wang, X. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. Part B 2014, 60, 111–118. [Google Scholar] [CrossRef]

- Saboori, A.; Novara, C.; Pavese, M.; Badini, C.; Giorgis, F.; Fino, P. An investigation on the sinterability and the compaction behavior of aluminum/graphene nanoplatelets (GNPs) prepared by powder metallurgy. J. Mater. Eng. Perform. 2017, 26, 993–999. [Google Scholar] [CrossRef]

- Saboori, A.; Pietroluongo, M.; Pavese, M.; Badini, C.; Fino, P. Influence of graphene nanoplatelets (GNPs) on compressibility and sinterability of al matrix nanocomposites prepared by powder metallurgy. In Proceedings of the World PM 2016 Congress and Exhibition, Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Microstructure and thermal conductivity of Al-Graphene composites fabricated by powder metallurgy and hot rolling techniques. Acta Met. Sin. 2017, 30, 675–687. [Google Scholar] [CrossRef]

- Saboori, A.; Casati, R.; Zanatta, A.; Pavese, M.; Badini, C.; Vedani, M. Effect of graphene nanoplatelets on microstructure and mechanical properties of AlSi10Mg nanocomposites produced by hot extrusion. Powder Metall. Met. Ceram. 2018, 56, 647–655. [Google Scholar] [CrossRef]

- Chen, B.; Bi, Q.; Yang, J.; Xia, Y.; Hao, J. Tribology international tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites. Tribol. Int. 2008, 41, 1145–1152. [Google Scholar] [CrossRef]

- Hanada, K.; Matsuzaki, K.; Sano, T. Thermal properties of diamond particle-dispersed Cu composites. J. Mater. Process. Technol. 2004, 153–154, 514–518. [Google Scholar] [CrossRef]

- Davis, J.R. Powder metallurgy: Copper and copper alloys. In ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 2001; ISBN 0-87170-726-8. [Google Scholar]

- Nadkarani, A. Dispersion Strengthened Metal Composites. U.S. Patent 4,752,334, 21 June 1988. [Google Scholar]

- Caron, R.N. Copper Alloys: Properties and Applications, 2nd ed.; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Kundig, K.J.A.; Cowie, J.G. Mechanical Engineers’ Handbook: Materials and Mechanical Design, 3rd ed.; Kutz, M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; ISBN 9780471449904. [Google Scholar]

- Zhao, S.; Zheng, Z.; Huang, Z.; Dong, S.; Luo, P.; Zhang, Z.; Wang, Y. Cu matrix composites reinforced with aligned carbon nanotubes: Mechanical, electrical and thermal properties. Mater. Sci. Eng. A 2016, 675, 82–91. [Google Scholar] [CrossRef]

- Yao, G.C.; Mei, Q.S.; Li, J.Y.; Li, C.L.; Ma, Y.; Chen, F.; Liu, M. Cu/C composites with a good combination of hardness and electrical conductivity fabricated from Cu and graphite by accumulative roll-bonding. Mater. Des. 2016, 110, 124–129. [Google Scholar] [CrossRef]

- Arnaud, C.; Lecouturier, F.; Mesguich, D.; Ferreira, N.; Chevallier, G.; Estournes, C.; Weibel, A.; Laurent, C. High strength and high conductivity double-walled carbon nanotube—Copper composite wires. Carbon N. Y. 2016, 96, 212–215. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Cu-GNPs Nanocomposite with improved thermal and mechanical properties. Acta Met. Sin. 2018, 31, 148–152. [Google Scholar] [CrossRef]

- Saboori, A.; Moheimani, S.K.; Pavese, M.; Badini, C.; Fino, P. New Nanocomposite materials with improved mechanical strength and tailored coefficient of thermal expansion for electro-packaging applications. Metals 2017, 7, 536. [Google Scholar] [CrossRef]

- Chu, K.; Wang, F.; Wang, X.; Huang, D. Anisotropic mechanical properties of graphene/copper composites with aligned graphene. Mater. Sci. Eng. A 2018, 713, 269–277. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A. Microstructure, electrical conductivity and hardness of multilayer graphene/copper nanocomposites synthesized by flake powder metallurgy. Met. Mater. Int. 2015, 21, 704–712. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A. Effect of the CNT content on microstructure, physical and mechanical properties of Cu-based electrical contact materials produced by flake powder metallurgy. Arab. J. Sci. Eng. 2015, 40, 2711–2720. [Google Scholar] [CrossRef]

- Mai, Y.J.; Chen, F.X.; Lian, W.Q.; Zhang, L.Y.; Liu, C.S.; Jie, X.H. Preparation and tribological behavior of copper matrix composites reinforced with nickel nanoparticles anchored graphene nanosheets. J. Alloys Compd. 2018, 756, 1–7. [Google Scholar] [CrossRef]

- Moustafa, S.F.; El-Badry, S.A.; Sanad, A.M.; Kieback, B. Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders. Wear 2002, 253, 699–710. [Google Scholar] [CrossRef]

- Moustafa, S.F.; El-Badry, S.A.; Sanad, A.M. Effect of graphite with and without copper coating on consolidation behaviour and sintering of copper–graphite composite. Powder Met. 1997, 40, 201–206. [Google Scholar] [CrossRef]

- Dey, A.; Pandey, K.M. Magnesium metal matrix composites—A review. Rev. Adv. Mater. Sci. 2015, 42, 58–67. [Google Scholar]

- Ye, H.; Liu, X.Y. Review of recent studies in magnesium. J. Mater. Sci. 2004, 39, 6153–6171. [Google Scholar] [CrossRef]

- Xiuqing, Z.; Haowei, W.; Lihua, L.; Xinying, T.; Naiheng, M. The mechanical properties of magnesium matrix composites reinforced with (TiB2 + TiC) ceramic particulates. Mater. Lett. 2005, 59, 2105–2109. [Google Scholar] [CrossRef]

- Hou, L.G.; Wu, R.Z.; Wang, X.D.; Zhang, J.H.; Zhang, M.L.; Dong, A.P.; Sun, B.D. Microstructure, mechanical properties and thermal conductivity of the short carbon fiber reinforced magnesium matrix composites. J. Alloys Compd. 2016, 695, 2820–2826. [Google Scholar] [CrossRef]

- Suresh, M.; Srinivasan, A.; Pillai, U.T.S.; Pai, B.C. The effect of charcoal addition on the grain refinement and ageing response of magnesium alloy AZ91. Mater. Sci. Eng. A 2011, 528, 8573–8578. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Hussain, S.; Gou, J.; Mao, J. Improved strength and ductility of magnesium with addition of aluminum and graphene nanoplatelets (Al + GNPs) using semi powder metallurgy method. J. Ind. Eng. Chem. 2015, 23, 243–250. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Shi, D.L.; Feng, X.Q.; Huang, Y.Y.; Hwang, K.C. Critical Evaluation of the Stiffening Effect of Carbon Nanotubes in Composites. In Advances in Fracture and Failure Prevention; Key Engineering Materials; Trans Tech Publications: Zürich, Switzerland, 2004; Volume 261, pp. 1487–1492. [Google Scholar]

- Habibi, M.K.; Paramsothy, M.; Hamouda, A.M.S.; Gupta, M. Using integrated hybrid (Al + CNT) reinforcement to simultaneously enhance strength and ductility of magnesium. Compos. Sci. Technol. 2011, 71, 734–741. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Jayalakshmi, S.; Gupta, M. Effect of ball milling the hybrid reinforcements on the microstructure and mechanical properties of Mg–(Ti + n-Al2O3) composites. J. Alloys Compd. 2011, 509, 7229–7237. [Google Scholar] [CrossRef]

- Tun, K.S.; Tungala, V.; Nguyen, Q.B.; Chan, J.; Kwok, R.; Kuma, J.V.M.; Gupta, M. Enhancing tensile and compressive strengths of magnesium using nanosize (Al2O3 + Cu) hybrid reinforcements. J. Compos. Mater. 2012, 46, 1879–1887. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Jayalakshmi, S.; Gupta, M. Effect of individual and combined addition of micro/nano-sized metallic elements on the microstructure and mechanical properties of pure Mg. Mater. Des. 2012, 37, 274–284. [Google Scholar] [CrossRef]

- Gupta, M.; Lai, M.O.; Saravanaranganathan, D. Synthesis, microstructure and properties characterization of disintegrated melt deposited Mg/SiC composites. J. Mater. Sci. 2000, 35, 2155–2165. [Google Scholar] [CrossRef]

- Chua, B.W.; Lu, L.; Lai, M.O. Influence of SiC particles on mechanical properties of Mg based composite. Compos. Struct. 1999, 47, 595–601. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Thermal Conductivity (W/m·K) | Thermal Expansion Coefficient (106/K) | Melting Point (°C) | Vickers Hardness (HV) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| α-Al2O3 | 3.95–3.98 | 35–39 | 7.1–8.4 | 2054–2072 | 1800–3000 | 365–393 |

| AlN | 3.05–3.26 | 130–180 | 2.5–5.3 | 2200–2230 | 1170–1530 | 308–346 |

| α-SiC | 3.15 | 42.5–270 | 4.3–5.8 | 2093–2400 | 2400–2500 | 386–476 |

| β-SiC | 3.16 | 135 | 4.5 | 2093 trans | 2700 | 262–468 |

| Diamond | 3.52 | 2400 | - | 3550 | 8000 | 930 |

| Graphite | 2.25 | 25–470 | 0.6–4.3 | - | - | 4.8–27 |

| SWCNTs | 1.8 | Up to 2900 | Negligible | - | - | 1000 |

| GNPs | 1.8–2.2 | 5300 | −0.8–0.7 | - | - | 1000 |

| Matrix | Reinforcement a | Content (wt %) | Fabrication Technique b | Mechanical Properties c | Ref. |

|---|---|---|---|---|---|

| Al | CNOs | 1.2 | HC + HEX | TS: 384 MPa | [122] |

| Al | CNTs | 2.1 | CVD | CS: 380 MPa | [123] |

| Al | CNTs | 0.5–1.0 | HR | TS: 90–200 MPa | [105] |

| HV: 44–56 | |||||

| Al | Cu coated CNTs | 0.5–1.0 | HR | TS: 90–160 MPa | [105] |

| HV: 61–79 | |||||

| Al | FLG | 0.7 vol % | BM + HR | TS: 440 MPa | [124] |

| Al-Cu-Mg | GNFs | 0.15–0.5 | HIP + EX | TS: 370–460 MPa | [125] |

| E: 72 MPa | |||||

| Al | GNFs | 0.5–1.0 | Cryomilling + HEX | TS: 173–248 MPa | [120] |

| Al | GNPs | 0.1 | BM + HIP + EX | TS: 260 MPa | [119] |

| HV: 84 | |||||

| Al | GNPs | 0.25–1.0 | BM + CPM | CS: 180 MPs | [5] |

| HV: 70 | |||||

| Al | GNPs | 0.25–1.0 | HC+ HEX | TS: 166–203 MPa | [126] |

| HV: 80–90 | |||||

| Al5083 | GNPs | 0.5–1.0 | BM + HEX | TS: 434–470 MPa | [16] |

| Al | GNS | 0.3 | CPM + EX | TS: 249 MPa | [3] |

| Al | Graphene | 0.1–0.5 | HP | TS: 95–110 MPa | [24] |

| Al7055 | Graphene | 1.0–5.0 | SPS | CS: 600–1200 MPs | [25] |

| HV: 90–150 | |||||

| Al | Graphene sheets | 2 | Liquid state | TS: 48.1 MPa | [20] |

| HV: 57.19 | |||||

| E: 87.93 MPa | |||||

| Al | Graphite | 2 | Liquid state | TS: 43.92 MPa | [20] |

| HV: 25.52 | |||||

| E: 58.54 MPa | |||||

| Al | RGO | 0.25–1.0 | BM + CPM | HV: 31.63 | [127] |

| Al-6061 | SCFs | 10 | Pressure infiltration | TS: 127.7 MPa | [41] |

| Al-6061 | GNPs | 1 | BM + HC | FS: 800 MPa | [128] |

| Matrix | Reinforcement a | Content (wt %) | Fabrication Technique b | Properties c | Ref. |

|---|---|---|---|---|---|

| Cu | GNPs | 0.5 | In-situ CVD | TS: 308 MPa | [19] |

| Cu | Graphene | 0.5 | CPM + HP | HV: 97 | [2] |

| EC: 96% IACS | |||||

| Cu | Graphite | 0.5 | CPM + HP | HV: 94 | [2] |

| EC: 75% IACS | |||||

| Cu | Graphene | 0–4 vol % | SPS | E: 90–140 MPa | [21] |

| Hardness: 1–1.8 GPa | |||||

| EC: 80–92% IACS | |||||

| Cu | GNSs | 0.5 | BM + HP | TS: 120–220 MPa | [22] |

| HV: 37–52 | |||||

| Cu | SWCNTs | 5 vol % | CPM + Forging | TS: 274 MPa | [139] |

| HV: 60 | |||||

| EC: 44–48% IACS | |||||

| TC: 310–378 W/m·K | |||||

| Cu | Graphite | 0.1 | Roll-bonding | HV: 110–160 | [140] |

| EC: 90–99% IACS | |||||

| Cu | CNTs | 0.5 vol % | SPS + wire drawing | TS: 558 MPa | [141] |

| EC: 91.2% IACS |

| Reinforcement | Content | Electrical Conductivity (%IACS) | Fabrication Method | Ref. |

|---|---|---|---|---|

| MLG | 1–5 wt % | 78.5-61.5 | Flake PM | [145] |

| CNT | 1–5 wt % | 74.6-5.3 | Flake PM | [146] |

| Nano-Graphite | 1–5 wt % | 78.5-68.3 | Flake PM | [49] |

| CNTs | 0.5 vol % | 91.2 | SPS + wire drawing | [141] |

| GNPs | 0.6 vol % | 88 | Molecular level mixing + SPS | [21] |

| Graphite | 8.0 wt % | 55 | Cu coating of graphene + sintering | [147,148,149] |

| Graphite | 0.1 vol % | 90% | Roll bonding | [140] |

| - | - | 52.3 | Sintering + Forging | [139] |

| SWCNTs | 5 vol % | 44.5 | Sintering + Forging | |

| - | - | 78 | Sintering + HIPping | [10] |

| GNPs | 2 vol % | 77 | Sintering + HIPping | [10] |

| GNPs | 4 vol % | 72.5 | Sintering + HIPping | [10] |

| GNPs | 8 vol % | 67.5 | Sintering + HIPping | [10] |

| Materials | 0.2% YS (MPa) | UTS (MPa) | Failure Strain (%) | Ref. |

|---|---|---|---|---|

| Pure Mg | 162 | 195 | 3.7 | [155] |

| Mg-1.0Al-1.0Sn | 161 | 236 | 16.7 | [1] |

| Mg-0.5Al-0.18GNPs | 173 | 230 | 10.7 | [155] |

| Mg-1.0Al-0.18GNPs | 190 | 254 | 15.5 | [155] |

| Mg-1.5Al-0.18GNPs | 209 | 268 | 12.7 | [155] |

| Mg-1.0Al-1.0Sn-0.18GNPs | 208 | 268 | 10.9 | [1] |

| Mg-1.5Al-0.18CNTs | 156 | 223 | 7 | [158] |

| Mg-5.6Ti-2.5Al2O3 | 168 | 214 | 6.8 | [159] |

| Mg-1Al2O3-0.9Cu | 202 | 232 | 4.1 | [160] |

| Mg-5.6Ti-3Cu | 197 | 225 | 2.6 | [161] |

| Mg-21.3SiC | 128 | 176 | 1.4 | [162] |

| AZ91-10SiC | 120 | 135 | 0.47 | [163] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saboori, A.; Dadkhah, M.; Fino, P.; Pavese, M. An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties. Metals 2018, 8, 423. https://doi.org/10.3390/met8060423

Saboori A, Dadkhah M, Fino P, Pavese M. An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties. Metals. 2018; 8(6):423. https://doi.org/10.3390/met8060423

Chicago/Turabian StyleSaboori, Abdollah, Mehran Dadkhah, Paolo Fino, and Matteo Pavese. 2018. "An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties" Metals 8, no. 6: 423. https://doi.org/10.3390/met8060423

APA StyleSaboori, A., Dadkhah, M., Fino, P., & Pavese, M. (2018). An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties. Metals, 8(6), 423. https://doi.org/10.3390/met8060423