Serrated Flow and Work-Hardening Behavior of China Low Activation Martensitic Steel (CLAM)

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

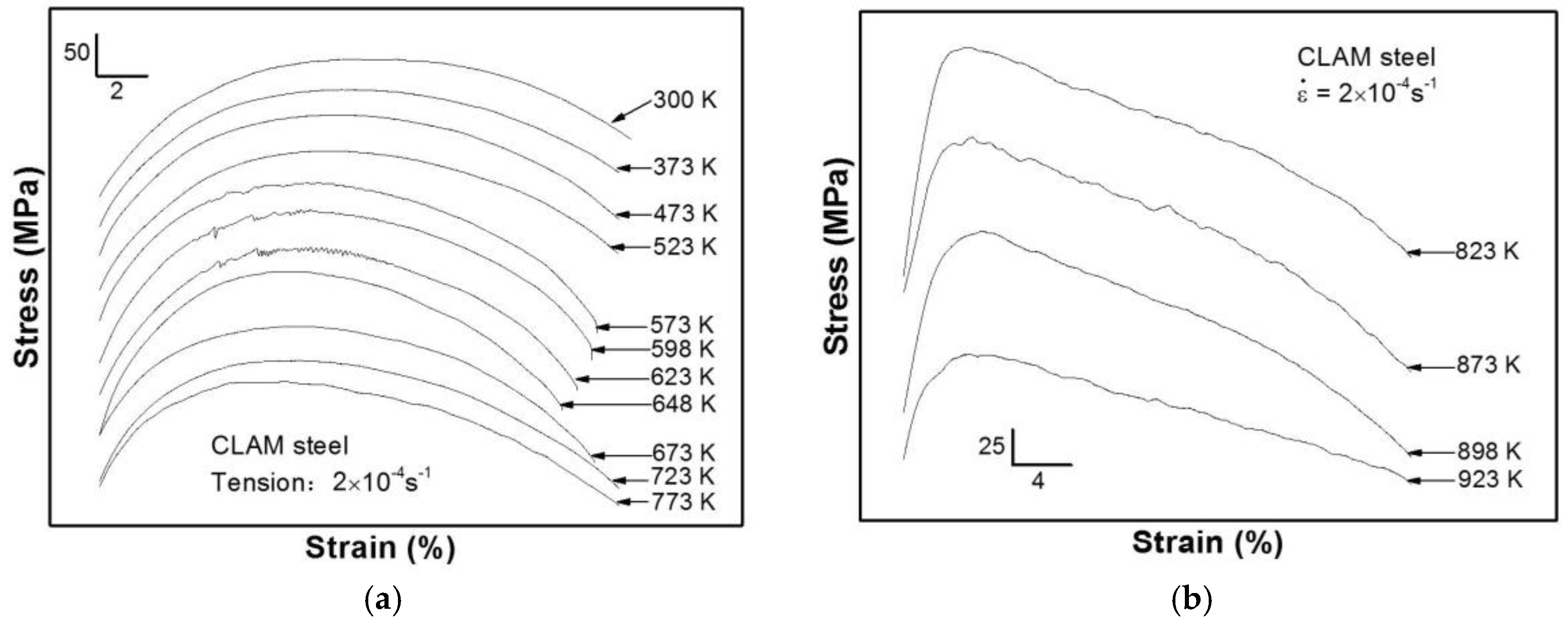

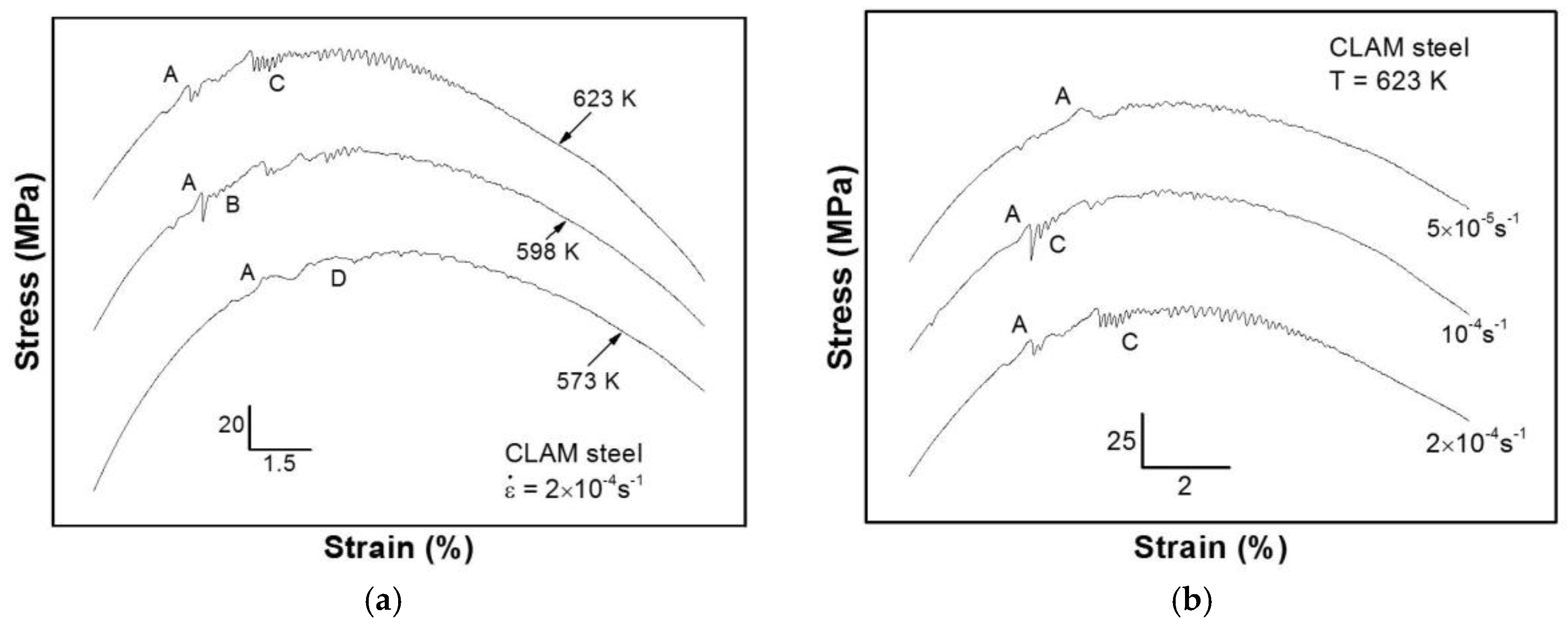

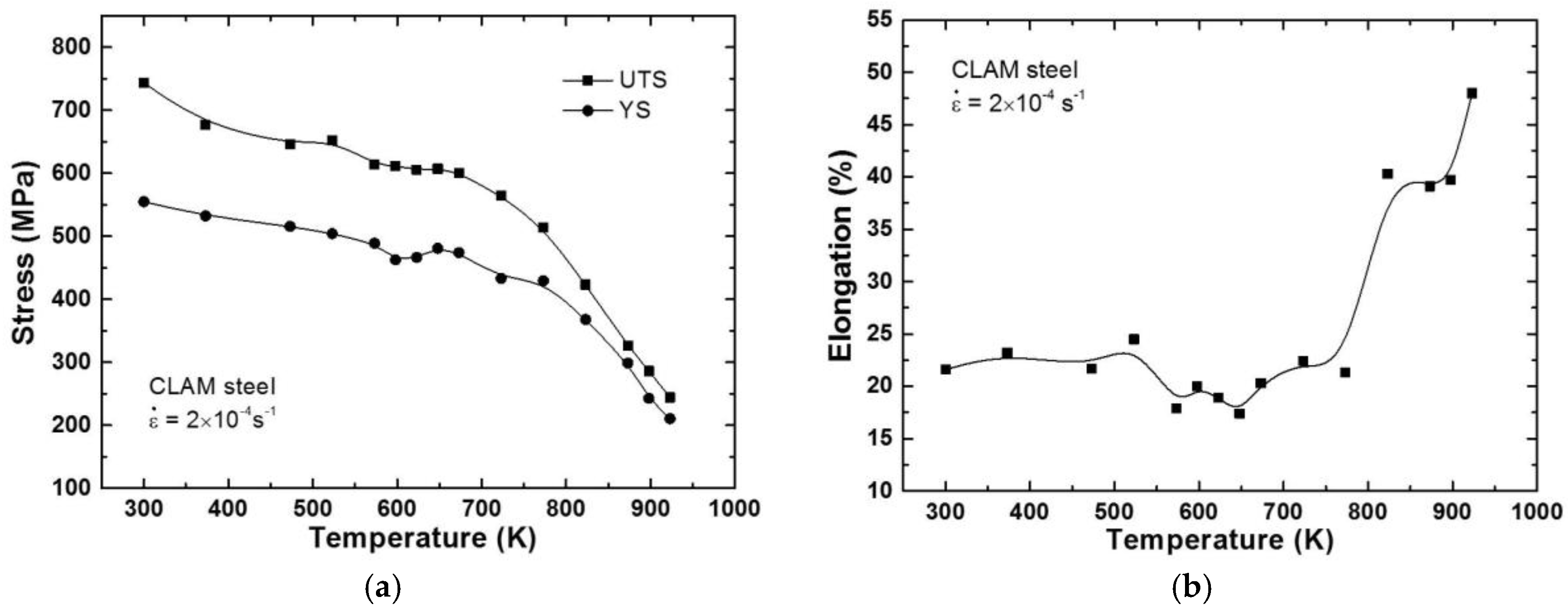

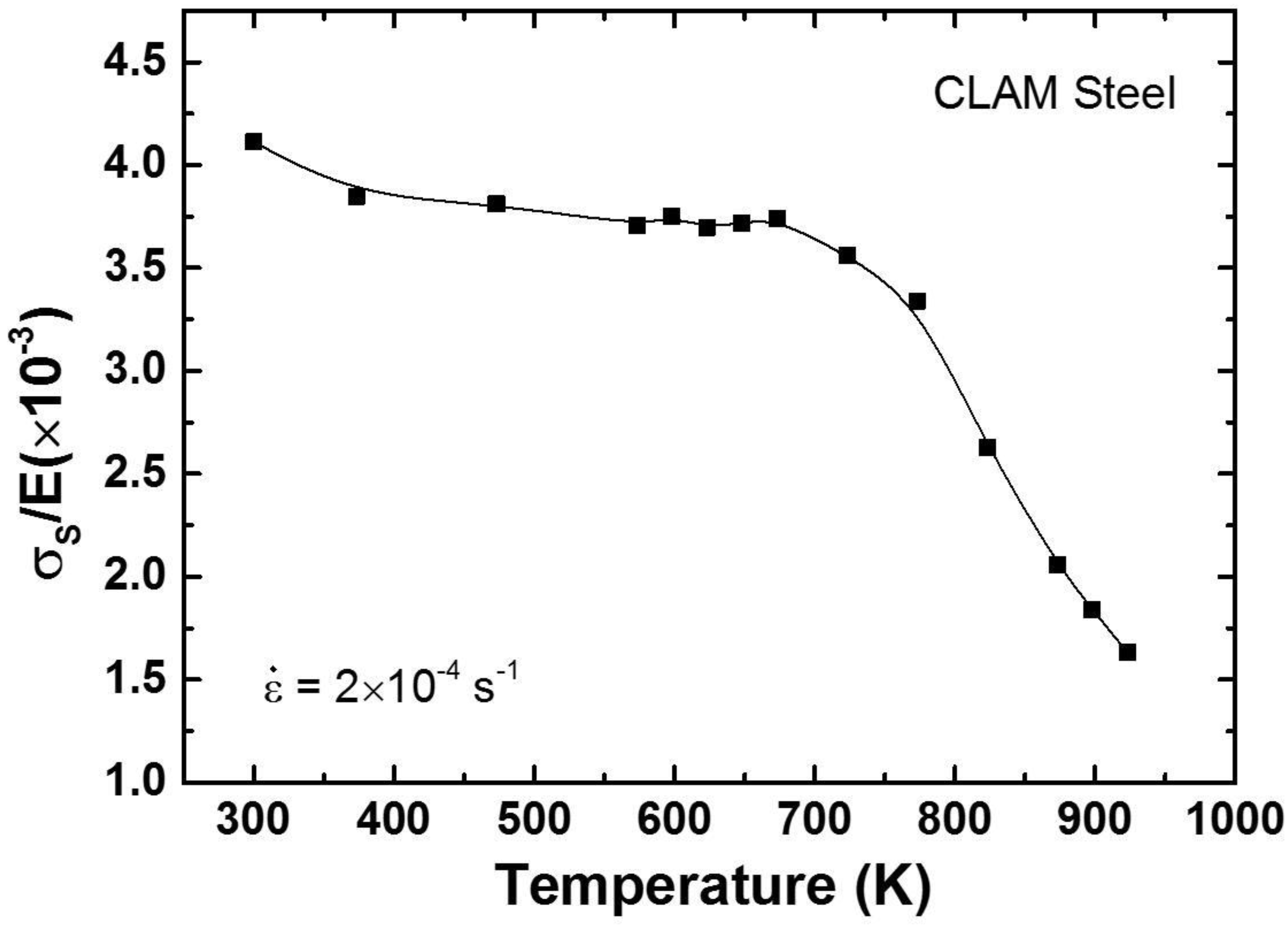

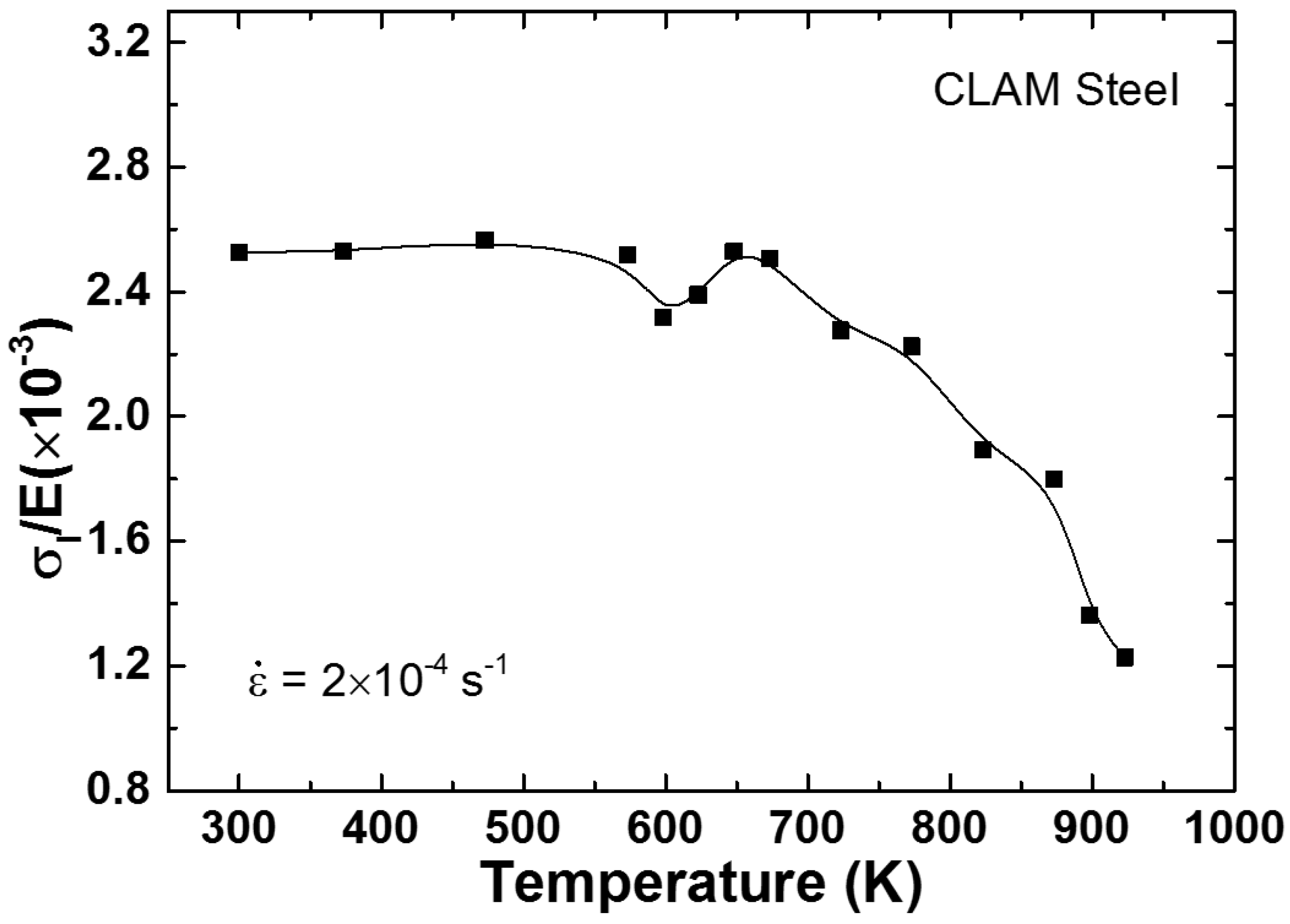

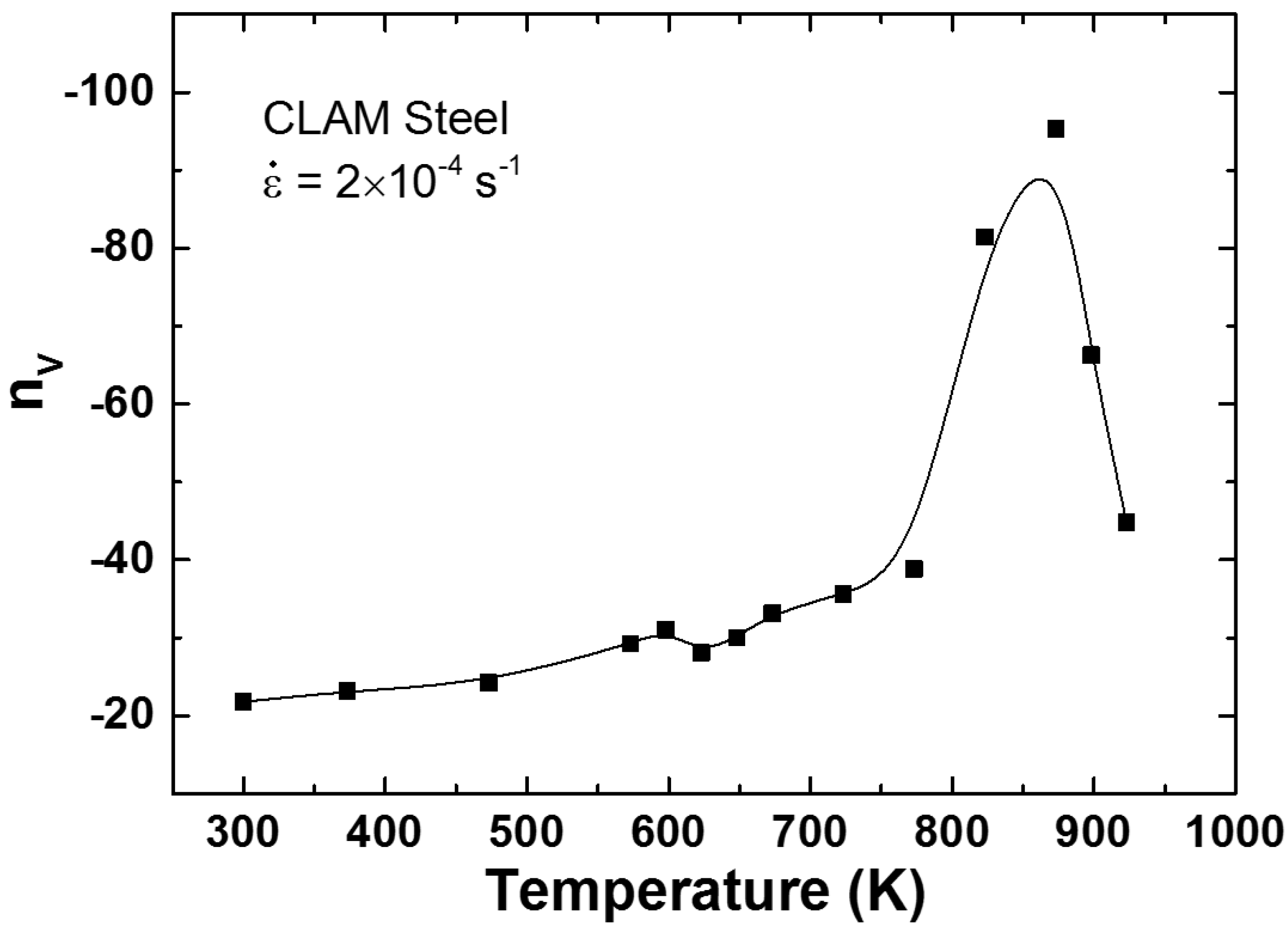

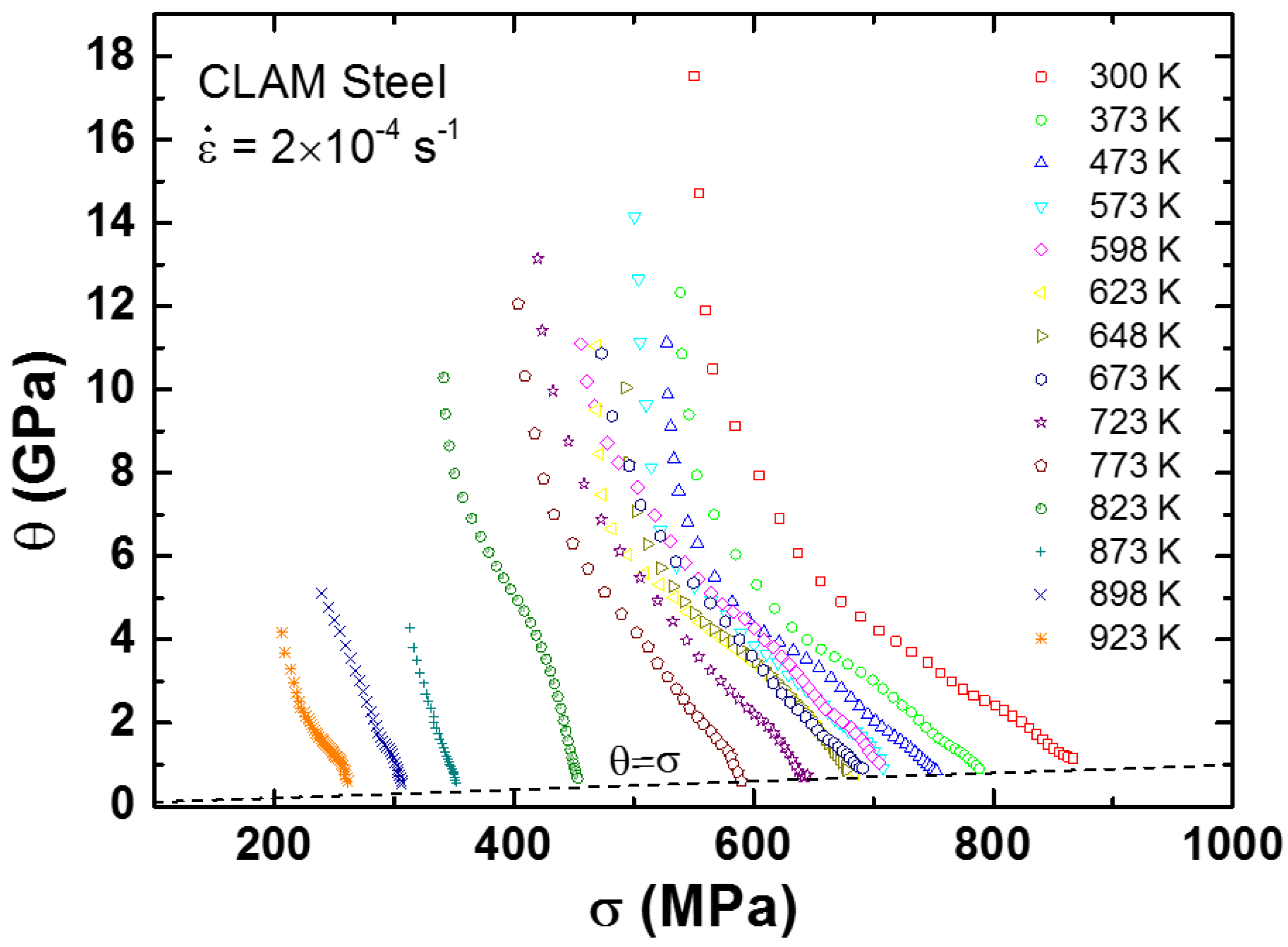

3.1. Serrated Flow Behavior

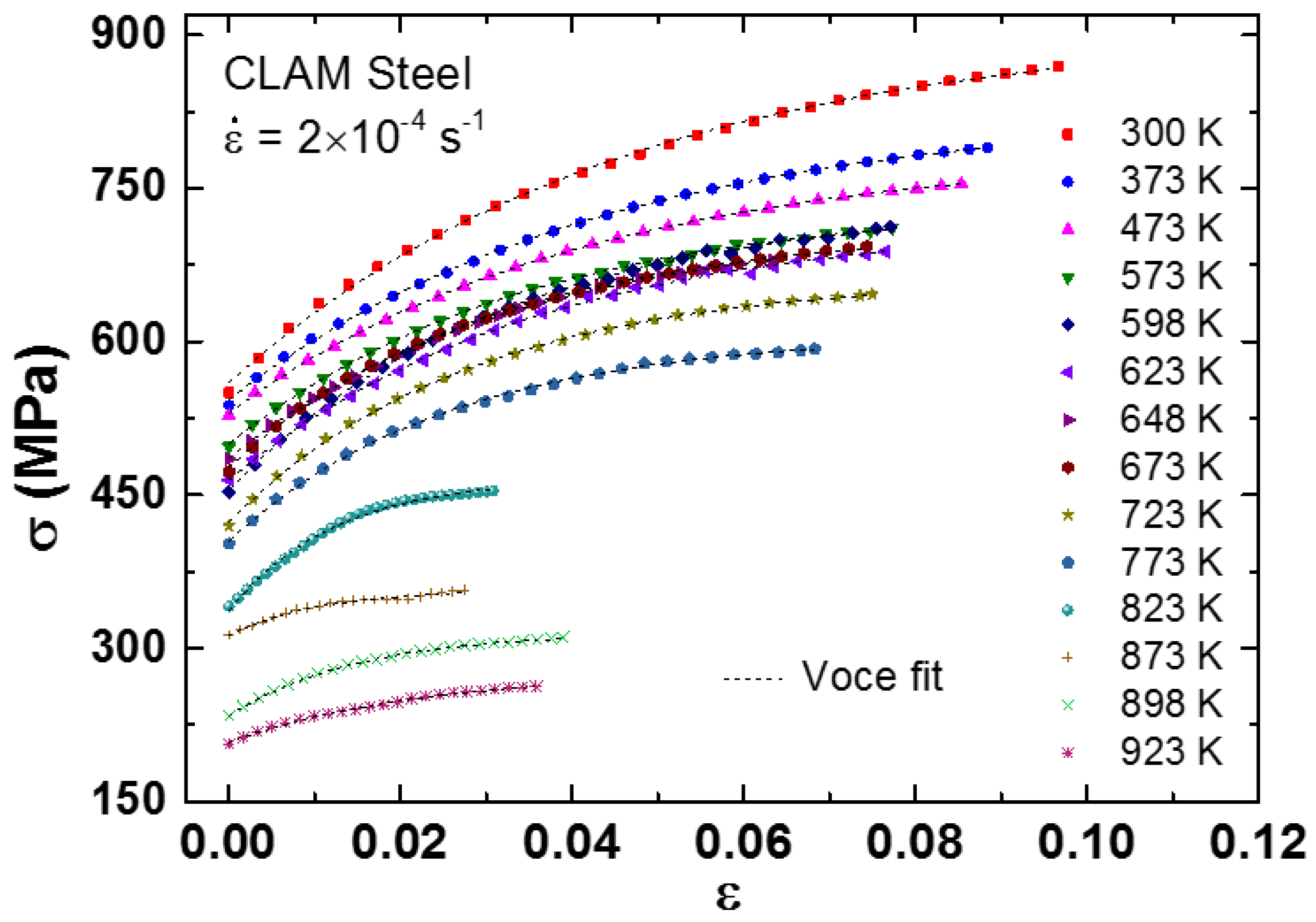

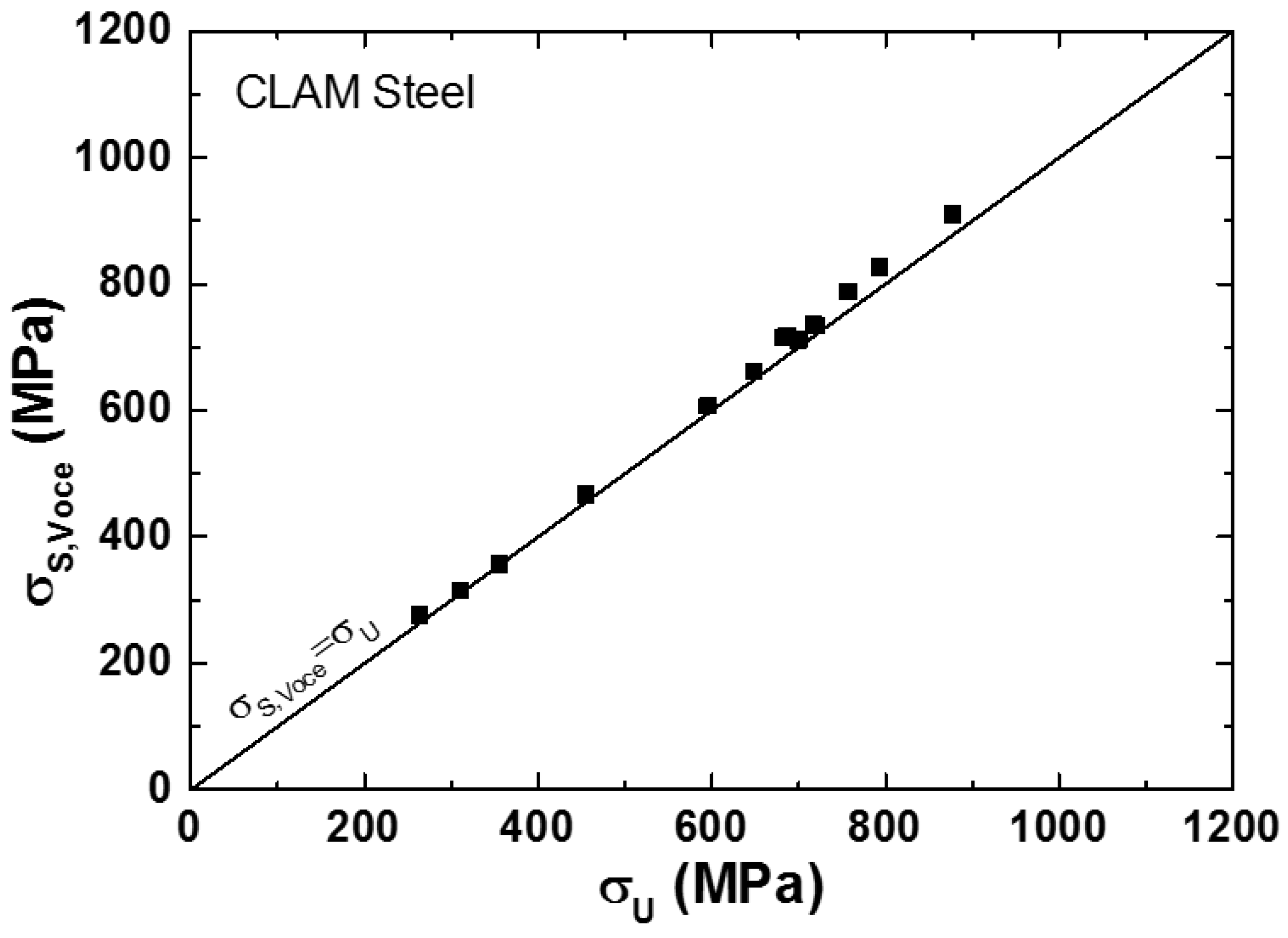

3.2. Work Hardening Behavior

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bloom, E.E.; Zinkle, S.J.; Wiffen, F.W. Materials to deliver the promise of fusionpower-progress and challenges. J. Nucl. Mater. 2004, 329–333, 12–19. [Google Scholar] [CrossRef]

- Zinkle, S.J. Advanced materials for fusion technology. Fusion Eng. Des. 2005, 74, 31–40. [Google Scholar] [CrossRef]

- Liu, F.; Yao, M. Assessment of thermo-mechanical behavior in CLAM steel first wall structures. Fusion Eng. Des. 2012, 87, 1–6. [Google Scholar] [CrossRef]

- Huang, Q.; Li, J.; Chen, Y. Study of irradiation effects in China low activation martensitic steel CLAM. J. Nucl. Mater. 2004, 329–333, 268–272. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Samuel, E.I.; Sainath, G.; Christopher, J.; Mathew, M.D. Influence of temperature and strain rate on tensile deformation and fracture behavior of P92 ferritic steel. Metall. Mater. Trans. A 2013, 44, 4979–4992. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Rao, K.B.S.; Mannan, S.L.; Kashyap, B.P. Serrated yielding in 9Cr–1Mo ferritic steel. Mater. Sci. Technol. 1999, 15, 791–797. [Google Scholar] [CrossRef]

- Choudhary, B.K. Influence of strain rate and temperature on serrated flow in 9Cr–1Mo ferritic steel. Mater. Sci. Eng. A 2013, 564, 303–309. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Srinivasan, V.S.; Mathew, M.D. Influence of strain rate and temperature on tensile properties of 9Cr-1Mo ferritic steel. Mater. High Temp. 2011, 28, 155–161. [Google Scholar] [CrossRef]

- Roy, A.K.; Kumar, P.; Maitra, D. Dynamic strain ageing of P91 grade steels of varied silicon content. Mater. Sci. Eng. A 2009, 499, 379–386. [Google Scholar] [CrossRef]

- Keller, C.; Margulies, M.M.; Guillot, I. Experimental analysis of the dynamic strain ageing for a modified T91 martensitic steel. Mater. Sci. Eng. A 2012, 536, 273–275. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Palaparti, D.P.R. Comparative tensile flow and work hardening behaviour of thin section and forged thick section 9Cr–1Mo ferritic steel in the framework of Voce equation and Kocks–Mecking approach. J. Nucl. Mater. 2012, 430, 72–81. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N.; Martínez, S. Behavior of austenitic stainless steels at high speed turning using specific force coefficients. Int. J. Adv. Manuf. Technol. 2012, 62, 505–515. [Google Scholar] [CrossRef]

- Urbikain, G.; Fernández, A.; López de Lacalle, L.N.; Gutiérrez, M.E. Stability lobes for general turning operations with slender tools in the tangential direction. Int. J. Mach. Tool Manuf. 2013, 67, 35–44. [Google Scholar] [CrossRef]

- Martínez Krahmer, D.; Polvorosa, R.; López de Lacalle, L.N.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for Specimen Manufacturing in Tensile Testing of Steel Plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Voce, E. A practical strain hardening function. Metallurgia 1955, 51, 219–226. [Google Scholar]

- Voce, E. The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Hollomon, J.H. Tensile deformation. Trans. AIME 1945, 162, 268–290. [Google Scholar]

- Ludwik, P. Elements der Technologischen Mechanik; Springer-Verlag Berlin Heidelberg GmbH: Leipzig, Germany, 1909; p. 32. ISBN 978-3-662-39265-2. [Google Scholar]

- Ludwigson, D.C. Modified stress-strain relation for FCC metals and alloys. Metall. Trans. 1971, 2, 2825–2828. [Google Scholar] [CrossRef]

- Estrin, Y. Dislocation-density-related constitutive modeling. In Unified Constitutive Laws for Plastic Deformation; Krausz, A.S., Krausz, K., Eds.; Academic Press: San Diego, CA, USA, 1996; pp. 69–106. ISBN 978-0124259706. [Google Scholar]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. Mater. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Kocks, U.F. Laws for work-hardening and low-temperature creep. J. Eng. Mater. Technol. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Palaparti, D.P.R.; Samuel, E.I. Analysis of tensile stress–strain and work-hardening behavior in 9Cr–1Mo ferritic steel. Metall. Mater. Trans. A 2013, 44, 212–223. [Google Scholar] [CrossRef]

- Christopher, J.; Choudhary, B.K.; Samuel, E.I.; Srinivasan, V.S.; Mathew, M.D. Tensile flow and work hardening behaviour of 9Cr-1Mo ferritic steel in the frame work of Voce relationship. Mater. Sci. Eng. A 2011, 528, 6589–6595. [Google Scholar] [CrossRef]

- Sainath, G.; Choudhary, B.K.; Christopher, J.; Samuel, E.I.; Mathew, M.D. Applicability of Voce equation for tensile flow and work hardening behaviour of P92 ferritic steel. Int. J. Pres. Ves. Pip. 2015, 132–133, 1–9. [Google Scholar] [CrossRef]

- Shastry, C.G.; Mathew, M.D.; Rao, K.B.S.; Mannan, S.L. Analysis of elevated temperature flow and work hardening behaviour of service-exposed 2.25Cr-1Mo steel using Voce equation. Int. J. Pres. Ves. Pip. 2004, 81, 297–301. [Google Scholar] [CrossRef]

- Kishore, R.; Sinha, T.K. Analysis of the stress-strain curves of a modified 9Cr-1Mo steel by the voce equation. Metall. Mater. Trans. A 1996, 27, 3340–3343. [Google Scholar] [CrossRef]

- Sivaprasad, P.V.; Venugopal, S.; Venkadesan, S. Tensile Flow and Work-Hardening Behavior of a Ti-Modified Austenitic Stainless Steel. Metall. Mater. Trans. A 1997, 28A, 171–178. [Google Scholar] [CrossRef]

- Samuel, E.I.; Choudhary, B.K.; Rao, K.B.S. Influence of temperature and strain rate on tensile work hardening behaviour of type 316 LN austenitic stainless steel. Scr. Mater. 2002, 46, 507–512. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Christopher, J.; Palaparti, D.P.R.; Samuel, E.I.; Mathew, M.D. Influence of temperature and post weld heat treatment on tensile stress-strain and work hardening behaviour of modified 9Cr-1Mo steel. Mater. Des. 2013, 52, 58–66. [Google Scholar] [CrossRef]

- Podriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Pink, E.; Grinberg, A. Serrated flow in a ferritic stainless steel. Mater. Sci. Eng. 1981, 51, 1–8. [Google Scholar] [CrossRef]

- Vanaja, J.; Laha, K.; Sam, S.; Nandagopal, M.; Selvi, S.P.; Mathew, M.D.; Jayakumar, T.; Kumar, E.R. Influence of strain rate and temperature on tensile properties and flow behavior of a reduced activation ferritic-martensitic steel. J. Nucl. Mater. 2012, 424, 116–122. [Google Scholar] [CrossRef]

- Vanaja, J.; Laha, K.; Nandagopal, M.; Sam, S.; Mathew, M.D.; Jayakumar, T.; Kumar, E.R. Effect of tungsten on tensile properties and flow behaviour of RAFM steel. J. Nucl. Mater. 2013, 433, 412–418. [Google Scholar] [CrossRef]

- McCormick, P.G. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

| C | N | Si | O | S | P | B | Mn | Cr | W | Ta | V | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.097 | 0.0092 | 0.056 | 0.004 | 0.0019 | 0.003 | 0.0012 | 0.49 | 8.85 | 1.47 | 0.12 | 0.21 | 0.01 |

| Temperature (K) | 300 | 373 | 473 | 573 | 598 | 623 | 648 |

| Reduced χ2 | 8.92 | 2.34 | 0.68 | 1.36 | 3.36 | 4.35 | 0.75 |

| Temperature (K) | 673 | 723 | 773 | 823 | 873 | 898 | 923 |

| Reduced χ2 | 2.41 | 2.39 | 2.72 | 5.02 | 2.32 | 0.19 | 1.14 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Shen, Y. Serrated Flow and Work-Hardening Behavior of China Low Activation Martensitic Steel (CLAM). Metals 2018, 8, 413. https://doi.org/10.3390/met8060413

Xu Z, Shen Y. Serrated Flow and Work-Hardening Behavior of China Low Activation Martensitic Steel (CLAM). Metals. 2018; 8(6):413. https://doi.org/10.3390/met8060413

Chicago/Turabian StyleXu, Zhiqiang, and Yinzhong Shen. 2018. "Serrated Flow and Work-Hardening Behavior of China Low Activation Martensitic Steel (CLAM)" Metals 8, no. 6: 413. https://doi.org/10.3390/met8060413