The Effect of Impingement Velocity and Angle Variation on the Erosion Corrosion Performance of API 5L-X65 Carbon Steel in a Flow Loop

Abstract

:1. Introduction

2. Experimental Procedure

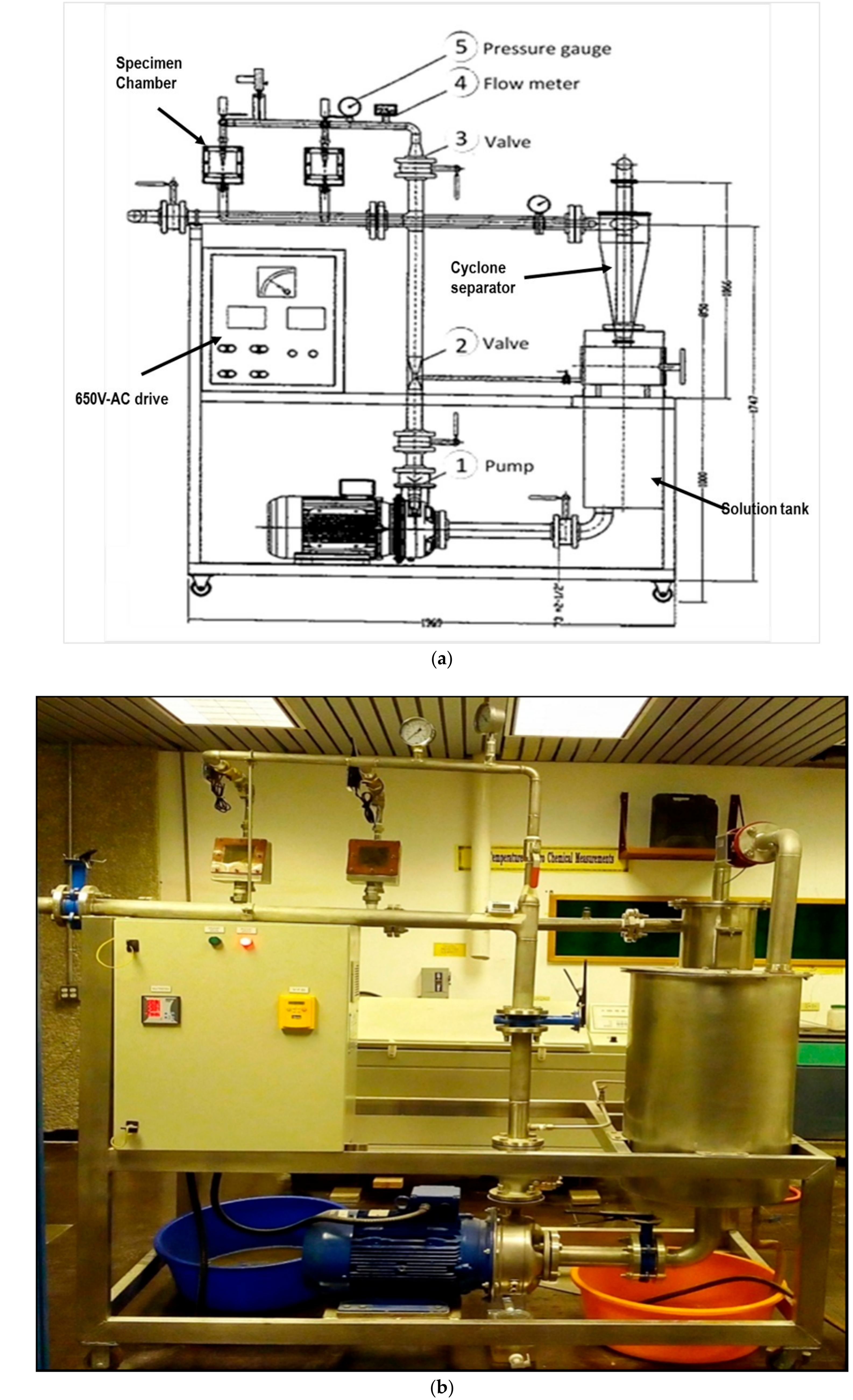

2.1. Erosion-Corrosion Test Apparatus

2.2. Test Specimens and Sand Particle Characterization

2.3. Test Procedure

3. Results and Discussion

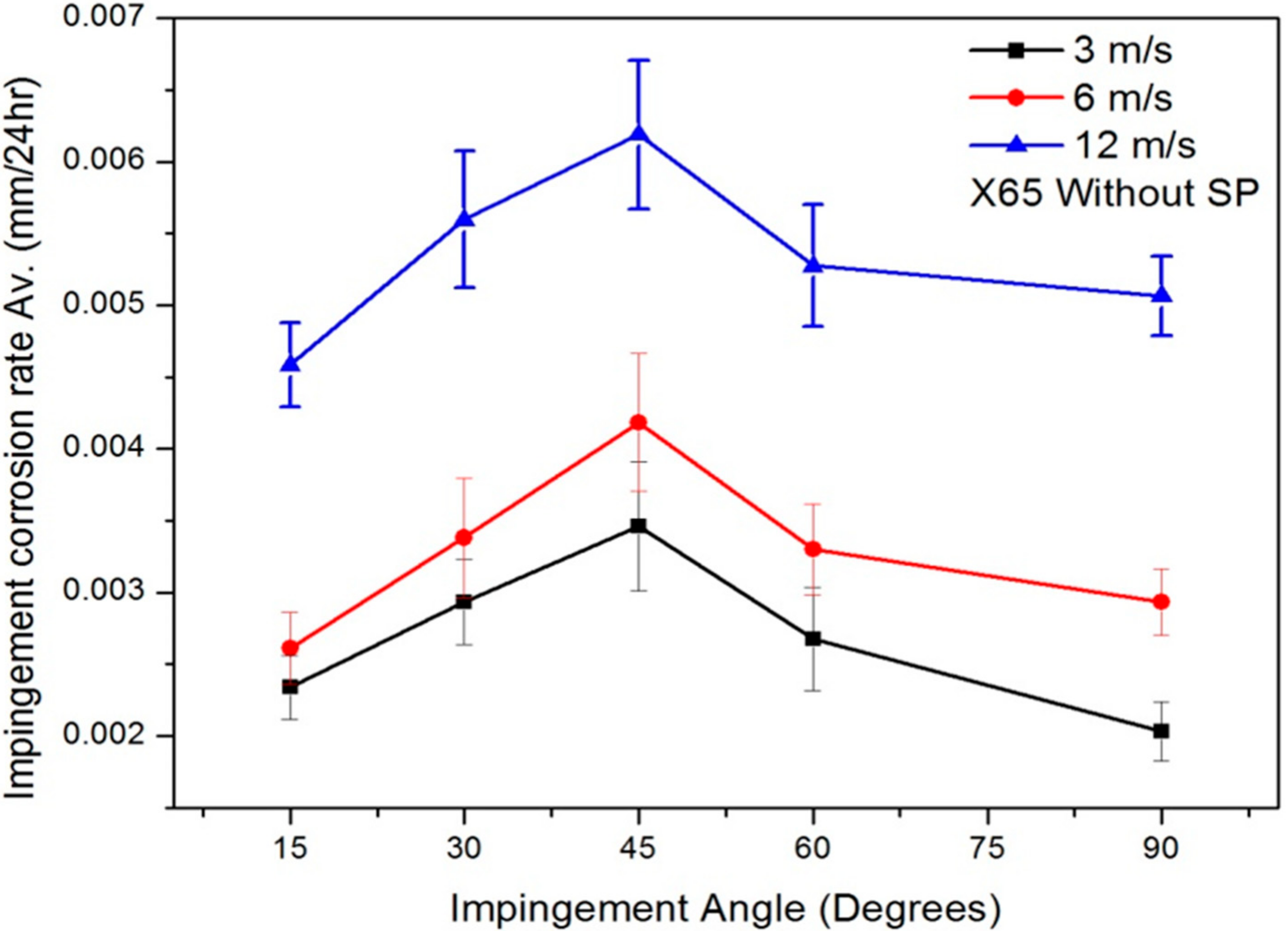

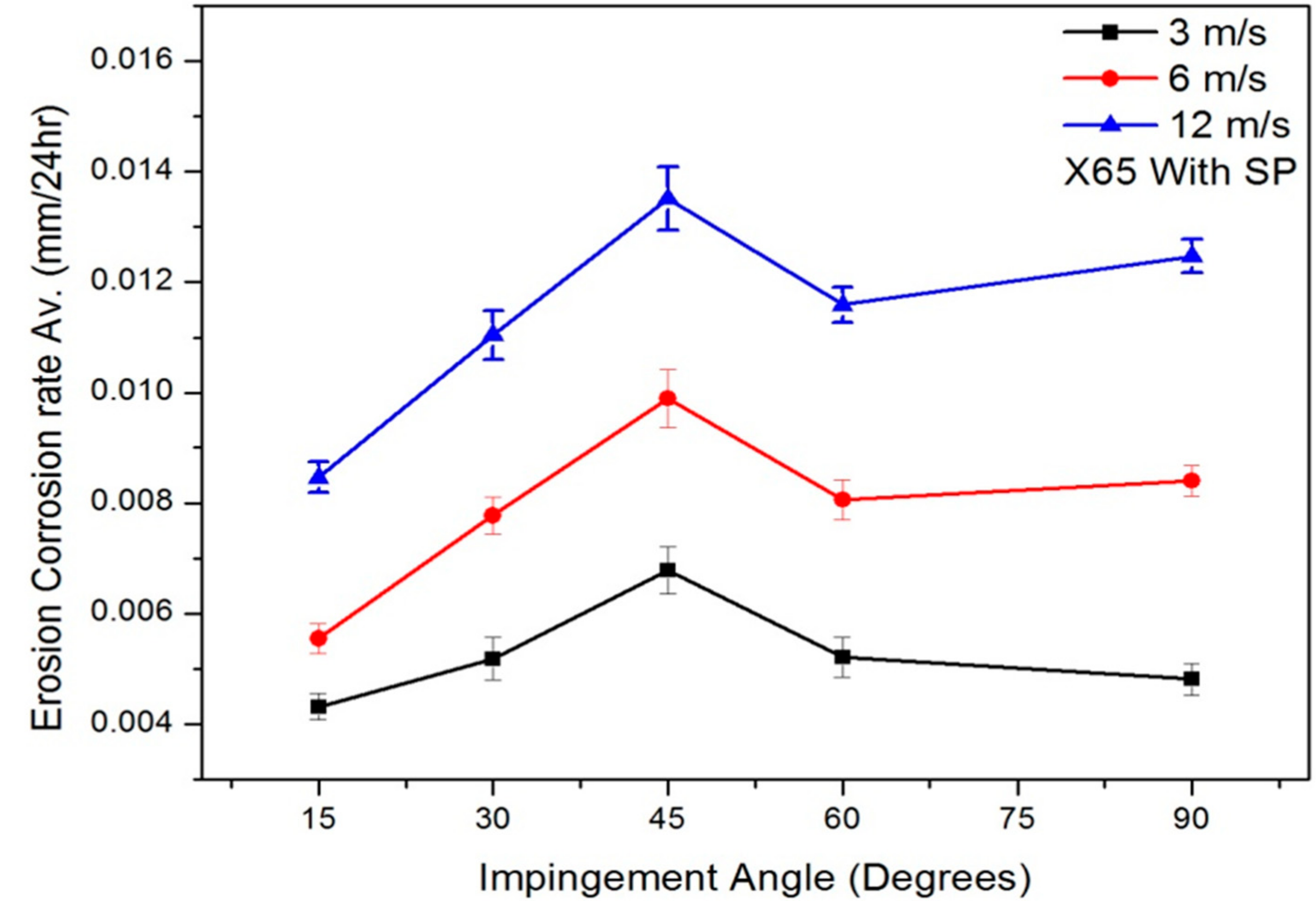

3.1. Effect of Impact Angle and Velocity on Corrosion Rate

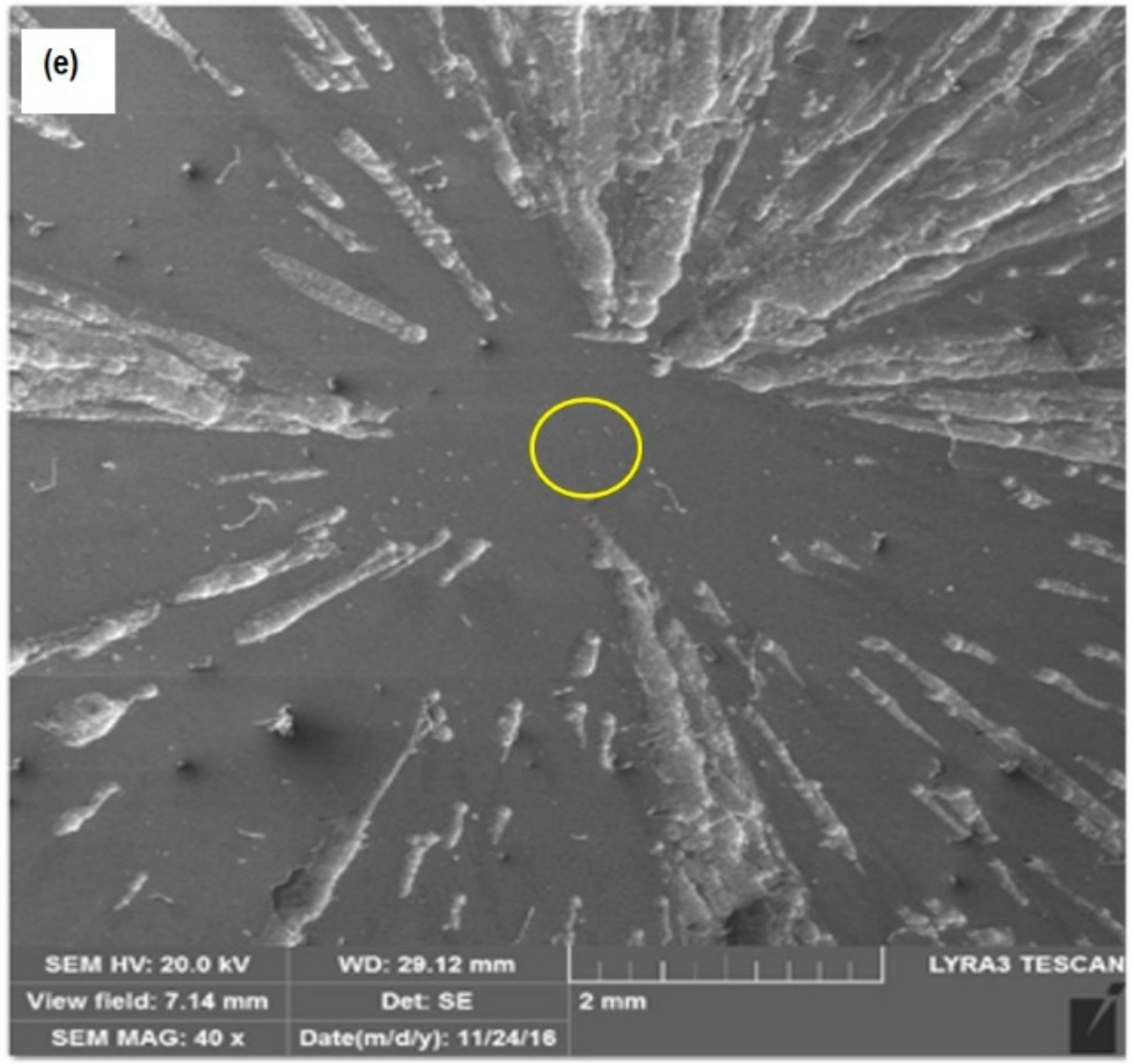

Surface Morphology of Corroded Surfaces

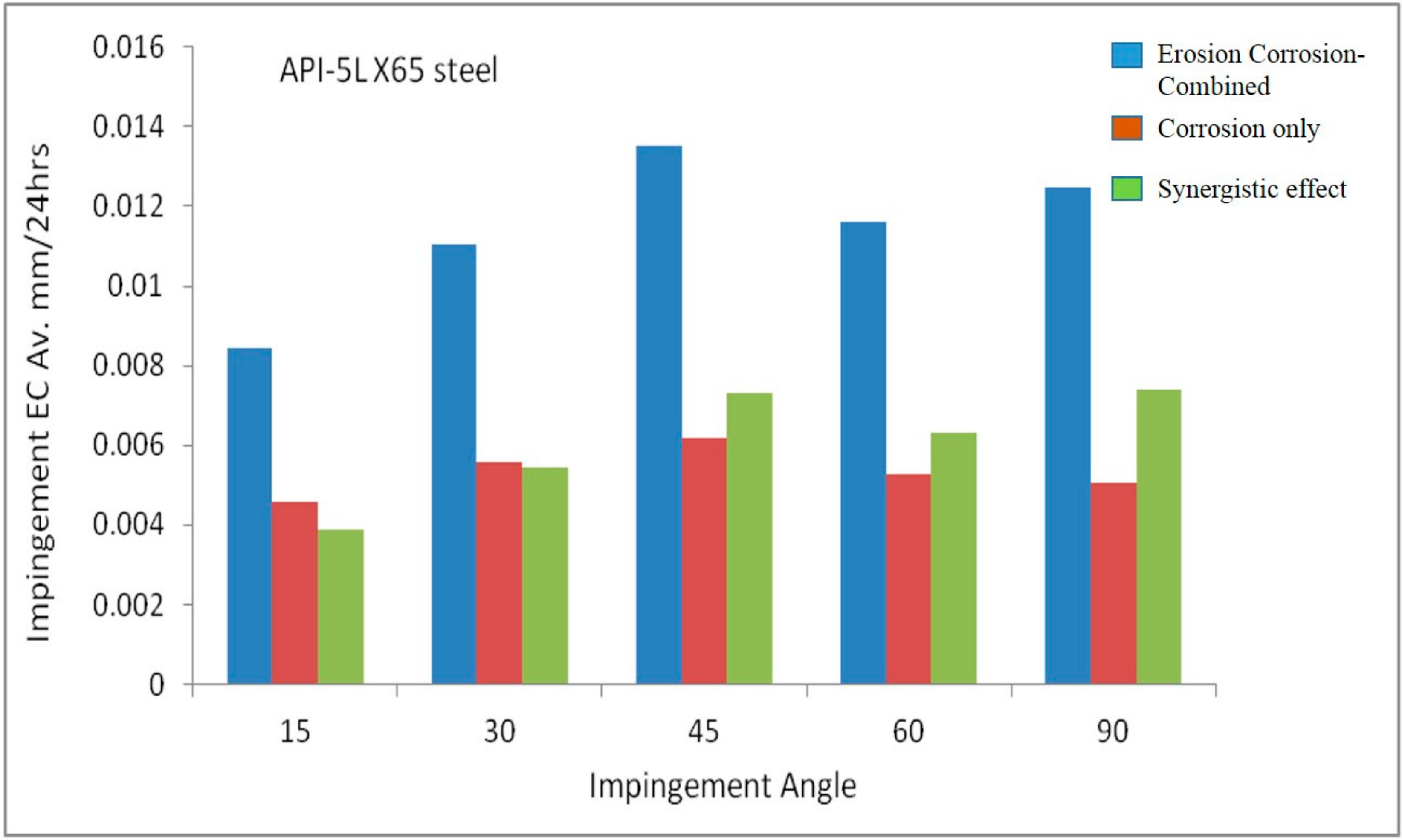

3.2. Erosion Corrosion and Mechanism

3.3. Correlation with Erosion Corrosion Model

3.4. Effect of Erosion on Corrosion

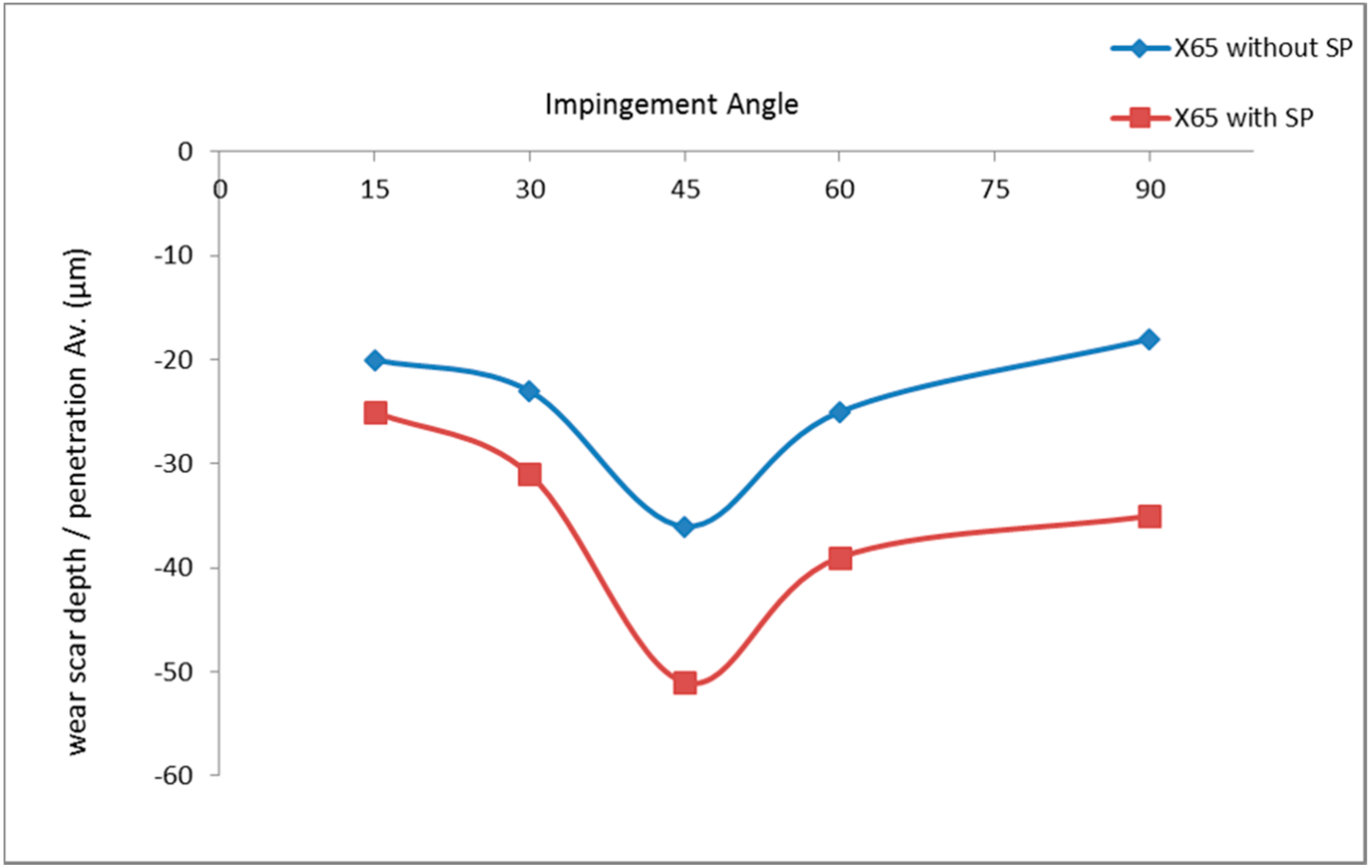

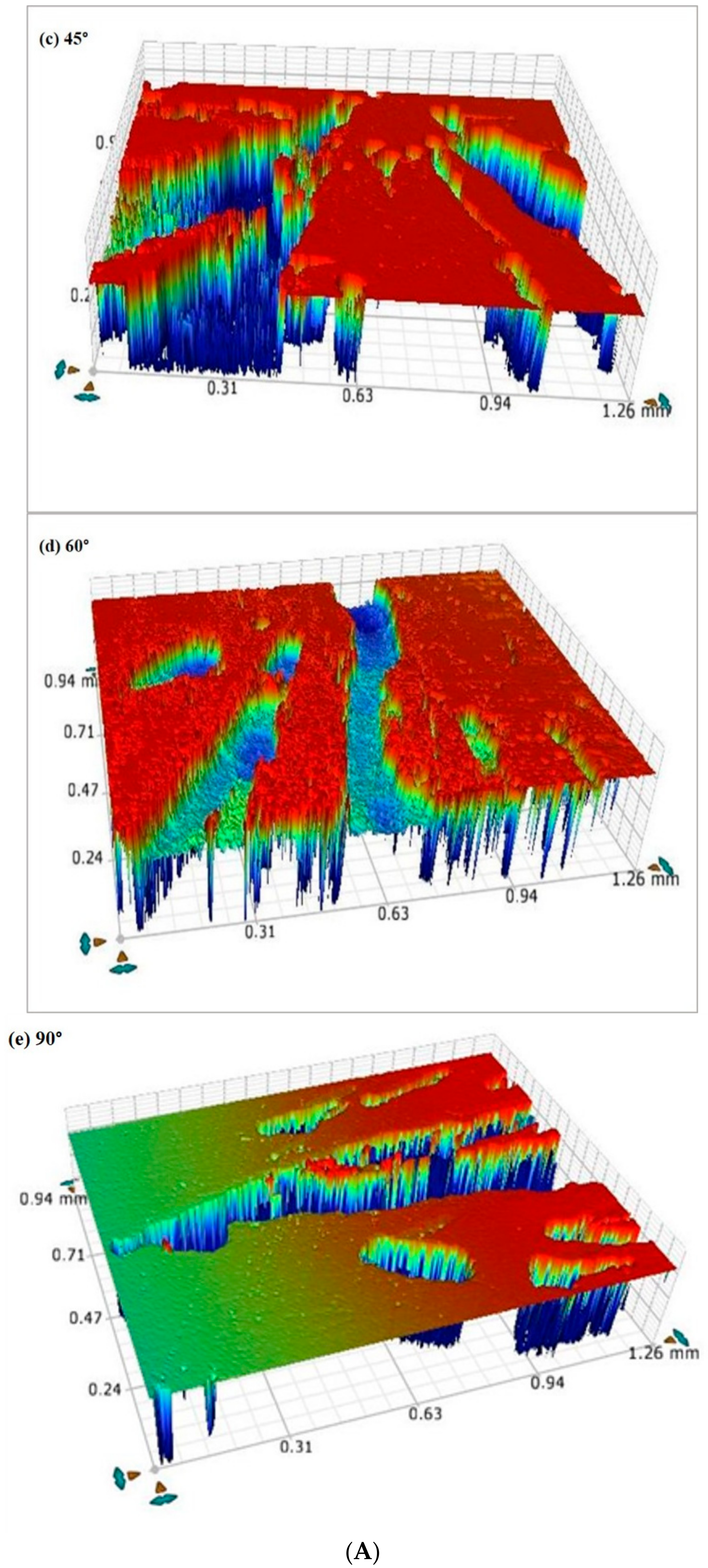

3.5. Wear Scar Penetration Depths Using Optical Profilometer

4. Conclusions

- The maximum corrosion and erosion corrosion rates were observed at 45° angle due to a balance between shearing force and normal impact force. However the synergistic effect at 45° and 90° angle was more significant as compared to other angles.

- The effect of erosion on corrosion is quite significant as striking solid particles cut the surface and activate the localised sites and thus accelerate the corrosion damage.

- Corrosion and erosion corrosion rate was increased with an increase in the impingement velocity. This was mainly due to high shear and normal impact stresses in the absence of solid particles and due to the high kinetic energy in the presence of solid particles causing more mass loss.

- Ploughing, elongated erosion scars, and metal cutting were the dominant erosion corrosion mechanisms at oblique angles, whereas extrusion, flattening of ridges and fracture were dominant at high angles.

- The corrosion product or oxide layer was not stable under these severe conditions of high velocity fluid impingement which resulted in more material loss.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fontana, M.G. Corrosion Engineering; Tata McGraw-Hill Education: New York, NY, USA, 2005. [Google Scholar]

- Levy, A.V. Solid Particle Erosion and Erosion-Corrosion of Materials; ASM International: Geauga County, OH, USA, 1995. [Google Scholar]

- Heidersbach, R. Metallurgy and Corrosion Control in Oil and Gas Production; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Pasha, A.; Ghasemi, H.; Neshati, J. Synergistic Erosion–Corrosion Behavior of X-65 Carbon Steel at Various Impingement Angles. J. Tribol. 2017, 139, 011105. [Google Scholar] [CrossRef]

- Neville, A.; Reyes, M.; Xu, H. Examining corrosion effects and corrosion/erosion interactions on metallic materials in aqueous slurries. Tribol. Int. 2002, 35, 643–650. [Google Scholar] [CrossRef]

- Javaherdashti, R.; Nwaoha, C.; Tan, H. Corrosion and Materials in the Oil and Gas Industries; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Levy, A. Erosion and erosion-corrosion of metals. Corrosion 1995, 51, 872–883. [Google Scholar] [CrossRef]

- Liang, G. Erosion-corrosion of carbon steel pipes in oil sands slurry studied by weight-loss testing and CFD simulation. J. Mater. Eng. Perform. 2013, 22, 3043–3048. [Google Scholar] [CrossRef]

- Mazumder, Q.H. Prediction of Erosion due to solid particle Impact in Single-Phase and Multiphase Flows. J. Press. Vessel Technol. 2007, 129, 576–582. [Google Scholar] [CrossRef]

- Giourntas, L.; Hodgkiess, T.; Galloway, A. Enhanced approach of assessing the corrosive wear of engineering materials under impingement. Wear 2015, 338, 155–163. [Google Scholar] [CrossRef] [Green Version]

- Sasaki, K.; Burstein, G. Erosion-corrosion of stainless steel under impingement by a fluid jet. Corros. Sci. 2007, 49, 92–102. [Google Scholar] [CrossRef]

- Khan, M.I.; Yasmin, T. Erosion-Corrosion of Low Carbon (AISI 1008 Steel) Ring Gasket Under Dynamic High Pressure CO2 Environment. J. Fail. Anal. Prev. 2014, 14, 537–548. [Google Scholar] [CrossRef]

- Barker, R.; Hu, X.; Neville, A.; Cushnaghan, S. Flow-induced corrosion and erosion-corrosion assessment of carbon steel pipework in oil and gas production. Corrosion 2013, 69, 193–203. [Google Scholar] [CrossRef]

- Neville, A.; Hodgkiess, T.; Xu, H. An electrochemical and microstructural assessment of erosion—Corrosion of cast iron. Wear 1999, 233, 523–534. [Google Scholar] [CrossRef]

- Neville, A.; Hodgkiess, T.; Dallas, J. A study of the erosion-corrosion behaviour of engineering steels for marine pumping applications. Wear 1995, 186, 497–507. [Google Scholar] [CrossRef]

- Jingjun, L.; Yuzhen, L.; Xiaoyu, L. Numerical simulation for carbon steel flow-induced corrosion in high-velocity flow seawater. Anti-Corros. Methods Mater. 2008, 55, 66–72. [Google Scholar] [CrossRef]

- Guanghong, Z.; Hongyan, D.; Yue, Z.; Nianlian, L. Corrosion-erosion wear behaviors of 13Cr24Mn0.44N stainless steel in saline-sand slurry. Tribol. Int. 2010, 43, 891–896. [Google Scholar] [CrossRef]

- Lin, F.; Shao, H. Effect of impact velocity on slurry erosion and a new design of a slurry erosion tester. Wear 1991, 143, 231–240. [Google Scholar] [CrossRef]

- Finnie, I.; Kabil, Y. On the formation of surface ripples during erosion. Wear 1965, 8, 60–69. [Google Scholar] [CrossRef]

- Wong, C.Y. Predicting the material loss around a hole due to sand erosion. Wear 2012, 276, 1–15. [Google Scholar] [CrossRef]

- Sundararajan, G.; Shewmon, P. A new model for the erosion of metals at normal incidence. Wear 1983, 84, 237–258. [Google Scholar] [CrossRef]

- Hutchings, I. A model for the erosion of metals by spherical at normal incidence. Wear 1981, 70, 269–281. [Google Scholar] [CrossRef]

- Chen, X.; McLaury, B.S.; Shirazi, S.A. Application and experimental validation of a computational fluid dynamics (CFD) based erosion prediction model in elbows and plugged tees. Comput. Fluids 2004, 33, 1251–1272. [Google Scholar] [CrossRef]

- Nguyen, B.Q.; Nguyen, V.B.; Lim, C.Y.; Gupta, L.M. Effect of impact angle and testing time on erosion of stainless steel at higher velocities. Wear 2014, 321, 87–93. [Google Scholar] [CrossRef]

- Ige, O.; Umoru, L. Effects of shear stress on the erosion-corrosion behaviour of X-65 carbon steel: A combined mass-loss and profilometry study. Tribol. Int. 2016, 94, 155–164. [Google Scholar] [CrossRef]

| Elements | C | Mn | Fe | Cu | Mo | Ni | Cr | S | V | Co | P |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% Compositions | 0.165 | 1.29 | 98.1 | 0.0548 | 0.0092 | 0.0183 | 0.0275 | 0.0062 | 0.0076 | 0.0063 | 0.0015 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toor, I.U.; Irshad, H.M.; Badr, H.M.; Samad, M.A. The Effect of Impingement Velocity and Angle Variation on the Erosion Corrosion Performance of API 5L-X65 Carbon Steel in a Flow Loop. Metals 2018, 8, 402. https://doi.org/10.3390/met8060402

Toor IU, Irshad HM, Badr HM, Samad MA. The Effect of Impingement Velocity and Angle Variation on the Erosion Corrosion Performance of API 5L-X65 Carbon Steel in a Flow Loop. Metals. 2018; 8(6):402. https://doi.org/10.3390/met8060402

Chicago/Turabian StyleToor, Ihsan UlHaq, Hafiz Muzammil Irshad, Hassan Mohamed Badr, and Mohammed Abdul Samad. 2018. "The Effect of Impingement Velocity and Angle Variation on the Erosion Corrosion Performance of API 5L-X65 Carbon Steel in a Flow Loop" Metals 8, no. 6: 402. https://doi.org/10.3390/met8060402