The Fabrication of All-Solid-State Lithium-Ion Batteries via Spark Plasma Sintering

Abstract

:1. Introduction

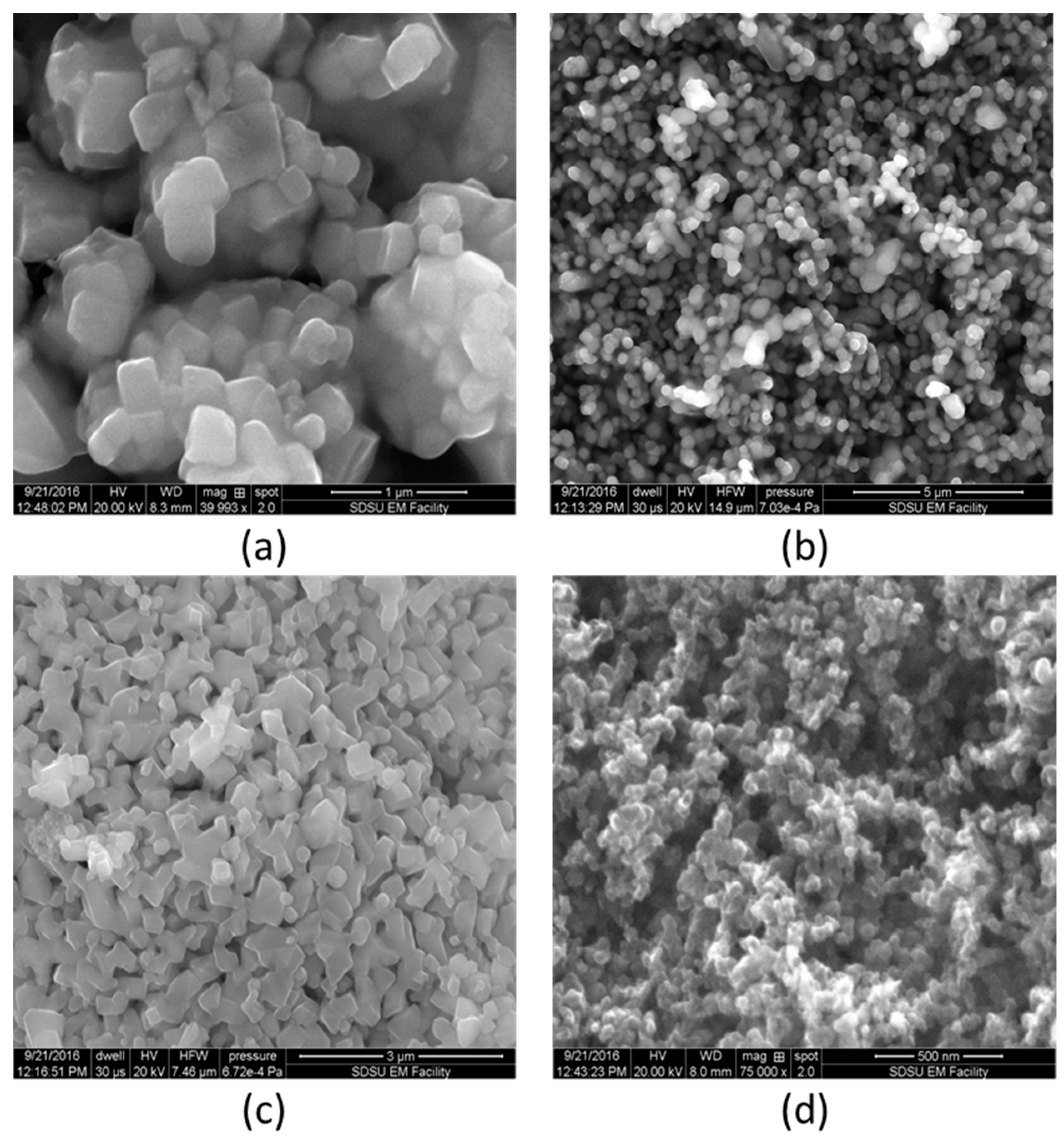

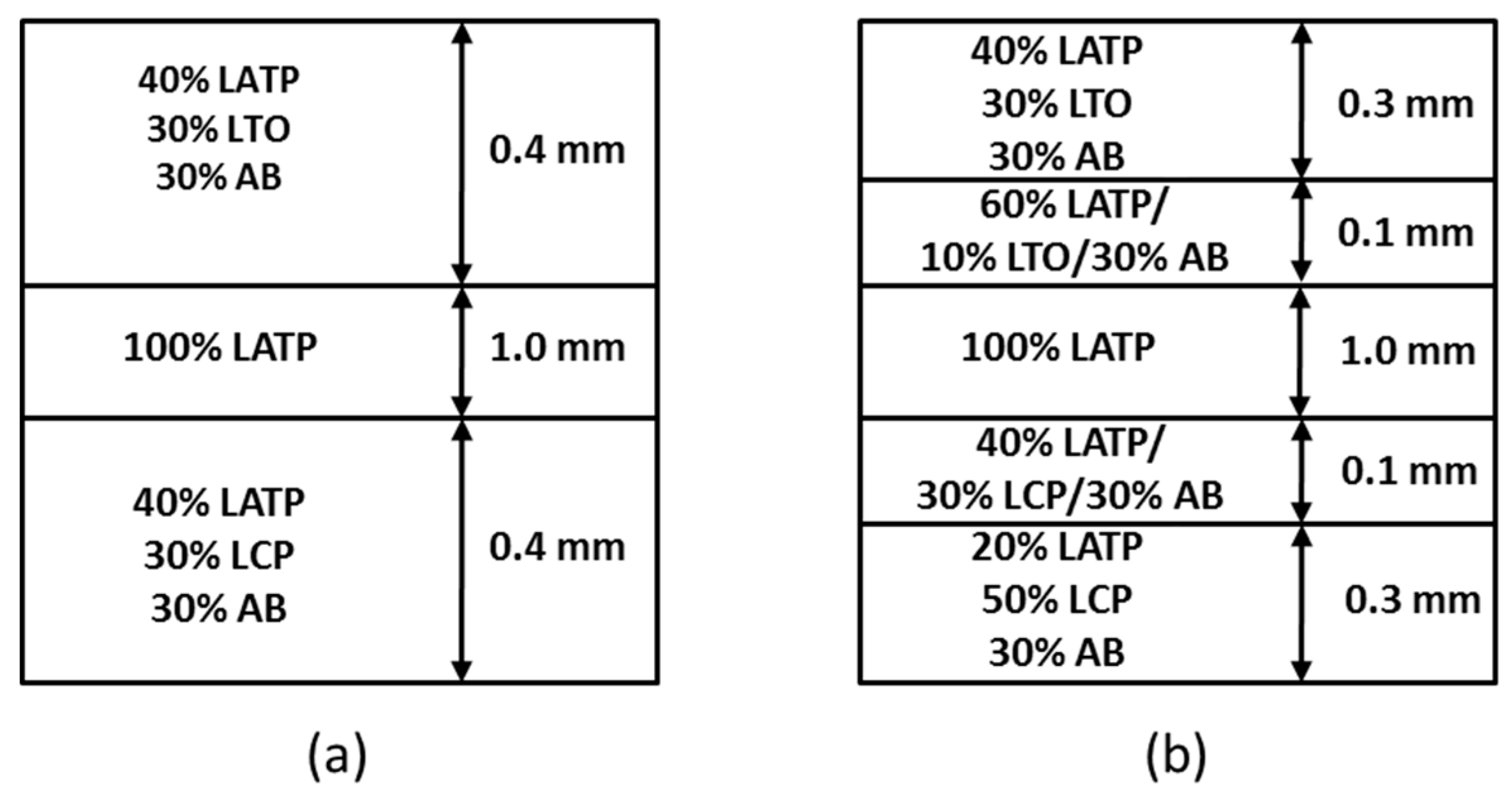

2. Materials and Methods

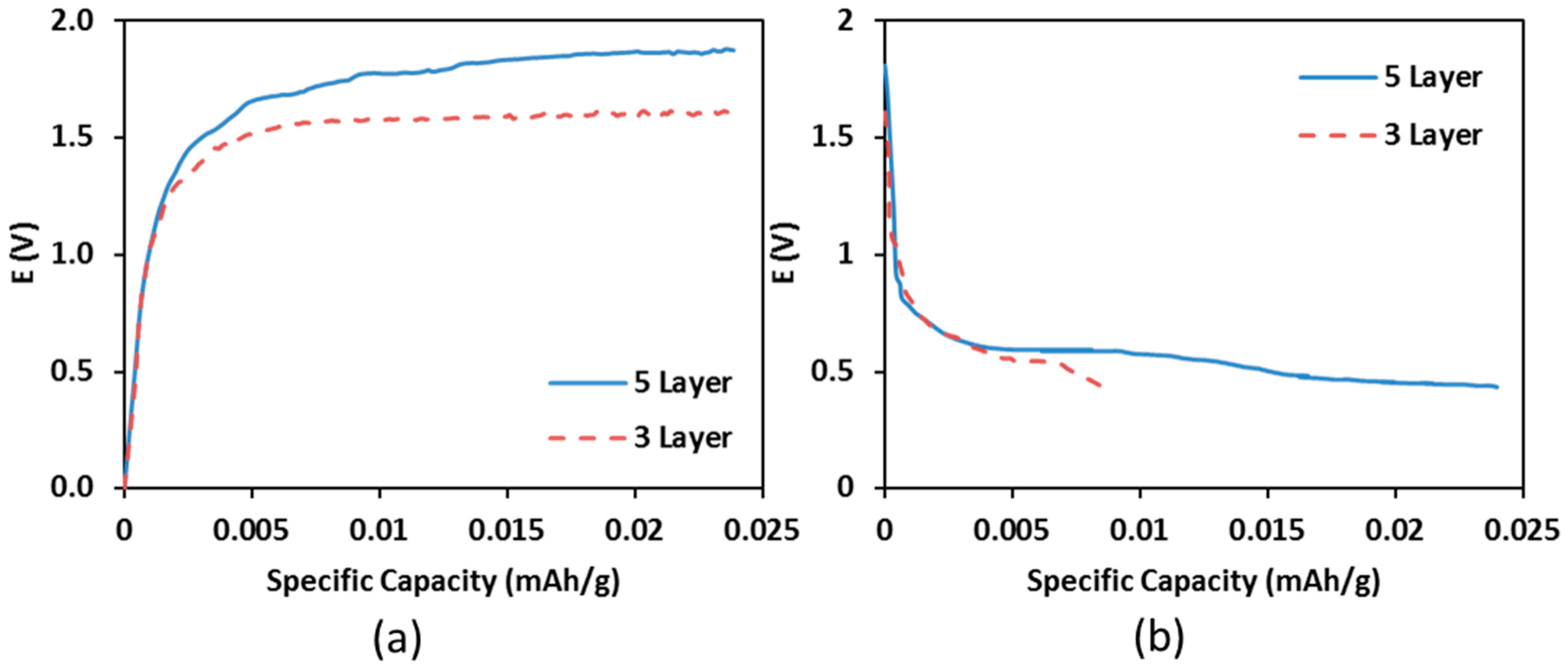

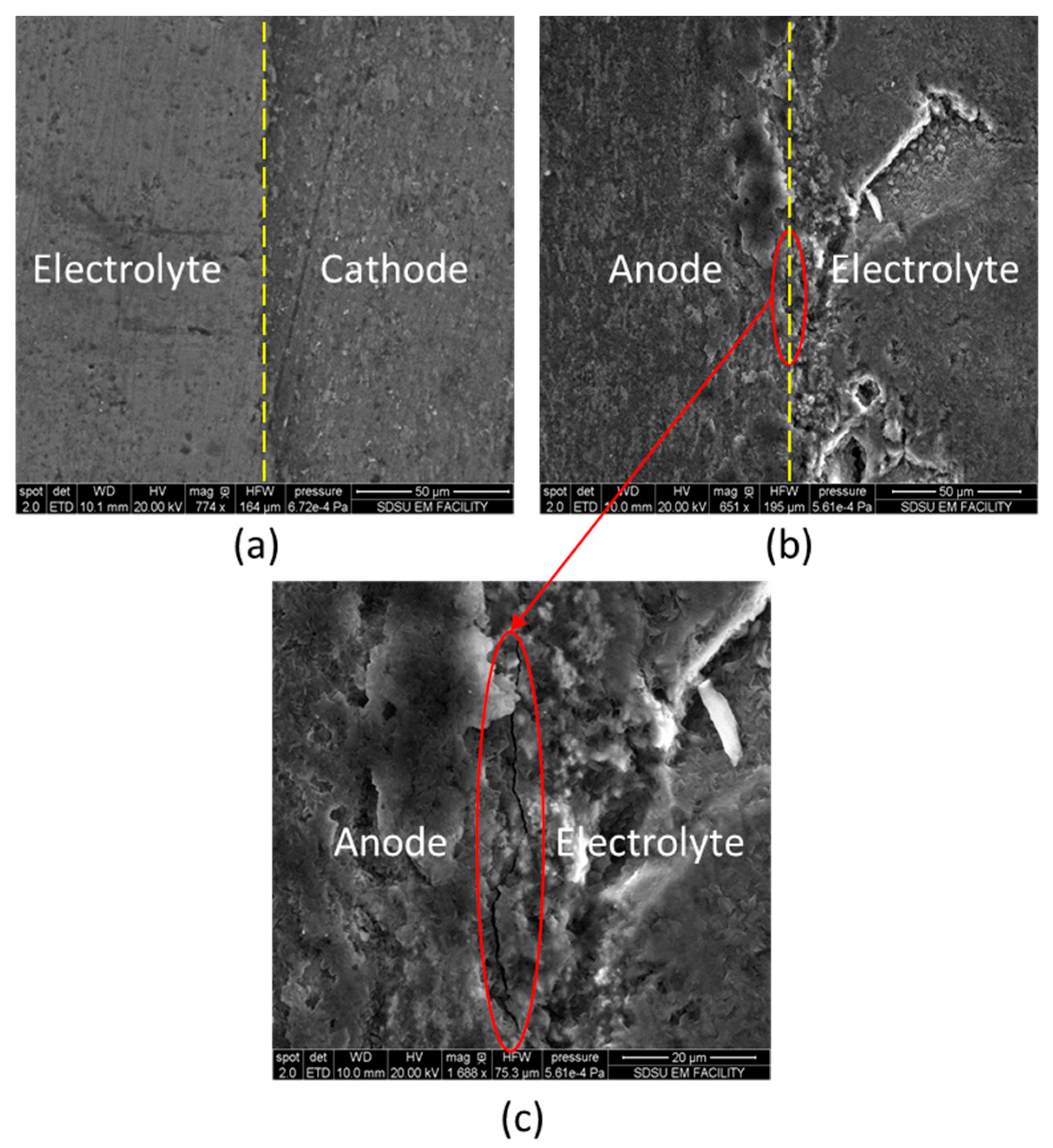

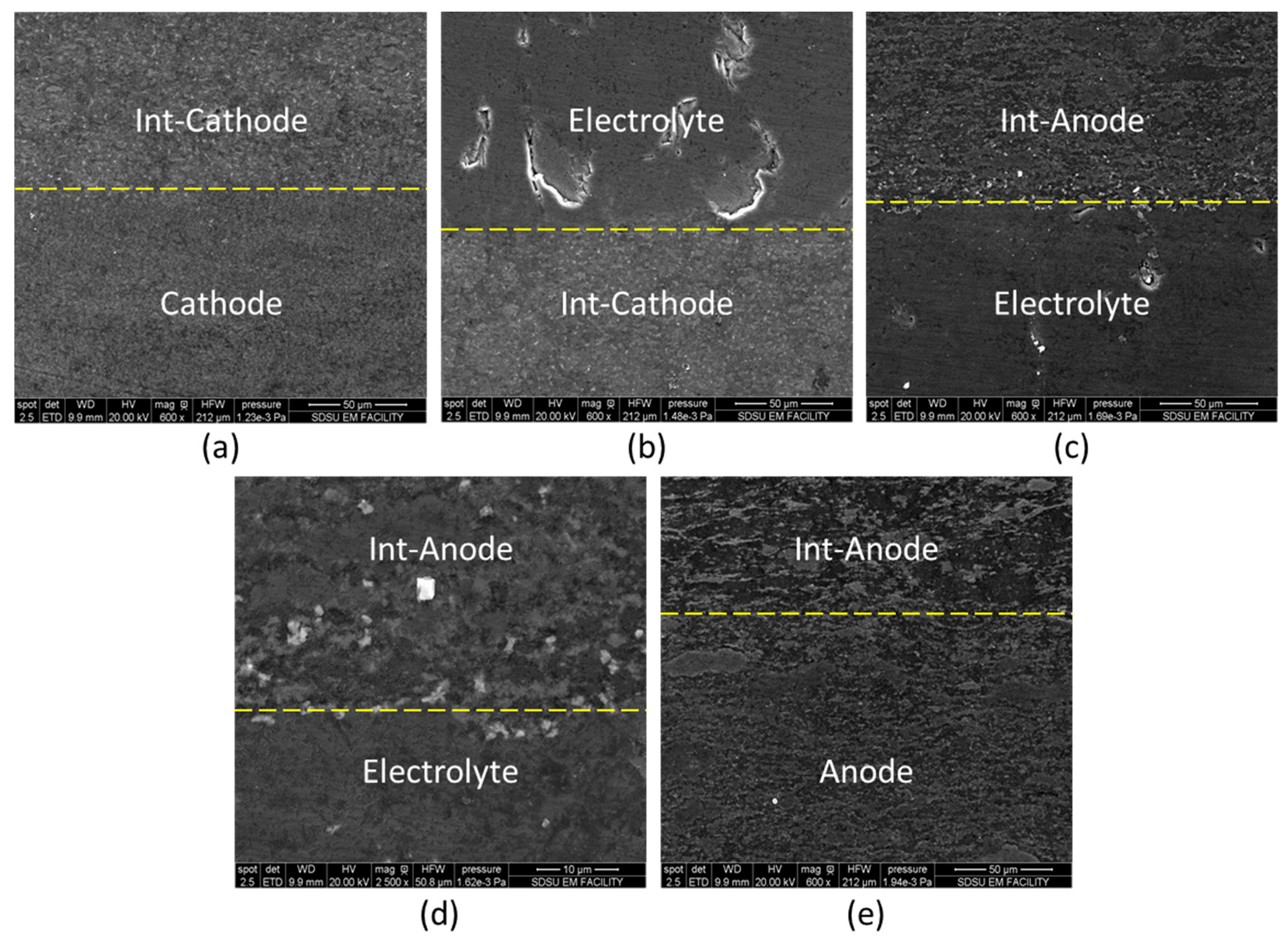

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thangadurai, V.; Weppner, W. Li6ALa2Ta2O12 (A = Sr, Ba): Novel garnet-like oxides for fast lithium ion conduction. Adv. Funct. Mater. 2005, 15, 107–112. [Google Scholar] [CrossRef]

- Fergus, J.W. Ceramic and polymeric solid electrolytes for lithium-ion batteries. J. Power Sources 2010, 195, 4554–4569. [Google Scholar] [CrossRef]

- Kali, R.; Mukhopadhyay, A. Spark plasma sintered/synthesized dense and nanostructured materials for solid-state Li-ion batteries: Overview and perspective. J. Power Sources 2014, 247, 920–931. [Google Scholar] [CrossRef]

- Inaguma, Y.; Chen, L.Q.; Itoh, M.; Nakamura, T.; Uchida, T.; Ikuta, H.; Wakihara, M. High Ionic-Conductivity in Lithium Lanthanum Titanate. Solid State Commun. 1993, 86, 689–693. [Google Scholar] [CrossRef]

- Inaguma, Y.; Chen, L.Q.; Itoh, M.; Nakamura, T. Candidate Compounds with Perovskite Structure for High Lithium Ionic-Conductivity. Solid State Ion. 1994, 70, 196–202. [Google Scholar] [CrossRef]

- Ling, M.E.; Zhu, X.H.; Jiang, Y.; Zhu, J.L. Comparative study of solid-state reaction and sol-gel process for synthesis of Zr-doped Li0.5La0.5TiO3 solid electrolytes. Ionics 2016, 22, 2151–2156. [Google Scholar] [CrossRef]

- Mei, A.; Wang, X.L.; Lan, J.L.; Feng, Y.C.; Geng, H.X.; Lin, Y.H.; Nan, C.W. Role of amorphous boundary layer in enhancing ionic conductivity of lithium-lanthanum-titanate electrolyte. Electrochim. Acta 2010, 55, 2958–2963. [Google Scholar] [CrossRef]

- Baek, S.W.; Lee, J.M.; Kim, T.Y.; Song, M.S.; Park, Y. Garnet related lithium ion conductor processed by spark plasma sintering for all solid state batteries. J. Power Sources 2014, 249, 197–206. [Google Scholar] [CrossRef]

- Li, Y.T.; Wang, C.A.; Xie, H.; Cheng, J.G.; Goodenough, J.B. High lithium ion conduction in garnet-type Li6La3ZrTaO12. Electrochem. Commun. 2011, 13, 1289–1292. [Google Scholar] [CrossRef]

- Kotobuki, M.; Kanamura, K.; Sato, Y.; Yoshida, T. Fabrication of all-solid-state lithium battery with lithium metal anode using Al2O3-added Li7La3Zr2O12 solid electrolyte. J. Power Sources 2011, 196, 7750–7754. [Google Scholar] [CrossRef]

- Li, C.L.; Liu, Y.F.; He, J.; Brinkman, K.S. Ga-substituted Li7La3Zr2O12: An investigation based on grain coarsening in garnet-type lithium ion conductors. J. Alloys Compd. 2017, 695, 3744–3752. [Google Scholar] [CrossRef]

- Geiger, C.A.; Alekseev, E.; Lazic, B.; Fisch, M.; Armbruster, T.; Langner, R.; Fechtelkord, M.; Kim, N.; Pettke, T.; Weppner, W. Crystal Chemistry and Stability of “Li7La3Zr2O12” Garnet: A Fast Lithium-Ion Conductor. Inorg. Chem. 2011, 50, 1089–1097. [Google Scholar] [CrossRef] [PubMed]

- Galven, C.; Fourquet, J.L.; Crosnier-Lopez, M.P.; Le Berre, F. Instability of the Lithium Garnet Li7La3Sn2O12: Li+/H+ Exchange and Structural Study. Chem. Mater. 2011, 23, 1892–1900. [Google Scholar] [CrossRef]

- Truong, L.; Howard, M.; Clemens, O.; Knight, K.S.; Slater, P.R.; Thangadurai, V. Facile proton conduction in H+/Li+ ion-exchanged garnet-type fast Li-ion conducting Li5La3Nb2O12. J. Mater. Chem. A 2013, 1, 13469–13475. [Google Scholar] [CrossRef]

- Wang, Y.X.; Klenk, M.; Page, K.; Lai, W. Local Structure and Dynamics of Lithium Garnet Ionic Conductors: A Model Material Li5La3Ta2O12. Chem. Mater. 2014, 26, 5613–5624. [Google Scholar] [CrossRef]

- Huang, M.A.; Liu, T.; Deng, Y.F.; Geng, H.X.; Shen, Y.; Lin, Y.H.; Nan, C.W. Effect of sintering temperature on structure and ionic conductivity of Li-7−xLa3Zr2O12−0.5x (x = 0.5 similar to 0.7) ceramics. Solid State Ion. 2011, 204, 41–45. [Google Scholar] [CrossRef]

- Takada, K.; Tansho, M.; Yanase, I.; Inada, T.; Kajiyama, A.; Kouguchi, M.; Kondo, S.; Watanabe, M. Lithium ion conduction in LiTi2(PO4)3. Solid State Ion. 2001, 139, 241–247. [Google Scholar] [CrossRef]

- Kang, J.; Chung, H.; Doh, C.; Kang, B.; Han, B. Integrated study of first principles calculations and experimental measurements for Li-ionic conductivity in Al-doped solid-state LiGe2(PO4)3 electrolyte. J. Power Sources 2015, 293, 11–16. [Google Scholar] [CrossRef]

- Kosova, N.V.; Devyatkina, E.T.; Stepanov, A.P.; Buzlukov, A.L. Lithium conductivity and lithium diffusion in NASICON-type Li1+xTi2−xAlx(PO4)3 (x = 0; 0.3) prepared by mechanical activation. Ionics 2008, 14, 303–311. [Google Scholar] [CrossRef]

- Rettenwander, D.; Welzl, A.; Pristat, S.; Tietz, F.; Taibl, S.; Redhammer, G.J.; Fleig, J. A microcontact impedance study on NASICON-type Li1+xAlxTi2−x(PO4)3 (0 ≤ x ≤ 0.5) single crystals. J. Mater. Chem. A 2016, 4, 1506–1513. [Google Scholar] [CrossRef]

- Xu, X.X.; Wen, Z.Y.; Wu, X.W.; Yang, X.L.; Gu, Z.H. Lithium ion-conducting glass-ceramics of Li1.5Al0.5Ge1.5(PO4)3−xLi2O (x = 0.0–0.20) with good electrical and electrochemical properties. J. Am. Ceram. Soc. 2007, 90, 2802–2806. [Google Scholar] [CrossRef]

- Hasegawa, S.; Imanishi, N.; Zhang, T.; Xie, J.; Hirano, A.; Takeda, Y.; Yamamoto, O. Study on lithium/air secondary batteries-Stability of NASICON-type lithium ion conducting glass-ceramics with water. J. Power Sources 2009, 189, 371–377. [Google Scholar] [CrossRef]

- He, K.; Zu, C.K.; Wang, Y.H.; Han, B.; Yin, X.Y.; Zhao, H.F.; Liu, Y.H.; Chen, J. Stability of lithium ion conductor NASICON structure glass ceramic in acid and alkaline aqueous solution. Solid State Ion. 2014, 254, 78–81. [Google Scholar] [CrossRef]

- Epp, V.; Ma, Q.L.; Hammer, E.M.; Tietz, F.; Wilkening, M. Very fast bulk Li ion diffusivity in crystalline Li1.5Al0.5Ti1.5(PO4)3 as seen using NMR relaxometry. Phys. Chem. Chem. Phys. 2015, 17, 32115–32121. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Ding, F.X.; Zhao, Y.G.; Wang, Y.D.; Li, J.L.; Yang, K.; Gao, F. Synthesis and electrochemical performance of Li4Ti5O12 submicrospheres coated with TiN as anode materials for lithium-ion battery. Ceram. Int. 2016, 42, 15464–15470. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.X.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Aliahmad, N.; Shrestha, S.; Varahramyan, K.; Agarwal, M. Poly (vinylidene fluoride-hexafluoro propylene) polymer electrolyte for paper-based and flexible battery applications. AIP Adv. 2016, 6, 65206. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Qian, D.N.; Wang, Z.Y.; Meng, Y.S.L. Recent progress in cathode materials research for advanced lithium ion batteries. Mater. Sci. Eng. R 2012, 73, 51–65. [Google Scholar] [CrossRef]

- Aboulaich, A.; Bouchet, R.; Delaizir, G.; Seznec, V.; Tortet, L.; Morcrette, M.; Rozier, P.; Tarascon, J.M.; Viallet, V.; Dolle, M. A New Approach to Develop Safe All-Inorganic Monolithic Li-Ion Batteries. Adv. Energy Mater. 2011, 1, 179–183. [Google Scholar] [CrossRef]

- Delaizir, G.; Viallet, V.; Aboulaich, A.; Bouchet, R.; Tortet, L.; Seznec, V.; Morcrette, M.; Tarascon, J.M.; Rozier, P.; Dolle, M. The Stone Age Revisited: Building a Monolithic Inorganic Lithium-Ion Battery. Adv. Funct. Mater. 2012, 22, 2140–2147. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Takeuchi, T.; Tabuchi, M.; Ado, K.; Kageyama, H. Densification of LiTi(PO4)3-based solid electrolytes by spark-plasma-sintering. J. Power Sources 1999, 81, 853–858. [Google Scholar] [CrossRef]

- Bordia, R.K.; Kang, S.-J.L.; Olevsky, E.A. Current understanding and future research directions at the onset of the next century of sintering science and technology. J. Am. Ceram. Soc. 2017, 100, 2314–2352. [Google Scholar] [CrossRef]

- Xu, X.X.; Wen, Z.Y.; Yang, X.L.; Chen, L.D. Dense nanostructured solid electrolyte with high Li-ion conductivity by spark plasma sintering technique. Mater. Res. Bull. 2008, 43, 2334–2341. [Google Scholar] [CrossRef]

- Kotobuki, M.; Isshiki, Y.; Munakata, H.; Kanamura, K. All-solid-state lithium battery with a three-dimensionally ordered Li1.5Al0.5Ti1.5 (PO4)3 electrode. Electrochim. Acta 2010, 55, 6892–6896. [Google Scholar] [CrossRef]

- Chang, C.M.; Lee, Y.I.; Hong, S.H.; Park, H.M. Spark plasma sintering of LiTi2(PO4)3-based solid electrolytes. J. Am. Ceram. Soc. 2005, 88, 1803–1807. [Google Scholar] [CrossRef]

- Allen, J.L.; Thompson, T.; Sakamoto, J.; Becker, C.R.; Jow, T.R.; Wolfenstine, J. Transport properties of LiCoPO4 and Fe-substituted LiCoPO4. J. Power Sources 2014, 254, 204–208. [Google Scholar] [CrossRef]

| No. | Temperature | Pressure | Holding | Anode | Cathod | Electrolyte | Joined |

|---|---|---|---|---|---|---|---|

| 1 | 650 °C | 45 MPa | 5 min | powder form | powder form | consolidated | No |

| 2 | 800 °C | 60 MPa | 10 min | partially consolidated | consolidated | consolidated | No |

| 3 | 825 °C | 80 MPa | 30 min | consolidated | consolidated | consolidated | Yes |

| 4 | 850 °C | 60 MPa | 10 min 1 | Melting occured at 850 °C | N/A | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Rechtin, J.; Olevsky, E.A. The Fabrication of All-Solid-State Lithium-Ion Batteries via Spark Plasma Sintering. Metals 2017, 7, 372. https://doi.org/10.3390/met7090372

Wei X, Rechtin J, Olevsky EA. The Fabrication of All-Solid-State Lithium-Ion Batteries via Spark Plasma Sintering. Metals. 2017; 7(9):372. https://doi.org/10.3390/met7090372

Chicago/Turabian StyleWei, Xialu, Jack Rechtin, and Eugene A. Olevsky. 2017. "The Fabrication of All-Solid-State Lithium-Ion Batteries via Spark Plasma Sintering" Metals 7, no. 9: 372. https://doi.org/10.3390/met7090372