Effects of Alloying Elements (Mo, Ni, and Cu) on the Austemperability of GGG-60 Ductile Cast Iron

Abstract

:1. Introduction

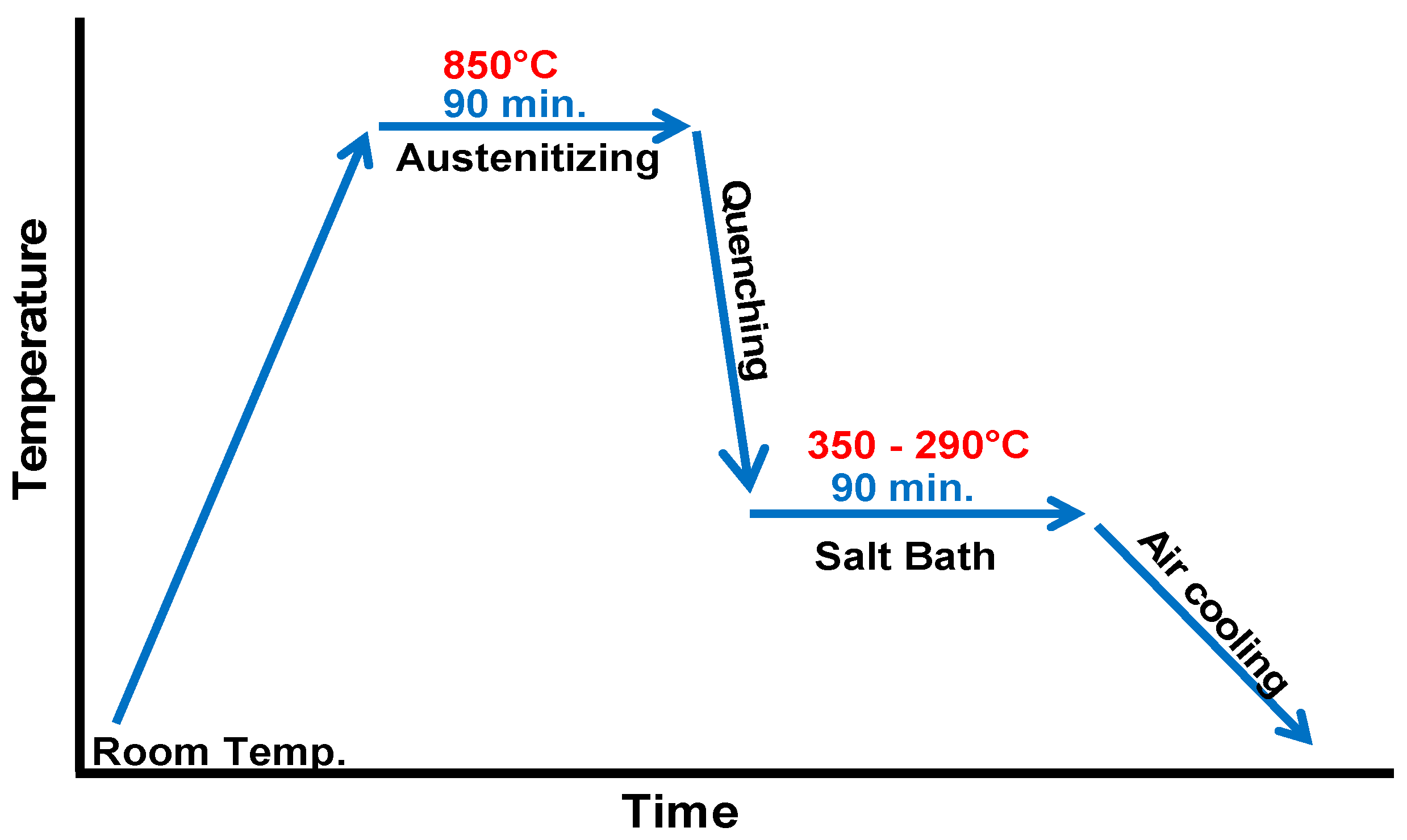

2. Materials and Methods

3. Results

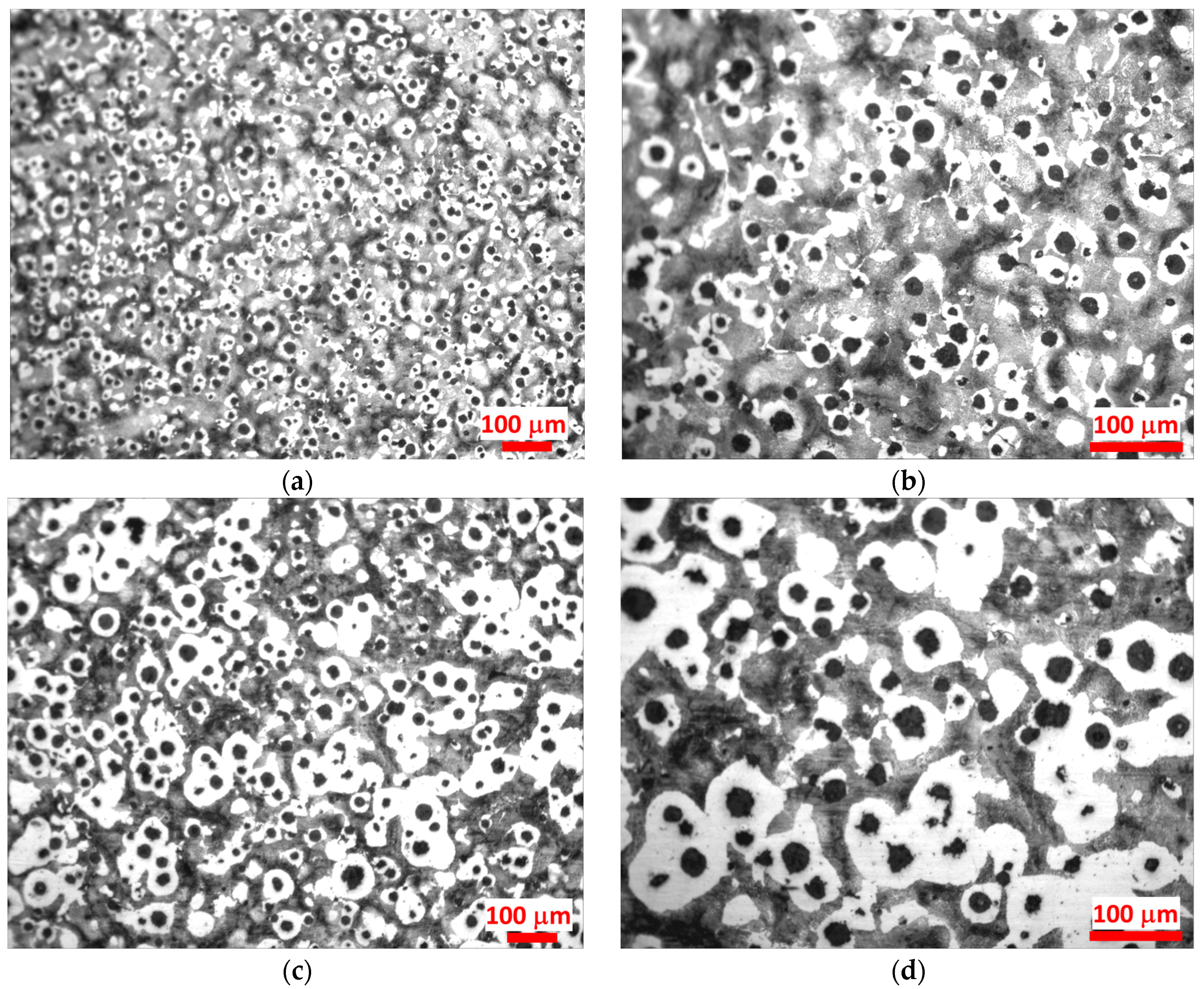

3.1. As-Cast Samples

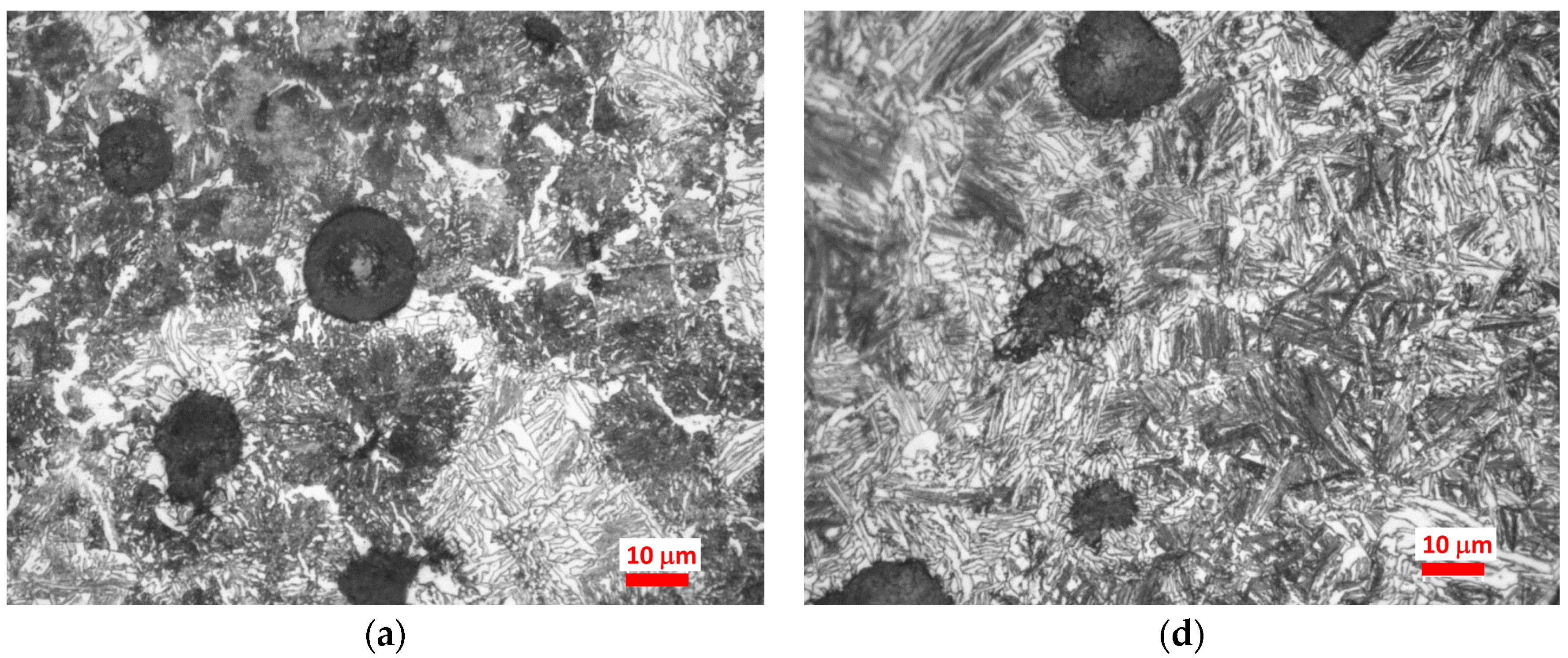

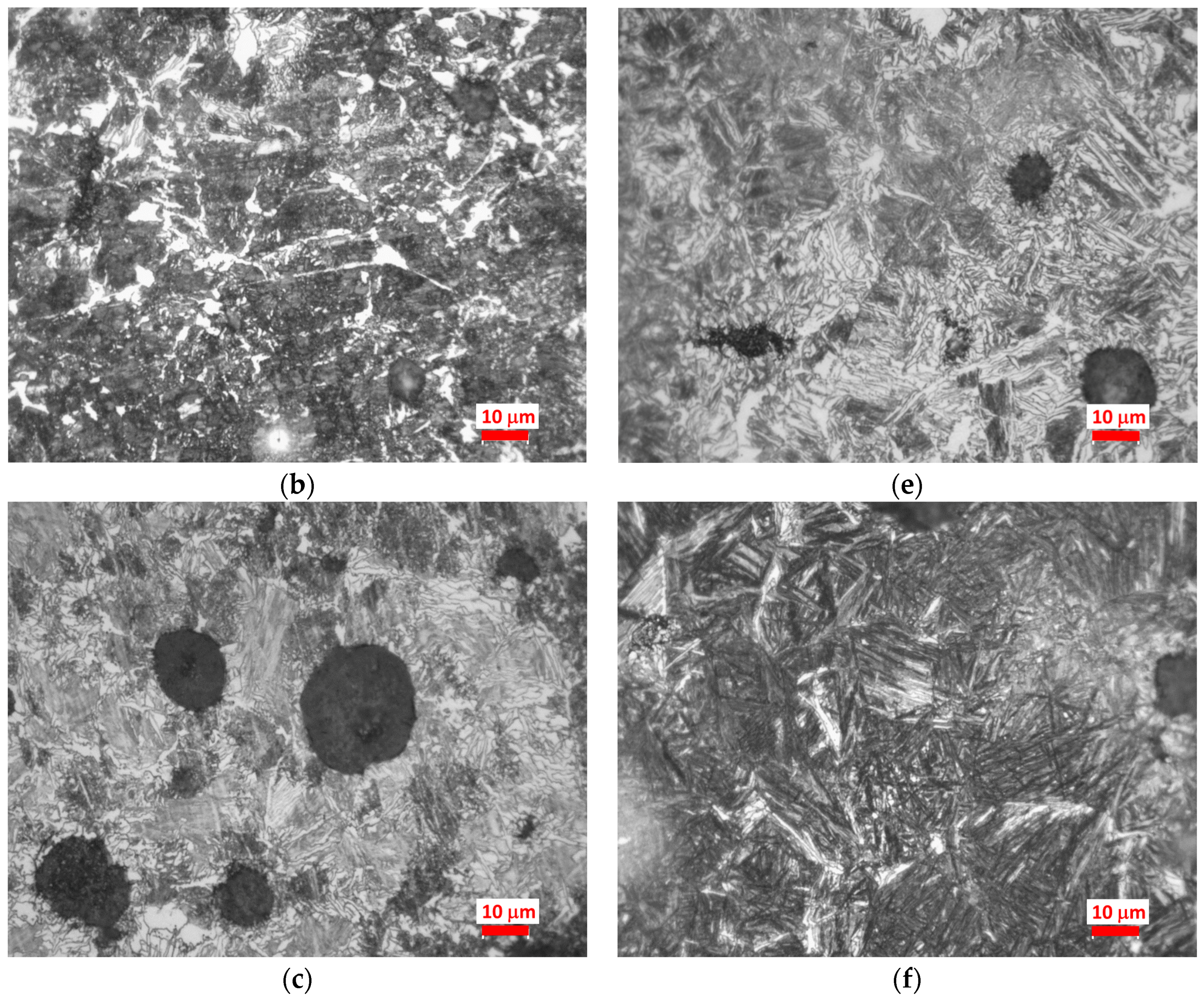

3.2. Austempered Samples-Microstructural Examination

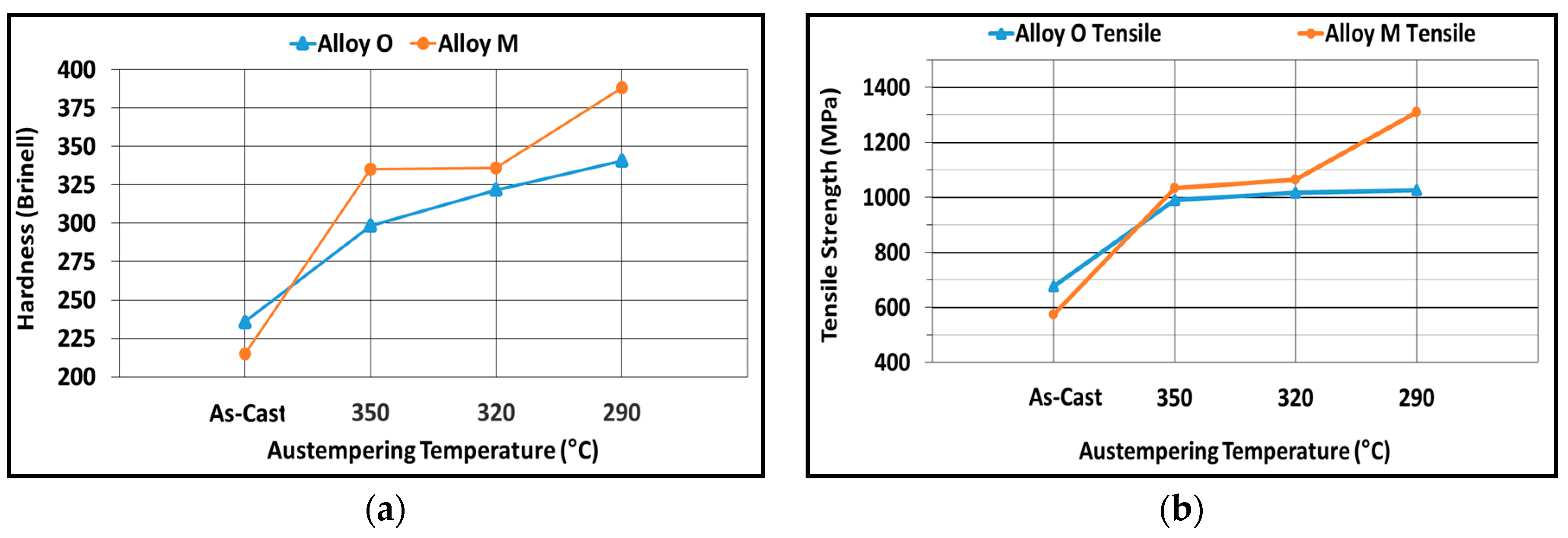

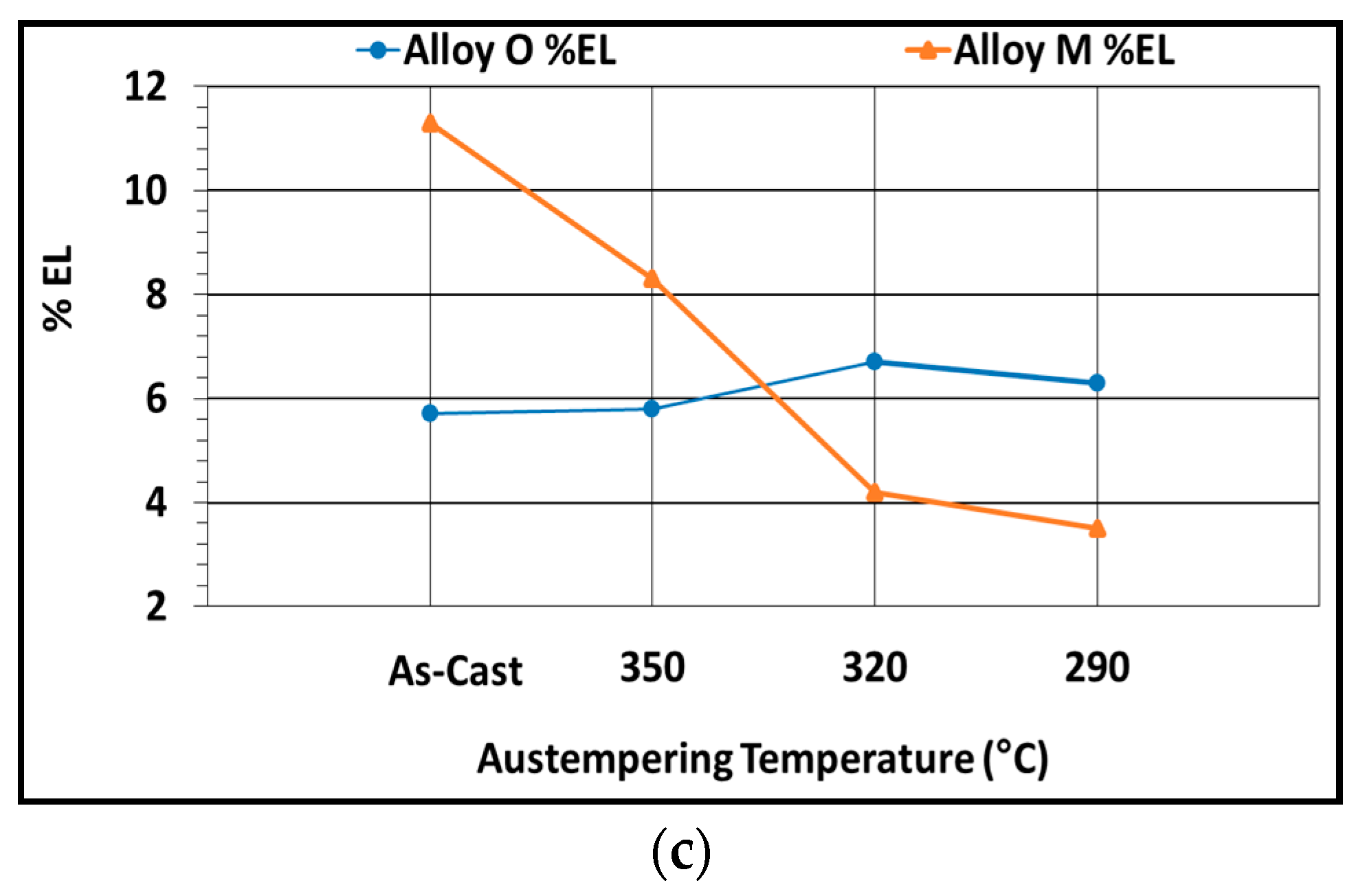

3.3. Austempered Samples-Hardness

3.4. Austempered Samples-Tensile Tests

3.5. Effects of Austempering Temperature and Alloying

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Blackmore, P.A.; Harding, R.A. The Effects of Metallurgical Process Variables on the Properties of Austempered Ductile Irons. J. Heat Treat. 1984, 3, 310–325. [Google Scholar] [CrossRef]

- Keough, J.R.; Hayrynen, K.L. Designing with Austempered Ductile Iron (ADI). AFS Proc. 2010, 2010, 10–129. [Google Scholar]

- Tun, T.; Lwin, K.T. Optimizing the Microstructure and Mechanical Properties of Austempered Ductile Iron for Automobile Differential Gear. J. Met. Mater. Miner. 2008, 18, 199–205. [Google Scholar]

- Yescas-Gonzales, M.A. Modelling the Microstructure and Mechanical Properties of Austempered Ductile Irons. Ph.D. Thesis, University of Cambridge, Cambridge, UK, November 2001. [Google Scholar]

- Meier, L.; Hofmann, M.; Saal, P.; Volk, W.; Hoffman, H. In-situ measurement of phase transformation kinetics in austempered ductile. Mater. Charact. 2013, 85, 124–133. [Google Scholar] [CrossRef]

- Pannerselvam, S.; Martic, C.J.; Putatunda, S.K.; Boileau, J.M. An investigation on the stability of austenite in Austempered Ductile Cast Iron (ADI). Mater. Sci. Eng. A 2015, 626, 237–246. [Google Scholar] [CrossRef]

- Binczyk, F.; Hanc, A.; Kowalski, A.; Furmanek, J. Austempering transformation kinetics of austempered ductile iron obtained by Mössbauer Spectroscopy. Arch. Foundry Eng. 2008, 8, 15–20. [Google Scholar]

- Yazdani, S.; Elliott, R. Influence of molybdenum on austempering behaviour of ductile iron Part 1—Austempering kinetics and mechanical properties of ductile iron containing 0.13% Mo. Mater. Sci. Technol. 1999, 15, 531–540. [Google Scholar] [CrossRef]

- Warsisnski, K. Evauation of Thermal Stability of Ausferrite in Austempered Ductile Iron Using Differential Scanning Calorimetry. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2017. [Google Scholar]

- Akça, C. Effect of Alloying Elements on the Austenite-Martensite Transformation in Austempered Spheroidal Graphite Cast Iron. Ph.D. Thesis, Yıldız Technical University, Yıldız, Turkey, 2005. [Google Scholar]

- Saal, P.; Meier, L.; Li, X.; Hofmann, M.; Hoelzel, M.; Wagner, J.N.; Volk, W. In Situ Study of the Influence of Nickel on the Phase Transformation Kinetics in Austempered Ductile Iron. Metall. Mater. Trans. A 2016, 47, 661–671. [Google Scholar] [CrossRef]

- Hayrynen, K.L. The Production of Austempered Ductile Iron (ADI). In Proceedings of the 2002 World Conference on ADI, Louisville, KY, USA, 26–27 September 2002; pp. 1–6. [Google Scholar]

- Hernandez-Avila, J.; Salinas-Rodriguez, E.; Cerecedo-Saenz, E.; Rivera-Landero, I.; Cardoso-Legorreta, E.; Flores-Badill, J.; Reyes-Valderrama, M.I. The Effect of Molybdenum on the Microstructure of Nodular Iron. Eur. Sci. J. 2015, 11, 377–388. [Google Scholar]

- Yazdani, S.; Elliott, R. Influence of molybdenum on austempering behaviour of ductile iron Part 2—Influence of austenitising temperature on austempering kinetics, mechanical properties, and hardenability of ductile iron containing 0.13%Mo. Mater. Sci. Technol. 1999, 15, 541–546. [Google Scholar] [CrossRef]

- Yazdani, S.; Elliott, R. Influence of molybdenum on austempering behaviour of ductile iron Part 3—Austempering kinetics, mechanical properties, and hardenability of ductile iron containing 0.25% Mo. Mater. Sci. Technol 1999, 15, 885–895. [Google Scholar] [CrossRef]

- Yazdani, S.; Elliott, R. Influence of molybdenum on austempering behaviour of ductile iron Part 4—Austempering behaviour of ductile iron containing 0.45% Mo. Mater. Sci. Technol. 1999, 15, 896–902. [Google Scholar] [CrossRef]

- Eric, O.; Jovanovic, M.; Sidanin, L.; Rajnovic, D.; Zec, S. The austempering study of alloyed ductile iron. Mater. Des. 2006, 27, 617–622. [Google Scholar] [CrossRef]

- Lin, B.Y.; Chen, E.T.; Lei, T.S. The Effect of Alloy Elements on the Microstructure and Properties of Austempered Ductile Irons. Scr. Metall. Mater. 1995, 32, 1363–1367. [Google Scholar] [CrossRef]

- Batra, U.; Ray, S.; Prabhakar, S.R. The Influence of Nickel and Copper on the Austempering of Ductile Iron. J. Mater. Eng. Perform. 2004, 13, 64–68. [Google Scholar] [CrossRef]

- Mi, Y. Effect of Cu, Mo, Si on the Content of Retained Austenite of Austempered Ductile Iron. Scr. Metall. Mater. 1995, 32, 1313–1317. [Google Scholar] [CrossRef]

- Lee, K.H.; Park, Y.W. Effects of Molybdenum on the Microstructure of Austempered Ductile Iron. J. Korea Foundry Soc. 1994, 14, 35–44. [Google Scholar]

- Thomas, T. Molybdenum in Ductile Iron, Hot Topics Issue #1; Ductile Iron Society: Strongvilee, OH, USA, 2007. [Google Scholar]

- Guzik, E.; Sokolnicki, M.; Krolikowski, M.; Ronduda, M.; Nowak, A. Prediction of Microstructure in ADI Castings. Arch. Metall. Mater. 2016, 61, 2159–2164. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, N.; Zhang, M.; Liantao, L.; Zeng, D. Microstructure and mechanical properties of austempered ductile iron with different strength grades. Mater. Lett. 2014, 119, 47–50. [Google Scholar] [CrossRef]

- Sahoo, S.K. A Study on the Effect of Austempering Temperature, Time and Copper Addition on the Mechanical Properties of Austempered Ductile Iron. Master’s Thesis, National Institute of Technology, Rourkela, India, 2012. [Google Scholar]

- Rasband, W. ImageJ; U.S. National Institutes of Health: Bethesda, MD, USA, 1997–2016.

- Guesser, W.; Koda, F.; Martinez, J.; Martinez, J.A.B.; Silva, C. Austempered Ductile Iron for Gears; SAE Technical Paper 2012-36-0305; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- BSI (British Standards Institution). EN 1564:2011 Founding—Ausferritic Spheroidal Graphite Cast Irons; BSI: London, UK, 2011. [Google Scholar]

- ASTM International. ASTM A897/A897M—03 Standard Specification for Austempered Ductile Iron Castings; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

| Alloy | C | Si | Mn | P | S | Ni | Cu | Mo | Mg | Cr | Al | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O | 3.64 | 2.20 | 0.03 | 0.039 | 0.010 | 0.37 | 0.52 | <0.001 | 0.05 | 0.01 | 0.01 | 0.004 | bal. |

| M | 3.76 | 2.19 | 0.14 | 0.041 | 0.013 | 0.21 | 0.41 | 0.21 | 0.04 | 0.01 | 0.01 | 0.008 |

| Experiment # | Temperature (°C) | Duration (min) |

|---|---|---|

| Exp. 1 | 350 | 90 |

| Exp. 2 | 320 | 90 |

| Exp. 3 | 290 | 90 |

| Sample | Brinell Hardness | |

|---|---|---|

| Alloy O | Alloy M | |

| As-cast | 236 ± 3.5 | 215 ± 4.2 |

| Exp. 1 | 299 ± 6.0 | 335 ± 5.1 |

| Exp. 2 | 322 ± 8.4 | 336 ± 23.4 |

| Exp. 3 | 341 ± 21.4 | 386 ± 22.0 |

| Sample | Alloy O | Alloy M | ||||

|---|---|---|---|---|---|---|

| Yield Strength (MPa) | Tensile Strength (MPa) | % EL | Yield Strength (MPa) | Tensile Strength (MPa) | % EL | |

| As-cast | 426 ± 5.1 | 677 ± 7.3 | 5.7 ± 0.7 | 356 ± 4.7 | 576 ± 6.9 | 11.3 ± 1.0 |

| Exp. 1 | 707 ± 12.6 | 992 ± 14.1 | 5.8 ± 0.8 | 863 ± 16.5 | 1035 ± 24.2 | 8.3 ± 1.3 |

| Exp. 2 | 724 ± 16.5 | 1018 ± 17.9 | 6.7 ± 1.0 | 937 ± 17.3 | 1065 ± 19.5 | 4.2 ± 1.1 |

| Exp. 3 | 739 ± 14.2 | 1027 ± 16.5 | 6.3 ± 0.8 | 1169 ± 21.5 | 1311 ± 23.2 | 3.5 ± 1.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konca, E.; Tur, K.; Koç, E. Effects of Alloying Elements (Mo, Ni, and Cu) on the Austemperability of GGG-60 Ductile Cast Iron. Metals 2017, 7, 320. https://doi.org/10.3390/met7080320

Konca E, Tur K, Koç E. Effects of Alloying Elements (Mo, Ni, and Cu) on the Austemperability of GGG-60 Ductile Cast Iron. Metals. 2017; 7(8):320. https://doi.org/10.3390/met7080320

Chicago/Turabian StyleKonca, Erkan, Kazım Tur, and Erkin Koç. 2017. "Effects of Alloying Elements (Mo, Ni, and Cu) on the Austemperability of GGG-60 Ductile Cast Iron" Metals 7, no. 8: 320. https://doi.org/10.3390/met7080320