A Finite Element Model to Simulate Defect Formation during Friction Stir Welding

Abstract

:1. Introduction

2. Material and Experimentation

3. Model Description

3.1. Governing Equations

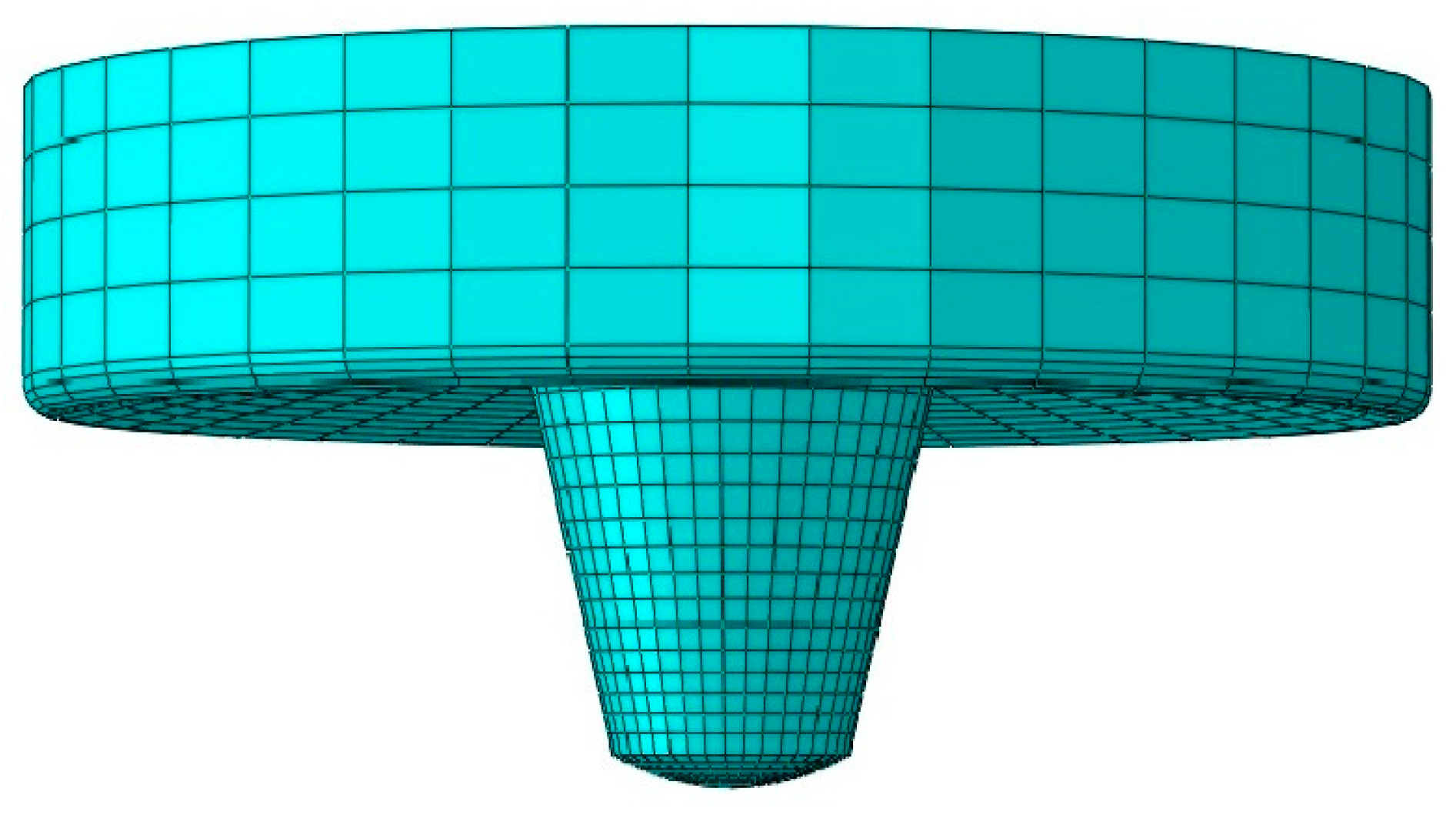

3.2. Geometrical Model and Mesh Generation

3.3. Heat Generation Model

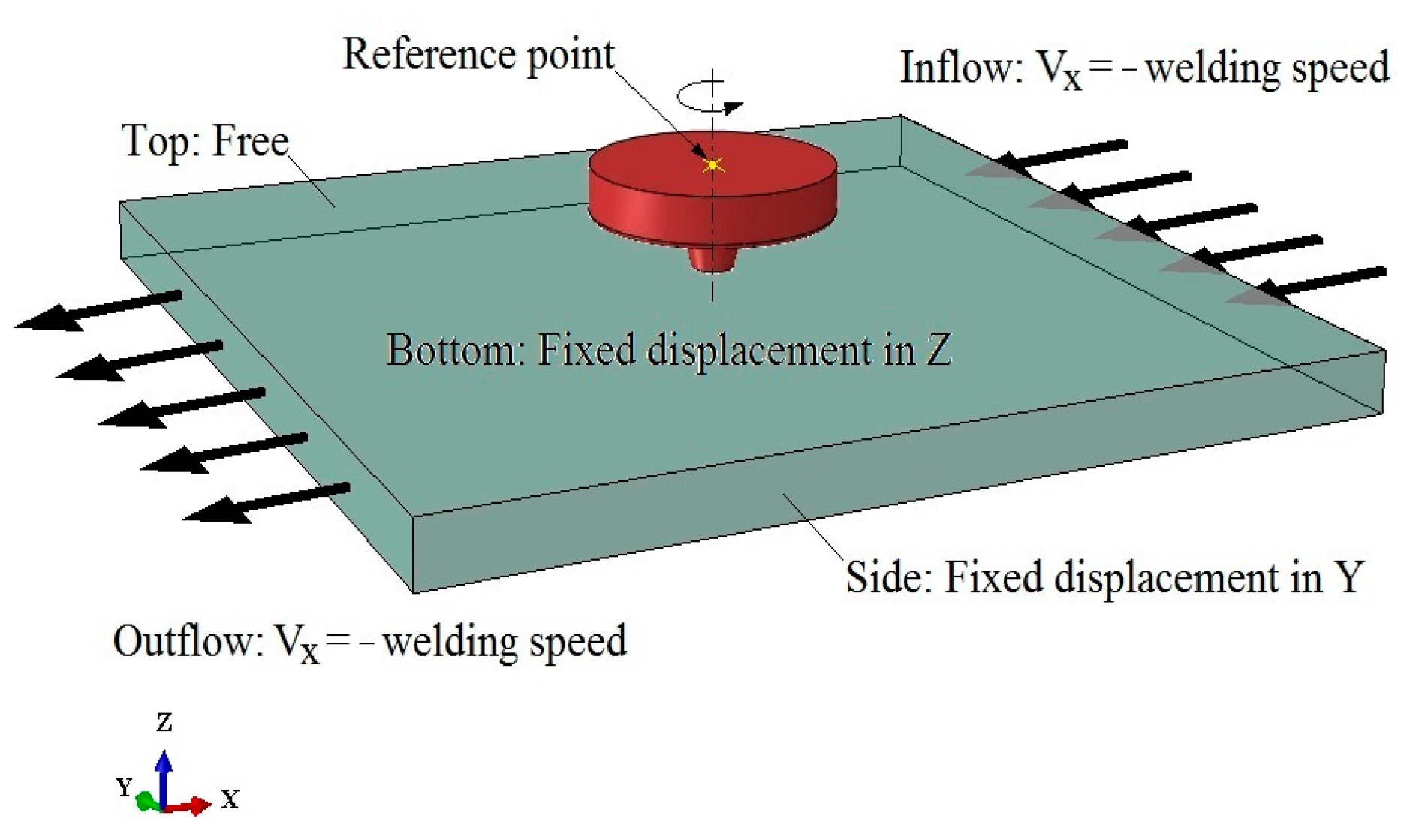

3.4. Boundary Conditions

3.4.1. Thermal Boundary Conditions

3.4.2. Velocity Boundary Conditions

3.5. Material Model

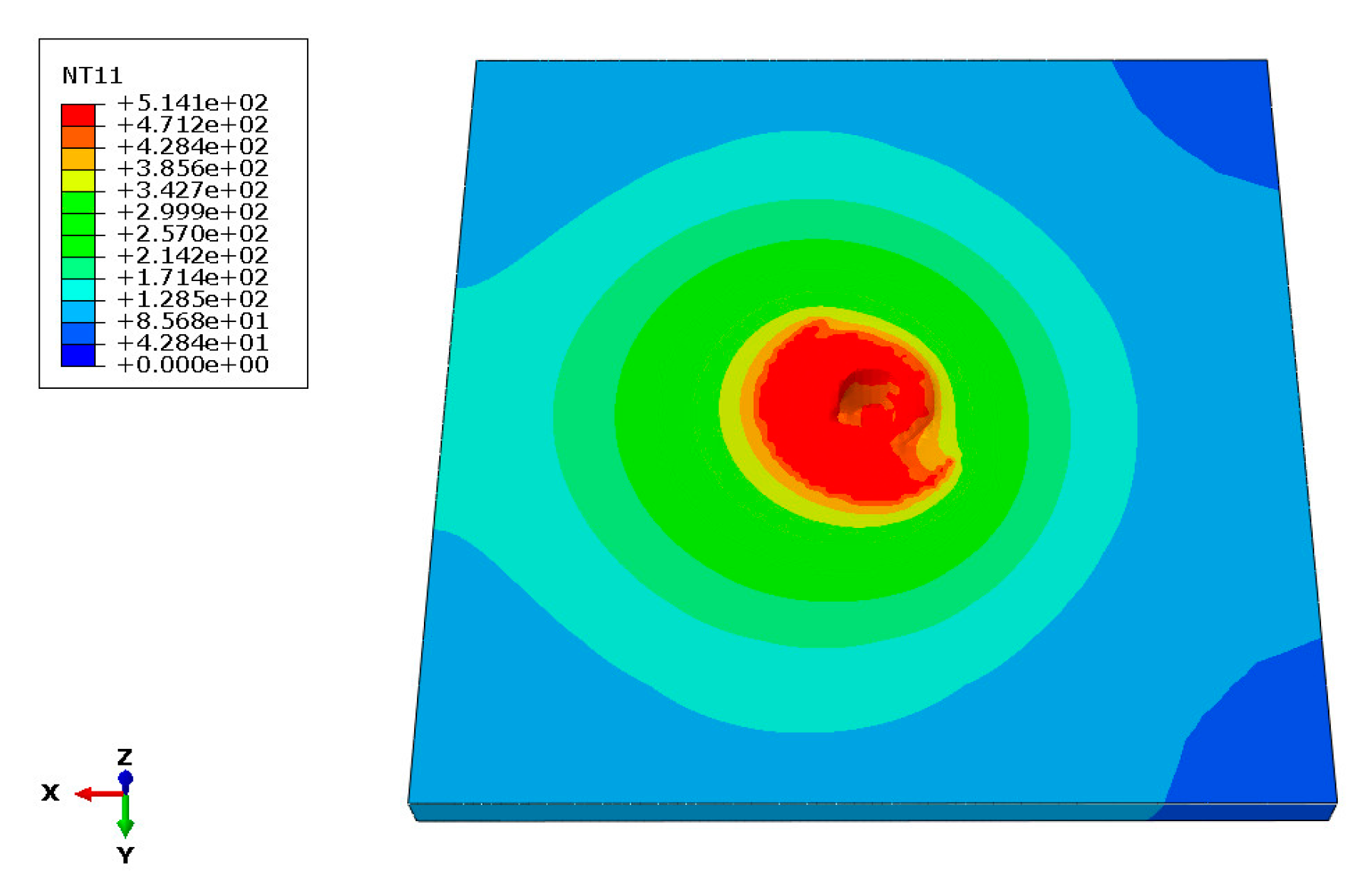

4. FE Results and Discussion

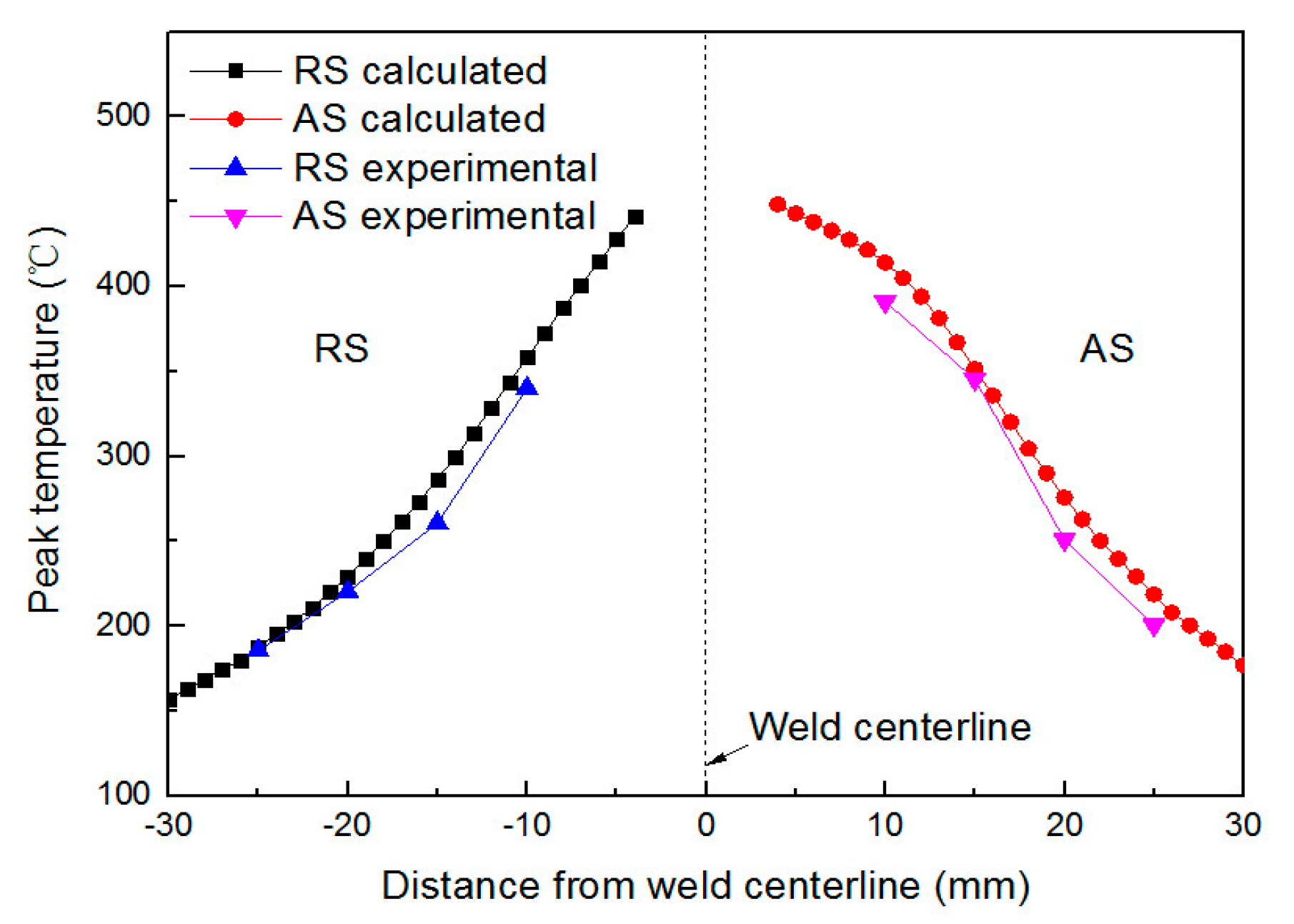

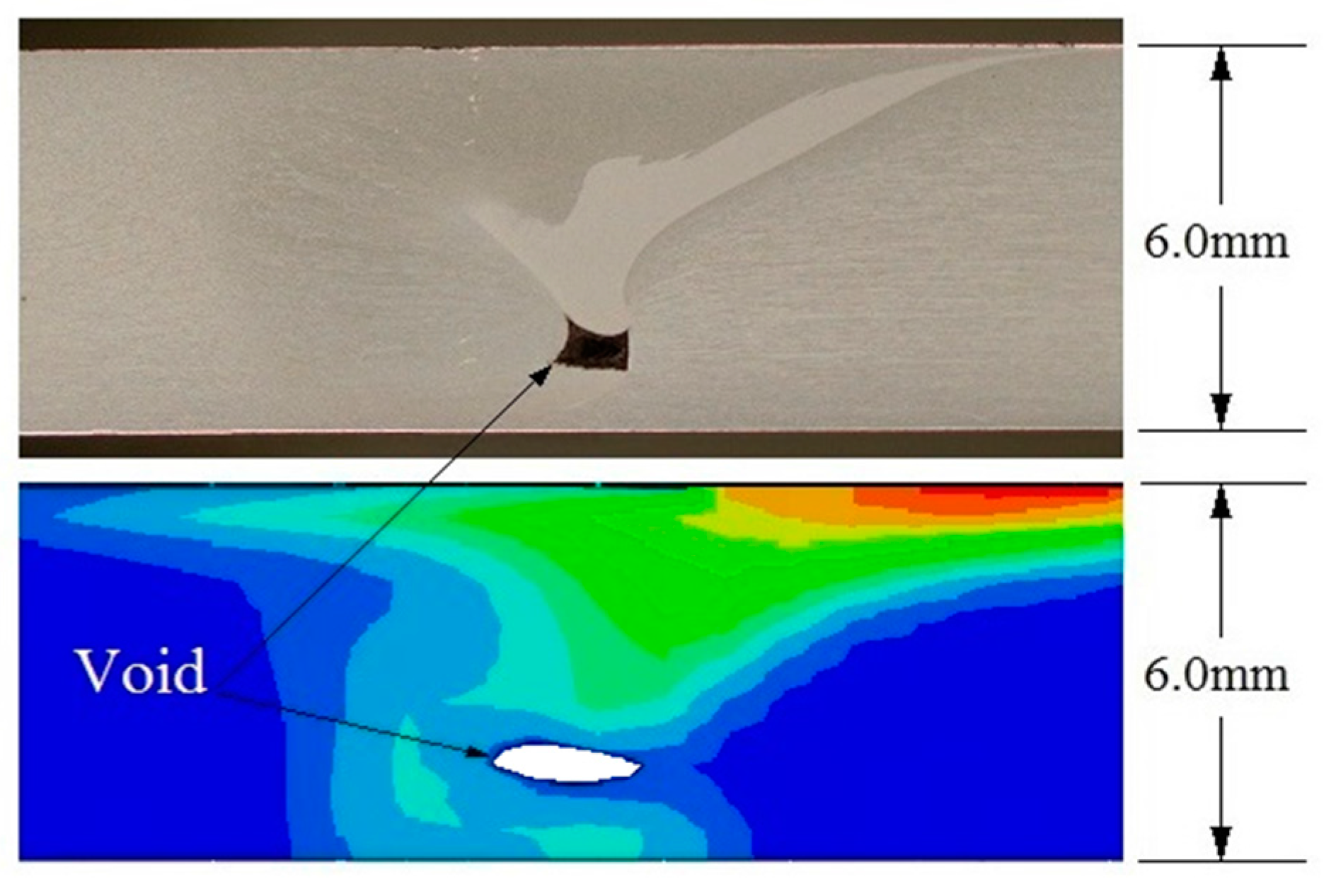

4.1. Verification of FE Model

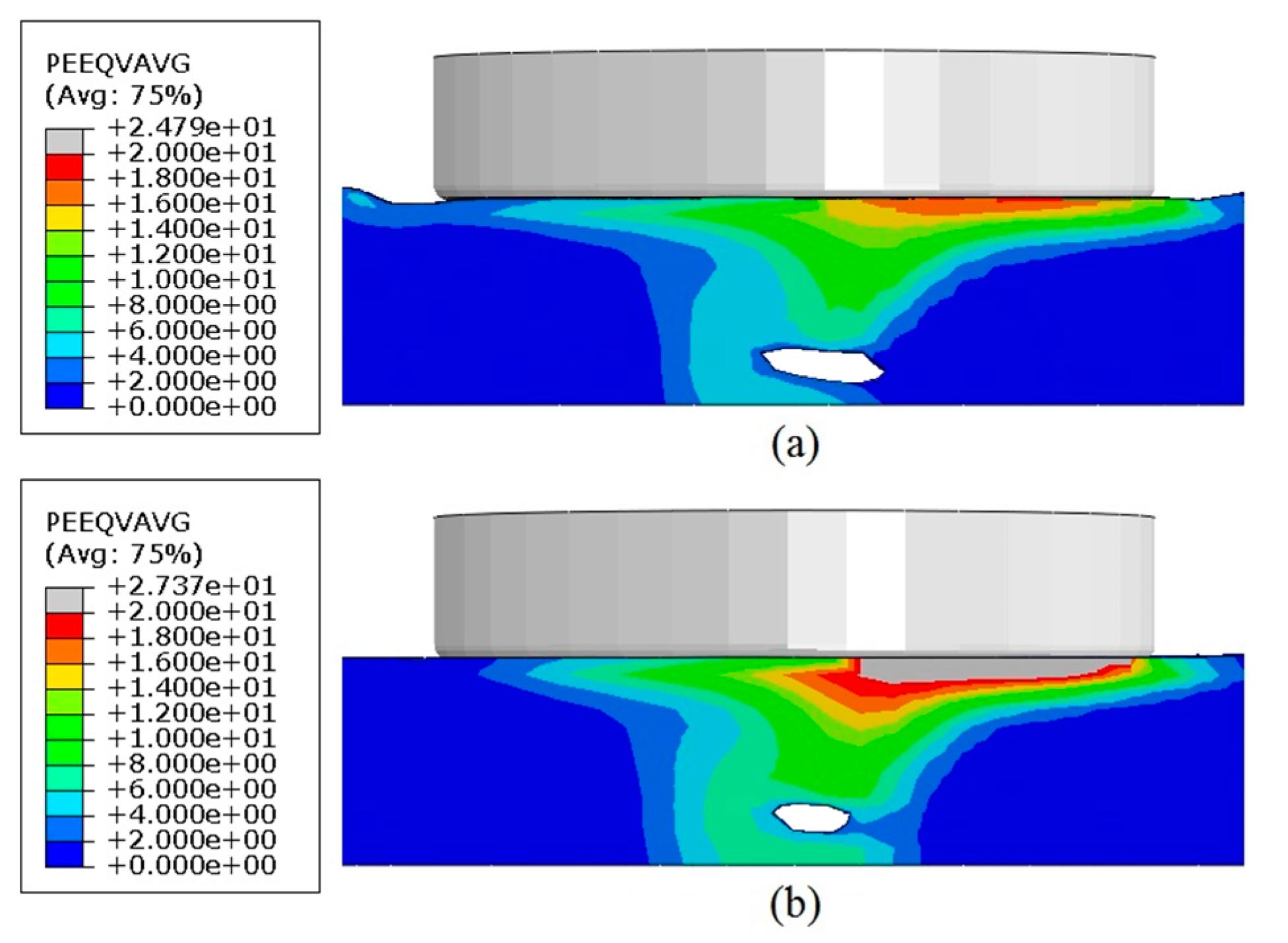

4.2. Effect of Welding Parameters

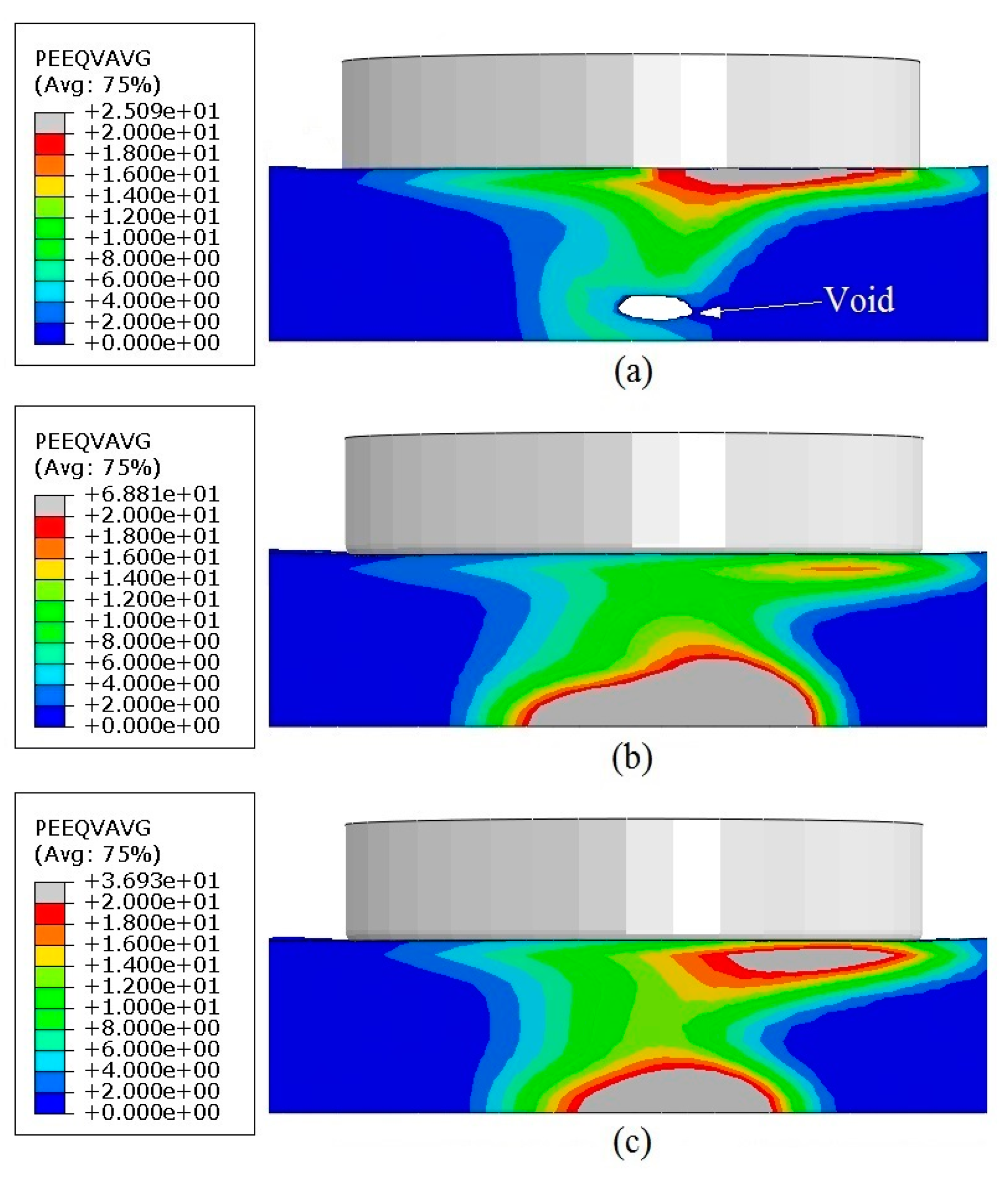

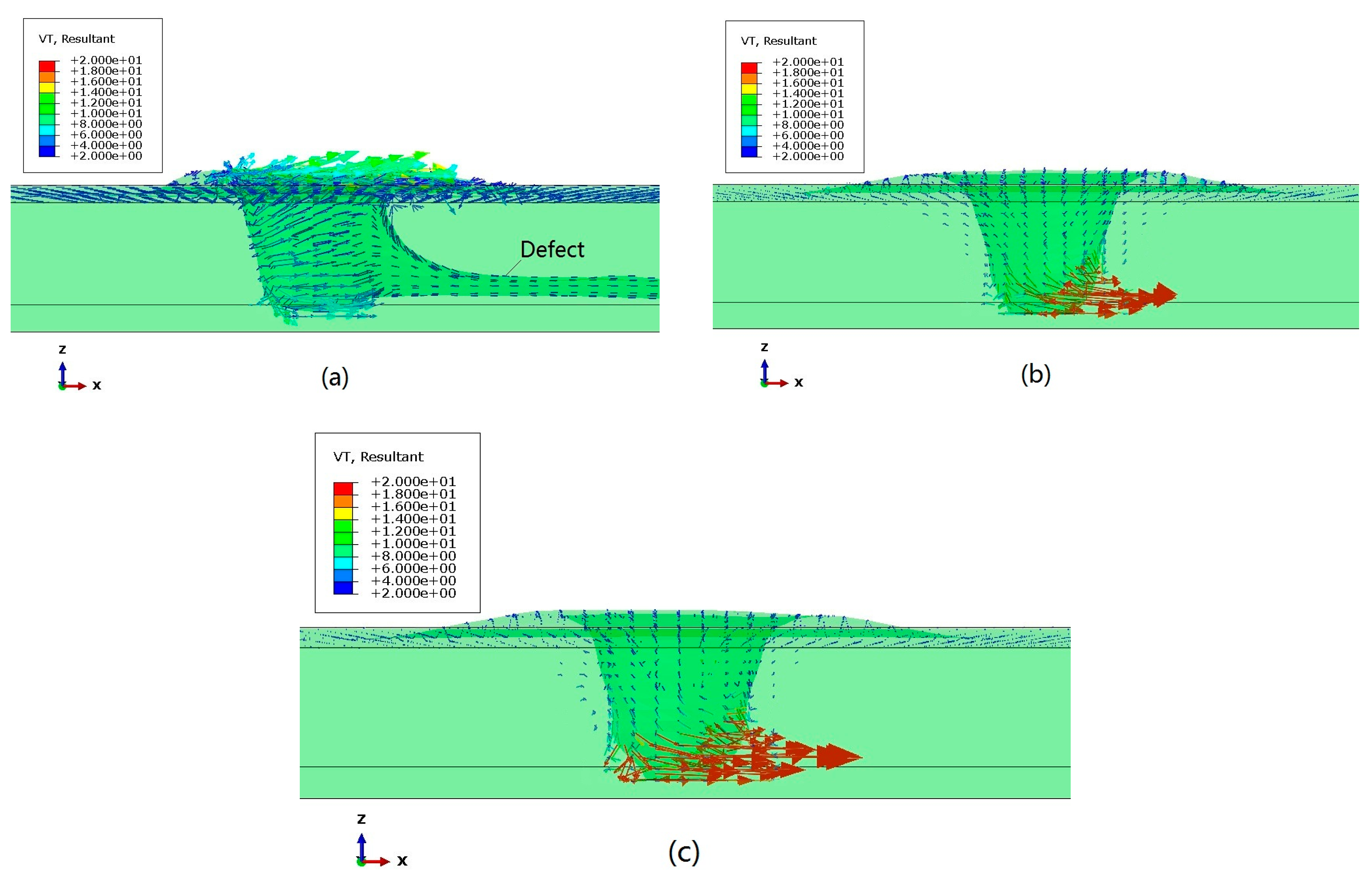

4.3. Effect of Tool Pin Profile

5. Conclusions

- The model can predict the plasticized zone shape and the presence of void in the weld quite accurately. However, the void size is overestimated.

- The void size is directly affected by welding parameters. Welding at low welding speed or high tool rotational speed could produce a smaller void.

- Compared with a smooth tool pin, a featured tool pin can enhance plastic flow in the weld, which contributes to reducing defect size and achieving defect-free weldment.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB9202203, GB Patent Application No. 9125978.8. U.S. Patent Application No. 5460317 A, 6 December 1991. [Google Scholar]

- Zhao, J.; Jiang, F.; Jian, H.G.; Wen, K.; Jiang, L.; Chen, X. Comparative investigation of tungsten inert gas and friction stir welding characteristics of Al-Mg-Sc alloy plates. Mater. Des. 2010, 31, 306–311. [Google Scholar] [CrossRef]

- Cavaliere, P.; Cabibbo, M.; Panella, F.; Squillace, A. 2198 Al-Li plates jointed by friction stir welding: Mechanical and microstructural behavior. Mater. Des. 2009, 30, 3622–3631. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- He, X. Thermo-mechanical modelling of friction stir welding process. Adv. Mater. Res. 2013, 774, 1155–1159. [Google Scholar] [CrossRef]

- Colligan, K. Material flow behavior during friction stir welding of aluminum. Weld. J. 1999, 172, 229–237. [Google Scholar]

- Seidel, T.U.; Reynolds, A.P. Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall. Mater. Trans. A 2001, 32, 2879–2884. [Google Scholar] [CrossRef]

- Schmidt, H.N.B.; Dickerson, T.L.; Hattel, J.H. Material flow in butt friction stir welds in AA2024-T3. Acta Mater. 2006, 54, 1199–1209. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Kovacevic, R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys. J. Mater. Eng. Perform. 2002, 11, 51–63. [Google Scholar] [CrossRef]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. The joint properties of dissimilar formed Al alloys by friction stir welding according to the fixed location of materials. Scr. Mater. 2003, 49, 423–428. [Google Scholar] [CrossRef]

- Krishnan, K.N. On the formation of onion rings in friction stir welds. Mater. Sci. Eng. A 2002, 327, 246–251. [Google Scholar] [CrossRef]

- Sutton, M.A.; Yang, B.; Reynolds, A.P.; Taylor, R. Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater. Sci. Eng. A 2002, 323, 160–166. [Google Scholar] [CrossRef]

- Seidel, T.U.; Reynolds, A.P. Two-dimensional friction stir welding process model based on fluid mechanics. Sci. Technol. Weld. Join. 2003, 8, 175–183. [Google Scholar] [CrossRef]

- Ulysse, P. Three-dimensional modeling of the friction stir-welding process. Int. J. Mach. Tools Manuf. 2002, 42, 1549–1557. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R. Development of the Trivex friction stir welding tool: Part II-3-Dimensional flow modelling. Sci. Technol. Weld. Join. 2004, 9, 352–361. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R. 3-Dimensional CFD modelling of flow round a threaded friction stir welding tool profile. J. Mater. Process. Technol. 2005, 169, 320–327. [Google Scholar] [CrossRef]

- Long, T.; Reynolds, A.P. Parametric studies of friction stir welding by commercial fluid dynamics simulation. Sci. Technol. Weld. Join. 2013, 11, 200–208. [Google Scholar] [CrossRef]

- Carlone, P.; Palazzo, G.S. Influence of process parameters on microstructure and mechanical properties in AA2024-T3 friction stir welding. Metall. Microstruct. Anal. 2013, 2, 213–222. [Google Scholar] [CrossRef]

- Deng, X.; Xu, S. Two-dimensional finite element simulation of material flow in the friction stir welding process. J. Manuf. Process. 2004, 6, 125–133. [Google Scholar] [CrossRef]

- Zhang, H.W.; Zhang, Z.; Chen, J.T. 3D modeling of material flow in friction stir welding under different process parameters. J. Mater. Process. Technol. 2007, 183, 62–70. [Google Scholar] [CrossRef]

- Schmidt, H.; Hattel, J. A local model for the thermomechanical conditions in friction stir welding. Model. Simul. Mater. Sci. Eng. 2005, 13, 77–93. [Google Scholar] [CrossRef]

- Guerdoux, S.; Fourment, L. A 3D numerical simulation of different phases of friction stir welding. Model. Simul. Mater. Sci. Eng. 2009, 17, 075001. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.W. Numerical studies on controlling of process parameters in friction stir welding. J. Mater. Process. Technol. 2009, 209, 241–270. [Google Scholar] [CrossRef]

- Buffa, G.; Hua, J.; Shivpuri, R.; Fratini, L. Design of the friction stir welding tool using the continuum based FEM model. Mater. Sci. Eng. A 2006, 419, 381–388. [Google Scholar] [CrossRef]

- Assidi, M.; Fourment, L. Accurate 3D friction stir welding simulation tool based on friction model calibration. Int. J. Mater. Form. 2009, 2, 327–330. [Google Scholar] [CrossRef]

- Dialami, N.; Chiumenti, M.; Cervera, M.; de Saracibar, C.A. An apropos kinematic framework for the numerical modelling of Friction Stir Welding. Comput. Struct. 2013, 117, 48–57. [Google Scholar] [CrossRef]

- Bussetta, P.; Dialami, N.; Boman, R.; Chiumenti, M.; de Saracibar, C.A.; Cervera, M.; Ponthot, J.-P. Comparison of a fluid and a solid approach for the numerical simulation of friction stir welding with a non-cylindrical pin. Steel Res. Int. 2014, 85, 968–979. [Google Scholar] [CrossRef]

- Noh, W.F. CEL: A time-dependent, two-space-dimensional, coupled eulerian-lagrange code. Methods Comput. Phys. 1964, 3, 117–179. [Google Scholar]

- Al-Badour, F.; Merah, N.; Shuaib, A.; Bazoune, A. Coupled Eulerian Lagrangian finite element modeling of friction stir welding processes. J. Mater. Process. Technol. 2013, 213, 1433–1439. [Google Scholar] [CrossRef]

- Benson, D.J.; Okazawa, S. Contact in a multi-material Eulerian finite element formulation. Comput. Methods Appl. Mech. Eng. 2004, 193, 4277–4298. [Google Scholar] [CrossRef]

- Benson, D.J. A mixture theory for contact in multi-material Eulerian formulations. Comput. Methods Appl. Mech. Eng. 1997, 140, 59–86. [Google Scholar] [CrossRef]

- Dassault Systemes. Abaqus 6.12 Documentation; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2012. [Google Scholar]

- Nandan, R.; Debroy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding-Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Zahmatkesh, B.; Enayati, M.H.; Karimzadeh, F. Tribological and microstructural evaluation of friction stir processed Al2024 alloy. Mater. Des. 2010, 31, 4891–4896. [Google Scholar] [CrossRef]

- Tutunchilar, S.; Haghpanahi, M.; Givi, M.K.B.; Asadi, P.; Bahemmat, P. Simulation of material flow in friction stir processing of a cast Al-Si alloy. Mater. Des. 2012, 40, 415–426. [Google Scholar] [CrossRef]

- Buffa, G.; Campanile, G.; Fratini, L.; Prisco, A. Friction stir welding of lap joints: Influence of process parameters on the metallurgical and mechanical properties. Mater. Sci. Eng. A 2009, 519, 19–26. [Google Scholar] [CrossRef]

- Al-Badour, F.; Merah, N.; Shuaib, A.; Bazoune, A. Thermo-mechanical finite element model of friction stir welding of dissimilar alloys. Int. J. Adv. Manuf. Technol. 2014, 72, 607–617. [Google Scholar] [CrossRef]

- Veljić, D.M.; Sedmak, A.S.; Rakin, M.P.; BAJIĆ, N.S.; Medjo, B.I.; Bajić, D.R.; Grabulov, V.K. Experimental and numerical thermo-mechanical analysis of friction stir welding of high-strength alluminium alloy. Therm. Sci. 2014, 18, 29–39. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Li, W.Y.; Han, J.; Li, J.L. Numerical analysis of joint temperature evolution during friction stir welding based on plastic deformation heat. China Weld. 2011, 20, 76–80. [Google Scholar]

- Li, H.; Mackenzie, D. Parametric finite-element studies on the effect of tool shape in friction stir welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1161–1173. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Soundararajan, V.; Zekovic, S.; Kovacevic, R. Thermo-mechanical model with adaptive boundary conditions for friction stir welding of Al 6061. Int. J. Mach. Tools Manuf. 2005, 45, 1577–1587. [Google Scholar] [CrossRef]

- Su, H.; Wu, C.S.; Pittner, A.; Rethmeier, M. Thermal energy generation and disribution in friction stir welding of aluminum alloys. Energy 2014, 77, 720–731. [Google Scholar] [CrossRef]

| T [°C] | ρ [kg m−3] | E [GPa] | v | α [10−6·°C−1] | CP [J kg−1·°C−1] | λ [W m−1·°C−1] |

|---|---|---|---|---|---|---|

| 25 | 2690 | 66.94 | 0.33 | 23.5 | 945 | 167 |

| 100 | 2690 | 63.21 | 0.334 | 24.6 | 978 | 177 |

| 149 | 2670 | 61.32 | 0.335 | 25.7 | 1000 | 184 |

| 204 | 2660 | 56.8 | 0.336 | 26.6 | 1030 | 192 |

| 260 | 2660 | 51.15 | 0.338 | 27.6 | 1052 | 201 |

| 316 | 2630 | 47.17 | 0.36 | 28.5 | 1080 | 207 |

| 371 | 2630 | 43.51 | 0.4 | 29.6 | 1100 | 217 |

| 427 | 2600 | 28.77 | 0.41 | 30.7 | 1130 | 223 |

| 482 | - | 20.2 | 0.42 | - | 1276 | - |

| A [MPa] | B [MPa] | C | n | m | Tref [°C] | Tmelt [°C] | |

|---|---|---|---|---|---|---|---|

| 324 | 114 | 0.002 | 0.42 | 1.34 | 24 | 583 | 1.0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Wang, M.; Zhang, H.; Zhang, X.; Yu, T.; Wu, Z. A Finite Element Model to Simulate Defect Formation during Friction Stir Welding. Metals 2017, 7, 256. https://doi.org/10.3390/met7070256

Zhu Z, Wang M, Zhang H, Zhang X, Yu T, Wu Z. A Finite Element Model to Simulate Defect Formation during Friction Stir Welding. Metals. 2017; 7(7):256. https://doi.org/10.3390/met7070256

Chicago/Turabian StyleZhu, Zhi, Min Wang, Huijie Zhang, Xiao Zhang, Tao Yu, and Zhenqiang Wu. 2017. "A Finite Element Model to Simulate Defect Formation during Friction Stir Welding" Metals 7, no. 7: 256. https://doi.org/10.3390/met7070256