Effect of Current on Structure and Macrosegregation in Dual Alloy Ingot Processed by Electroslag Remelting

Abstract

:1. Introduction

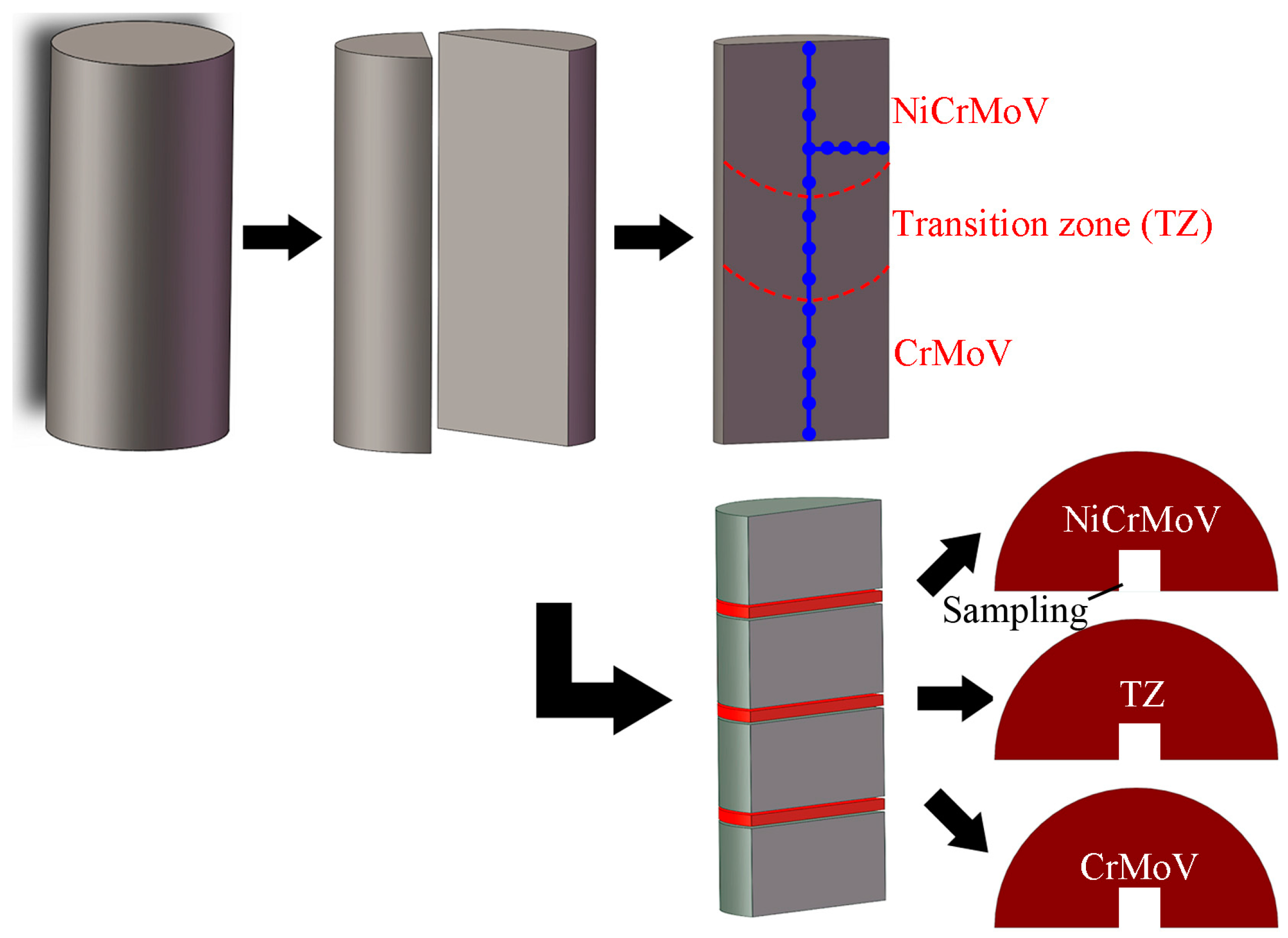

2. Experimental Section

2.1. Experimental Apparatus and Method

2.2. Specimen Preparation and Analyzing Methods

3. Results and Discussion

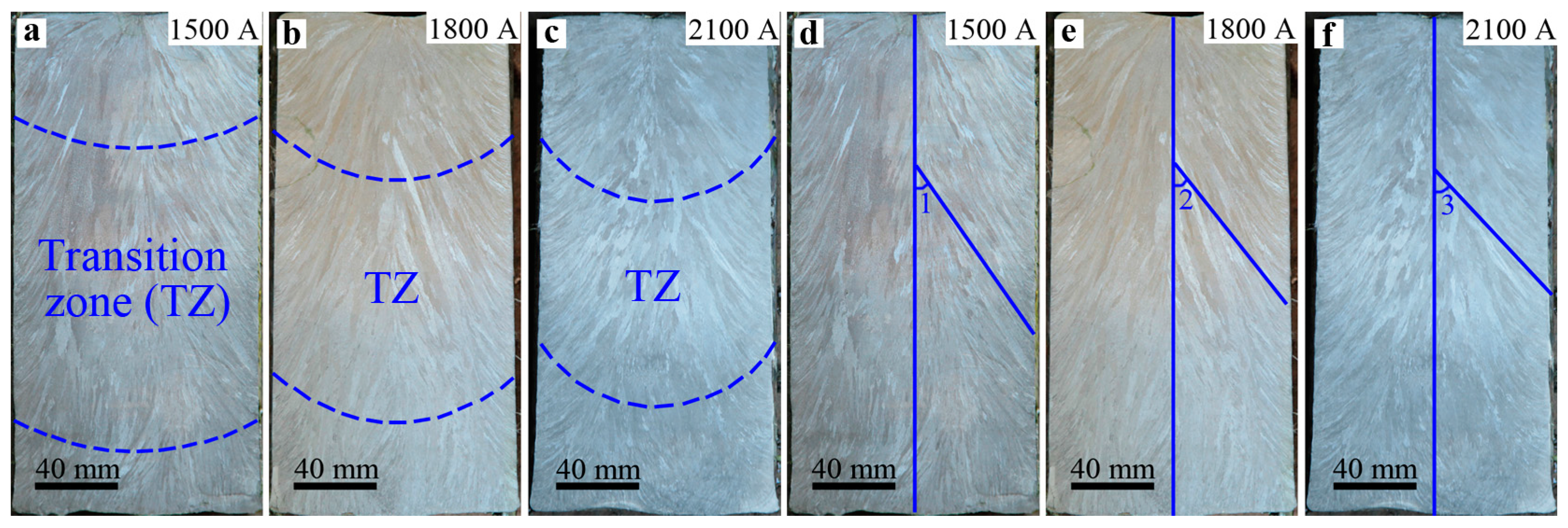

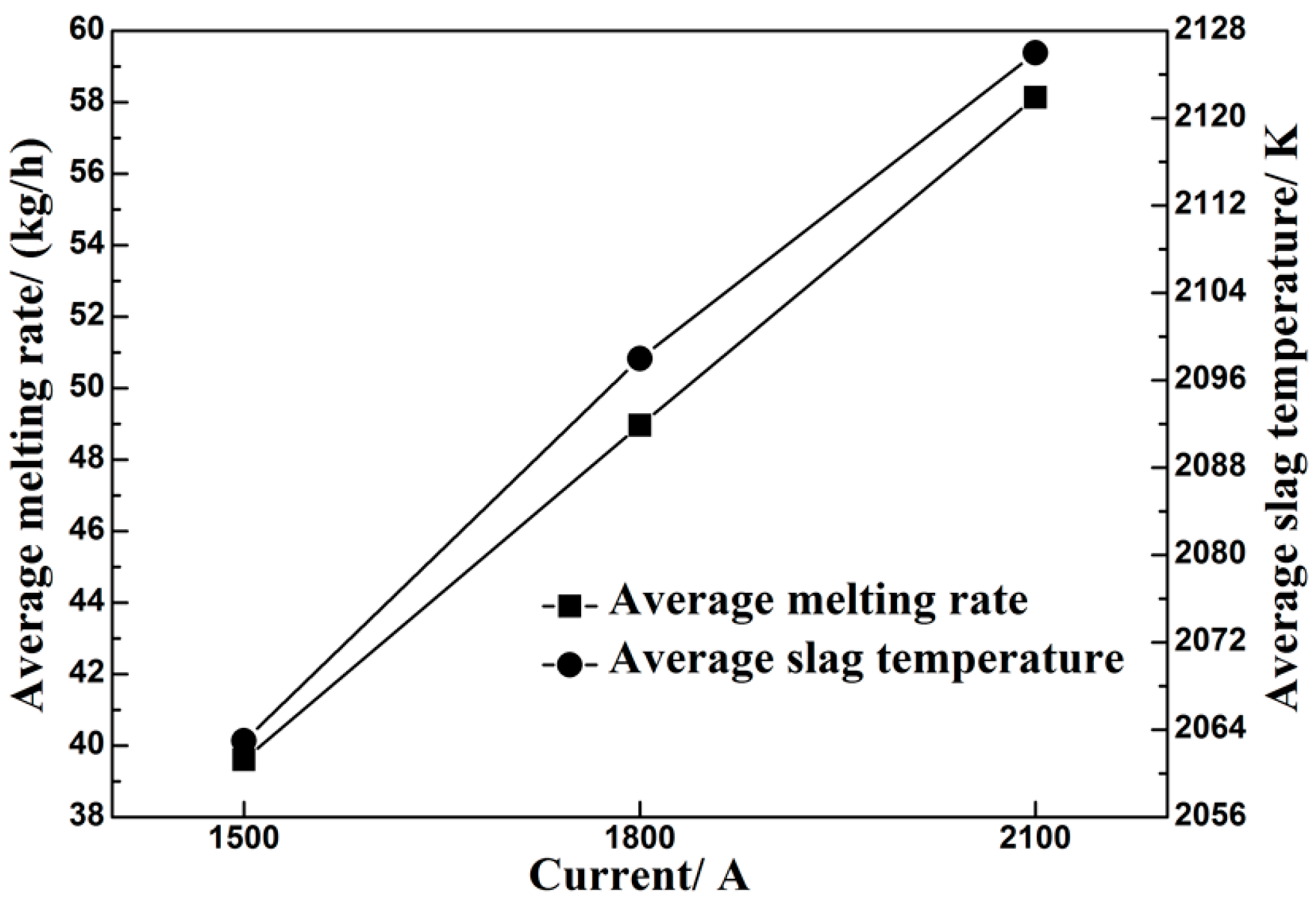

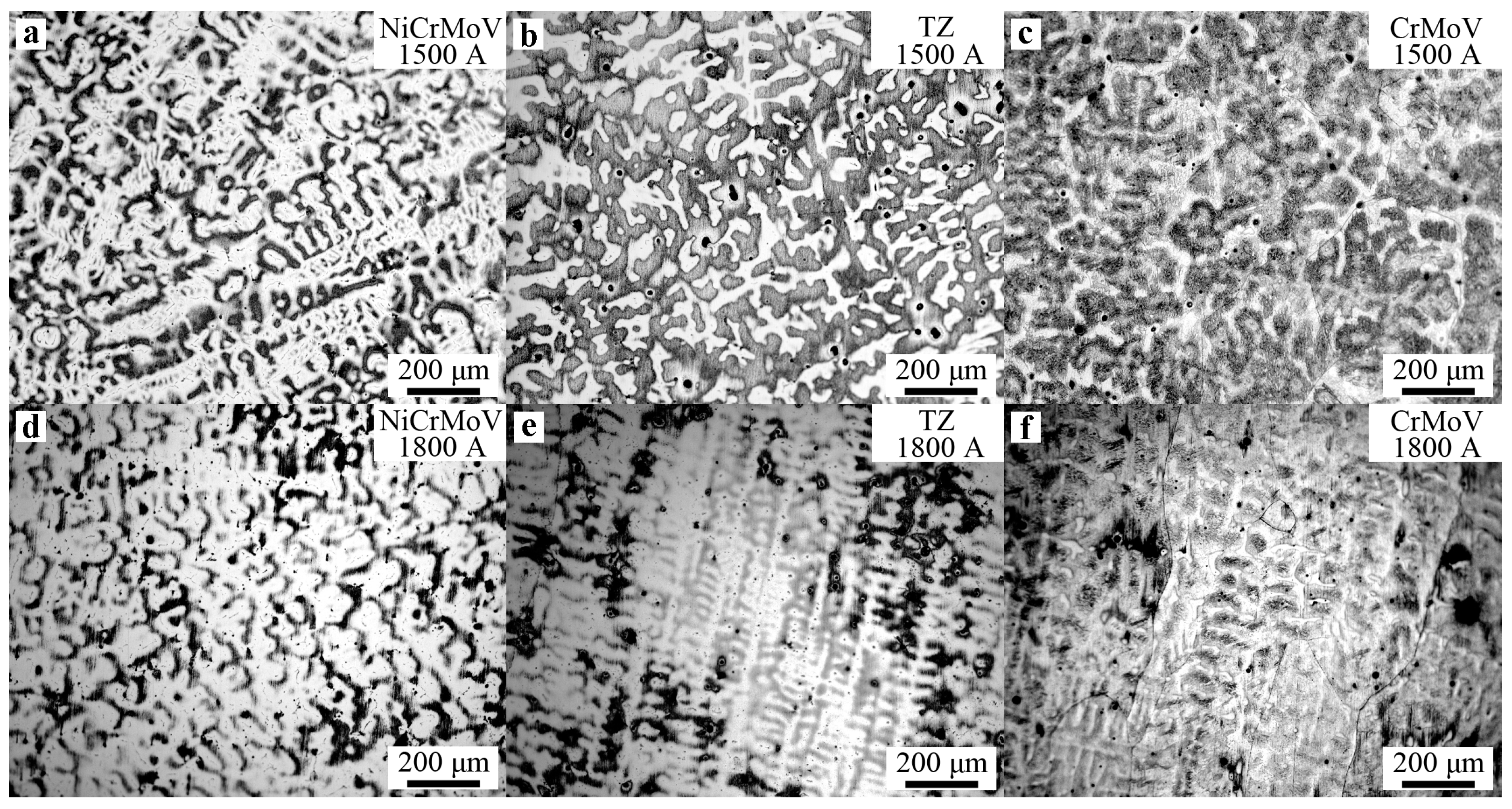

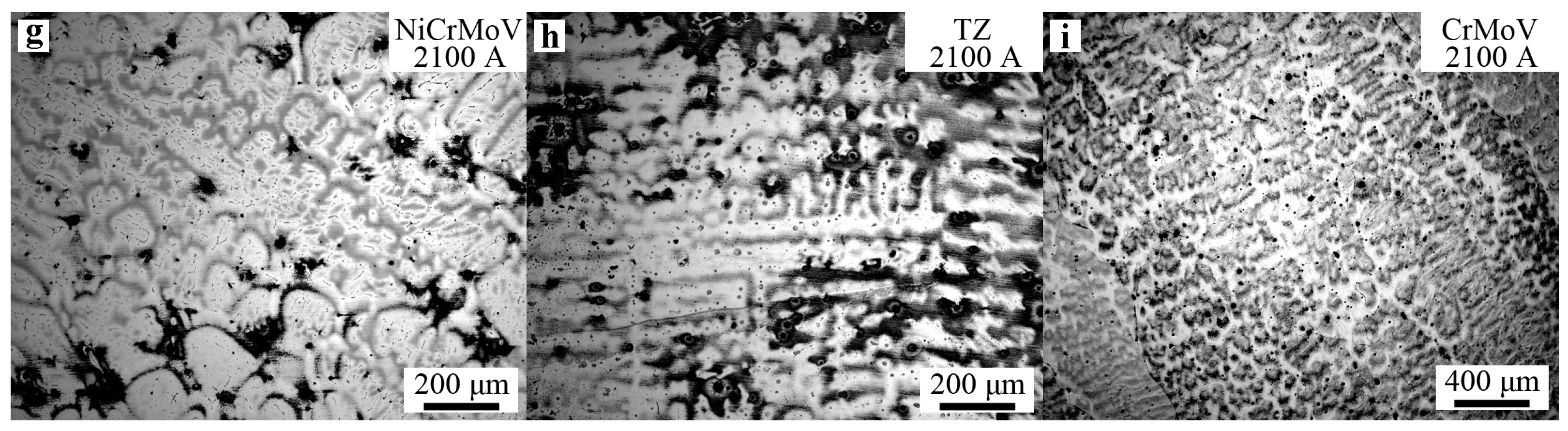

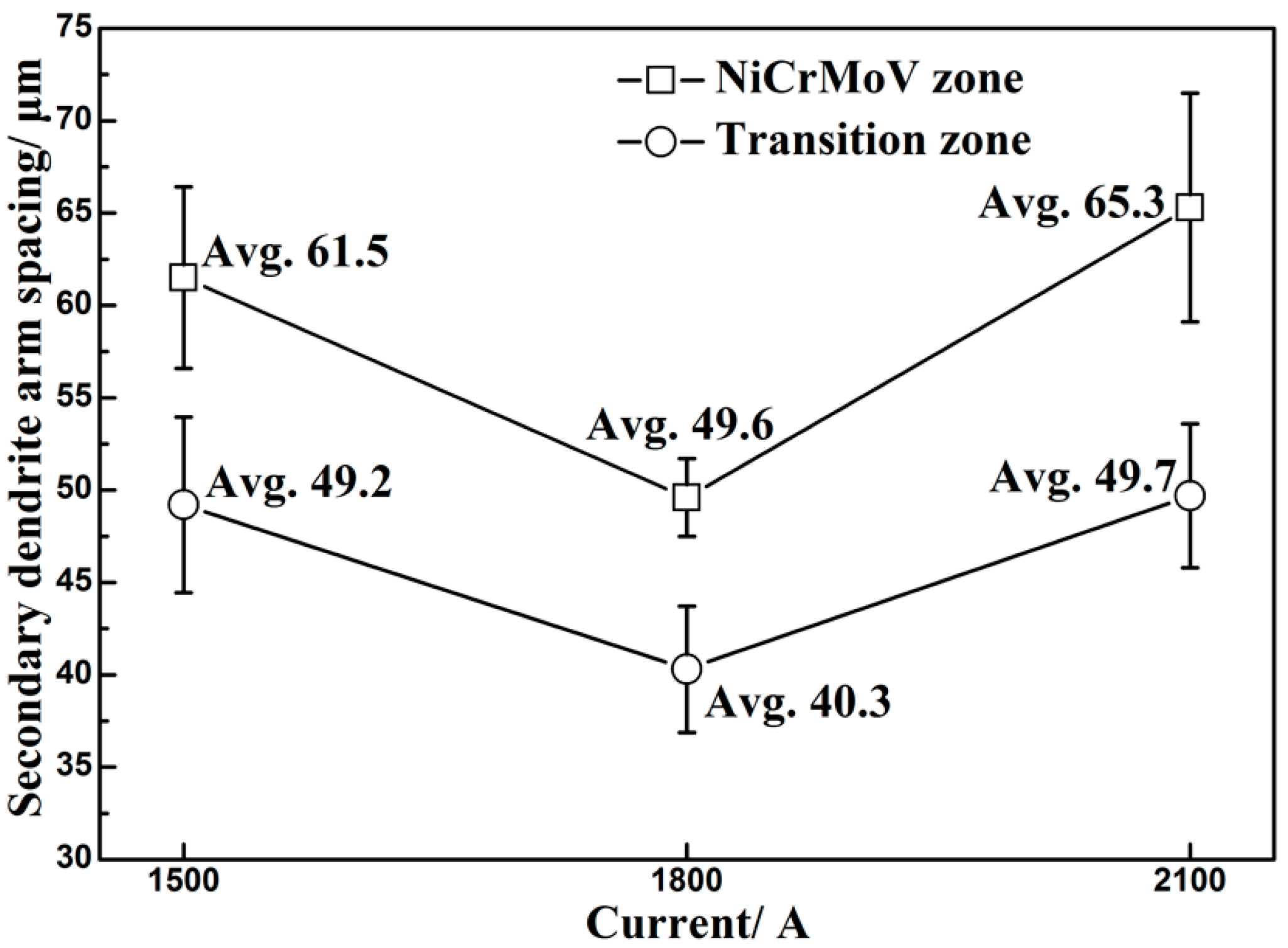

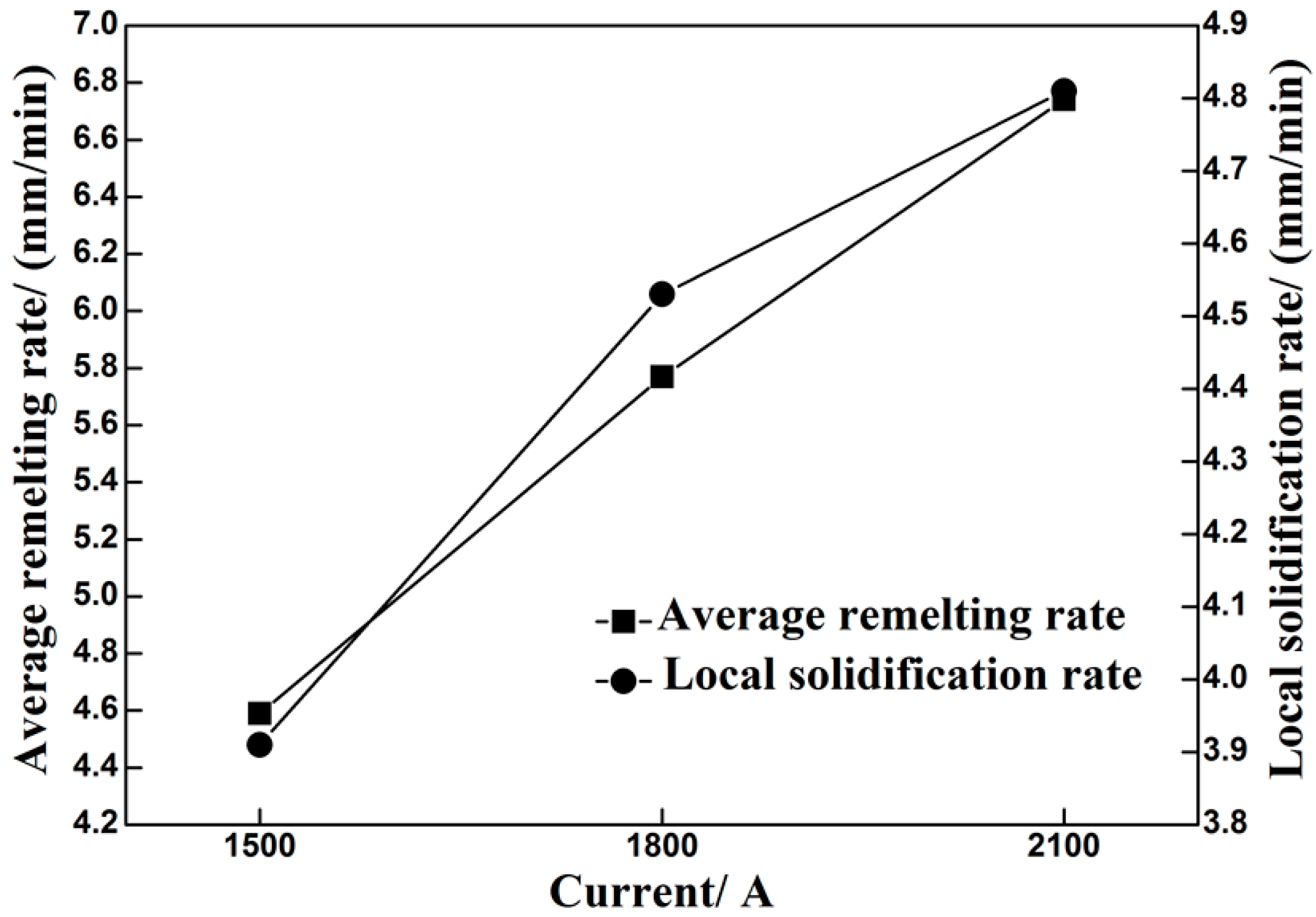

3.1. Macro- and Microstructure Characterization of Three Ingots Made via ESR with Different Currents

3.2. Macrosegregation of Three Ingots Made via ESR with Different Currents

4. Conclusions

- (1)

- The macrostructures of three ingots are nearly similar. The thin equiaxed grains region is situated under the ingot surface, and the columnar grains region lies inside the ingot. The typical columnar structure shows no discontinuity among the CrMoV zone, the transition zone and NiCrMoV zone in three ingots. With the increase of the current, the grain growth angle (the angle between grain growth direction and axis of ingot) increases due to the deeper molten metal pool.

- (2)

- The SDAS firstly decreases, then increases with the increase of the current. The SDAS is dominated by the combined effect of the local solidification rate and thickness of the mushy region. With a current of 1800 A, the SDAS is the smallest and the cooling rate is the fastest, indicating that less dendrite segregation and finer precipitates exist in the ingot.

- (3)

- With the increase of the current, the thickness of the transition zone decreases. The macrosegregation becomes severer due to the fiercer flows forced by the Lorentz force and the thermal buoyancy force. The cooling rate first increases, then decreases, which is dominated by a combined effect of the flows between the mushy region and metal pool and the temperature gradient at the mushy zone of the solidification front.

- (4)

- Under the comprehensive consideration, the dual alloy ingot processed by the ESR with a current of 1800 A is the best due to the smallest SDAS, the appropriate grain growth angle, moderate macrosegregation and thickness of the transition zone. The present work clarifies the effect of the current on the structure and macrosegregation in the dual alloy ingot processed by the ESR, providing a reference for the parameter election of the manufacture of the dual alloy rotor to be used in steam turbines using a combined cycle.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ESR | Electroslag remelting |

| TZ | Transition Zone |

| ICP-AES | Inductively Coupled Plasma-Atomic Emission Spectroscopy |

| OM | Optical Microscopy |

| SDAS | Secondary Dendrite Arm-Spacing |

| LST | Local Solidification Time |

References

- Wang, Q.; Yan, H.; Ren, N.; Li, B. Effect of current on solute transport in electroslag remelting dual alloy ingot. Appl. Therm. Eng. 2016, 101, 546–567. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Comparing the methods in determining residual life on the basis of creep tests of low-alloy Cr-Mo-V cast steels operated beyond the design service life. Int. J. Press. Vessels Pip. 2017, 152, 1–6. [Google Scholar] [CrossRef]

- Sroka, M.; Zieliński, A.; Dziuba-Kałuża, M. Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time. Metals 2017, 7, 82. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Estimation of long-term creep strength in austenitic power plant steels. Mater. Sci. Technol. 2016, 32, 780–785. [Google Scholar] [CrossRef]

- Li, Z.B. Electroslag Metallurgy Theory and Practice; Metallurgical Industry Press: Beijing, China, 2010; pp. 17–18. (In Chinese) [Google Scholar]

- Wang, Q.; Li, B. Numerical investigation on the effect of fill ratio on macrosegregation in electroslag remelting ingot. Appl. Therm. Eng. 2015, 91, 116–125. [Google Scholar] [CrossRef]

- Jiang, Z.H. Physical Chemistry and Transport Phenomena for Electroslag Metallurgy; Northeastern University Press: Shenyang, China, 2000; pp. 143–146. (In Chinese) [Google Scholar]

- Liu, Y.; Zhang, Z.; Li, G.; Wang, Q; Wang, L.; Li, B. The structural evolution and segregation in a dual alloy ingot processed by electroslag remelting. Metals 2016, 6, 325. [Google Scholar] [CrossRef]

- Kajikawa, K.; Ganesh, S.; Kimura, K.; Kudo, H.; Nakamura, T.; Tanaka, Y.; Schwant, R.; Gatazka, F.; Yang, L. Forging for advanced trubine applications: Development of multiple alloy rotor forging for turbine application. Ironmak. Steelmak. 2007, 34, 216–220. [Google Scholar] [CrossRef]

- Rao, L.; Zhao, J.H.; Zhao, Z.X.; Ding, G.; Geng, M.P. Macro-and microstructure evolution of 5CrNiMo steel ingots during electroslag remelting process. J. Iron Steel Res. Int. 2014, 21, 644–652. [Google Scholar]

- Chang, L.Z.; Shi, X.F.; Yang, H.S.; Li, Z.B. Effect of low-frequency AC power supply during electroslag remelting on qualities of alloy steel. J. Iron Steel Res. Int. 2009, 16, 7–11. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Fu, H. Dendritic arm spacing and microsegregation of directionally solidified superalloy DZ22 at various solidification rates. Acta Metall. Sin. 1995, 31, 329–332. (In Chinese) [Google Scholar]

- Li, B.; Wang, Q.; Wang, F.; Chen, M. A coupled cellular automaton-finite-element mathematical model for the multiscale phenomena of electroslag remelting H13 die steel ingot. JOM 2014, 66, 1153–1165. [Google Scholar] [CrossRef]

- Ma, D.; Zhou, J.; Chen, Z.; Zhang, Z.; Chen, Q.; Li, D. Influence of thermal homogenization treatment on structure and impact toughness of H13 ESR steel. J. Iron Steel Res. Int. 2009, 16, 56–60. [Google Scholar] [CrossRef]

- Mitchell, A. Solidification in remelting processes. Mater. Sci. Eng. A 2005, 413, 10–18. [Google Scholar] [CrossRef]

- Hernandez-Morales, B.; Mitchell, A. Review of mathematical models of fluid flow, heat transfer, and mass transfer in electroslag remelting process. Ironmak. Steelmak. 1999, 26, 423–438. [Google Scholar] [CrossRef]

- Mitchell, A.; Joshi, S.; Cameron, J. Electrode temperature gradients in the electroslag process. Metall. Trans. 1971, 2, 561–567. [Google Scholar] [CrossRef]

- Mitchell, A.; Joshi, S. The thermal characteristics of the electroslag process. Metall. Trans. 1973, 4, 631–642. [Google Scholar] [CrossRef]

- Fezi, K.; Yanke, J.; Krane, M.J.M. Macrosegregation during electroslag remelting of alloy 625. Metall. Mater. Trans. B 2015, 46, 766–779. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, F.; Li, B.; Tsukihashi, F. A three-dimensional comprehensive model for prediction of macrosegregation in electroslag remelting ingot. ISIJ Int. 2015, 55, 1010–1016. [Google Scholar] [CrossRef]

- Jardy, A.; Ablitzer, D.; Wadier, J.F. Magnetohydronamic and thermal behavior of electroslag remelting slags. Metall. Mater. Trans. B 1991, 22, 111–120. [Google Scholar] [CrossRef]

- Kharicha, A.; Ludwig, A.; Wu, M. On melting of electrodes during electro-slag remelting. ISIJ Int. 2014, 54, 1621–1628. [Google Scholar] [CrossRef]

- Medina, S.F.; Andres, M.P. Electrical Field in the Resistivity Medium (Slag) of the ESR Process: Influence on Ingot Production and Quality. Ironmak. Steelmak. 1987, 14, 110–121. [Google Scholar]

- Zhong, Y.; Qiang, L.; Fang, Y.; Wang, H.; Peng, M.; Dong, L.; Zheng, T.; Lei, Z.; Ren, W.; Ren, Z. Effect of transverse static magnetic field on microstructure and properties of GCr15 bearing steel in electroslag continuous casting process. Mater. Sci. Eng. A 2016, 660, 118–126. [Google Scholar] [CrossRef]

- Won, Y.M.; Thomas, B.G. Simple model of microsegregation during solidification of steels. Metall. Mater. Trans. A 2001, 32, 1755–1767. [Google Scholar] [CrossRef]

- Dong, J.; Cui, J.; Zeng, X.; Ding, W. Effect of low-frequency electromagnetic field on microstructures and macrosegregation of Φ270 mm DC ingots of an Al-Zn-Mg-Cu-Zr alloy. Mater. Lett. 2005, 59, 1502–1506. [Google Scholar] [CrossRef]

- Zhang, B.; Cui, J.; Lu, G. Effect of low-frequency magnetic field on macrosegregation of continuous casting aluminum alloys. Mater. Lett. 2003, 57, 1707–1711. [Google Scholar] [CrossRef]

- Schneider, M.C.; Beckermann, C. Formation of macrosegregation by multicomponent thermosolutal convection during the solidification of steel. Metall. Mater. Trans. A 1995, 26, 2373–2388. [Google Scholar] [CrossRef]

- Weber, V.; Jardy, A.; Dussoubs, B.; Ablitzer, D.; Ryberon, S.; Schmitt, V.; Hans, S.; Poisson, H. A comprehensive model of the electroslag remelting process: Description and validation. Metall. Mater. Trans. B 2009, 40, 271–280. [Google Scholar] [CrossRef]

| Electrode | C | Mn | Si | P | S | Cr | Ni | Mo | Nb | Al | Ti | T.[O] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elec. NiCrMoV | 0.106 | 1.67 | 0.37 | 0.018 | 0.039 | 16.28 | 7.45 | 0.117 | 0.039 | 0.009 | 0.012 | 0.0156 |

| Elec. CrMoV | 0.074 | 3.94 | 0.40 | 0.020 | 0.011 | 12.25 | 5.85 | 0.140 | 0.032 | 0.014 | 0.008 | 0.0121 |

| ESR Ingots | [%C] | ||

|---|---|---|---|

| 1500 A | 1800 A | 2100 A | |

| NiCrMoV | 0.108 | 0.103 | 0.107 |

| TZ | 0.091 | 0.093 | 0.094 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, Z.; Li, G.; Wang, Q.; Wang, L.; Li, B. Effect of Current on Structure and Macrosegregation in Dual Alloy Ingot Processed by Electroslag Remelting. Metals 2017, 7, 185. https://doi.org/10.3390/met7060185

Liu Y, Zhang Z, Li G, Wang Q, Wang L, Li B. Effect of Current on Structure and Macrosegregation in Dual Alloy Ingot Processed by Electroslag Remelting. Metals. 2017; 7(6):185. https://doi.org/10.3390/met7060185

Chicago/Turabian StyleLiu, Yu, Zhao Zhang, Guangqiang Li, Qiang Wang, Li Wang, and Baokuan Li. 2017. "Effect of Current on Structure and Macrosegregation in Dual Alloy Ingot Processed by Electroslag Remelting" Metals 7, no. 6: 185. https://doi.org/10.3390/met7060185