2. Materials and Methods

Starting materials in powder form (Fe3Al (<100 µm); Ametek Ltd., Eighty Four, PA, USA and TiC (<5 µm); Alfa Aesar, Ward Hill, MA, USA) were milled together for 3 h, using a high-energy ball mill (Zoz GmbH, Wenden, Germany). Two of the contents of retained TiC were chosen: 30 and 50 vol. %. The weight ratio of ball-to-powder was chosen to be 10:1 and the milling process was carried out in an argon atmosphere in order to prevent oxidation.

Mild steel plates were chosen as the substrate. Prior to deposition, the substrate plates were sand-blasted to roughen the surface and then washed with acetone. The feedstock powder was sprayed on the substrate using a Praxair JP-8000 HVOF (Concord, NH, USA) spray system.

Table 1 indicates the basic projection parameters.

An X-ray diffractometer (XRD, SIEMENS, D5000, Karlsruhe, Germany) was used to identify phase composition of the starting powders and the sprayed coatings. The analysis was done with CuKα (λ = 1.54056 Å) using a scan speed and steps of 1°/min. and 0.02°, respectively. A 2θ range of 20–90 was chosen in which all major reflections of Fe3Al and TiC are covered. Microstructural studies and chemical analysis were carried out using a scanning electron microscope equipped with energy dispersive X-ray spectroscopy (EDX, PGT Avalon, Princeton Gamma Tech Instruments, Princeton, NJ, USA). Electron probe microanalysis (EPMA) was performed for elemental mapping. A high resolution SEM (Hitachi High-Technologies, SU–8230, Rexdale, ON, Canada) was utilized for microscopic analyses of the fracture surface.

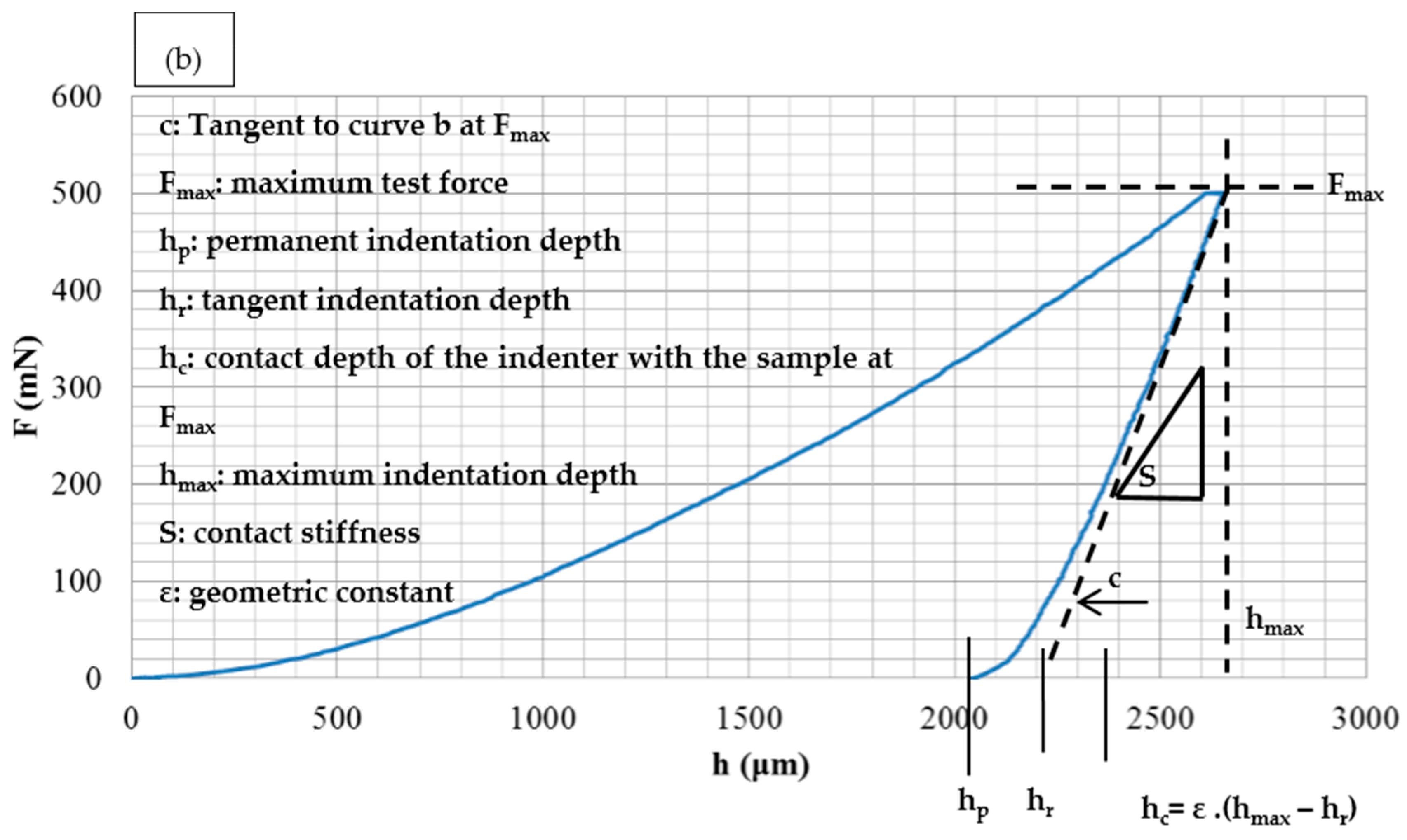

In order to evaluate the mechanical properties of the coatings, microindentation was carried out on a polished cross-section of the coatings, using a CSM instrument (CSM, Peseux, Switzerland) equipped with a Vickers tip. Maximum load of indentation was 500 mN with a loading time of 30 s. The load-displacement curves, according to the most widely used standard Oliver-Pharr [

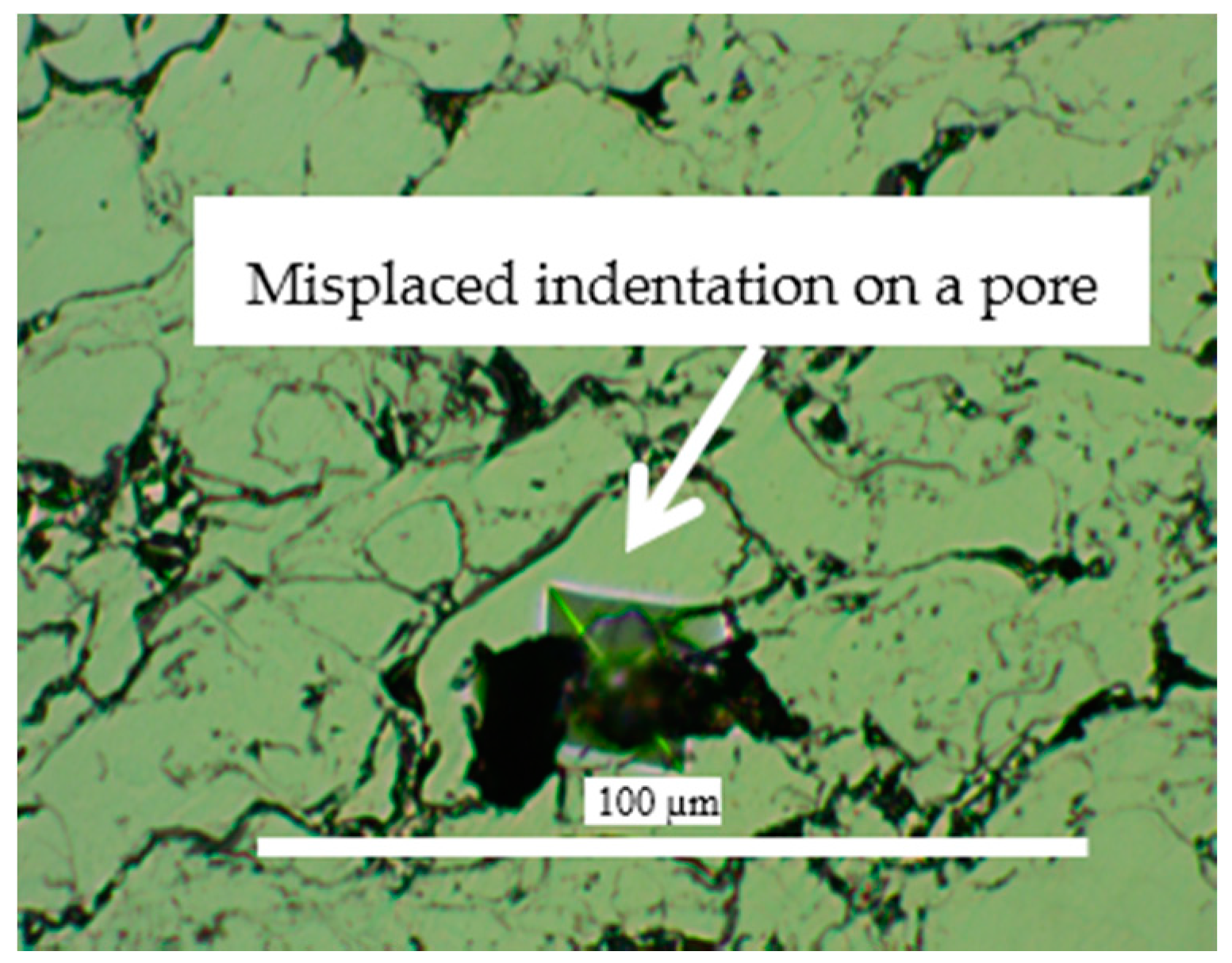

12] procedure, were recorded and the mechanical properties of the coatings (hardness, elastic modulus) were evaluated. An average value of 50 indentations is reported for each specimen. The average mechanical properties reported for each specimen should not depend on local imperfections of the microstructure (such as indentation on pores or undesired phases), an example of which is shown in

Figure 1 (indentation on a pore). Such uncertain hardness and elastic modulus values have been deleted before reporting the average value. A three-point bending test at room temperature was used to break the coating and study the fracture surface. Using Instron-Satec press (T20000, Grove City, PA, USA), the force was applied with a 2 mm/min speed on the opposite side of the coated surface of the sample. The sample was thus bent until large cracks appeared on the surface. The fractured surfaces of the cracks were then examined using the high-resolution scanning electron microscope.

Prior to the sliding tests, the specimens were mounted in an epoxy resin and then polished to obtain a surface roughness (

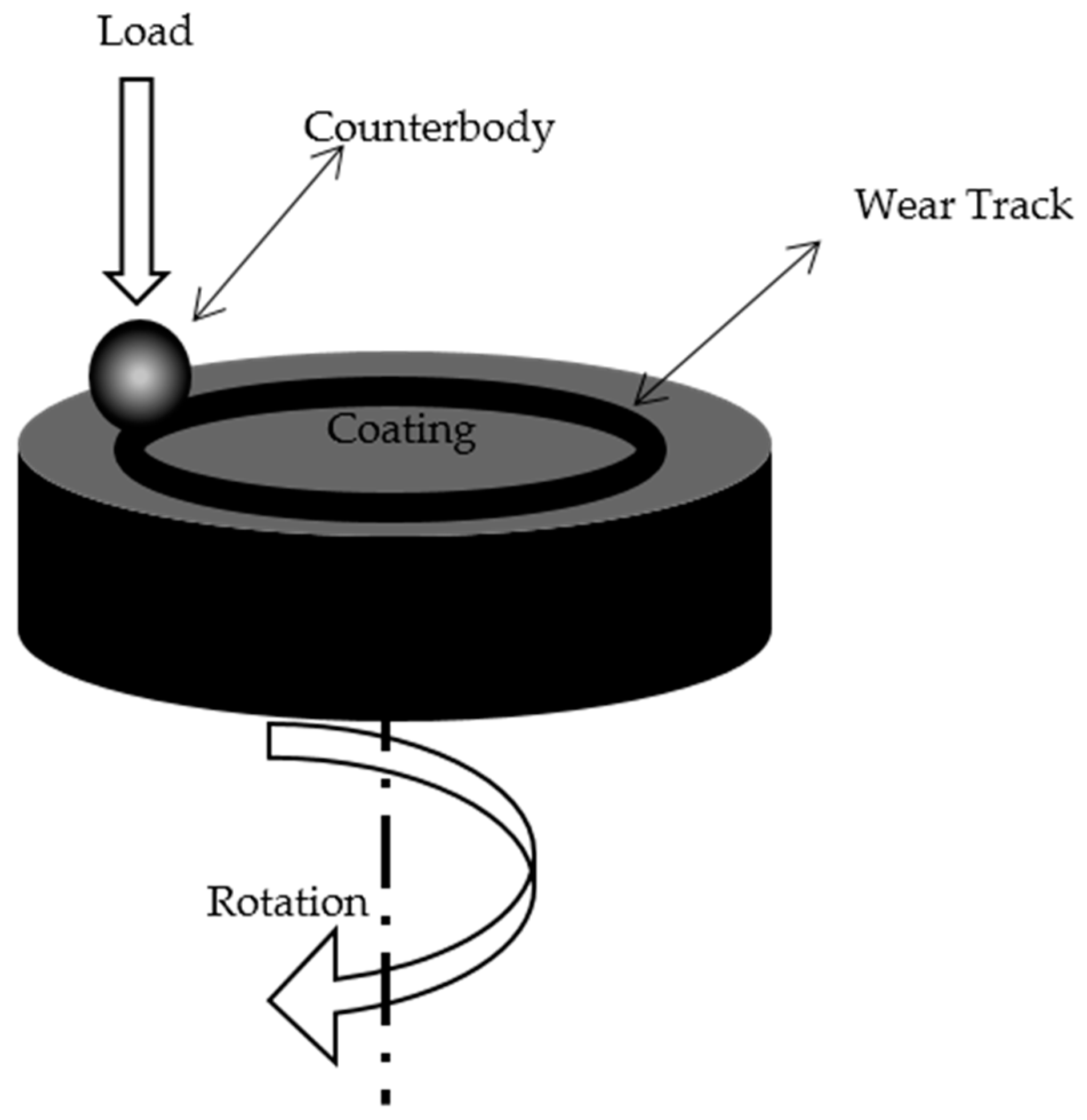

Ra) of about 0.8. Dry sliding wear tests (ball-on-disc) were carried in air at room temperature according to ASTM G99–05. The ball-on-disk tribometer is schematically shown in

Figure 2. A 6.33 mm diameter alumina ball was used as the counterpart sliding against the coating surface. In ball-on-disk tests, it is preferable to use a harder ball than the coating in order to induce more wear on the coating rather than on the ball. Al

2O

3 balls with a Vickers hardness of 1700 were used in this study. Each test was conducted with a new ball in order to retain uniform test conditions. A constant load of 5 N, a sliding speed of 0.1 m·s

−1 and a sliding distance of 1000 m were used during the tests. The cross-sectional worn area of the wear tracks was measured with a Dektak–150 surface profilometer (Bruker Corporation, San Jose, CA, USA) in order to calculate the worn volume. Finally, the wear rate was calculated as:

where

V is the worn volume,

W (N) is the applied load, and

s (m) is the total sliding distance.

3. Results and Discussion

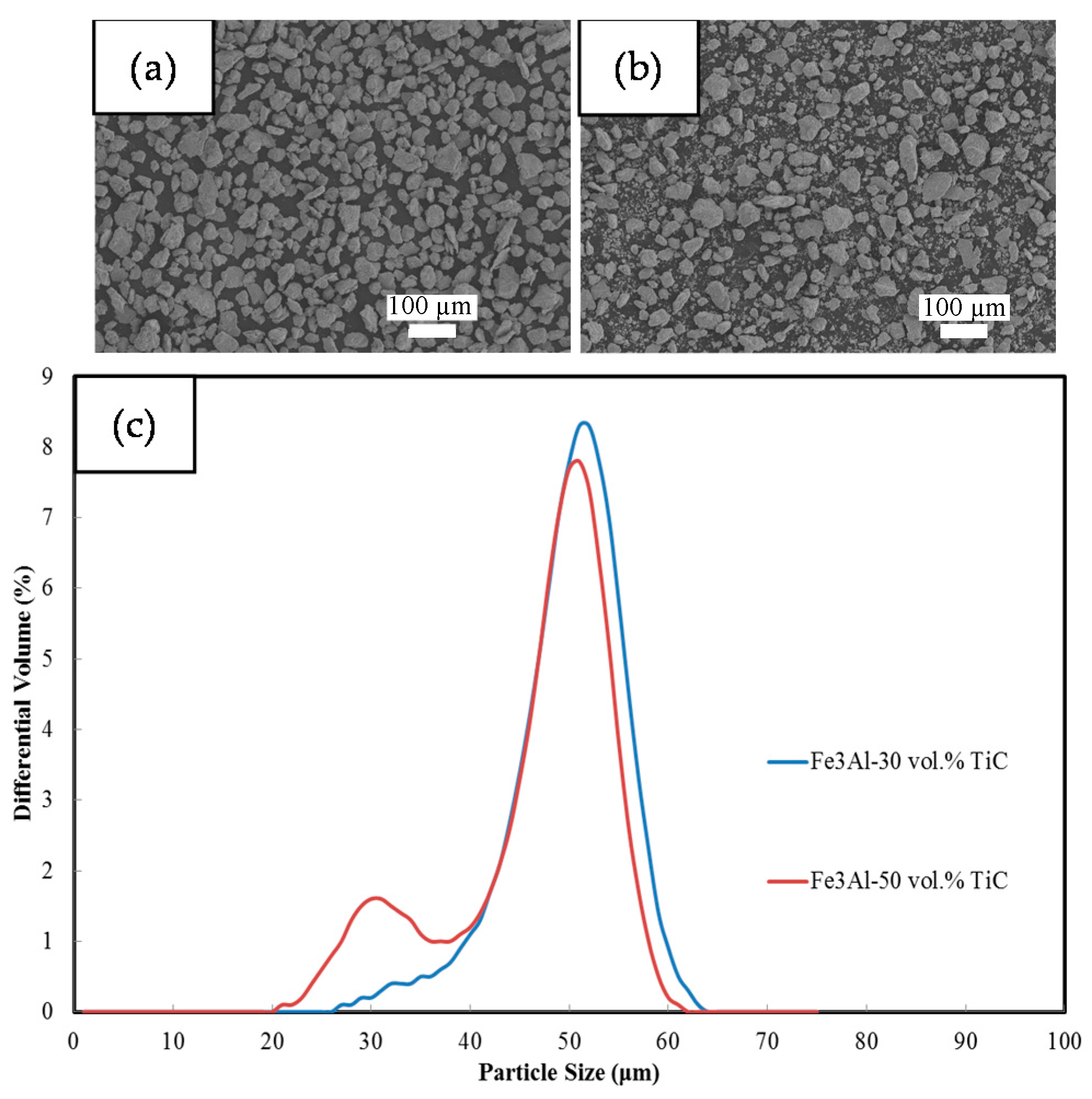

Figure 3 shows the SEM images of the Fe

3Al–TiC milled composite powders. The particles have irregular shape, which is common for powders processed with high-energy ball milling. The particle size distribution profile of the milled powders (

Figure 3c) shows a bimodal particle size distribution with two peaks at around 30 and 55 μm. The sample with 50 vol. % TiC shows a more pronounced peak at small sizes, which is due to the higher ceramic volume fraction, making the composite more fragile. Despite having a bimodal size distribution and irregular shape feedstock powder, this morphology and size enabled easy supply and good flow of the feedstock powder to the HVOF gun during the spraying process.

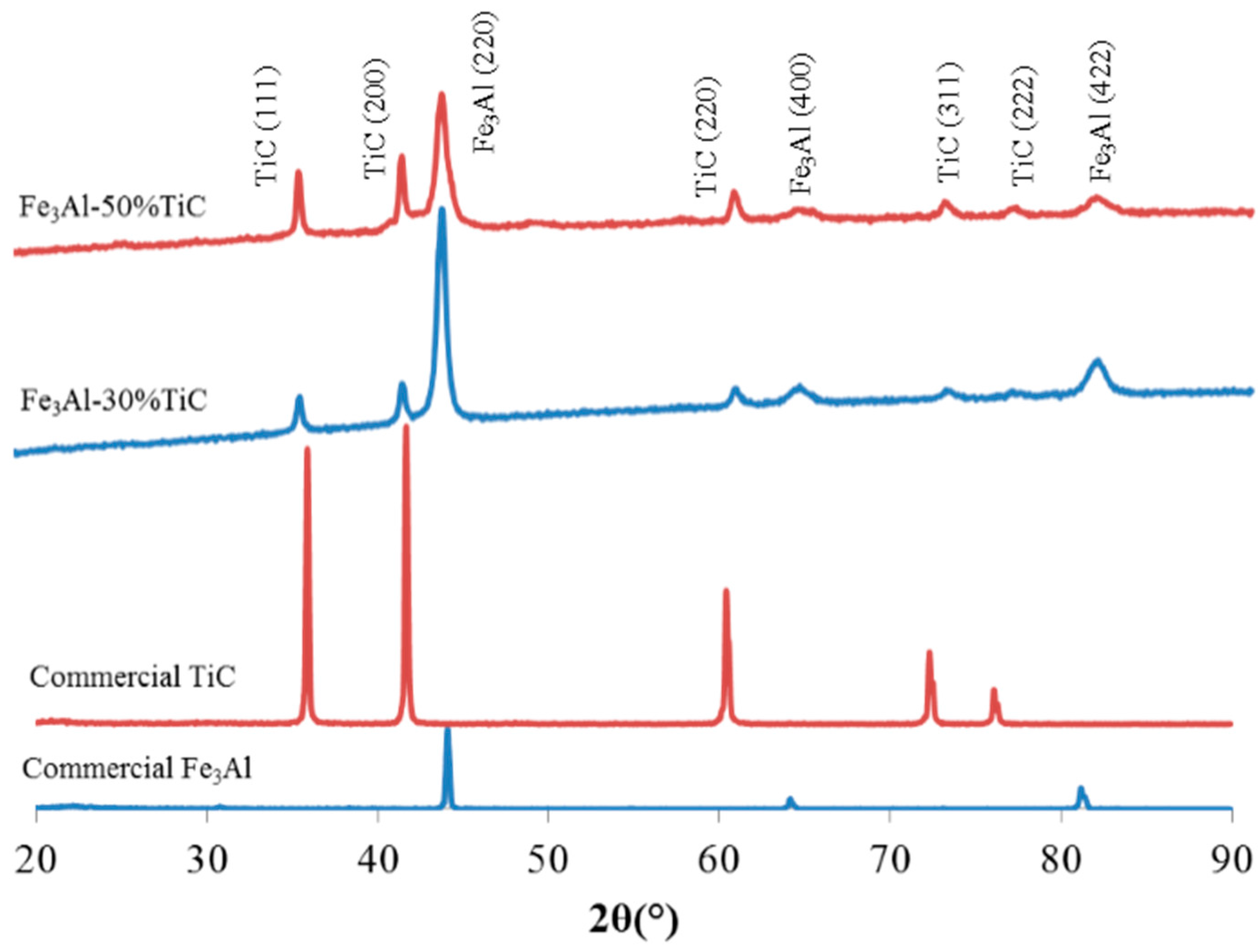

XRD patterns of the Fe

3Al and TiC starting powders as well as those for the HVOF deposited composite coatings are presented in

Figure 4. It is clear that the phases of the as-sprayed coatings did not significantly differ from that of the starting powders. The slight peak broadening observed in the coatings could be associated with the residual stress due to the high level of plastic deformation and the subsequent elevated cooling rate. It is shown that the samples mostly consist of two major phases, namely iron aluminide and titanium carbide, with no other detectable phases, e.g., oxide or complex decomposed carbides. In fact, the HVOF flame temperature and the particle residential time in the flame are not high enough to trigger a reaction. Similar results were reported by Isalgue et al. [

13], who compared the phase composition of TiC-reinforced cermets deposited by HVOF and Plasma Spray techniques. These authors observed less decomposition of TiC during HVOF deposition.

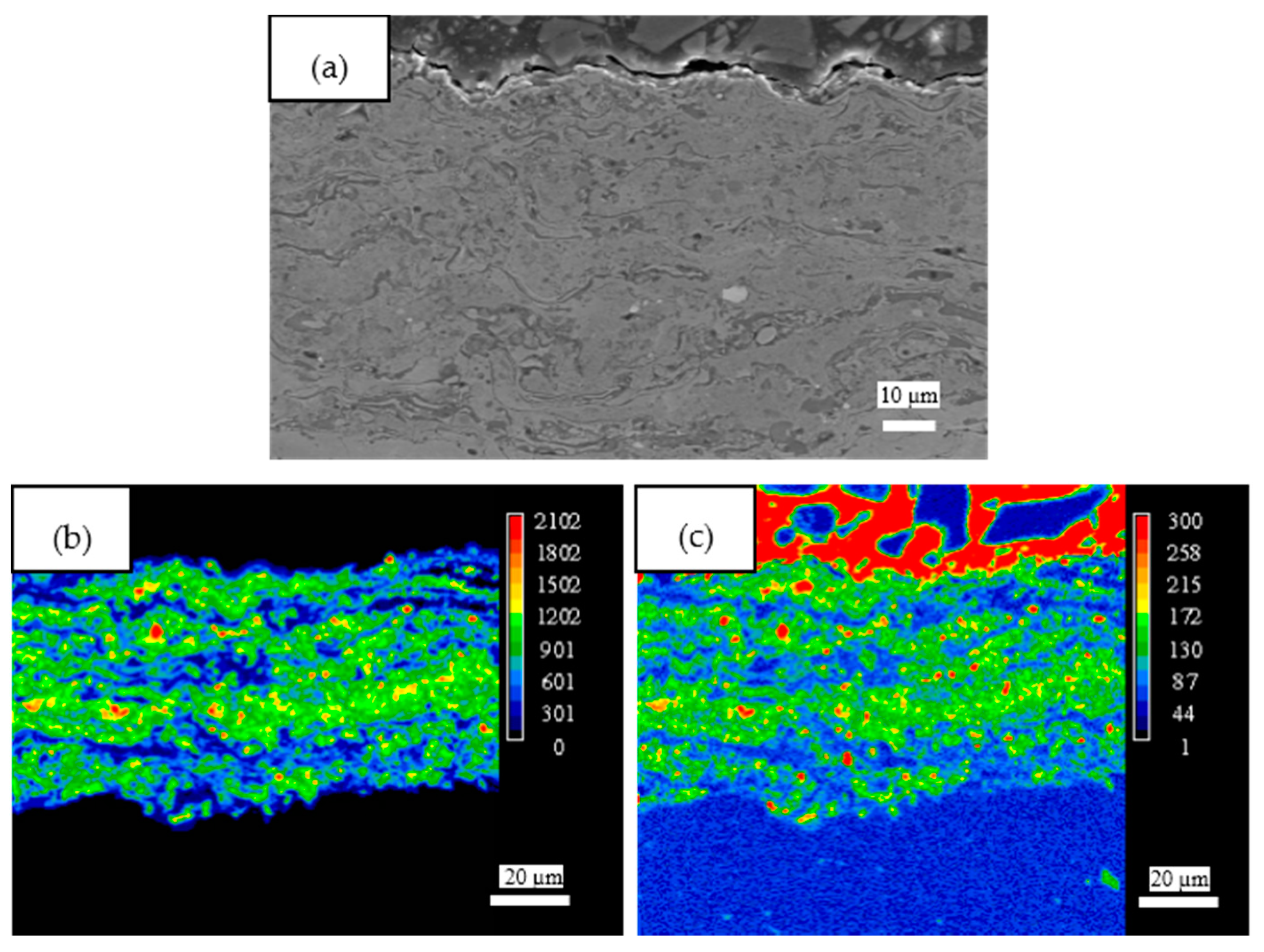

Figure 5a shows the typical microstructure from the polished surface of a coating obtained by Fe

3Al–50 vol. % TiC feedstock. The coating consists of relatively dense (porosity <5%, measured by image analyzing method) and homogenous lamellar microstructure which seems to be well-bonded to the steel substrate. The thickness is around 80 µm.

Figure 5b,c show the elemental distribution of titanium and carbon, respectively, in the coating. The images reveal that the reinforcing TiC particles are fairly well distributed throughout the microstructure of the coatings. The size of the TiC particles are less than 5 µm, as expected from the initial size of the TiC particles in the milled powder.

Figure 6 shows microindentation traces for each sample as well as their corresponding force-displacement curves. The size of the indentation trace is getting smaller as the TiC fraction increases. The force-displacement curves also show a smaller displacement for the samples with higher TiC loadings. A schematic representation of indenter-sample contact cross section is illustrated in

Figure 7a. A graphical view of load-displacement data is also presented in

Figure 7b, which defines experimental quantities involved in the hardness and elastic modulus measurements using the microindentation method.

With the addition of TiC particles into the coating microstructure, maximum indentation depth (

hmax) drops, indicating a considerable raise in the hardness of the samples. On the other hand, the results showed that the composite coatings have higher elastic modulus than the unreinforced Fe

3Al coatings. The hardness (

H) and effective elastic modulus (

Eeff) can be calculated from the load-displacement data, as follows,

and

where

Fmax is the maximum load,

A is the contact area after the indentation and β is a constant which depends on the geometry of the indenter (1.012 for a square shape trace [

11]). The effective modulus, which accounts for the fact that during the indentation, elastic deformation occurs in both the indenter and the specimen, is given by Equation (4),

where

Ei and

νi are the Young’s modulus and Poisson’s ratio for the indenter (for diamond indenter,

Ei = 1141 GPa and

νi = 0.07 [

14]), and

E and ν are the same quantities for the sample. According to Equation 3, contact area and

E have an inverse relationship.

Table 2 shows the resulting microhardness and elastic modulus of the coatings obtained from the force-displacement curves. Thus, it is obvious that the incorporation of TiC particles not only increases the hardness but also has a significant effect on increasing the elastic modulus of the sample. Similar results on the effect of titanium diboride particles on properties of the Fe–Al system have been reported [

8,

15].

The coefficient of friction (CoF) and dry sliding wear rates of the coatings were both measured in this study. However, CoF of the samples were between 0.8–1.0 and this does not seem to follow the trend of hardness or wear rates.

Table 2 also presents the sliding wear rates of the coatings. It is seen that the wear resistance of the coatings increases with increasing TiC content most likely because of the high hardness of TiC particles (2900–3200 HV). Unreinforced iron aluminide coating exhibits the highest wear rate (1.5 × 10

−3 mm

3·N

−1·m

−1), while with 30 vol. % of TiC addition, the wear rate of the composite is significantly reduced to approximately 4 × 10

−6 mm

3·N

−1·m

−1. The wear rate decreases a little more when the volume fraction of TiC particles increases from 30 to 50 vol. %. For the coatings made from unreinforced Fe

3Al, the alumina counterpart can easily penetrate the coating during sliding, resulting in significant material losses from the surface. In the Fe

3Al–TiC composite coatings, the material removal is reduced due to the presence of TiC particles, which protect the matrix during sliding. It seems that this protection is very efficient with 30 vol. % of reinforcing particles but a further increase to 50 vol. % does not improve wear resistance significantly.

Researchers have discussed the relationship between wear rate and elastic modulus (

E) in sliding wear [

16]. This is not surprising since higher elastic modulus results in a smaller contact area between the counterpart and the coating. At the same time, materials with high elastic modulus often exhibit high harnesses as well [

11]. Therefore, the consideration of both hardness and elastic modulus is important in order to explain the tribological behavior of a coating.

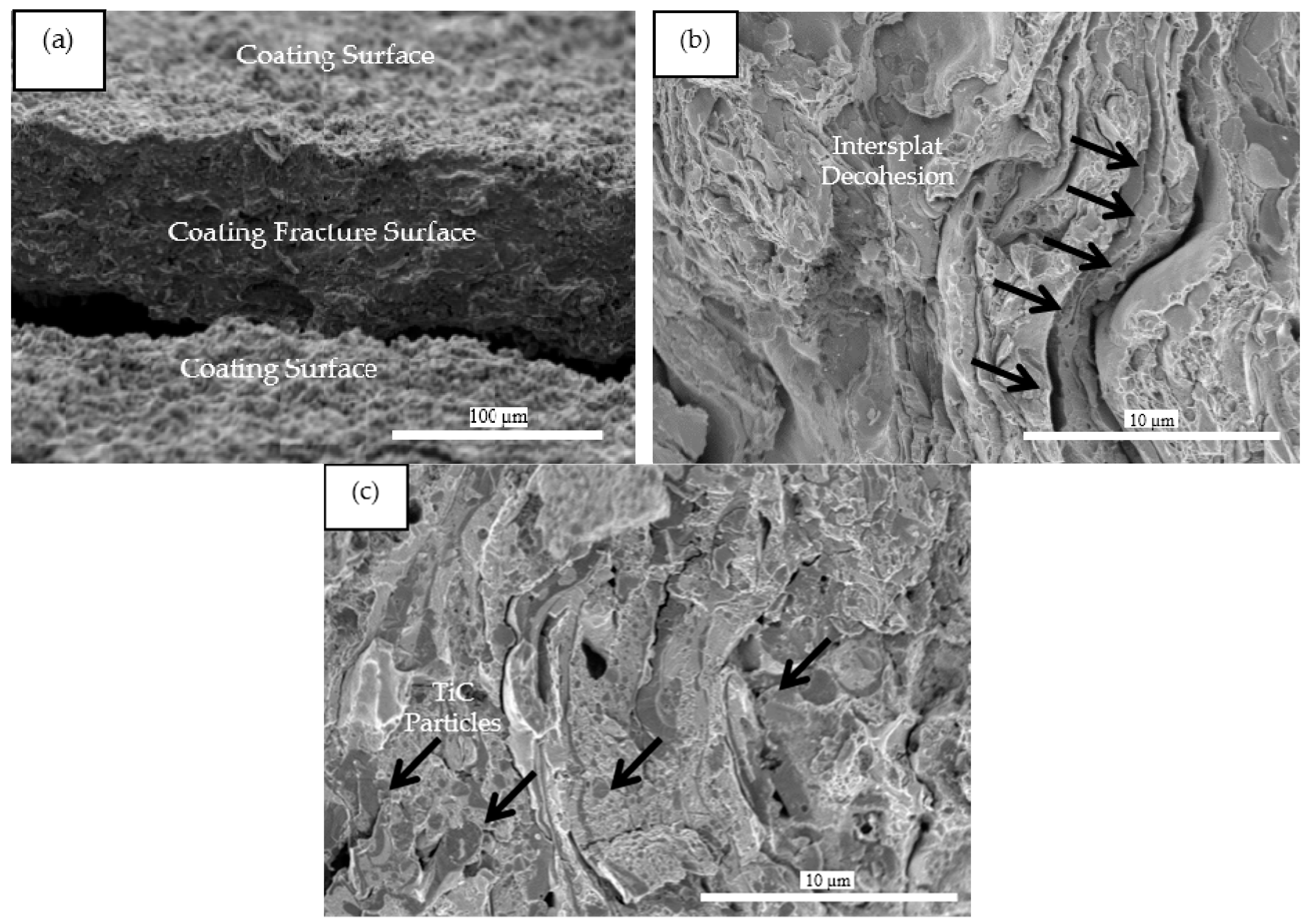

To further investigate the behavior of TiC particles within the composite coatings and their possible contribution to the wear resistance, the coated samples were fractured at room temperature (along with the substrate) using a bending setup. The SEM images of the fractured surface of the unreinforced and 50 vol. % TiC composite coating are shown in

Figure 8.

Figure 8a shows a low magnification image of a fractured coating, generated by the bending test.

Figure 8b,c show the fracture surfaces at higher magnification for unreinforced and composite samples. A lamellar structure, which is characteristic of thermally sprayed coatings [

7,

8], is found in both samples. TiC grains, surrounded by the matrix, are clearly observed in the composite coating (see arrows in

Figure 8c). However, it was found that there were distinct differences in the microstructural features of the two fractured coatings.

Figure 8b shows that the unreinforced coating is more plastically deformed, has numerous cracks and to some extent, has a porous structure, which could affect crack propagation during the wear tests [

17]. In this case, material removal occurs largely by the delamination of splats in combination with the plastic deformation, as evidenced by the fracture surface profile of the coating [

18]. Significantly fewer cracks are observed in the fractured surface of the TiC-reinforced coating (

Figure 8c). The reinforced coating shows a more uniform fractured surface with the TiC particles fully integrated within the matrix. Arrows in

Figure 8c show examples of interfaces between Fe

3Al and TiC. This is also evidenced in

Figure 9, which suggests that the TiC particles are very well bonded to the matrix. It should be mentioned that matrix-particle detachment may or may not be revealed at higher resolution studies such as TEM analyses. In

Figure 9, some TiC particles remain bonded to the matrix even after the fracture. As the projection conditions were the same for all samples, it seems that in addition to providing higher hardness and rigidity, the presence of cohesive TiC particles reduces the delamination of the coating by limiting crack propagation within the structure during wear tests. In

Figure 9 one might also observe a mixed ductile (presence of dimples) and cleavage fracture in the presence of TiC particles in the composite coating. The superior properties of the Fe

3Al–TiC coatings are thus a result of this strengthening phenomenon.

Figure 10 shows microscopic images of the surface of coatings with wear tracks. A much wider and deeper wear track profile is observed for the unreinforced iron aluminide coating. In other words, it is observed that the wear track of the composite coatings has a remarkably smaller width with considerably less depth. Different magnifications in

Figure 10a,c were selected to reveal details in the wear tracks.

Figure 10 also presents the worn surfaces of the coatings at higher magnification (

Figure 10b,d). The worn surface topographies indicate that the dominant wear mechanism for the unreinforced Fe

3Al coatings is different from that for the composite Fe

3Al–TiC coatings. This is in agreement with the findings that have been reported for other thermal spray composite coatings [

19,

20]. Since the hardness of the alumina ball (2000 HV) is much higher than that of the Fe

3Al matrix (≈300 HV), the wear marks on the unreinforced sample have been created by the plowing action of the alumina counterpart during the wear test, leading to significant delamination. Conversely, it can be seen from

Figure 10d that only a few delamination marks appear on the worn surfaces of Fe

3Al–TiC composite coating. The reinforcing particles are detectable on the top surface of the coating after sliding, indicating that they are well bonded to the matrix. When the retained TiC particles are well anchored into the matrix, they prevent the removal of the soft matrix by micro-cutting mechanisms, as observed in other composite materials [

21]. It is thus evident that the TiC particles effectively protect the aluminide matrix and limit the material removal by the Al

2O

3 counterpart.