Grain Refinement Mechanism of the As-Cast and As-Extruded Mg–14Li Alloys with Al or Sn Addition

Abstract

:1. Introduction

2. Materials and Methods

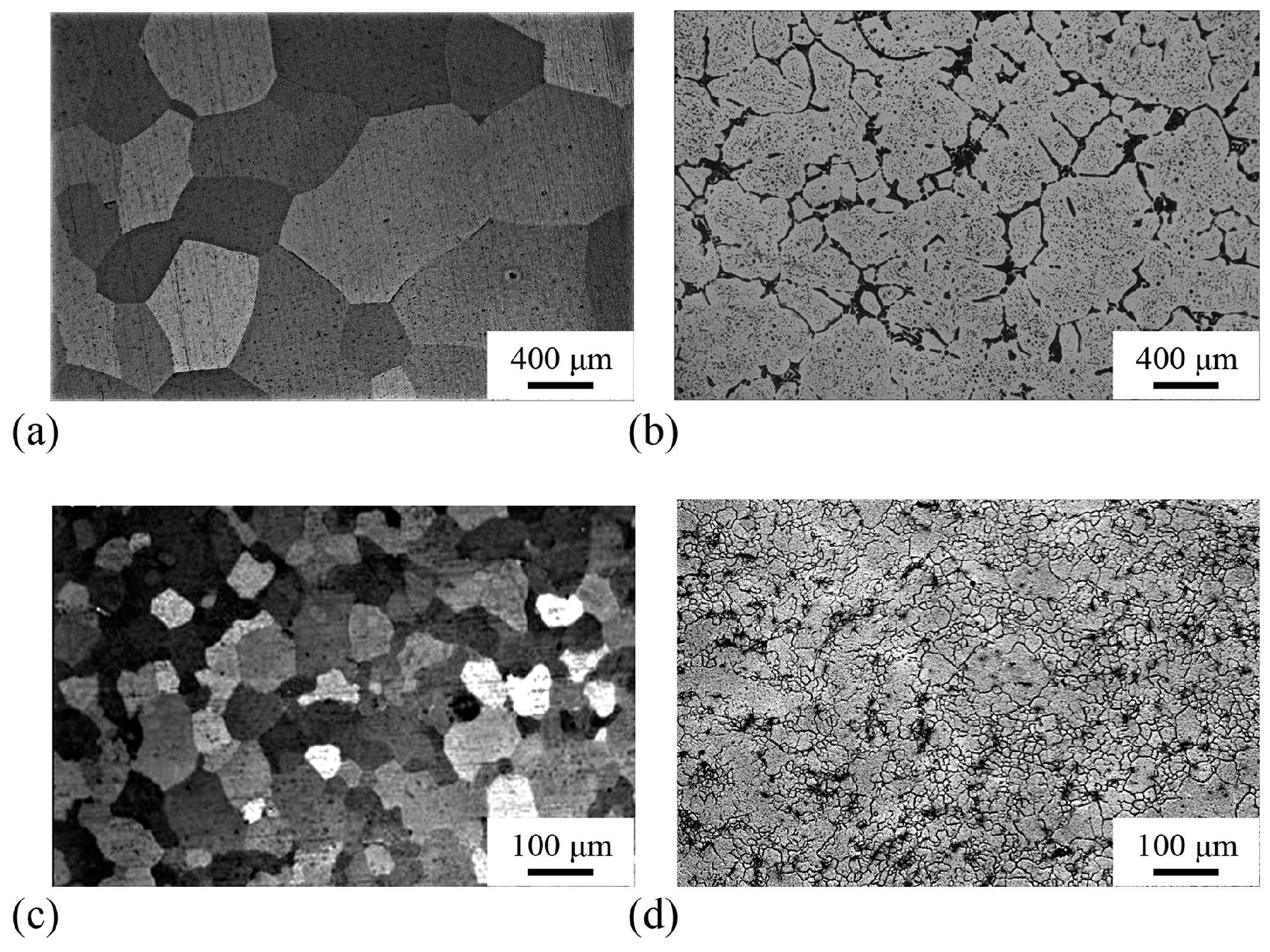

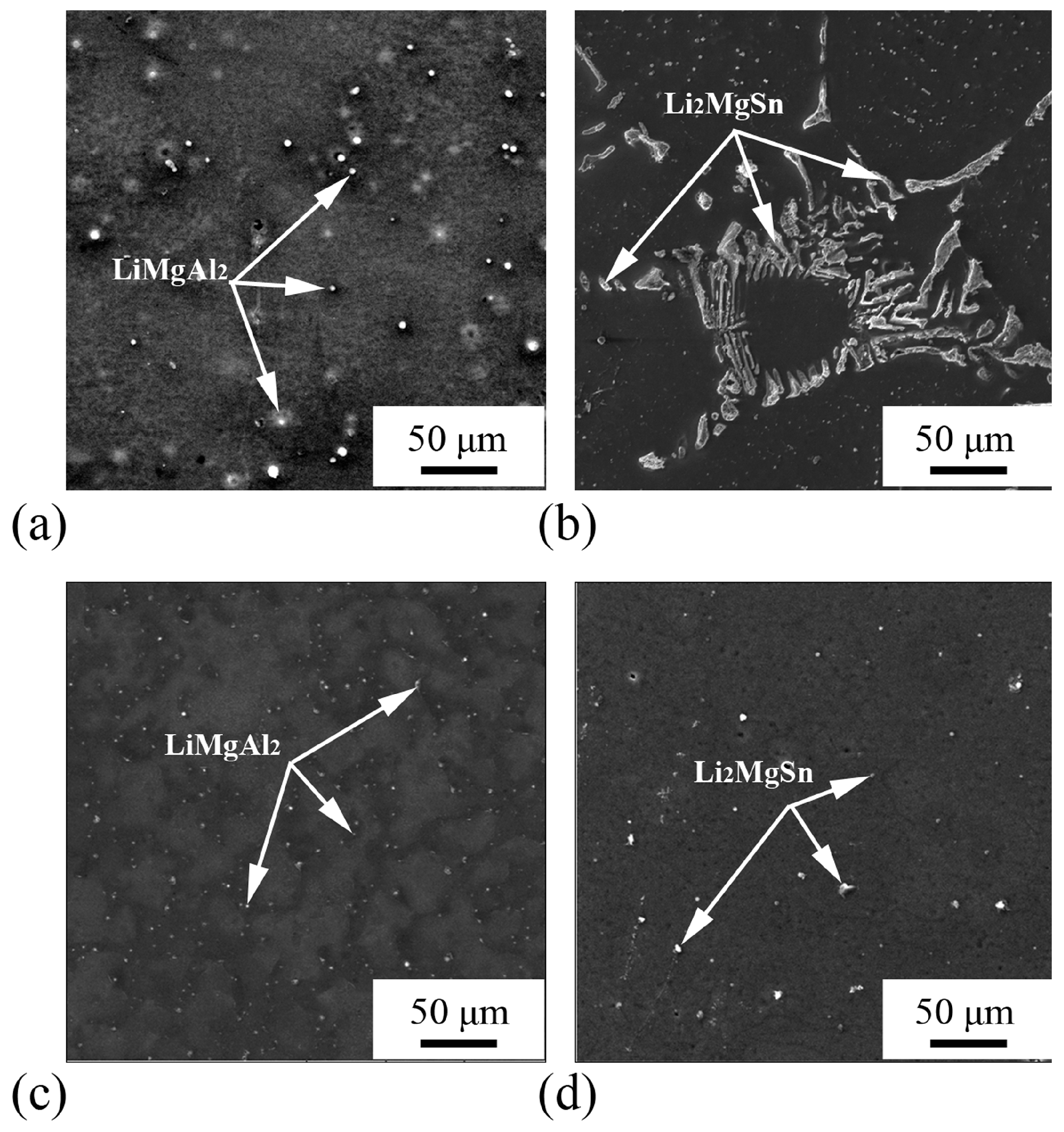

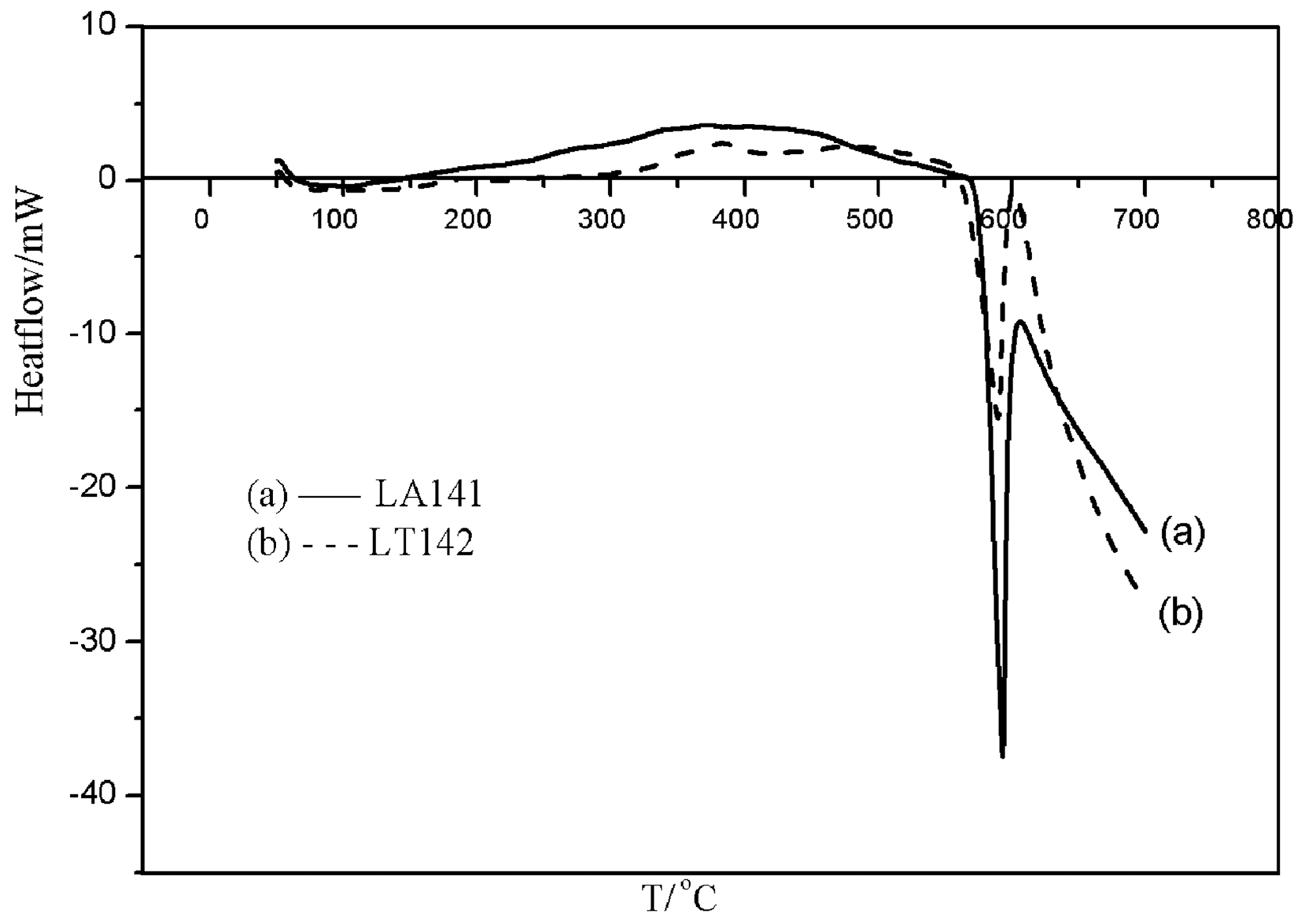

3. Results

4. Discussion

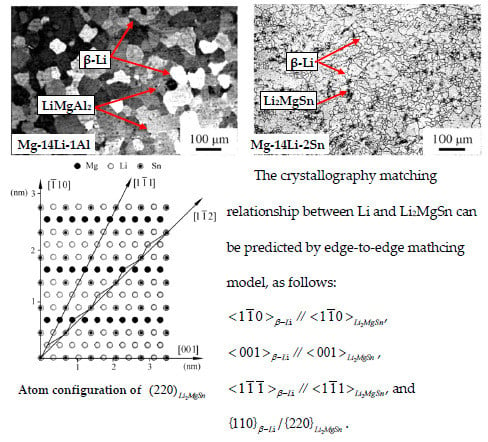

4.1. Mechanism of Grain Refinement in the As-Cast Alloys

4.2. Mechanism of Grain Refinement in the As-Extruded Alloys

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rao, G.S.; Prasad, Y. Grain boundary strengthening in strongly textured magnesium produced by hot rolling. Metall. Mater. Trans. A 1982, 13, 2219–2226. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Lu, X.; Yang, Y.; Wang, Z. Microstructure, texture and mechanical properties of hot-rolled Mg–4Al–2Sn–0.5Y–0.4Nd alloy. J. Magnes. Alloy 2016, 4, 207–213. [Google Scholar] [CrossRef]

- Chen, Z.H. Wrought Magnesium Alloy, 1st ed.; Chemical Industry Press: Beijing, China, 2005; pp. 48–57. [Google Scholar]

- Moser, Z.; Zakulski, W.; Schwitzgebel, G. Thermodynamic studies and the phase diagram of the Li–Mg system. Metall. Mater. Trans. A 1996, 30, 1120–1128. [Google Scholar]

- Zou, Y.; Zhang, L.; Wang, H.; Tong, X.; Zhang, M.; Zhang, Z. Texture evolution and their effects on the mechanical properties of duplex Mg–Li alloy. J. Alloy. Compd. 2016, 669, 72–78. [Google Scholar] [CrossRef]

- Counts, W.A.; Friák, M.; Raabe, D.; Neugebauer, J. Using ab initio calculations in designing bcc Mg–Li alloys for ultra-lightweight applications. Acta Mater. 2009, 57, 69–76. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, J.H.; Niu, Z.Y.; Li, J.Q. Effect of La-Rich Misch Metal on Microstructure and Mechanical Properties of As-Extruded Mg–14Li–3Al Alloy. Adv. Mater. Res. 2012, 391, 32–36. [Google Scholar] [CrossRef]

- Yoshida, Y.; Cisar, L.; Kamado, S.; Kojima, Y. Low temperature superplasticity of ECAE processed Mg–10% Li–1% Zn alloy. Mater. Trans. 2002, 43, 2419–2423. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium: Properties—Applications—Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Jackson, J.; Frost, P.; Loonam, A.C.; Eastwood, L.; Lorig, C. Magnesium–lithium base alloys preparation, fabrication, and general characteristics. Trans. AIME 1949, 185, 149–168. [Google Scholar]

- Yang, Y.; Peng, X.; Ren, F.; Wen, H.; Su, J.; Xie, W. Constitutive Modeling and Hot Deformation Behavior of Duplex Structured Mg–Li–Al–Sr Alloy. J. Mater. Sci. Technol. 2016, 32, 1289–1296. [Google Scholar] [CrossRef]

- Xu, T.; Peng, X.; Jiang, J.; Xie, W.; Chen, Y.; Zhang, X. Comparative study on the microstructure and mechanical properties of Mg–Li–Al based alloys with yttrium and strontium addition. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2015, 30, 626–630. [Google Scholar] [CrossRef]

- Kim, J.T.; Park, G.H.; Kim, Y.S.; Hong, S.H.; Park, H.J.; Suh, J.Y.; Son, H.T.; Lee, M.-H.; Park, J.M.; Kim, K.B. Effect of Ca addition on the plastic deformation behavior of extruded Mg–11Li-3Al–1Sn–0.4Mn alloy. J. Alloy. Compd. 2016, 687, 821–826. [Google Scholar] [CrossRef]

- Hansen, F.; Eschurmann, G.F. The deformation and strengthening mechanisms of the multiphase Mg–Li–A1 alloys. Metals 1986, 40, 1–6. [Google Scholar]

- Jiang, B.; Liu, Y.; Li, R.; Xiang, Q.; Zeng, Y.; Pan, F. Effects of Yttrium and Strontium Addition on Electrochemical Behavior of Mg–14Li–1Al Alloys. Rare Metal Mater. Eng. 2013, 42, 1999–2003. [Google Scholar]

- Morishige, T.; Ueno, K.; Okano, M. Effect of Impurity Fe Concentration on the Corrosion Behavior of Mg–14 mass% Li–1 mass% Al Alloy. Mater. Trans. 2014, 55, 1506–1509. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, W.; Wu, S.D.; Jiang, C.B.; Li, S.X.; Xu, Y.B. Mechanical properties of a two-phase alloy Mg–8%Li–1%Al processed by equal channel angular pressing. Mater. Sci. Eng. A 2003, 360, 345–349. [Google Scholar] [CrossRef]

- Jiang, J.; Bi, G.; Wang, G.; Jiang, Q.; Lian, J.; Jiang, Z. Strain-hardening and warm deformation behaviors of extruded Mg–Sn–Yb alloy sheet. J. Magnes. Alloy. 2014, 2, 116–123. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Elsayed, F.R.; Nakata, T.; Ohkubo, T.; Kamado, S.; Hono, K. Strong and ductile heat-treatable Mg–Sn–Zn–Al wrought alloys. Acta Mater. 2015, 99, 176–186. [Google Scholar] [CrossRef]

- Kim, B.; Lee, J.G.; Park, S.S. Superplasticity and load relaxation behavior of extruded Mg–8Sn–3Al–1Zn alloy at 250 °C. Mater. Sci. Eng. A 2016, 656, 234–240. [Google Scholar] [CrossRef]

- Lv, B.; Peng, J.; Peng, Y.; Tang, A. The effect of addition of Nd and Ce on the microstructure and mechanical properties of ZM21 Mg alloy. J. Magnes. Alloy 2013, 1, 94–100. [Google Scholar] [CrossRef]

- Jiang, B.; Yin, H.M.; Yang, Q.S.; Li, R.H.; Pan, F.S. Effect of stannum addition on microstructure of as-cast and as-extruded Mg–5Li alloys. Trans. Nonferr. Metal Soc. China 2011, 21, 2378–2383. [Google Scholar] [CrossRef]

- Zeng, Y.; Jiang, B.; Zhang, M.X.; Yin, H.M.; Li, R.H.; Pan, F.S. Effect of Mg24Y5 intermetallic particles on grain refinement of Mg–9Li alloy. Intermetallics 2014, 45, 18–23. [Google Scholar] [CrossRef]

- Yi, Q.X. Study on the preparation technology, microstructure, and mechanical property of Mg–14Li–X alloys. Master’s Thesis, Hunan University, Hunan, China, 2007. [Google Scholar]

- Лякишев, Н.П. Metal Binary System Phase Diagrams Handbook; Guo, Q.W., Ed.; Chemical Industry Press: Beijing, China, 2009; p. 875. [Google Scholar]

- Wang, J.F.; Dan-Dan, X.U.; Ruo-Peng, L.U.; Pan, F.S. Damping properties of as-cast Mg–xLi–1Al alloys with different phase composition. Trans. Nonferr. Metals Soc. China 2014, 24, 334–338. [Google Scholar] [CrossRef]

- Straumal, B.B.; Baretzky, B.; Kogtenkova, O.A.; Straumal, A.B.; Sidorenko, A.S. Wetting of grain boundaries in Al by the solid Al3Mg2 phase. J. Mater. Sci. 2009, 45, 2057–2061. [Google Scholar] [CrossRef]

- Protasova, S.G.; Kogtenkova, O.A.; Straumal, B.B.; Zięba, P.; Baretzky, B. Inversed solid-phase grain boundary wetting in the Al–Zn system. J. Mater. Sci. 2011, 46, 4349–4353. [Google Scholar] [CrossRef]

- Easton, M.; Stjohn, D. Grain refinement of aluminum alloys: Part I. the nucleant and solute paradigms—A review of the literature. Metall. Mater. Trans. A 1999, 30, 1613–1623. [Google Scholar] [CrossRef]

- Easton, M.; StJohn, D. Grain refinement of aluminum alloys: Part II. Confirmation of, and a mechanism for, the solute paradigm. Metall. Mater. Trans. A 1999, 30, 1625–1633. [Google Scholar] [CrossRef]

- Fu, H.M.; Qiu, D.; Zhang, M.X.; Wang, H.; Kelly, P.M.; Taylor, J.A. The development of a new grain refiner for magnesium alloys using the edge-to-edge model. J. Alloy. Compd. 2008, 456, 390–394. [Google Scholar] [CrossRef]

- Greer, A.L.; Bunn, A.M.; Tronche, A.; Evans, P.V.; Bristow, D.J. Modelling of inoculation of metallic melts: Application to grain refinement of aluminium by Al–Ti–B. Acta Mater. 2000, 48, 2823–2835. [Google Scholar] [CrossRef]

- Greer, A.L.; Cooper, P.S.; Meredith, M.W.; Schneider, W.; Schumacher, P.; Spittle, J.A.; Tronche, A. Grain Refinement of Aluminium Alloys by Inoculation. Adv. Eng. Mater. 2003, 5, 81–91. [Google Scholar] [CrossRef]

- Kaibyshev, R. 5–Dynamic recrystallization in magnesium alloys. In Advances in Wrought Magnesium Alloys; Bettles, C., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 186–225. [Google Scholar]

- Humphreys, F.; Kalu, P. Dislocation-particle interactions during high temperature deformation of two-phase aluminium alloys. Acta Metall. 1987, 35, 2815–2829. [Google Scholar] [CrossRef]

- McQueen, H. Development of dynamic recrystallization theory. Mater. Sci. Eng. A 2004, 387, 203–208. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. Edge-to-edge matching and its applications: Part I. Application to the simple HCP/BCC system. Acta Mater. 2005, 53, 1073–1084. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, D.; Wang, F.; Taylor, J.A.; Zhang, M. The grain refining mechanism of cast zinc through silver inoculation. Acta Mater. 2014, 79, 315–326. [Google Scholar] [CrossRef]

- Qiu, D.; Zhang, M.; Kelly, P.; Furuhara, T. Discovery of plate-shaped athermal ω phase forming pairs with α′ martensite in a Ti–5.26 wt. % Cr Alloy. Scr. Mater. 2013, 69, 752–755. [Google Scholar] [CrossRef]

- PCPDFWIN v.2.3, JCPDS Card Nos. 08-0283; International Center for Diffraction Data: Newtown Square, PA, USA, 2002.

- Pauly, H.; Weiss, A.; Witte, H. Face Centred Cubic Alloys of Composition Li2MgX with Body-Centred Substructure. Z. Metallkd 1968, 59, 414–418. [Google Scholar]

| Intermetallics | The Mismatch between the Intermetallics and Matrix (%) | ||||

|---|---|---|---|---|---|

| LiMgAl2 | / | / | / | / | / |

| 6.85 | 61.54 | 31.25 | 65.73 | 56.05 | |

| Li2MgSn | / | / | / | / | / |

| 57.66 | 3.62 | 67.13 | 45.46 | 35.80 | |

| Direction Pairs | The Misfit (%) between the Direction Pairs in Li2MgSn and Li | ||||

|---|---|---|---|---|---|

| No. 1–5 | / | / | / | / | / |

| 57.38 | 3.62 | 11.28 | 3.62 | 40.98 | |

| No. 6–9 | / | / | / | / | - |

| 31.85 | 36.53 | 16.53 | 3.62 | - | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Jiang, B.; Li, R.; Yin, H.; Al-Ezzi, S. Grain Refinement Mechanism of the As-Cast and As-Extruded Mg–14Li Alloys with Al or Sn Addition. Metals 2017, 7, 172. https://doi.org/10.3390/met7050172

Zeng Y, Jiang B, Li R, Yin H, Al-Ezzi S. Grain Refinement Mechanism of the As-Cast and As-Extruded Mg–14Li Alloys with Al or Sn Addition. Metals. 2017; 7(5):172. https://doi.org/10.3390/met7050172

Chicago/Turabian StyleZeng, Ying, Bin Jiang, Ruihong Li, Hengmei Yin, and Salih Al-Ezzi. 2017. "Grain Refinement Mechanism of the As-Cast and As-Extruded Mg–14Li Alloys with Al or Sn Addition" Metals 7, no. 5: 172. https://doi.org/10.3390/met7050172