The Phase Composition and Microstructure of AlxCoCrFeNiTi Alloys for the Development of High-Entropy Alloy Systems

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Chemical Composition of the Cast Samples

3.2. Melting Behavior of the Cast Samples

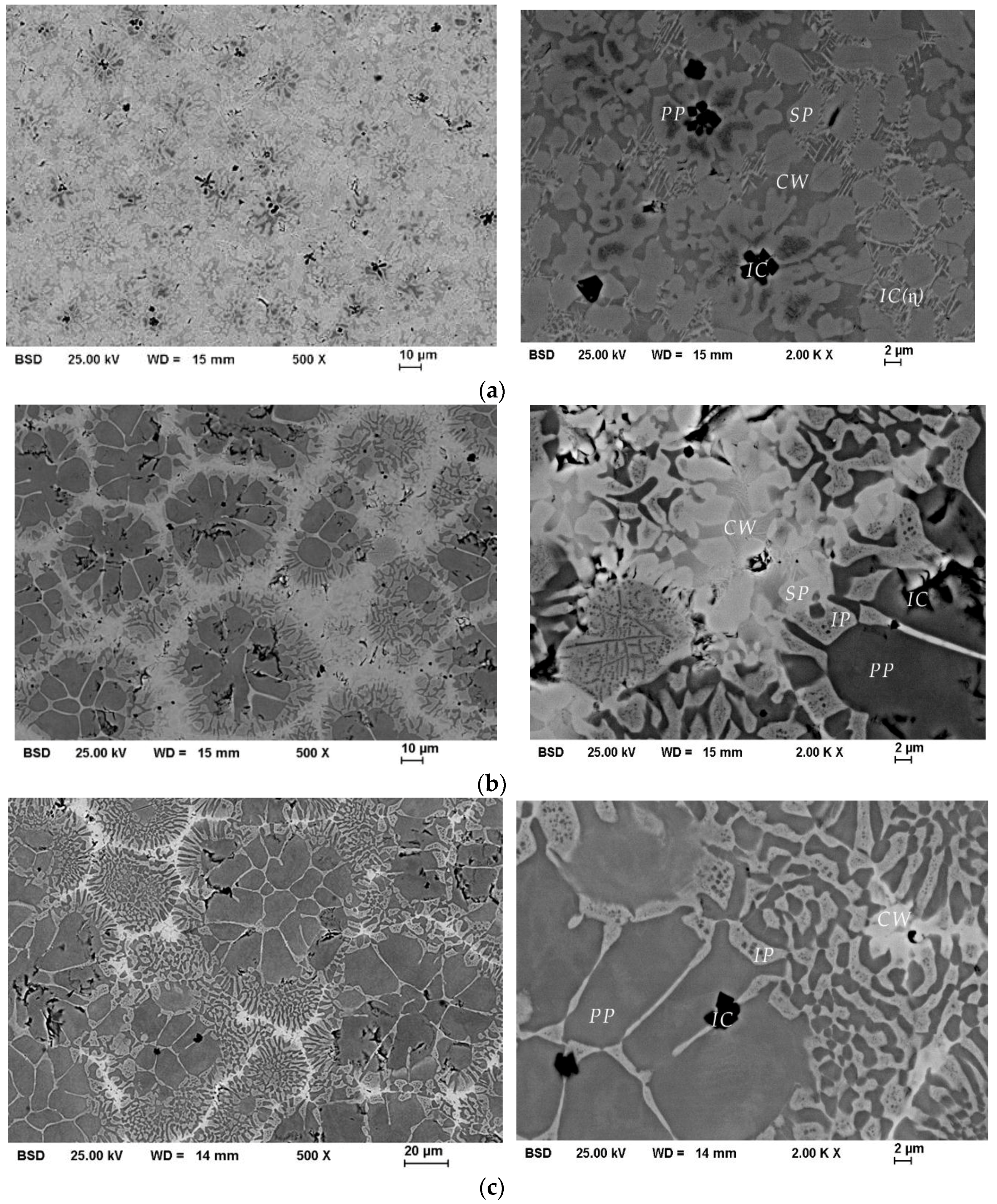

3.3. Microstructure of the Cast Samples

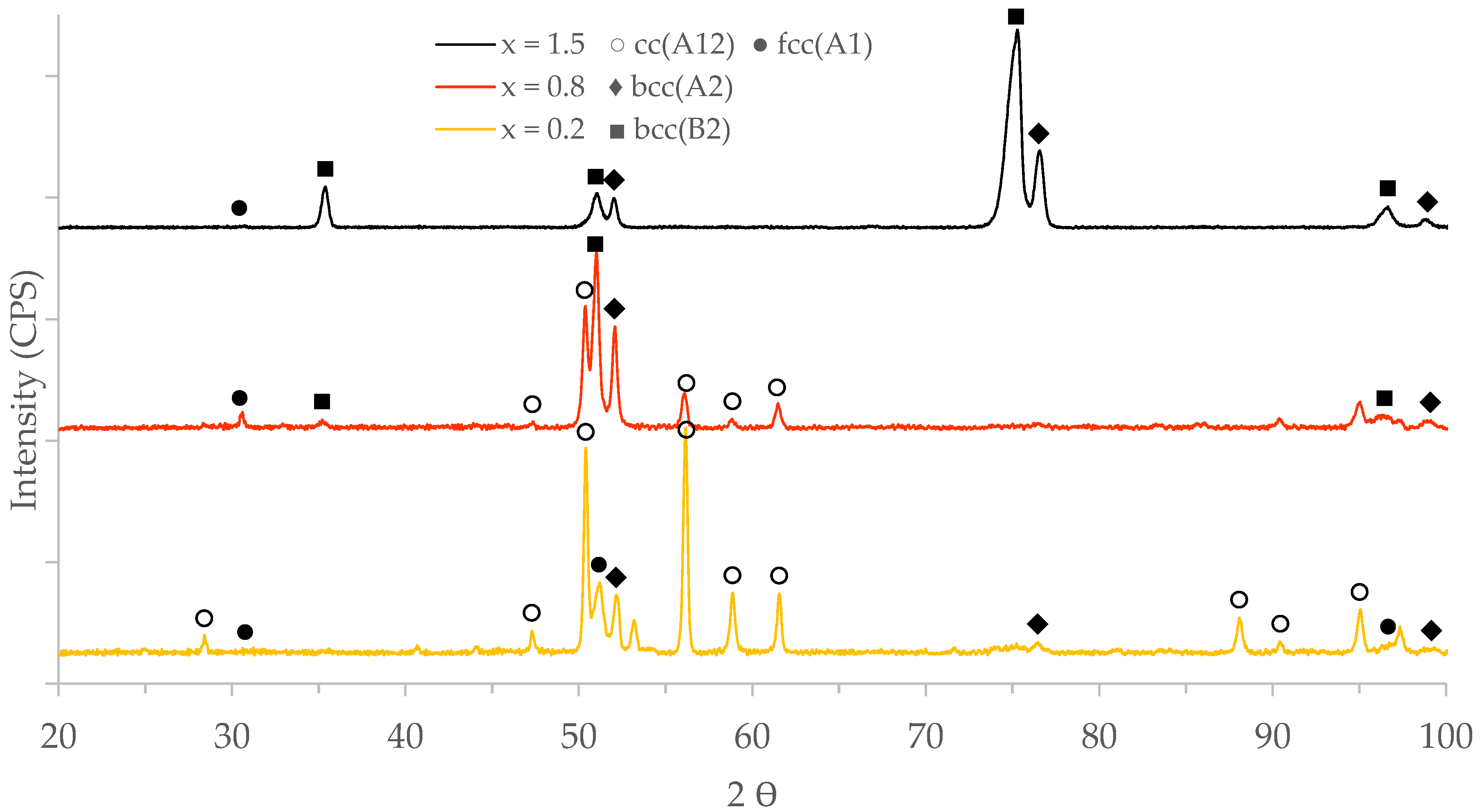

3.4. Phase Determination

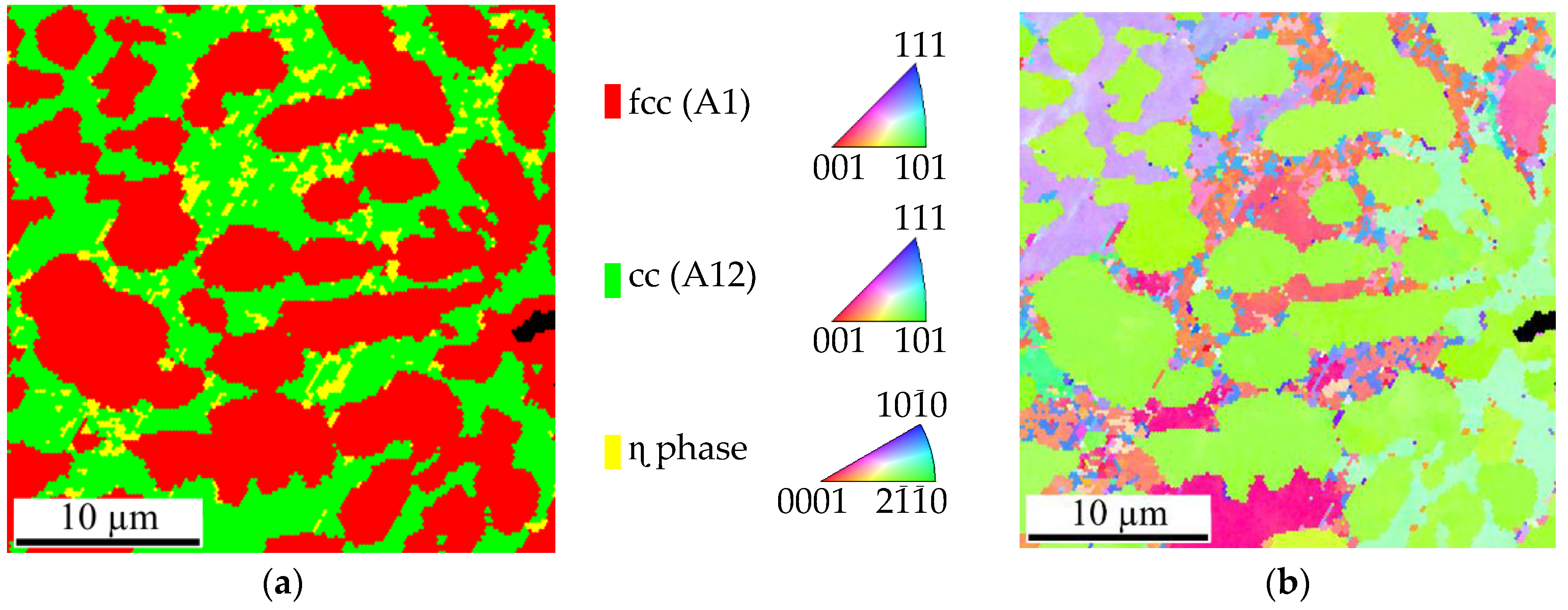

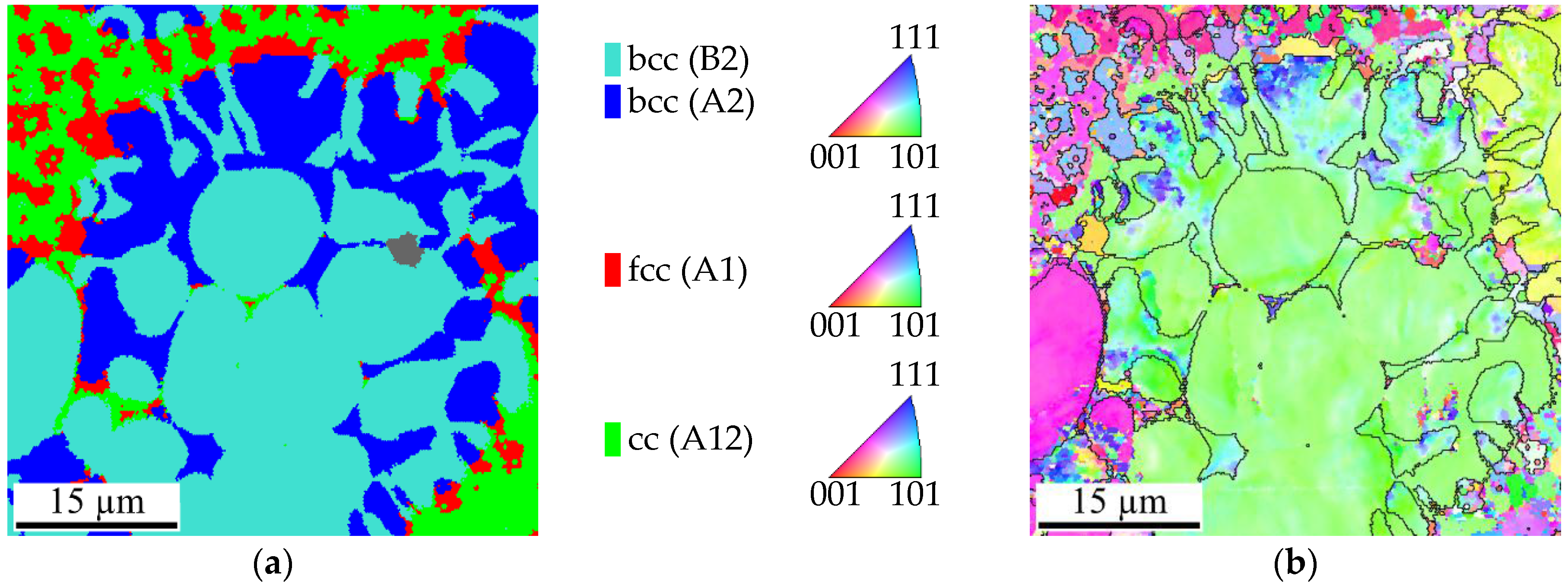

3.5. Phase Assignment

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.; Miller, J.; Senkov, O.; Woodward, C.; Uchic, M.; Tiley, J. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Eur. J. Control 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Tsai, M.; Yeh, J.-W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 3, 107–123. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Kohrt, C.; Lampke, T. Processing of AlCoCrFeNiTi high entropy alloy by atmospheric plasma spraying. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 012015. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 2012, 532, 480–486. [Google Scholar] [CrossRef]

- Zhu, J.M.; Fu, H.M.; Zhang, H.F.; Wang, A.M.; Li, H.; Hu, Z.Q. Synthesis and properties of multiprincipal component AlCoCrFeNiSix alloys. Mater. Sci. Eng. A 2010, 527, 7210–7214. [Google Scholar] [CrossRef]

- Zhu, J.M.; Fu, H.M.; Zhang, H.F.; Wang, A.M.; Li, H.; Hu, Z.Q. Microstructures and compressive properties of multicomponent AlCoCrFeNiMox alloys. J. Alloys Compd. 2010, 497, 52–56. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Juan, C.C.; Wang, W.R.; Sheu, T.S.; Yeh, J.W.; Chen, S.K. On the superior hot hardness and softening resistance of AlCoCrxFeMo0.5 Ni high-entropy alloys. Mater. Sci. Eng. A 2011, 528, 3581–3588. [Google Scholar] [CrossRef]

- Hume-Rothery, W. Research on the Nature, Properties and Conditions of Formation of Intermetallic Compounds, with Special Reference to Certain Compounds of Tin. J. Inst. Met. 1926, 35, 295–361. [Google Scholar]

- Guo, S.; Ng, C.; Lu, J.; Liu, C. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Zhu, Z.; Ma, K.; Wang, Q.; Shek, C. Compositional dependence of phase formation and mechanical properties in three CoCrFeNi-(Mn/Al/Cu) high entropy alloys. Intermetallics 2016, 79, 1–11. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, Z. Effects of annealing treatment on phase composition and microstructure of CoCrFeNiTiAlx high-entropy alloys. Intermetallics 2012, 22, 24–32. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Wu, P.; Liu, N.; Yang, W.; Zhu, Z.; Lu, Y.; Wang, X. Microstructure and solidification behavior of multicomponent CoCrCuxFeMoNi high-entropy alloys. Mater. Sci. Eng. A 2015, 642, 142–149. [Google Scholar] [CrossRef]

- Feng, R.; Gao, M.; Lee, C.; Mathes, M.; Zuo, T.; Chen, S.; Hawk, J.; Zhang, Y.; Liaw, P. Design of Light-Weight High-Entropy Alloys. Entropy 2016, 18, 333. [Google Scholar] [CrossRef]

- Soare, V.; Mitrica, D.; Constantin, I.; Badilita, V.; Stoiciu, F.; Popescu, A.-M.; Carcea, I. Influence of remelting on microstructure, hardness and corrosion behaviour of AlCoCrFeNiTi high entropy alloy. Mater. Sci. Technol. 2015, 10, 1194–2200. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Lee, C.-F.; Shun, T.-T. Age Hardening of the Al0.5CoCrNiTi0.5 High-Entropy Alloy. Metall. Mater. Trans. A 2014, 45A, 191–195. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys: Fundamentals and Applications, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

| Element | Al | Co | Cr | Fe | Ni | Ti |

|---|---|---|---|---|---|---|

| atom % | 3.9 | 19.2 | 19.2 | 19.2 | 19.2 | 19.2 |

| wt % | 1.9 | 21.1 | 18.7 | 20.0 | 21.1 | 17.2 |

| x | 0.2 | 1 | 1 | 1 | 1 | 1 |

| atom % | 13.8 | 17.2 | 17.2 | 17.2 | 17.2 | 17.2 |

| wt % | 7.3 | 20.0 | 17.7 | 18.9 | 19.9 | 16.2 |

| x | 0.8 | 1 | 1 | 1 | 1 | 1 |

| atom % | 23.1 | 15.4 | 15.4 | 15.4 | 15.4 | 15.4 |

| wt % | 12.9 | 18.8 | 16.6 | 17.8 | 18.7 | 15.3 |

| x | 1.5 | 1 | 1 | 1 | 1 | 1 |

| Mean Quantity (g) | Droplet Size (mm) | Vacuum Pressure (mbar) | Argon Pressure (bar) | Gas Purity (%) | Current (A) |

|---|---|---|---|---|---|

| 10 | 20 | 2 × 10−4 | 1.1 | 99.9999 | 250 |

| Element | Al | Co | Cr | Fe | Ni | Ti | VEC |

|---|---|---|---|---|---|---|---|

| atom % | 3.0 | 19.4 | 19.9 | 20.0 | 20.0 | 17.7 | 7.3 |

| wt % | 1.5 | 21.2 | 19.2 | 20.7 | 21.7 | 15.7 | |

| x | 0.16 | 1.0 | 1.0 | 1.0 | 1.0 | 0.9 | |

| atom % | 14.3 | 17.4 | 17.3 | 17.0 | 17.9 | 16.1 | 6.8 |

| wt % | 7.6 | 20.2 | 17.7 | 18.7 | 20.7 | 15.2 | |

| x | 0.83 | 1.0 | 1.0 | 1.0 | 1.1 | 0.9 | |

| atom % | 22.7 | 16.2 | 15.1 | 15.4 | 16.7 | 13.8 | 6.5 |

| wt % | 12.6 | 19.7 | 162 | 17.7 | 20.2 | 13.7 | |

| x | 1.47 | 1.1 | 1.0 | 1.0 | 1.1 | 0.9 |

| Phase | Structure | Al | Co | Cr | Fe | Ni | Ti | Local VEC | |

|---|---|---|---|---|---|---|---|---|---|

| x = 0.2 | IC | 6.7 | 8.1 | 13.8 | 9.5 | 5.7 | 56.2 | 5.34 | |

| primary phase | bcc (A2) | 5.2 | 14.9 | 38.7 | 23.6 | 11.9 | 5.8 | 7.12 | |

| secondary phase | fcc (A1) | 2.1 | 20.5 | 23.5 | 22.4 | 15.7 | 15.8 | 7.31 | |

| cell wall | cc (A12) | 8.6 | 21.1 | 8.9 | 12.9 | 26.2 | 22.4 | 7.23 | |

| IC (η-phase) | 2.2 | 19.2 | 11.1 | 16.5 | 30.9 | 20.0 | 7.68 | ||

| x = 0.8 | IC | 68.3 | 7.7 | 2.5 | 3.6 | 7.8 | 10.1 | 4.37 | |

| primary phase | bcc (B2) | 25.8 | 20.6 | 4.3 | 7.5 | 21.9 | 20.0 | 6.47 | |

| interdendritic phase | bcc (A2) | 4.5 | 14.5 | 36.7 | 27.8 | 9.7 | 6.8 | 7.11 | |

| secondary phase | fcc (A1) | 2.6 | 18.0 | 24.7 | 27.4 | 12.5 | 14.8 | 7.22 | |

| cell wall | cc (A12) | 9.9 | 19.2 | 8.8 | 15.4 | 25.9 | 20.9 | 7.20 | |

| x = 1.5 | IC | 70.5 | 4.8 | 7.6 | 6.0 | 4.4 | 6.7 | 4.20 | |

| primary phase | bcc (B2) | 31.1 | 19.7 | 4.9 | 8.4 | 19.8 | 16.1 | 6.30 | |

| interdendritic phase | bcc (A2) | 9.6 | 11.1 | 36.6 | 28.5 | 7.5 | 6.6 | 6.78 | |

| cell wall | fcc (A1) | 3.6 | 14.3 | 22.3 | 31.0 | 13.5 | 15.2 | 7.18 | |

| Struktur-Bericht | Lattice | Structure Type | Pearson Symbol | Space Group | Lattice Parameter (Å) | Detected for x |

|---|---|---|---|---|---|---|

| A1 | fcc | Cu | cF4 | (225) | a = 5.88 | 0.2, 0.8, 1.5 |

| A2 | bcc | W | cI2 | (229) | a = 2.88 | 0.2, 0.8, 1.5 |

| B2 | bcc | CsCl | cP2 | (221) | a = 2.94 | 0.8, 1.5 |

| A12 | centered cluster (cc) | α-Mn | cI58 | (217) | a = 8.91 | 0.2, 0.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindner, T.; Löbel, M.; Mehner, T.; Dietrich, D.; Lampke, T. The Phase Composition and Microstructure of AlxCoCrFeNiTi Alloys for the Development of High-Entropy Alloy Systems. Metals 2017, 7, 162. https://doi.org/10.3390/met7050162

Lindner T, Löbel M, Mehner T, Dietrich D, Lampke T. The Phase Composition and Microstructure of AlxCoCrFeNiTi Alloys for the Development of High-Entropy Alloy Systems. Metals. 2017; 7(5):162. https://doi.org/10.3390/met7050162

Chicago/Turabian StyleLindner, Thomas, Martin Löbel, Thomas Mehner, Dagmar Dietrich, and Thomas Lampke. 2017. "The Phase Composition and Microstructure of AlxCoCrFeNiTi Alloys for the Development of High-Entropy Alloy Systems" Metals 7, no. 5: 162. https://doi.org/10.3390/met7050162