Surface Modelling of Nanostructured Copper Subjected to Erosion-Corrosion

Abstract

:1. Introduction

2. Experiment Procedures

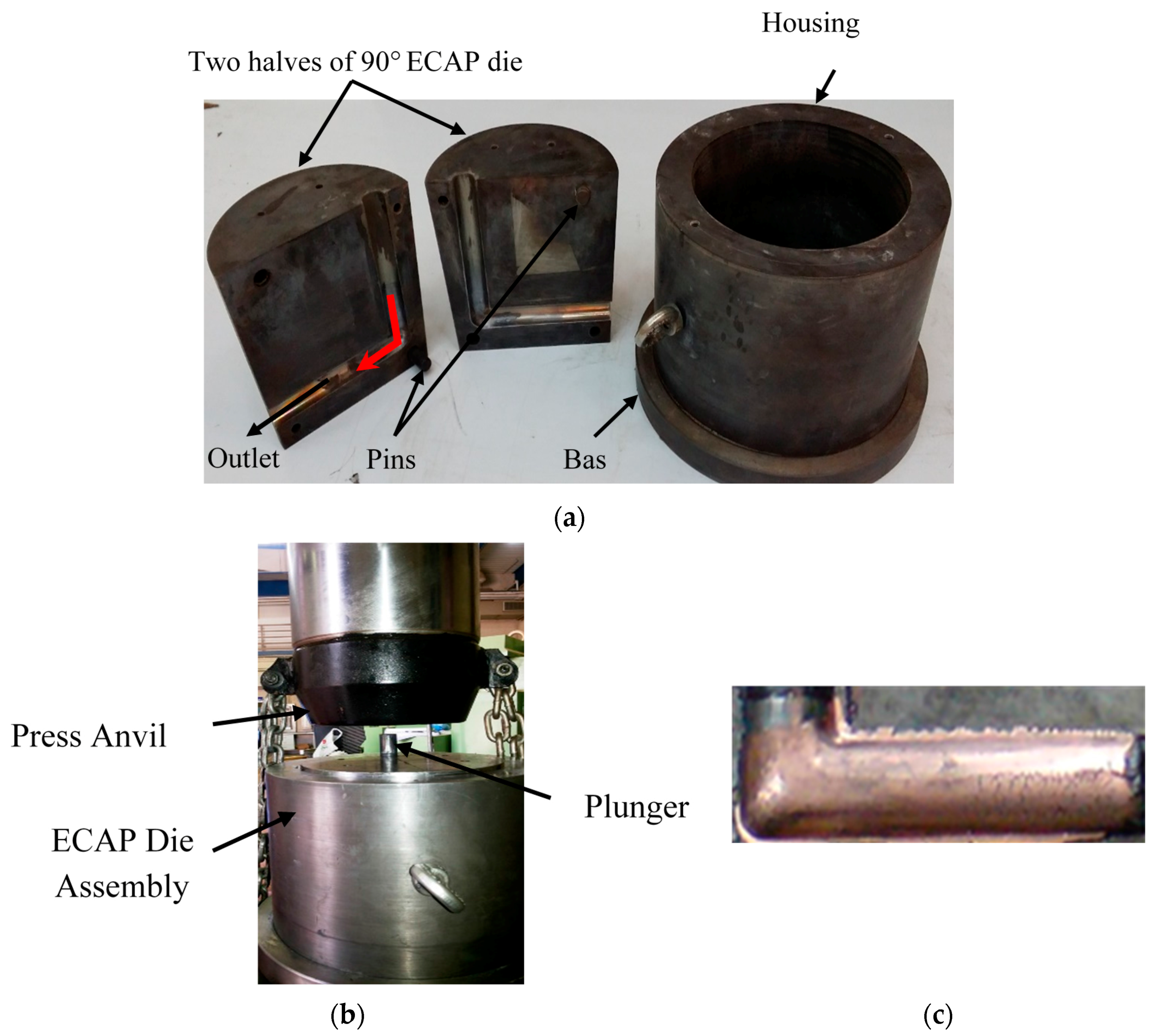

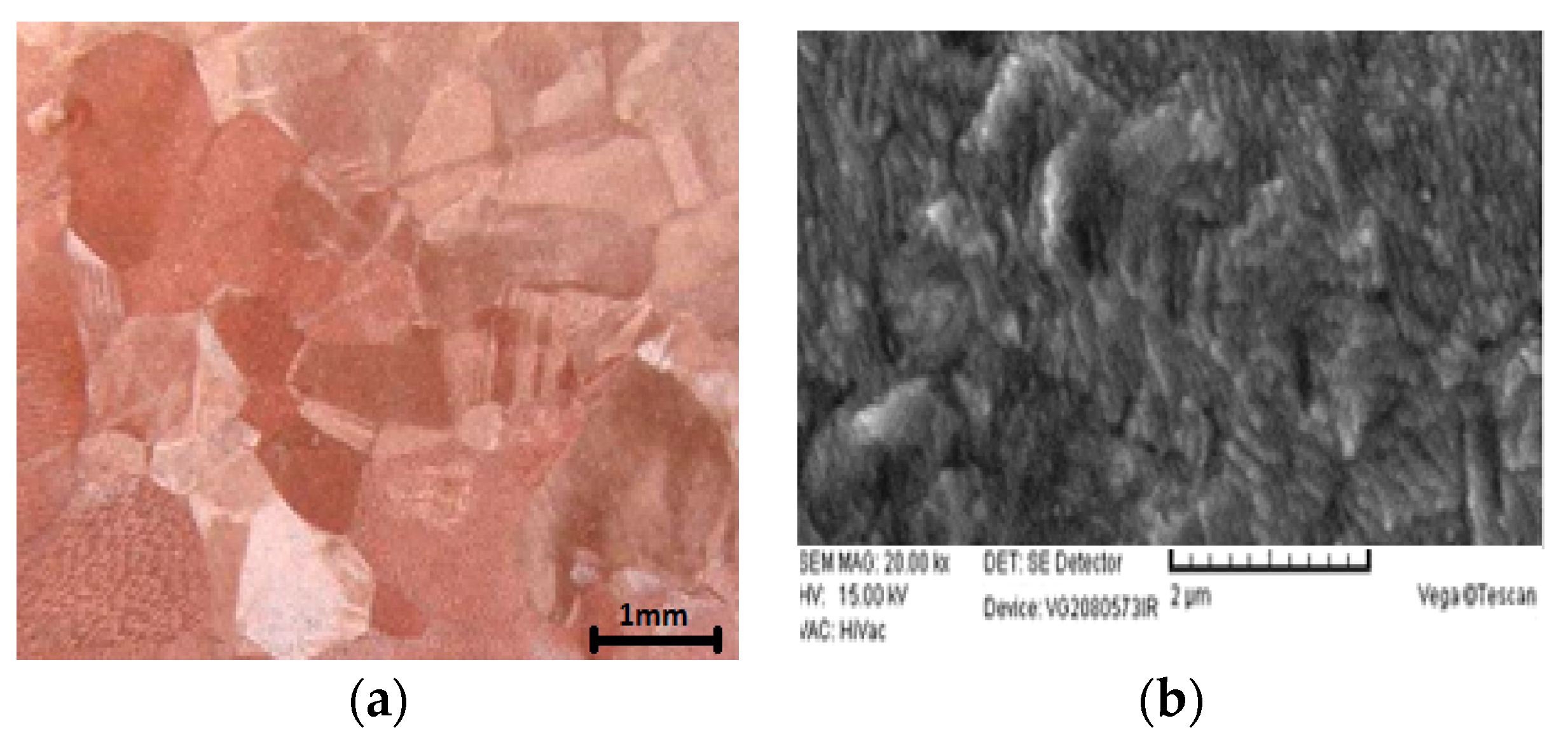

2.1. ECAP Process

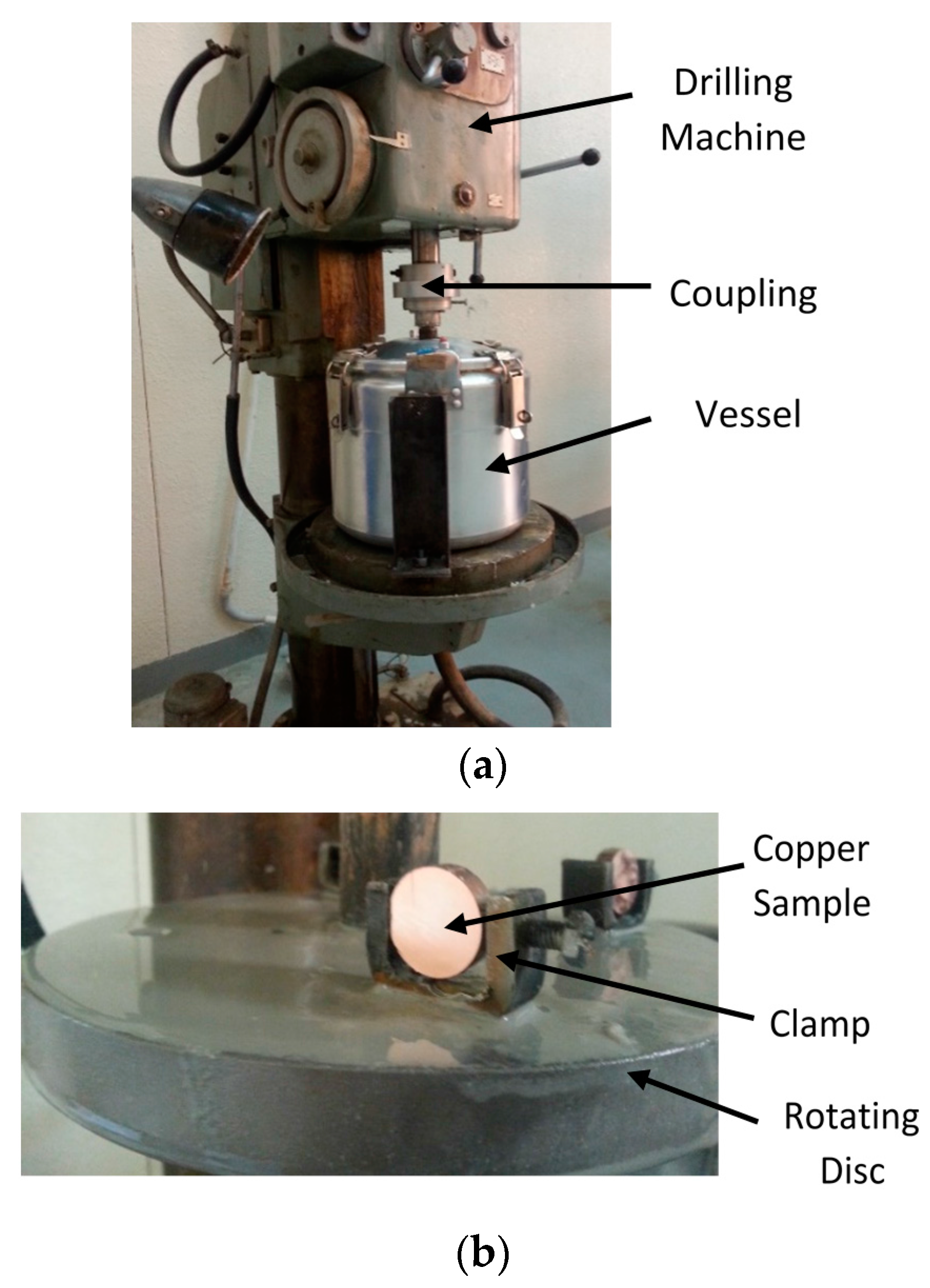

2.2. Erosion-Corrosion Experiments

3. Results and Discussion

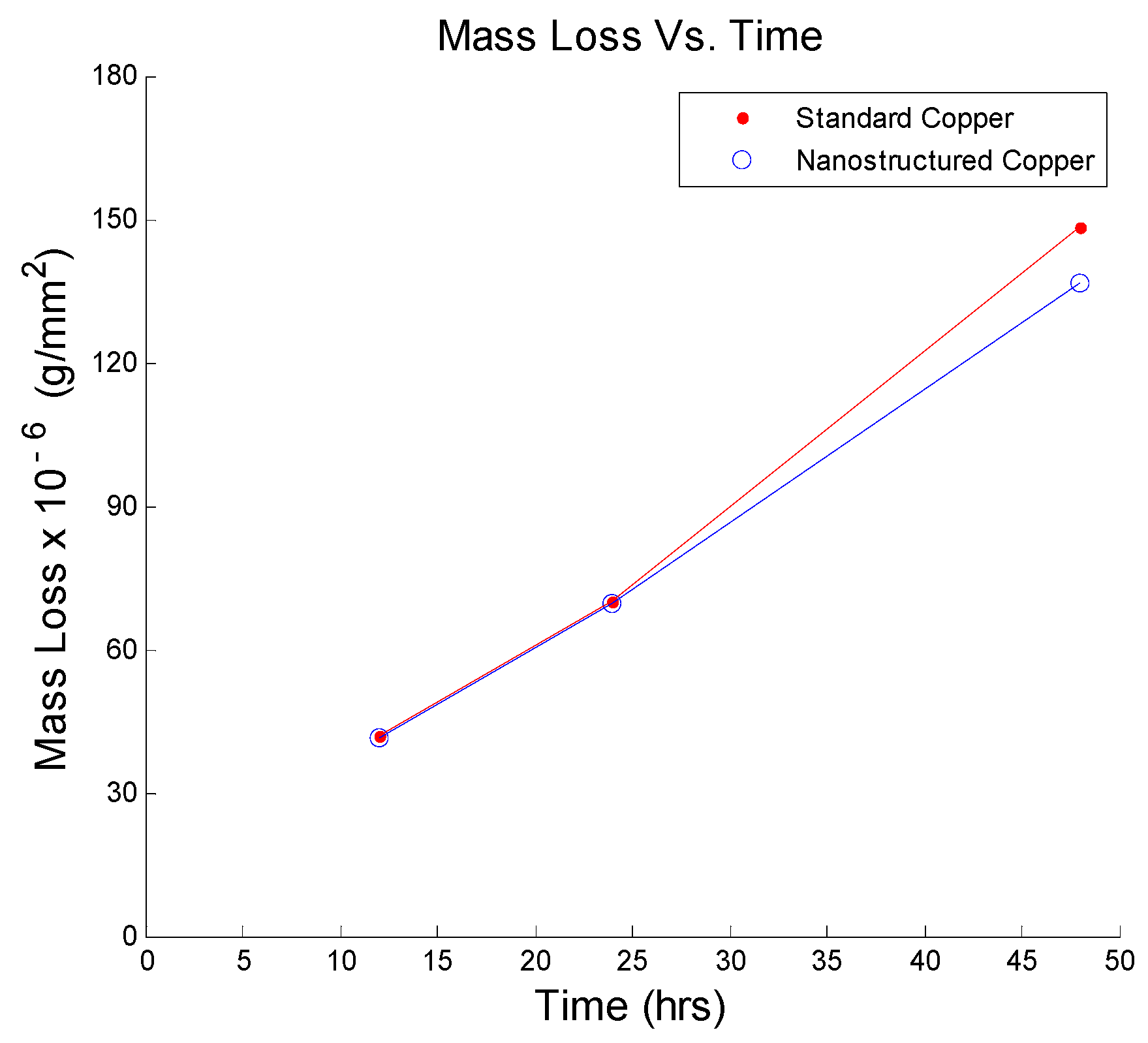

3.1. Comparison of E-C for Coarse and Nanostructured Grain COPPER

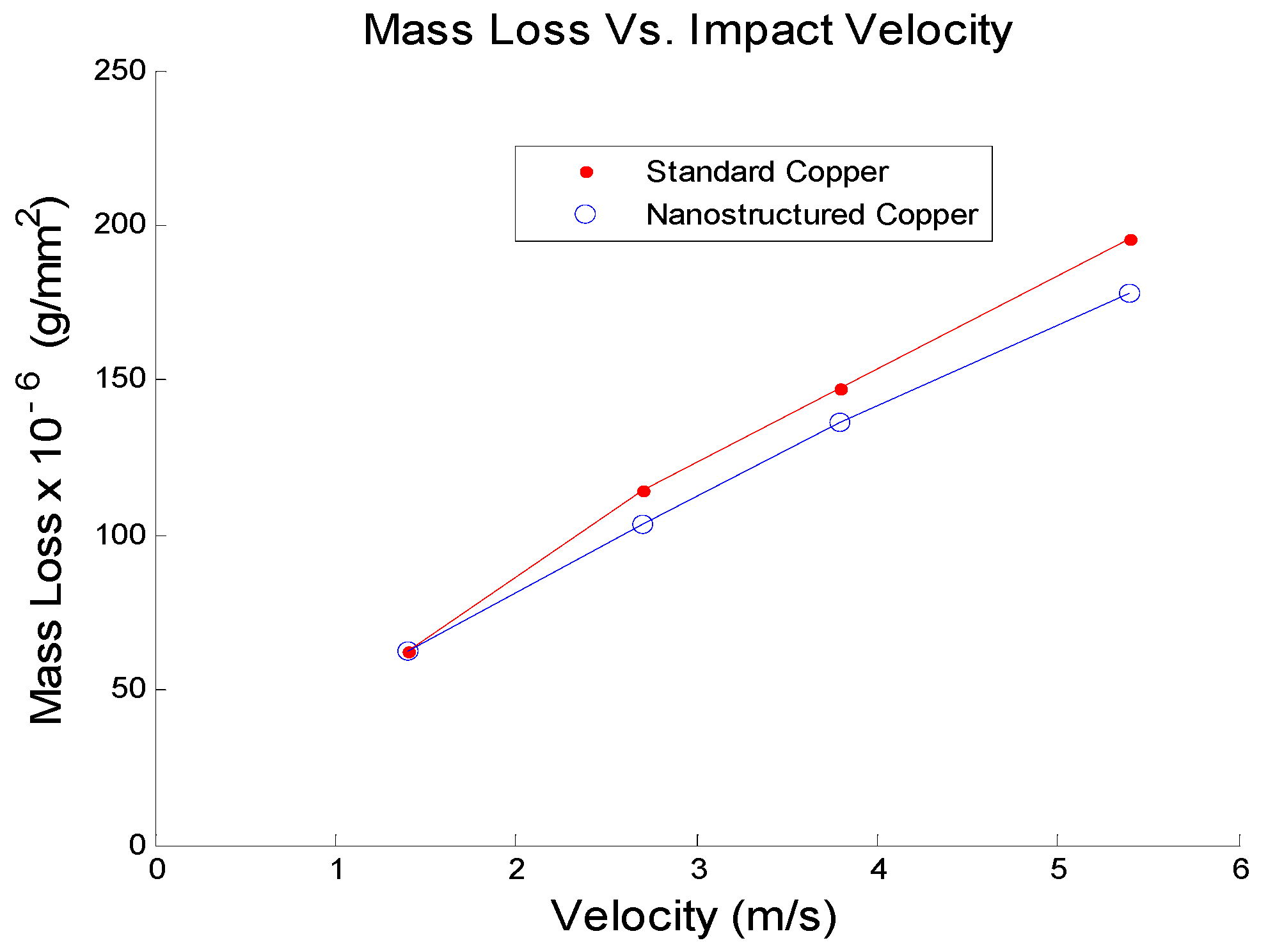

3.1.1. Impact Velocity Effect

3.1.2. Time Effect

3.1.3. Erodent Concentration Effect

3.2. Combined Effect of Time, Impact Velocity, and Erodent Concentration on E-C of Nanostructured Copper

3.2.1. Data Points for the Experiments

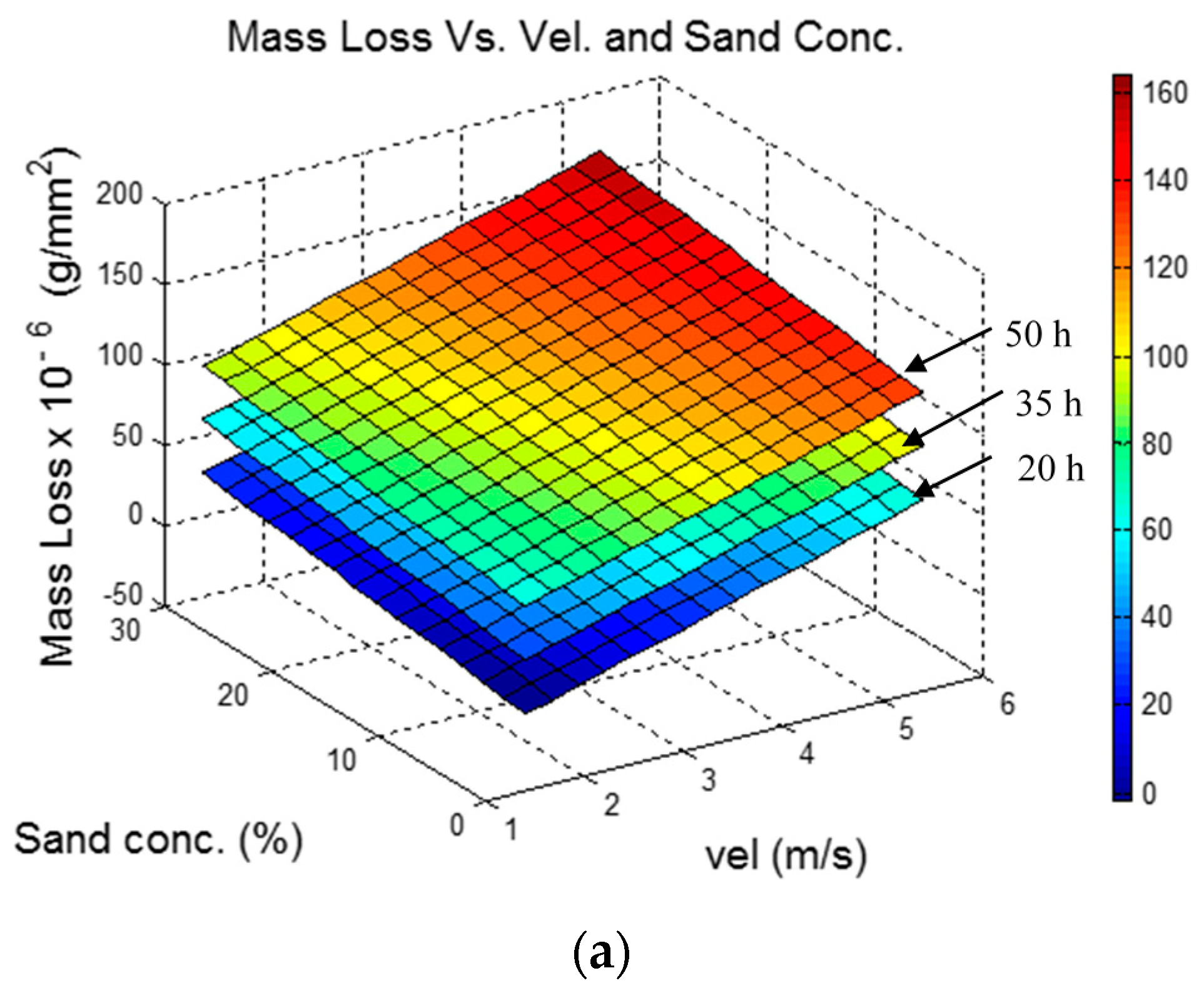

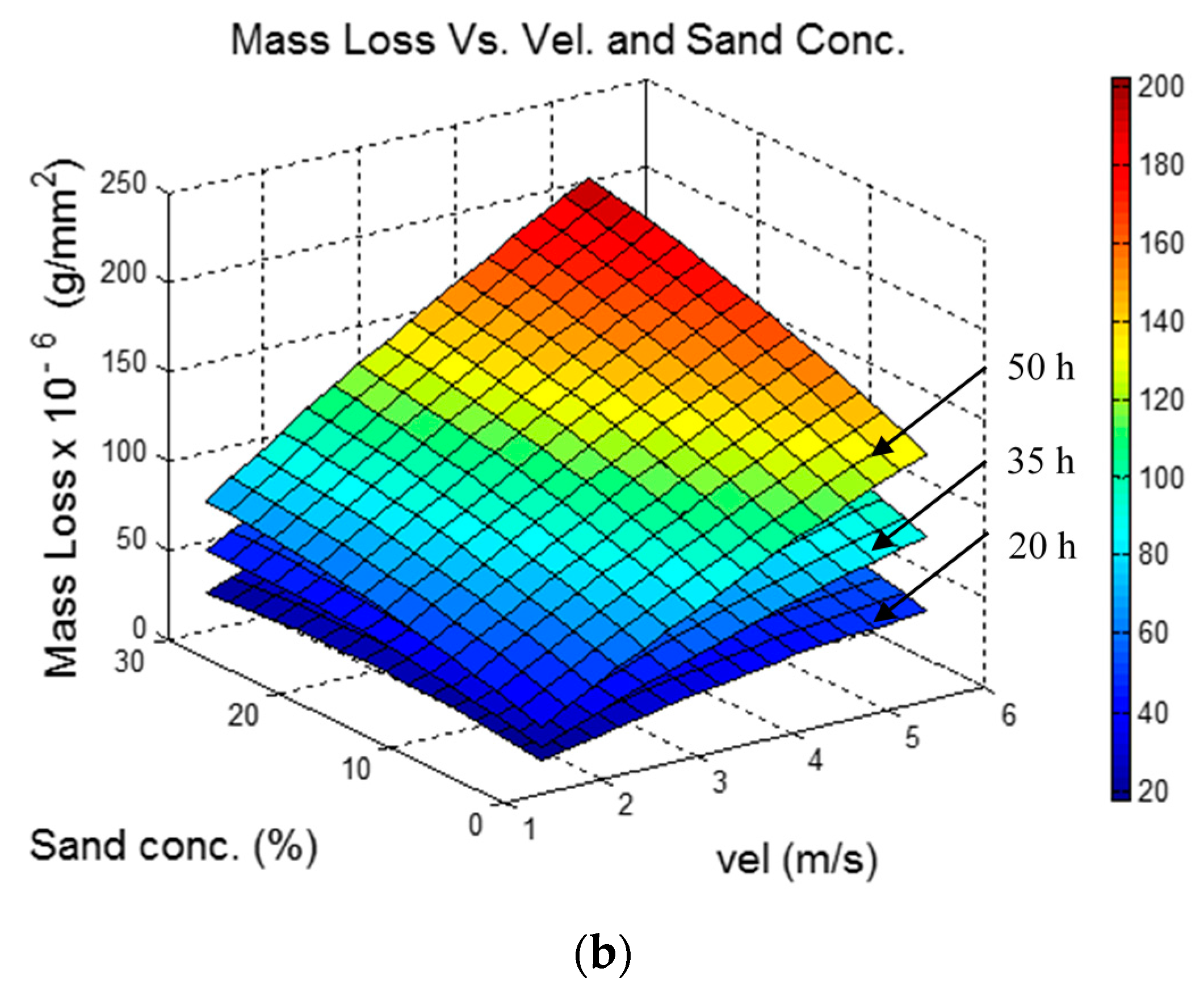

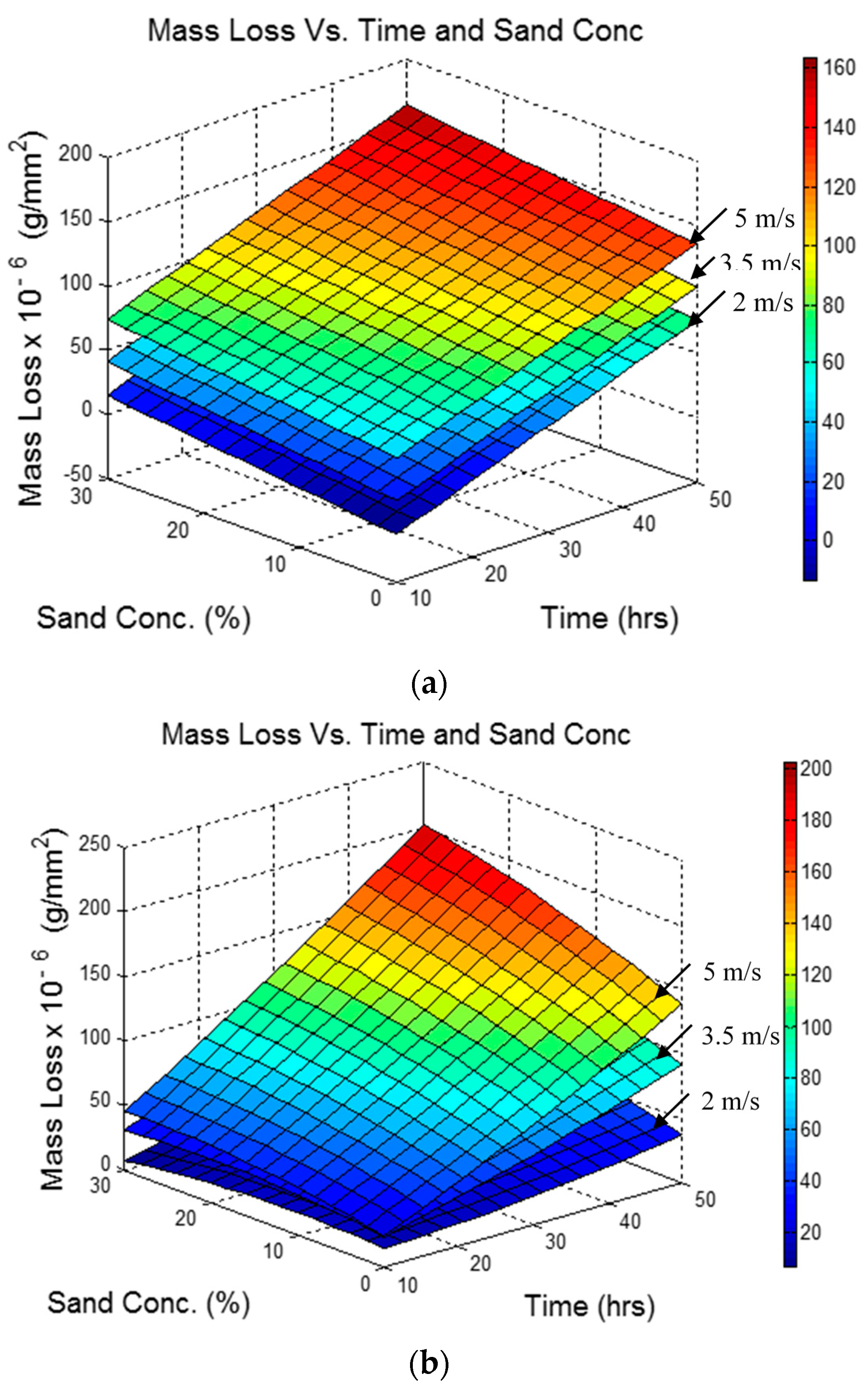

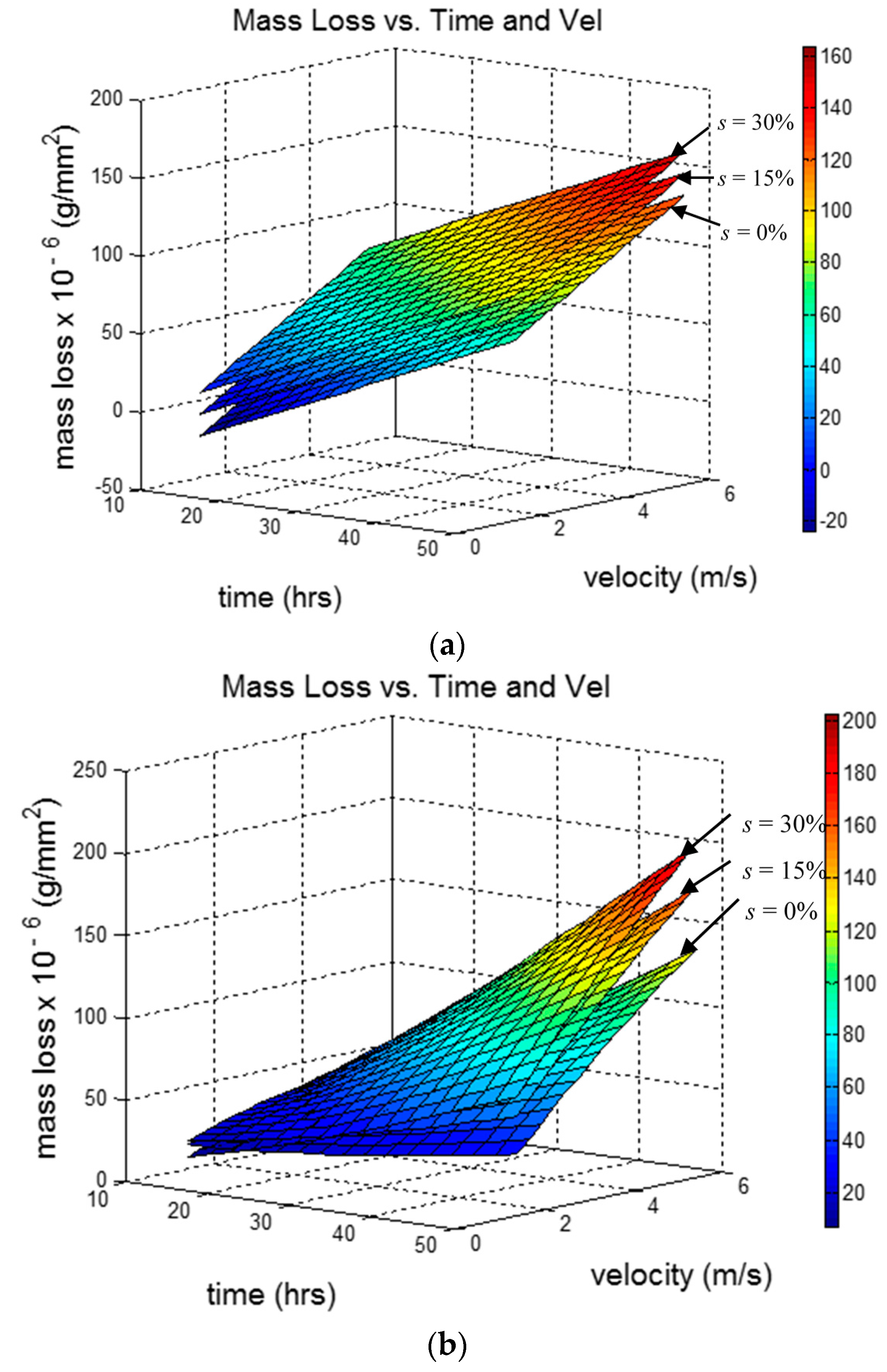

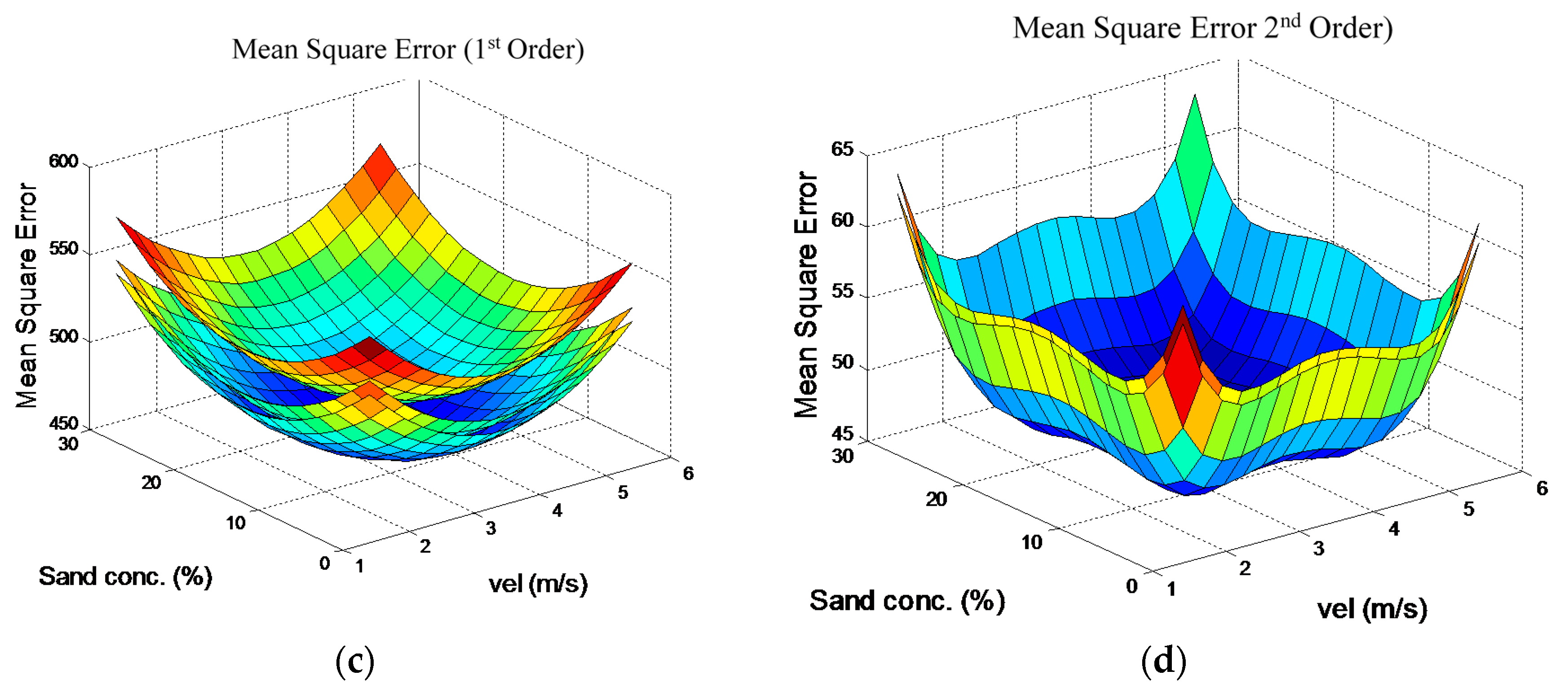

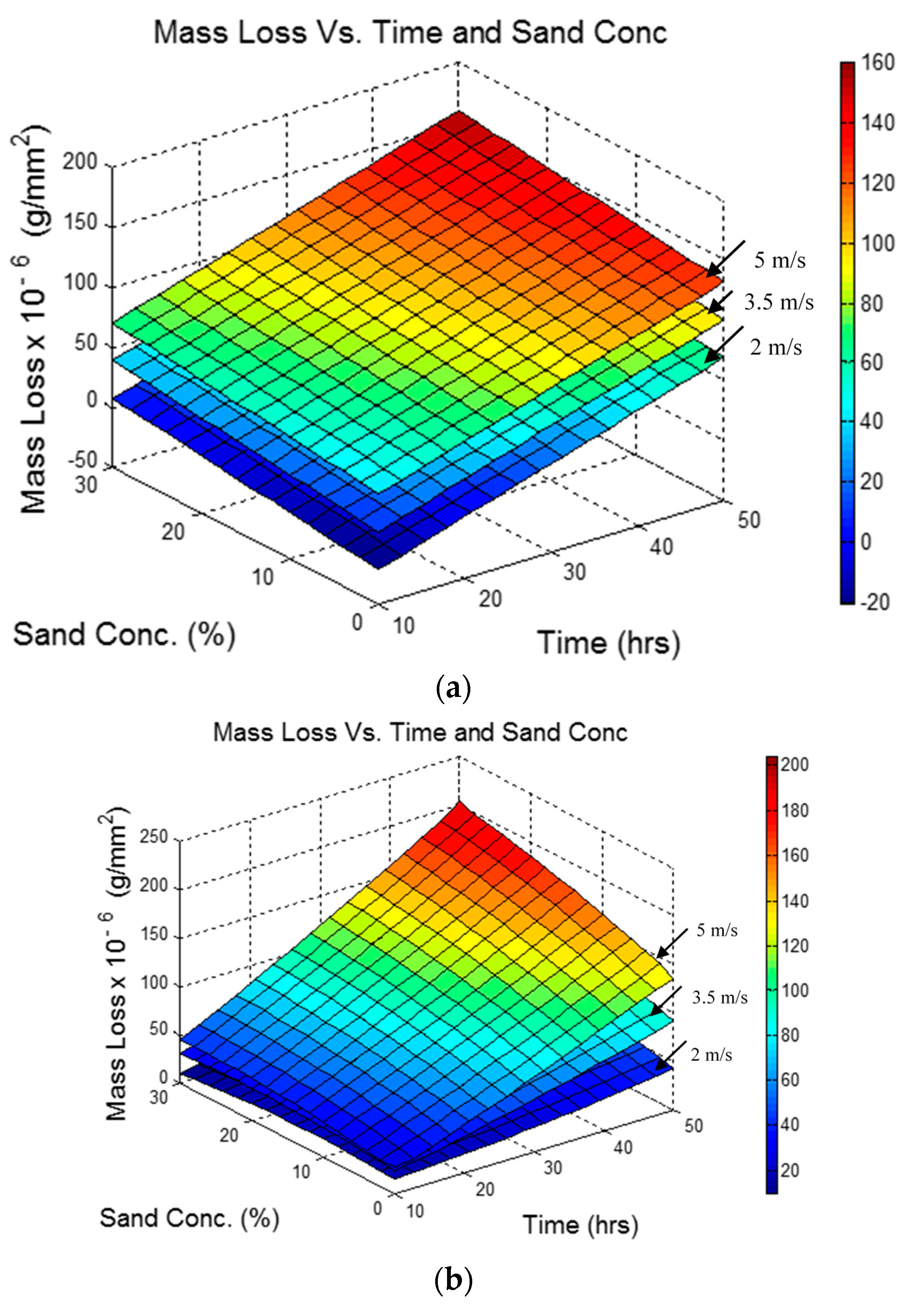

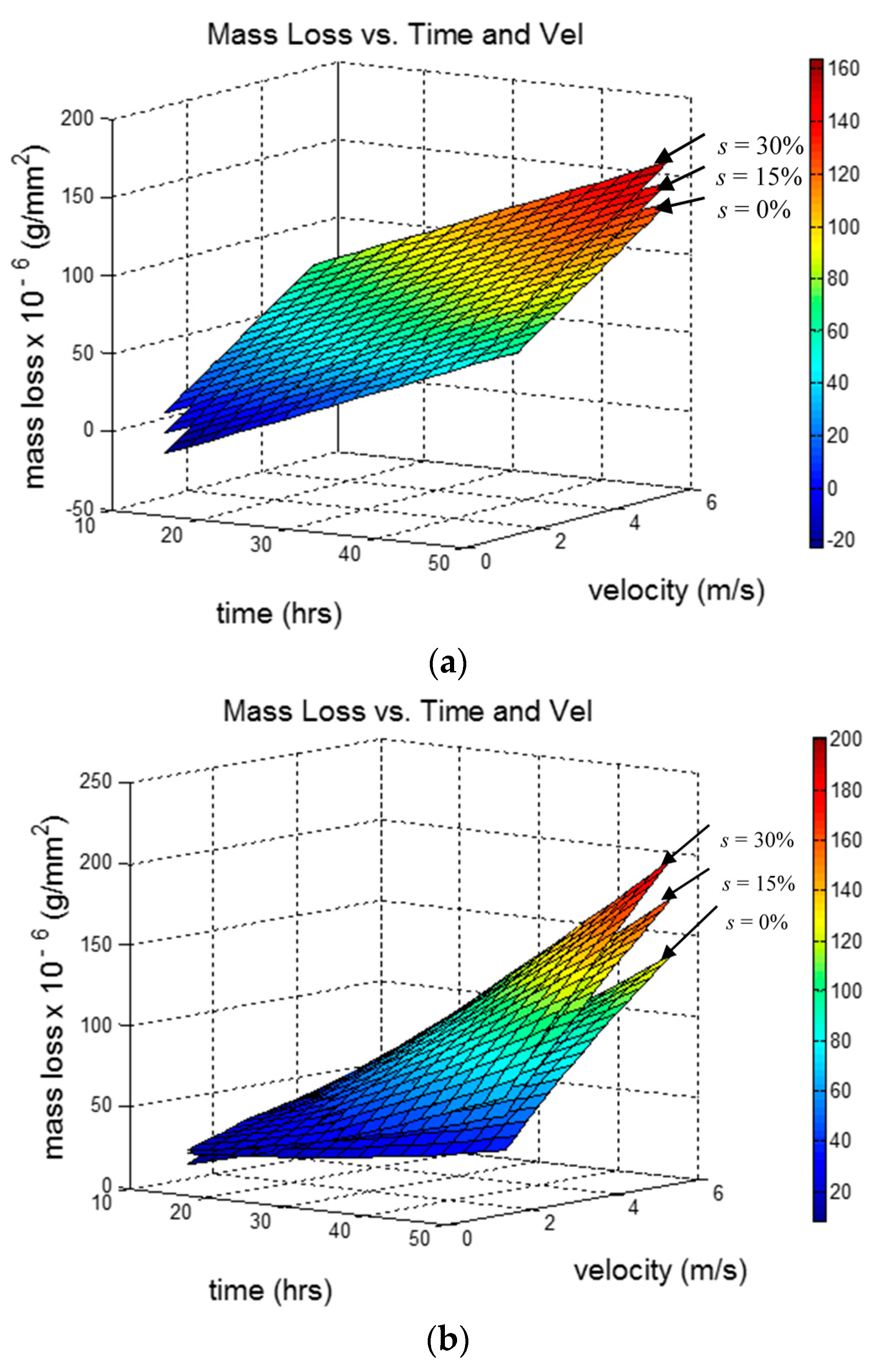

3.2.2. Surface Fitting

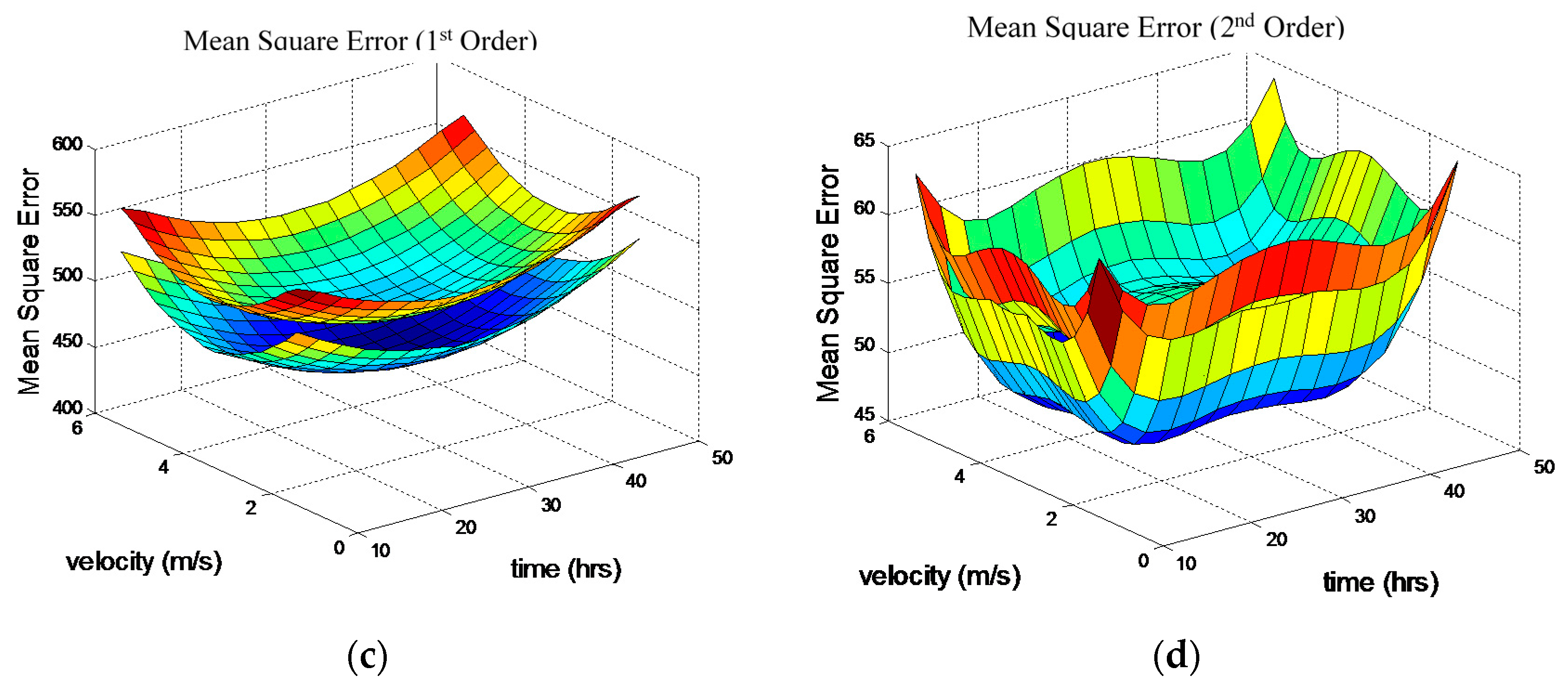

Polynomials Regression

3.3. Discussion

3.3.1. Trend of the Surface

3.3.2. Effect of Testing Time, Impact Velocity, and Sand Concentration

4. Conclusions

- The E-C of nanostructured copper is better described by a quadratic function of the testing time, impact velocity, and sand concentration than a linear function.

- The E-C of nanostructured copper increases with an increasing testing time, impact velocity, and sand concentration.

- Mass loss due to E-C is more severe for higher impact velocities. This possibly occurs because the increased velocity raises the impact energy of the sand particles on the test specimen and the reaction rate with the corrosive agent, thus accelerating the mass loss.

- The polynomial regression and Kriging techniques were effective in fitting the surfaces to the experimental data to allow for a visualization of the trends. For the polynomial regression, the coefficient of determination was 0.986, indicating a good fit for the second-order polynomial. In the case of the Kriging approach, the MSE for the quadratic model were found to be much lower than those of the linear model, further strengthening the argument that the trend is quadratic.

- Simultaneously increasing the three test parameters (testing time, impact velocity, and sand concentration) causes a more significant increase in the E-C of nanostructured copper than the sum of individually increasing each parameter.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yang, Y.; Cheng, Y.F. Parametric effects on the erosion-corrosion rate and mechanism of carbon steel pipes in oil sands slurry. Wear 2012, 276–277, 141–148. [Google Scholar] [CrossRef]

- Tian, B.R.; Cheng, Y.F. Erosion–corrosion of hydro-transport pipes in oil sand slurries. Bull. Electrochem. 2006, 22, 329–335. [Google Scholar]

- Tian, B.R.; Cheng, Y.F. Electrochemical corrosion behavior of X-65 steel in the simulated oil sand slurry. I: Effects of hydrodynamic condition. Corros. Sci. 2008, 50, 773–779. [Google Scholar] [CrossRef]

- Zhang, G.A.; Cheng, Y.F. Electrochemical corrosion of X65 pipe steel in oil/water emulsion. Corros. Sci. 2009, 51, 901–907. [Google Scholar] [CrossRef]

- Tian, B.R.; Cheng, Y.F. Electrolytic deposition of Ni–Co–Al2O3 composite coating on pipe steel for corrosion/erosion resistance in oil sand slurry. Electrochim. Acta 2007, 53, 511–517. [Google Scholar] [CrossRef]

- Guo, H.X.; Lu, B.T.; Luo, J.L. Interaction of mechanical and electrochemical factors in erosion-corrosion of carbon steel. Electrochim. Acta 2005, 51, 315–323. [Google Scholar] [CrossRef]

- Neville, A.; Reza, F.; Chiovelli, S.; Revega, T. Erosion–corrosion behaviour of WC based MMCs in liquid-solid slurries. Wear 2005, 259, 181–195. [Google Scholar] [CrossRef]

- Kamdi, Z.; Shipway, P.H.; Voisey, K.T.; Sturgeon, A.J. Abrasive wear behavior of conventional and large-particle tungsten carbide-based cermet coatings as a function of abrasive size and type. Wear 2011, 271, 1264–1272. [Google Scholar] [CrossRef]

- Hussain, E.A.M.; Robinson, M.J. Erosion–corrosion of 2205 duplex stainless steel in flowing seawater containing sand particles. Corros. Sci. 2007, 49, 1737–1754. [Google Scholar] [CrossRef]

- Neville, A.; Hodgkiess, T.; Xu, H. An electrochemical and microstructural assessment of erosion-corrosion of cast-iron. Wear 1999, 233–235, 523–534. [Google Scholar] [CrossRef]

- Clark, H.M. The influence of flow field in slurry erosion. Wear 1992, 152, 223–240. [Google Scholar] [CrossRef]

- Souza, V.A.D.; Neville, A. Aspects of microstructure on the synergy and overall material loss of thermal spray coatings in erosion-corrosion environments. Wear 2007, 263, 339–346. [Google Scholar] [CrossRef]

- Stack, M.M.; Pungwiwat, N. Particulate erosion-corrosion of Al in aqueous conditions: Some perspectives on pH effects on the erosion–corrosion map. Tribol. Int. 2002, 35, 651–660. [Google Scholar] [CrossRef]

- Neville, A.; Reyes, M.; Xu, H. Examining corrosion effects and corrosion/erosion interactions on metallic materials in aqueous slurries. Tribol. Int. 2002, 35, 643–650. [Google Scholar] [CrossRef]

- Quddus, A.; Al-Hadrami, L.M. Influence of solution hydrodynamics on the deposition of CaSO4 scale on aluminum. J. Thermophys. Heat Transf. 2011, 25, 112–118. [Google Scholar] [CrossRef]

- Maciel, J.M.; Agostinho, S.M.L. Use of a rotating cylinder electrode in corrosion studies of a 90/10 Cu–Ni alloy in 0.5 mol·L−1 H2SO4 media. J. Appl. Electrochem. 2000, 30, 981–985. [Google Scholar] [CrossRef]

- Novák, P.; Macenauer, A. Erosion-corrosion of passive metals by solid particles. Corros. Sci. 1993, 35, 635–640. [Google Scholar] [CrossRef]

- Hong, T.; Jepson, W.P. Corrosion inhibitor studies in large flow loop at high temperature and high pressure. Corros. Sci. 2001, 43, 1839–1849. [Google Scholar] [CrossRef]

- Hassani, S.; Roberts, K.P.; Shirazi, S.A.; Shadley, J.R.; Rybicki, E.F.; Joia, C. Characterization and prediction of chemical inhibition performance for erosion-corrosion conditions in sweet oil and gas production. Corrosion 2012, 68, 885–896. [Google Scholar] [CrossRef]

- Rihan, R.O.; Nešić, S. Erosion-corrosion of mild steel in hot caustic. Part I: NaOH solution. Corros. Sci. 2006, 48, 2633–2659. [Google Scholar] [CrossRef]

- Islam, M.A.; Farhat, Z.N. Mechanical and electrochemical synergism of API X42 pipeline steel during erosion-corrosion. J. Bio- Tribo-Corros. 2015, 1, 26. [Google Scholar] [CrossRef]

- Koike, M.H. Erosion-corrosion of stainless steel pipes under two-phase flow with steam quality 26%. J. Nucl. Mater. 2005, 342, 125–130. [Google Scholar] [CrossRef]

- Sasaki, K.; Burstein, G.T. Erosion-corrosion of stainless steel under impingement by a fluid jet. Corros. Sci. 2007, 49, 92–102. [Google Scholar] [CrossRef]

- Mitelea, I.; Micu, L.M.; Bordeaşu, I.; Crăciunescu, C.M. Cavitation erosion of sensitized UNS S31803 duplex stainless steels. J. Mater. Eng. Perform. 2016, 25, 1939–1944. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Bai, S.L.; Liu, Z.D. Surface characterization and erosion-corrosion behavior of Q235 steel in dynamic flow. Tribol. Lett. 2014, 53, 271–279. [Google Scholar] [CrossRef]

- Dular, M.; Osterman, A. Pit clustering in cavitation erosion. Wear 2008, 265, 811–820. [Google Scholar] [CrossRef]

- Rajahram, S.S.; Harvey, T.J.; Wood, R.J.K. Erosion-corrosion resistance of engineering materials in various test conditions. Wear 2009, 267, 244–254. [Google Scholar] [CrossRef]

- Burstein, G.T.; Sasaki, K. Effect of impact angle on slurry erosion-corrosion of 304L stainless steel. Wear 2000, 240, 80–94. [Google Scholar] [CrossRef]

- Abbade, N.P.; Crnkovic, S.J. Sand-water slurry erosion of API 5L X65 pipe steel as quenched from intercritical temperature. Tribol. Int. 2000, 33, 811–816. [Google Scholar] [CrossRef]

- Meng, H.; Hu, X.; Neville, A. A systematic erosion-corrosion study of two stainless steels in marine conditions via experimental design. Wear 2007, 263, 355–362. [Google Scholar] [CrossRef]

- Nawale, E.A.; Mohammed, A.A.; Sondus, M. Study the effect of erosion-corrosion of Al-Mg-Si alloy in marine environment. Eng. Technol. J. 2013, 31, 254–264. [Google Scholar]

- Wang, L.; Qiu, N.; Hellmann, D.H.; Zhu, X. An experimental study on cavitation erosion-corrosion performance of ANSI 1020 and ANSI 4135 steel. J. Mech. Sci. Technol. 2016, 30, 533–539. [Google Scholar] [CrossRef]

- Irfan, O.M.; El-Nasr, A.A.; Al-Mufadi, F. Erosion-corrosion behaviour of AA 6066 aluminium alloy. Int. J. Mech. Eng. 2014, 3, 15–24. [Google Scholar]

- Irfan, O.M. Erosion-corrosion behavior of nano-structured pure copper under different flowing velocities. Int. J. Mech. Mechatron. Eng. 2015, 15, 48–52. [Google Scholar]

- Sakamoto, A.; Yamasaki, T.; Matsumura, M. Erosion-corrosion tests on copper alloys for water tap use. Wear 1995, 186–187, 548–554. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Djavanroodi, F. Experimental and numerical analyses of pure copper during ECFE process as a novel severe plastic deformation method. Prog. Nat. Sci. 2014, 24, 68–74. [Google Scholar] [CrossRef]

- Hosseini, E.; Kazeminezhad, M. The effect of ECAP die shape on nano-structure of materials. Comput. Mater. Sci. 2009, 44, 962–967. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Shaeri, M.; Salehi, M.T.; Seyyedein, S.H.; Djavanroodi, F. Microstructure and texture evolution of Al-7075 alloy processed by equal channel angular pressing. Trans. Nonferr. Met. Soc. China 2015, 25, 1367–1375. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. Manuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Šedivý, O.; Beneš, V.; Ponížil, P.; Král, P.; Sklenička, V. Quantitative characterization of microstructure of pure copper processed by ECAP. Image Anal. Stereol. 2013, 32, 65–75. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, H.; Singh, N.; Chavan, N.M.; Kumar, S.; Joshi, S.V. Development of erosion-corrosion-resistant cold-spray nanostructured Ni–20Cr coating for coal-fired boiler applications. J. Therm. Spray Technol. 2015, 24, 1441–1449. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, H.; Singh, N.; Joshi, R.S. Erosion–corrosion behavior of cold-spray nanostructured Ni–20Cr coatings in actual boiler environment. Wear 2015, 332–333, 1035–1043. [Google Scholar] [CrossRef]

- Dean, A.M.; Voss, D. Design and Analysis of Experiments; Springer: New York, NY, USA, 1999. [Google Scholar]

- Oehlert, G.W. A First Course in Design and Analysis of Experiments. 2010. Available online: http://hdl.handle.net/11299/168002 (accessed on 3 December 2016).

- Wood, R.J.K. Erosion-corrosion interactions and their effect on marine and offshore material. Wear 2006, 261, 1012–1023. [Google Scholar] [CrossRef]

- Barik, R.C.; Wharton, J.A.; Wood, R.J.K.; Tan, K.S.; Stokes, K.R. Erosion and erosion-corrosion performance of cast and thermally sprayed nickel–aluminium bronze. Wear 2005, 259, 230–242. [Google Scholar] [CrossRef]

- Sasaki, K.; Burstein, G.T. The generation of surface roughness during slurry erosion-corrosion and its effect on the pitting potential. Corros. Sci. 1996, 38, 2111–2120. [Google Scholar] [CrossRef]

- Chapra, S.C.; Canale, R.P. Numerical Methods for Engineers, 7th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Martin, J.D.; Simpson, T.W. Use of Kriging models to approximate deterministic computer models. AIAA J. 2005, 43, 853–863. [Google Scholar] [CrossRef]

- Lophaven, S.N.; Nielsen, H.B.; Søndergaard, J. DACE: A MATLAB Kriging Toolbox Version 2.0; Technical Report IMM-TR-2002-12; Technical University of Denmark: Lyngby, Denmark, 2002. [Google Scholar]

| Content | Cu | Fe | Pb | S | As | Sb | Bi |

|---|---|---|---|---|---|---|---|

| Composition (%) | 99.95 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.001 |

| Test Variables | Units | Lower Bound | Upper Bound |

|---|---|---|---|

| Test Time | hours | 10 | 50 |

| Impact Velocity | m/s | 1.4 | 5.4 |

| Sand Concentration | % | 0 | 30 |

| Test No. | Time (h) | Impact Velocity (m/s) | Sand Concentration % |

|---|---|---|---|

| 1 | 10 | 1.4 | 0 |

| 2 | 10 | 1.4 | 30 |

| 3 | 10 | 5.4 | 0 |

| 4 | 10 | 5.4 | 30 |

| 5 | 50 | 1.4 | 0 |

| 6 | 50 | 1.4 | 30 |

| 7 | 50 | 5.4 | 0 |

| 8 | 50 | 5.4 | 30 |

| 9 | 10 | 3.4 | 15 |

| 10 | 50 | 3.4 | 15 |

| 11 | 30 | 1.4 | 15 |

| 12 | 30 | 5.4 | 15 |

| 13 | 30 | 3.4 | 0 |

| 14 | 30 | 3.4 | 30 |

| 15 | 30 | 3.4 | 15 |

| Test No. | Time (h) | Impact Velocity (m/s) | Sand Concentration (%) | Mass Loss Per Unit Area (μg/mm2) | ||

|---|---|---|---|---|---|---|

| Specimen 1 | Specimen 2 | Mean | ||||

| 1 | 10 | 1.4 | 0 | 7.6 | 10.2 | 8.9 |

| 2 | 10 | 1.4 | 30 | 11.3 | 12.8 | 12.1 |

| 3 | 10 | 5.4 | 0 | 29.2 | 31.5 | 30.4 |

| 4 | 10 | 5.4 | 30 | 42.3 | 49.8 | 46.1 |

| 5 | 50 | 1.4 | 0 | 38.0 | 32.9 | 35.4 |

| 6 | 50 | 1.4 | 30 | 60.8 | 70.2 | 65.5 |

| 7 | 50 | 5.4 | 0 | 130.6 | 134.7 | 132.6 |

| 8 | 50 | 5.4 | 30 | 210.3 | 204.7 | 207.5 |

| 9 | 10 | 3.4 | 15 | 26.8 | 30.3 | 28.6 |

| 10 | 50 | 3.4 | 15 | 136.7 | 126.1 | 131.4 |

| 11 | 30 | 1.4 | 15 | 43.3 | 45.4 | 44.3 |

| 12 | 30 | 5.4 | 15 | 102.9 | 97.2 | 100.0 |

| 13 | 30 | 3.4 | 0 | 62.9 | 61.5 | 62.2 |

| 14 | 30 | 3.4 | 30 | 74.7 | 83.5 | 79.1 |

| 15 | 30 | 3.4 | 15 | 64.5 | 67.0 | 65.8 |

| Polynomial Order | 1st Order | 2nd Order |

|---|---|---|

| Coefficient of Determination (r2) | 0.844 | 0.986 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irfan, O.M.; Mukras, S.M.S.; Al-Mufadi, F.A.; Djavanroodi, F. Surface Modelling of Nanostructured Copper Subjected to Erosion-Corrosion. Metals 2017, 7, 155. https://doi.org/10.3390/met7050155

Irfan OM, Mukras SMS, Al-Mufadi FA, Djavanroodi F. Surface Modelling of Nanostructured Copper Subjected to Erosion-Corrosion. Metals. 2017; 7(5):155. https://doi.org/10.3390/met7050155

Chicago/Turabian StyleIrfan, Osama M., Saad M. S. Mukras, Fahad A. Al-Mufadi, and Faramarz Djavanroodi. 2017. "Surface Modelling of Nanostructured Copper Subjected to Erosion-Corrosion" Metals 7, no. 5: 155. https://doi.org/10.3390/met7050155