Deformation Behavior of Al0.25CoCrFeNi High-Entropy Alloy after Recrystallization

Abstract

:1. Introduction

2. Experiments

3. Results and Discussion

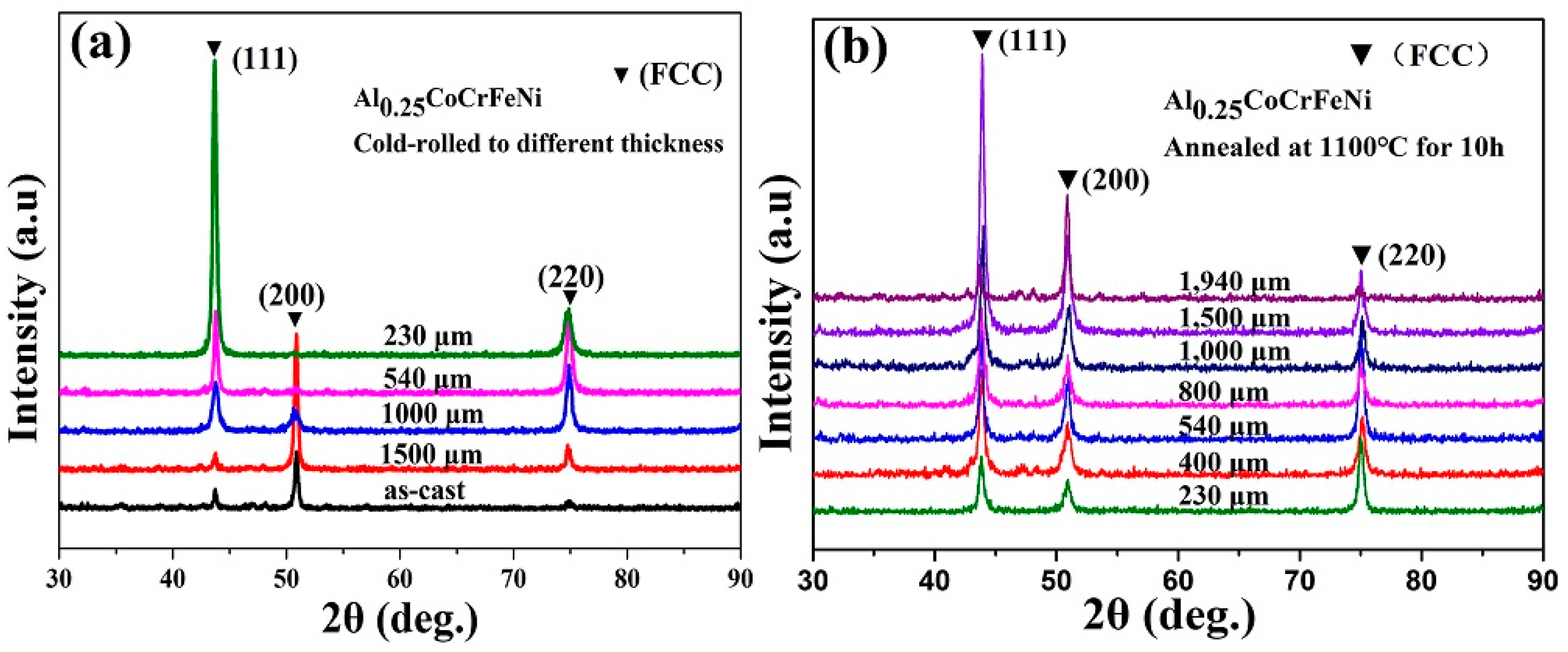

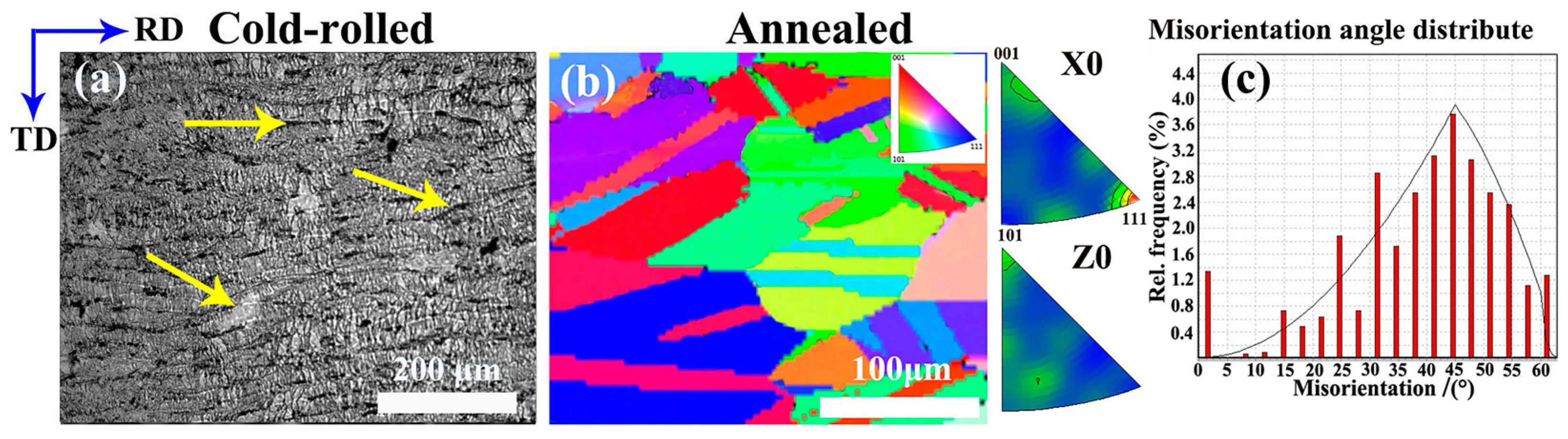

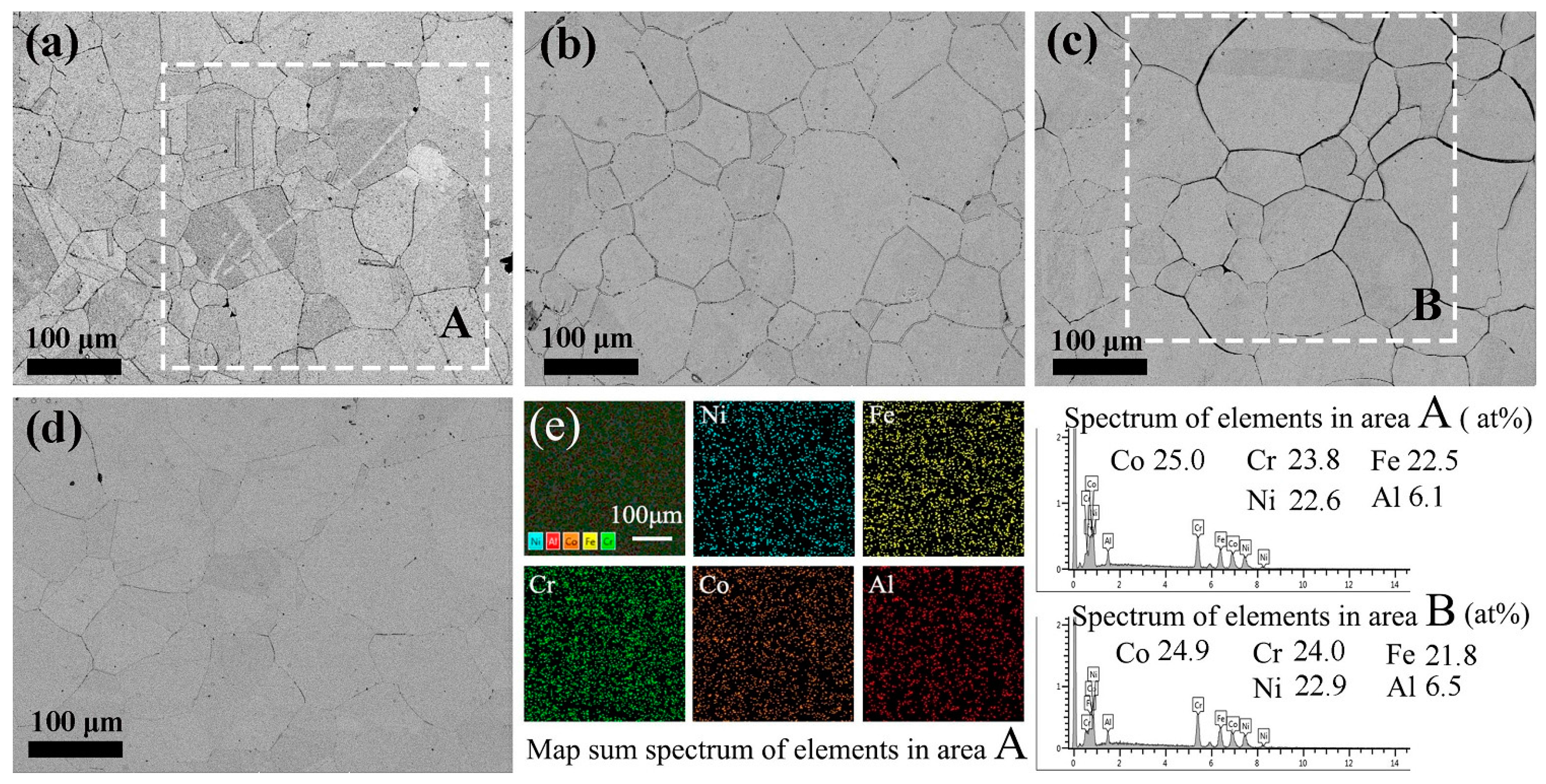

3.1. Phase and Microstructure after Heat Treatment

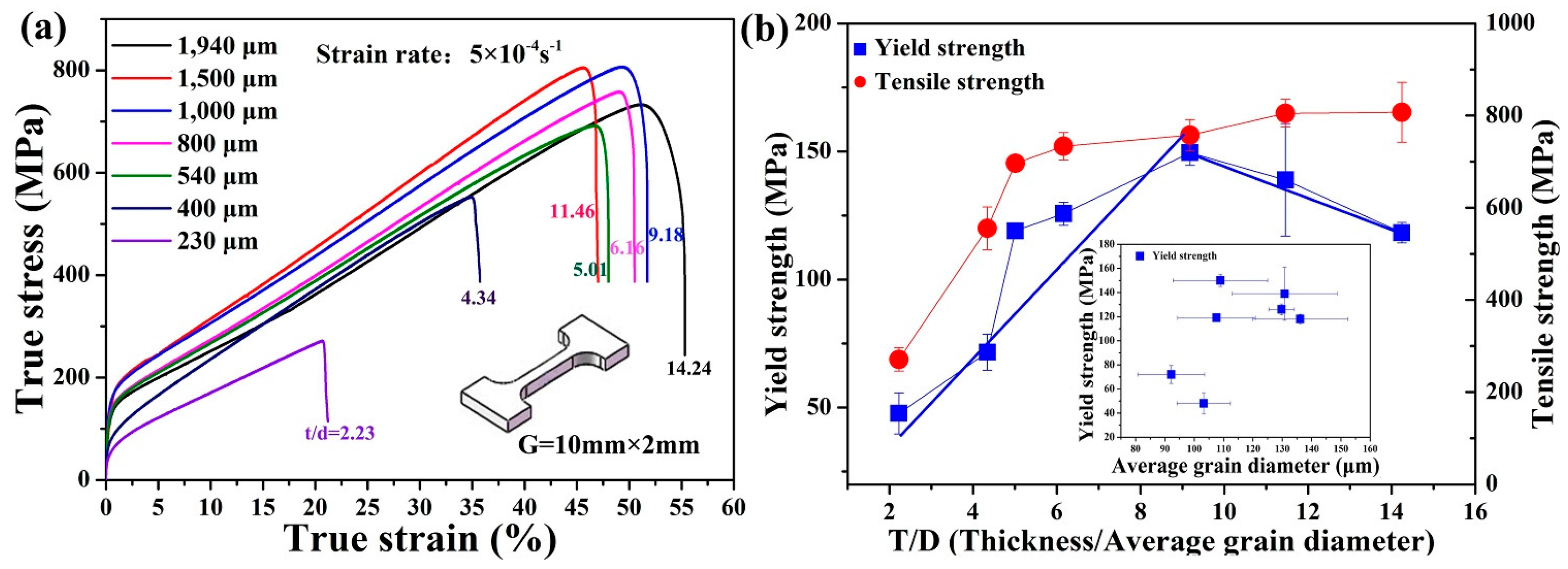

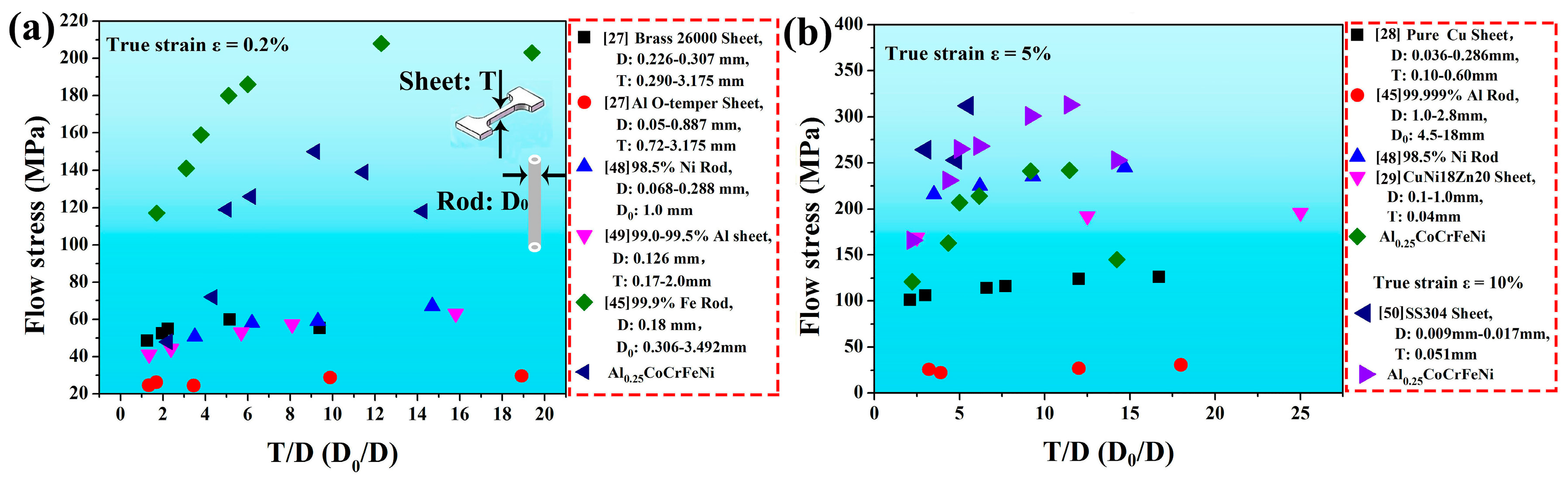

3.2. Size Effects in Thin-Sheet HEAs

4. Conclusions

- Cold-rolled Al0.25CoCrFeNi HEAs remain in a single FCC phase and obtain recrystallization microstructures after annealing at 1100 °C for 10 h.

- This model: can be easily implemented in single FCC phase Al0.25CoCrFeNi HEA to efficiently simulate the yield strength of very thin sheets.

- For 2.23 < t/d < 9.18, the size effect has to be considered, and both the yielding strength and ultimate strength decrease with the decrease of the t/d ratio.

- The stretchability (formability) for microforming worsens as the t/d ratio decreases, especially when the t/d ratio is lower than about 6.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Jin, S.J.; Gan, J.Y.; Chen, T.S.; Shun, T.T. Nanostructured high entropy alloy with multiple principal element. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yao, H.W.; Qiao, J.W.; Gao, M.C.; Hawk, J.A.; Ma, S.G.; Zhou, H.F.; Zhang, Y. Nb Tav-(Ti,W) refractory high-entropy alloys: Experiments and modeling. Mater. Sci. Eng. 2016, 674, 203–211. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miller, J.D.; Miracle, D.B.; Woodward, C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 2015, 6, 6529. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci.: Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Qiao, J.W.; Ma, S.G.; Gao, M.C.; Yang, H.J.; Chen, M.W.; Zhang, Y. A hexagonal close-packed high-entropy alloy: The effect of entropy. Mater. Des. 2016, 96, 10–15. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B. A new thermodynamic parameter to predict formation of solid solution or intermetallic phases in high entropy alloys. J. Alloys Compd. 2016, 658, 603–607. [Google Scholar] [CrossRef]

- Lu, Z.P.; Wang, H.; Chen, M.W.; Baker, I.; Yeh, J.W.; Liu, C.T.; Nieh, T.G. An assessment on the future development of high-entropy alloys: Summary from a recent workshop. Intermetallics 2015, 66, 67–76. [Google Scholar] [CrossRef]

- King, D.J.M.; Middleburgh, S.C.; McGregor, A.G.; Cortie, M.B. Predicting the formation and stability of single phase high-entropy alloys. Acta Mater. 2016, 104, 172–179. [Google Scholar] [CrossRef]

- Tong, C.J.; Chen, Y.L.; Chen, S.K.; Yeh, J.W.; Shun, T.T.; Tsau, C.H.; Lin, S.J. Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall. Mater. Trans. A 2005, 36, 881–893. [Google Scholar] [CrossRef]

- Shun, T.T.; Du, Y.C. Microstructure and tensile behaviors of fcc Al0.3CoCrFeNi high entropy alloy. J. Alloys Compd. 2009, 479, 157–160. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Y. The ultrahigh charpy impact toughness of forged AlxCoCrFeNi high entropy alloys at room and cryogenic temperatures. Intermetallics 2016, 70, 24–28. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Feng, T.; Zhang, Y.; Sha, G.; Lewandowski, J.J.; Liaw, P.K.; Zhang, Y. High-entropy Al0.3CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017, 123, 285–294. [Google Scholar] [CrossRef]

- Tang, Q.H.; Huang, Y.; Huang, Y.Y.; Liao, X.Z.; Langdon, T.G.; Dai, P.Q. Hardening of an Al0.3CoCrFeNi high entropy alloy via high-pressure torsion and thermal annealing. Mater. Lett. 2015, 151, 126–129. [Google Scholar] [CrossRef]

- Komarasamy, M.; Kumar, N.; Mishra, R.S.; Liaw, P.K. Anomalies in the deformation mechanism and kinetics of coarse-grained high entropy alloy. Mater. Sci. Eng. 2016, 654, 256–263. [Google Scholar] [CrossRef]

- Zou, Y.; Maiti, S.; Steurer, W.; Spolenak, R. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 2014, 65, 85–97. [Google Scholar] [CrossRef]

- Praveen, S.; Murty, B.S.; Kottada, R.S. Phase evolution and densification behavior of nanocrystalline multicomponent high entropy alloys during spark plasma sintering. JOM 2013, 65, 1797–1804. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of fcc-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Wang, F.J.; Zhang, Y.; Chen, G.L.; Davies, H.A. Cooling rate and size effect on the microstructure and mechanical properties of AlCoCrFeNi high entropy alloy. J. Eng. Mater. Technol. 2009, 131, 034501. [Google Scholar] [CrossRef]

- Raghavan, R.; Kirchlechner, C.; Jaya, B.N.; Feuerbacher, M.; Dehm, G. Mechanical size effects in a single crystalline equiatomic fecrcomnni high entropy alloy. Scr. Mater. 2017, 129, 52–55. [Google Scholar] [CrossRef]

- Fu, M.W.; Yong, M.S.; Tong, K.K.; Danno, A. Design solution evaluation for metal forming product development. Int. J. Adv. Manuf. Technol. 2007, 38, 249–257. [Google Scholar] [CrossRef]

- Vollertsen, F.; Biermann, D.; Hansen, H.N.; Jawahir, I.S.; Kuzman, K. Size effects in manufacturing of metallic components. CIRP Ann.-Manuf. Technol. 2009, 58, 566–587. [Google Scholar] [CrossRef]

- Status of the Mems Industry 2013. Available online: http://www.prweb.com/releases/2013/9/prweb11160611.htm (accessed on 24 March 2017).

- Geiger, M.; Vollertsen, F.; Kals, R. Fundamentals on the manufacturing of sheet metal microparts. CIRP Ann. Manuf. Technol. 1996, 45, 277–282. [Google Scholar] [CrossRef]

- Vollertsen, F.; Hu, Z.; Niehoff, H.S.; Theiler, C. State of the art in micro forming and investigations into micro deep drawing. J. Mater. Process. Technol. 2004, 151, 70–79. [Google Scholar] [CrossRef]

- Gau, J.T.; Principe, C.; Wang, J. An experimental study on size effects on flow stress and formability of aluminm and brass for microforming. J. Mater. Process. Technol. 2007, 184, 42–46. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Experimental studies and numerical modeling of the specimen and grain size effects on the flow stress of sheet metal in microforming. Mater. Sci. Eng. 2011, 528, 7674–7683. [Google Scholar] [CrossRef]

- Kals, T.A.; Eckstein, R. Miniaturization in sheet metal working. J. Mater. Process. Technol. 2000, 103, 95–101. [Google Scholar] [CrossRef]

- Michel, J.F.; Picart, P. Size effects on the constitutive behaviour for brass in sheet metal forming. J. Mater. Process. Technol. 2003, 141, 439–446. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Annual Book of ASTM Standards: Metallography; Nondestructive Testing; ASTM: New York, NY, USA, 1985; pp. 115–148. [Google Scholar]

- Tsai, M.H.; Tsai, K.Y.; Tsai, C.W.; Lee, C.; Juan, C.C.; Yeh, J.W. Criterion for sigma phase formation in Cr- and V-containing high-entropy alloys. Mater. Res. Lett. 2013, 1, 207–212. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Ozerov, M.S.; Zherebtsov, S.V.; Salishchev, G.A. Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing. Mater. Lett. 2016, 185, 1–4. [Google Scholar] [CrossRef]

- Kao, Y.-F.; Chen, T.-J.; Chen, S.-K.; Yeh, J.-W. Microstructure and mechanical property of as-cast, homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Gao, M.C. Design of High-Entropy Alloys. In High-Entropy Alloys: Fundamentals and Applications; Gao, M.C., Yeh, J.W., Liaw, P.K., Zhang, Y., Eds.; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Bhattacharjee, P.P.; Sathiaraj, G.D.; Zaid, M.; Gatti, J.R.; Lee, C.; Tsai, C.W.; Yeh, J.W. Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy. J. Alloys Compd. 2014, 587, 544–552. [Google Scholar] [CrossRef]

- Pickering, E.J.; Muñoz-Moreno, R.; Stone, H.J.; Jones, N.G. Precipitation in the equiatomic high-entropy alloy CrMnFeCoNi. Scr. Mater. 2016, 113, 106–109. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, S.F.; Qiao, J.W.; Wang, Z.H.; Gao, M.C.; Jiao, Z.M.; Yang, H.J.; Zhang, Y. Superior high tensile elongation of a single-crystal CoCrFeNiAl0.3 high-entropy alloy by bridgman solidification. Intermetallics 2014, 54, 104–109. [Google Scholar] [CrossRef]

- Engel, U. Tribology in microforming. Wear 2006, 260, 265–273. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 22–28. [Google Scholar]

- Braunovic, M. The petch relation and grain boundary hardening. Can. Metall. Q. 2013, 13, 211–214. [Google Scholar] [CrossRef]

- Yu, D.Y.W. The yield strength of thin copper films on kapton. J. Appl. Phys. 2004, 95, 2991. [Google Scholar] [CrossRef]

- Venkatraman, R.; Bravman, J.C. Separation of film thickness and grain boundary strengthening effects in Al thin films on Si. J. Mater. Res. 2011, 7, 2040–2048. [Google Scholar] [CrossRef]

- Hansen, N. The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. Mater. 1977, 25, 863–869. [Google Scholar] [CrossRef]

- Messne, A.; Engel, U.; Kals, R.; Vollertsen, F. Size effect in the fe-simulation of micro-forming processes. J. Mater. Process. Technol. 1994, 45, 371–376. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, M.C.; Ma, S.G.; Yang, H.J.; Wang, Z.H.; Ziomek-Moroz, M.; Qiao, J.W. Effect of cold rolling on the microstructure and mechanical properties of Al0.25CoCrFe1.25Ni1.25 high-entropy alloy. Mater. Sci. Eng. 2015, 645, 163–169. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Xu, J.; Zhang, P.; Shan, D.; Guo, B.; Wang, Z. Tensile deformation behaviors of pure nickel fine wire with a few grains across diameter. Trans. Nonferr. Met. Soc. China 2016, 26, 1765–1774. [Google Scholar] [CrossRef]

- Raulea, L.V.; Goijaerrs, A.M.; Govear, L.E.; Baaijens, F.P.T. Size effects in the processing of thin metal sheets. J. Mater. Process. Technol. 2001, 115, 44–48. [Google Scholar] [CrossRef]

- Mahabunphachai, S.; Koç, M. Investigation of size effects on material behavior of thin sheet metals using hydraulic bulge testing at micro/meso-scales. Int. J. Mach. Tools Manuf. 2008, 48, 1014–1029. [Google Scholar] [CrossRef]

| Thickness/μm | Diameter/μm | T/D (t/d) | σy/MPa | σt/MPa | εu/% |

|---|---|---|---|---|---|

| 230 | 103.22 ± 9.08 | 2.23 | 48 ± 8.5 | 271 ± 25.6 | 20.7 ± 1.4 |

| 400 | 92.14 ± 11.41 | 4.34 | 72 ± 7.4 | 556 ± 46.0 | 34.9 ± 1.0 |

| 540 | 107.58 ± 13.26 | 5.01 | 119 ± 0.7 | 697 ± 8.7 | 47.9 ± 1.7 |

| 800 | 129.77 ± 4.38 | 6.16 | 126 ± 4.5 | 734 ± 30.0 | 50.4 ± 0.9 |

| 1000 | 108.92 ± 17.85 | 9.18 | 150 ± 5.0 | 758 ± 34.0 | 51.1 ± 1.3 |

| 1500 | 130.83 ± 16.13 | 11.46 | 139 ± 22.7 | 805 ± 30.9 | 46.8 ± 1.74 |

| 1940 | 136.15 ± 16.20 | 14.24 | 118 ± 4.0 | 807 ± 75.5 | 55.2 ± 0.9 |

| T/D (t/d) | 2.23 | 4.34 | 5.01 | 6.16 | 9.18 | 9.18 | 11.46 | 14.24 |

|---|---|---|---|---|---|---|---|---|

| k | −904.8 | −855.5 | −923.9 | −1015.5 | −929.6 | 1135.6 | 1158.3 | 1036.0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Zhang, M.; Yang, H.; Qiao, J. Deformation Behavior of Al0.25CoCrFeNi High-Entropy Alloy after Recrystallization. Metals 2017, 7, 111. https://doi.org/10.3390/met7040111

Hou J, Zhang M, Yang H, Qiao J. Deformation Behavior of Al0.25CoCrFeNi High-Entropy Alloy after Recrystallization. Metals. 2017; 7(4):111. https://doi.org/10.3390/met7040111

Chicago/Turabian StyleHou, Jinxiong, Min Zhang, Huijun Yang, and Junwei Qiao. 2017. "Deformation Behavior of Al0.25CoCrFeNi High-Entropy Alloy after Recrystallization" Metals 7, no. 4: 111. https://doi.org/10.3390/met7040111

APA StyleHou, J., Zhang, M., Yang, H., & Qiao, J. (2017). Deformation Behavior of Al0.25CoCrFeNi High-Entropy Alloy after Recrystallization. Metals, 7(4), 111. https://doi.org/10.3390/met7040111