1. Introduction

When a cycling loading is applied to a cracked body, a monotonic plastic zone (MPZ) forms at the crack tip in the first cycle. If linear elastic conditions apply during loading and ∆

K stays as a valid crack tip parameter, compressive stress develops within the plastic zone during unloading by elastic unloading of the adjacent material. In a small region within the MPZ, the maximum compressive stress exceeds the yield strength, resulting in a reversing plastic flow called the cyclic plastic zone (CPZ) [

1].

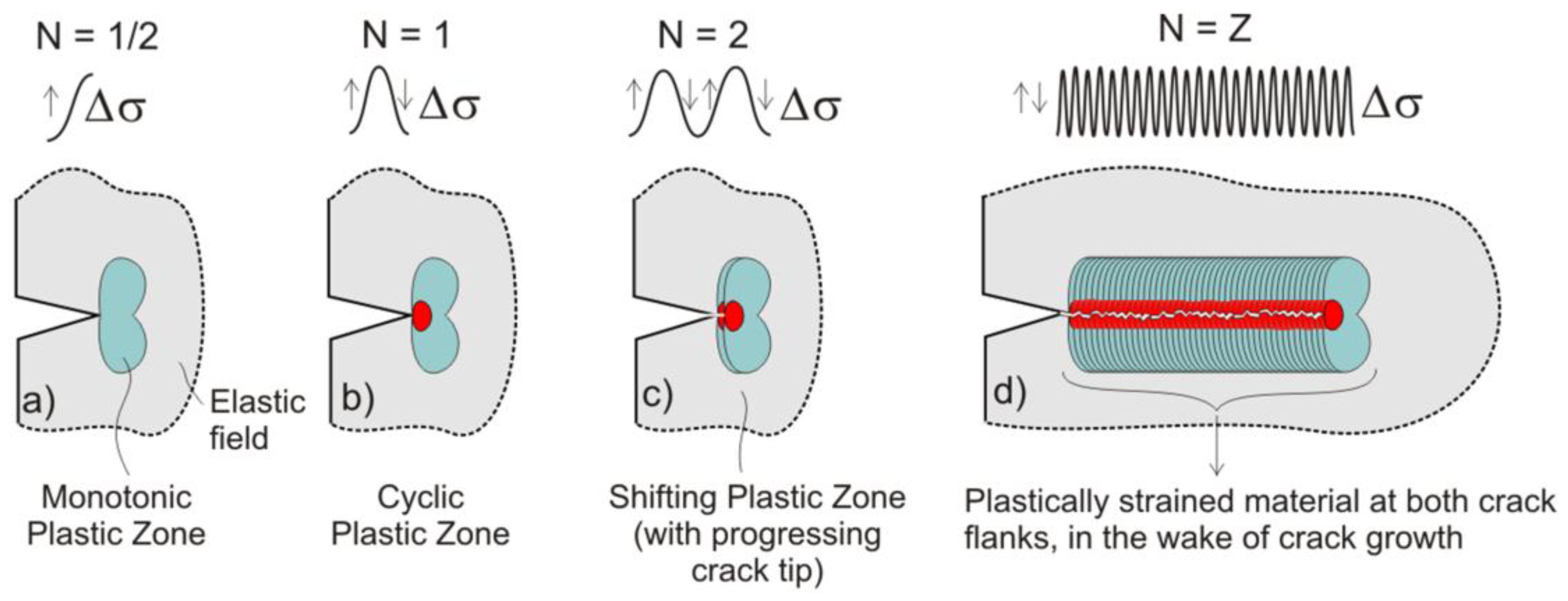

A schematic view of the formation of a plastic zone at the tip of a progressing fatigue crack showing the formation of the MPZ and CPZ is demonstrated in

Figure 1a–d. As the crack grows, the plastic zone forms a wake of plastically strained material along both flanks of the crack (cf.

Figure 1d).

An estimate of the MPZ for the plane stress condition made by Irwin [

2] is given in the following Equation (1):

whereby

2ry is the plastic zone size according to Irwin,

Kmax is the maximum applied stress intensity (at the peak of the fatigue load; σ = σ

max), σ

YS is the materials’ yield stress,

K is the applied stress intensity, σ the applied bulk stress,

C a geometry factor [

3], and

a the crack length.

The mechanical properties of the material and the state of stress govern the size and shape of the plastic zone, as well as the distribution of stress and strain within the plastic zone itself. In general, the cyclic plastic zone is approximately one quarter of the size of the monotonic plastic zone [

4].

How to quantitatively describe the propagation of cracks has been one of the most significant problems in fracture mechanics. The plastic zone size at the crack tip is a very important characteristic of the crack behaviour; it has obvious physical meaning, and can be directly observed in experiments.

There are various techniques that have been used to characterize the plastic zone size [

4,

5]. The microhardness technique is perhaps the most widely used. It is applicable when the plastic zone ahead of a fatigue crack is cyclically loaded, which leads to hardening or softening. This can be done by taking hardness indentations in front of and around the crack tip. Depending on the density and arrangement of dislocation and consequently on the strain history, hardness indentation can be used to reveal the plastic zone size. The monotonic plastic zone can be identified by a nearly constant hardness, while it increases parabolically in the cyclic plastic zone [

4]. However, the spatial resolution of hardness measurements is very poor, and hence such local hardness measurements do not give any insight into the distribution of plastic strain around the crack tip.

Etching is another microstructural method that can be used to reveal the plastic zone. In a remarkable work of Hahn et al. [

5], the shape and size of the plastic zone in Fe-3%Si Steel was determined. They could also confirm the plastic zone size by theoretical calculations. In this technique, specimens containing cracks were etched with an appropriate etchant. Because of the high amount of deformation and high dislocation density at the crack tip and wake, the microstructure responds differently to etching, and therefore the plastic zone can be easily observed as a dark- or light-etched region. One of the main challenges of this method is finding the proper etchant solution, and it is not applicable for all alloys.

Alternatively, orientation contrast microscopy can be used for gauging local plastic strain in the microstructure [

6]. It has been widely recognized that when averaged in a small volume of material, dislocations can be categorized either as statistically stored dislocations (SSDs) with a net Burgers vector close to zero, and geometrically necessary dislocations (GNDs), which give rise to a non-zero closing vector when integrated over a local volume [

7,

8]. The GNDs are also known as non-redundant dislocations and involve a local crystal rotation, which may be determined by orientation contrast microscopy measurements, conventionally with an angular resolution of 0.5° to 1.0° (depending on material characteristics and the measurement setup). Therefore, the density of GNDs can be estimated by local orientation measurements on the condition that a material model is available that connects the local orientation gradients with the dislocation density.

A number of models have been proposed in the literature [

9,

10,

11,

12] which associate the local orientation gradient with the density of GNDs. This connection is generally based on the Nye dislocation tensor

αij, which bears a linear connection with the lattice curvature tensor

κij = ∂θ

i/∂

xj, whereby θ

i is the misorientation in direction

i. The total density of GNDs ρ

GND is given by

. The in-plane components of the lattice curvature tensor

κij (with

j ≠ 3) can be derived from crystal orientation scans by electron backscattered diffraction (EBSD). Hence, EBSD may provide the potential to map localized plastic deformation at the microstructural length scale by monitoring the local orientation gradients [

13,

14]. It is the objective of the present paper to gauge whether this potential can be employed to quantitatively identify the plastic zone size around the tip of a fatigue crack in an aluminium alloy.

4. Discussion

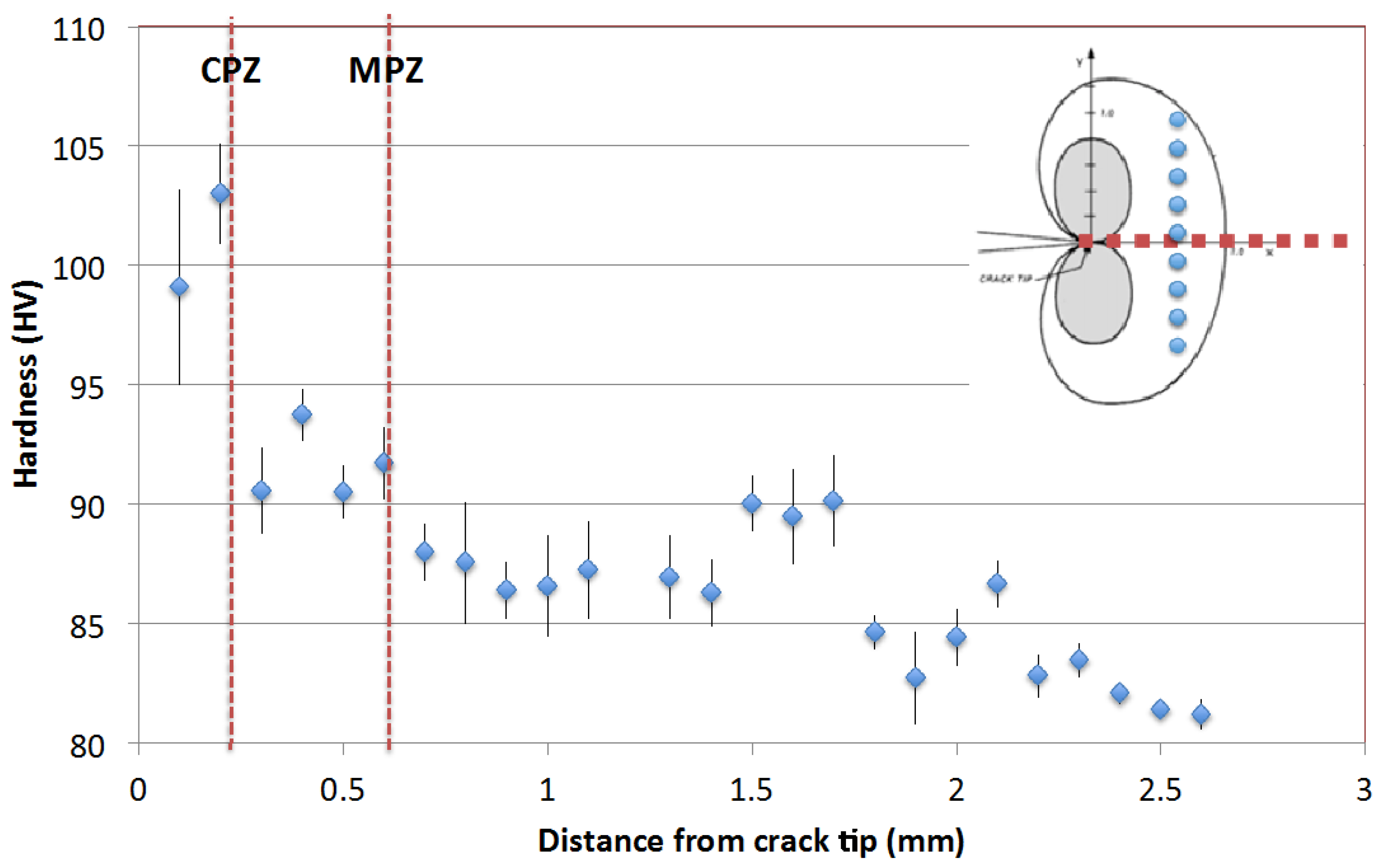

Vickers microhardness measurements indicate the MPZ and CPZ size of ~0.6 mm and ~0.2 mm, respectively (cf.

Figure 3). These values are in reasonable agreement with the theoretical estimated values of MPZ and CPZ size of 0.53 mm and 0.13 mm, respectively, as derived from Equation (1) with

Kmax = 5.62 MPa √

m and

C = 1.17 [

3], whereby CPZ = (1/4) *MPZ [

4].

The Nye tensor connects the density of GNDs to the lattice curvature tensor. In a simplified one-dimensional (scalar) representation assuming only parallel edge dislocations of the same sign, this tensor relation can be expressed as (cf.

Figure 5) [

7]:

whereby

κ is the lattice curvature dθ/d

x, ρ the density of GNDs, and

b the Burgers vector. On the simplified lattice geometry of

Figure 5, it can be seen that the curvature

κ = 1/

R = dθd

x. In a discrete representation, the local dθ/d

x value can be approximated as ∆ < θ > /∆

x, whereby ∆ < θ > is the local average misorientation as quantified by the KAM parameter in an EBSD measurement and ∆

x is the distance over which the misorientation is evaluated.

Figure 5 equally shows that the shear strain tg(dθ) ≈ dθ is approximately equal to the local lattice misorientation dθ in the approximation of very small (shear) strains. If it is assumed that the angular resolution limit of EBSD is approximately equal to 1.0° (0.0174 rad), then this corresponds to a plastic shear detection limit of ~1.7%.

The misorientation corresponding to the plastic zone at the crack tip—as revealed by the KAM parameter—is shown in

Figure 4c. This map suggests a plastic wake size of less than 30 μm, which is much smaller than the size obtained from the hardness measurements and theoretical calculations as mentioned above. Therefore, this can suggest that the magnitude of strain in the plastic zone is not high enough to be gauged with EBSD. Hence, the following experiment was performed to determine if the noise dominates the misorientation maps for strain levels below a critical threshold.

A plastic strain was applied to a tensile test sample of the same aluminium alloy with tensile strains ranging from 1% to 25% at fracture. Orientation contrast maps were measured with a step size of 0.3 μm on each of the tensile samples in four different locations (scanned area 200 × 300 μm

2), and the scan average KAM value was extracted for each scan; thereafter, the average value and the standard deviation was determined for the set of four scans. The procedure was repeated for different values of nearest neighbours: 2nd, 3rd, 4th, 6th, 8th, and 10th nearest neighbours were considered. The dependence of the KAM value on the tensile plastic strain is shown in

Figure 6.

According to the theoretical expectation, it was confirmed that no specific tendency could be observed up to a plastic strain level of ~1.5%, indicating that the accumulated plastic strain at the crack tip is less than the detectable limit. For plastic strains exceeding the critical value of ~1.5%, noise no longer determines the average KAM value, and there is an ascending correspondence between the KAM value and the plastic strain, which was also observed by Kamaya et al. [

13].

The work of Besel et al. [

17], in which they determined the plastic zone size with 3D numerical finite element method (FEM) simulations and digital image correlation (DIC), shows that the main part of the plastic zone also has strain values less than 1%. Therefore, the results of Besel et al. [

17] are consistent with the present EBSD results. In

Figure 4c it can be observed that only a small part (<30 μm) of the plastic zone exhibits intensified KAM values corresponding to strain values higher than 1.5%.

It should be noted that—according to the simplified model of Equation (2)—there is a linear relation between the GND dislocation density and the lattice curvature. Ignoring the simplifications of this model, it can be observed that the slope of this curve is positive but with descending second derivative, just as the predicted evolutions by theoretical dislocation balance equations [

18,

19].

Acknowledgments

The authors would like to acknowledge Hadi Pirgazi (Ghent University, Belgium) for his contribution to the EBSD measurements. Additionally acknowledged is a group of TU-Delft bachelor students (Casper G.J. Hügel, Sylvia L. Van Kreveld, Dirk V.A. Mutters and Bert J. Vogel), who collaborated in carrying out part of the experiments. The authors also are indebted to the Belgian IAP Inter-university attraction poles program P7/21 for financial support.

Author Contributions

This publication is a collective work of all co-authors, with shared responsibility for the text and content of the paper. Sepideh Ghodrat and Leo A.I. Kestens conceived and designed the experiments; Sepideh Ghodrat and Ton Riemslag performed the experiments; Sepideh Ghodrat and Leo A.I. Kestens analyzed the data; all authors contributed in writing the paper, based on an initial version drafted by the first author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Saxena, A.; Muhlstein, C.L. Fatigue Crack Growth Testing; ASM International, Member/Customer Service Center: Materials Park, OH, USA, 1996; Volume 19, pp. 410–412. [Google Scholar]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering; John Wiley & Sons, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Tada, H.; Paris, P.C.; Irwin, G.R. The Stress Analysis of Cracks Handbook; ASM International, Member/Customer Service Center: Materials Park, OH, USA, 2000. [Google Scholar]

- Ugˇuz, A.; Martin, J.W. Plastic zone size measurement techniques for metallic materials. Mater. Charact. 1996, 37, 105–118. [Google Scholar] [CrossRef]

- Hahn, G.T.; Hoagland, R.G.; Rosenfield, A.R. Local Yielding Attending Fatigue Crack Growth. Metall. Trans. 1972, 3, 1189–1202. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A Review of Strain Analysis Using Electron Backscatter Diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D.; Hansen, N. Geometrically necessary, incidental and subgrain boundaries. Scr. Metall. Mater. 1991, 25, 1557–1562. [Google Scholar] [CrossRef]

- Hardin, T.J.; Adams, B.L.; Fullwood, D.T.; Wagoner, R.H.; Homer, E.R. Estimation of the full Nye’s tensor and its gradients by micro-mechanical stereo-inference using EBSD dislocation microscopy. Int. J. Plast. 2013, 50, 146–157. [Google Scholar] [CrossRef]

- El-Dasher, B.S.; Adams, B.L.; Rollett, A.D. Viewpoint: experimental recovery of geometrically necessary dislocation density in polycrystals. Scr. Mater. 2003, 48, 141–145. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- Ruggles, T.J.; Fullwood, D.T. Estimations of bulk geometrically necessary dislocation density using high resolution EBSD. Ultramicroscopy 2013, 133, 8–15. [Google Scholar] [CrossRef] [PubMed]

- Kamaya, M.; Wilkinson, A.J.; Titchmarsh, J.M. Measurement of plastic strain of polycrystalline material by electron backscatter diffraction. Nucl. Eng. Des. 2005, 235, 713–725. [Google Scholar] [CrossRef]

- Kamaya, M.; Wilkinson, A.J.; Titchmarsh, J.M. Quantification of plastic strain of stainless steel and nickel alloy by electron backscatter diffraction. Acta Mater. 2006, 54, 539–548. [Google Scholar] [CrossRef]

- Wright, S.I. EDAX-TSL® Software vs. 8 (2016), Users Manual; EDAX Inc.: Draper, UT, USA, 2016. [Google Scholar]

- Ghodrat, S. Thermo-Mechanical Fatigue of Compacted Graphite Iron in Diesel Engine Components. PhD Thesis, Delft University of Technology, Delft, The Netherlands, 10 June 2013. [Google Scholar]

- Besel, M.; Breitbarth, E. Advanced analysis of crack tip plastic zone under cyclic loading. Int. J. Fatigue 2016, 93, 92–108. [Google Scholar] [CrossRef]

- Bergström, Y. A dislocation model for the stress-strain behaviour of polycrystalline α-Fe with special emphasis on the variation of the densities of mobile and immobile dislocations. Mater. Sci. Eng. 1970, 5, 193–200. [Google Scholar] [CrossRef]

- Bergström, Y.; Granbom, Y.; Sterkenburg, D.; Sterkenburg, D.A. Dislocation-Based Theory for the Deformation Hardening Behavior of DP Steels: Impact of Martensite Content and Ferrite Grain Size. J. Metall. 2010, 2010, 1–16. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).