Precipitation Behavior of Carbides in H13 Hot Work Die Steel and Its Strengthening during Tempering

Abstract

:1. Introduction

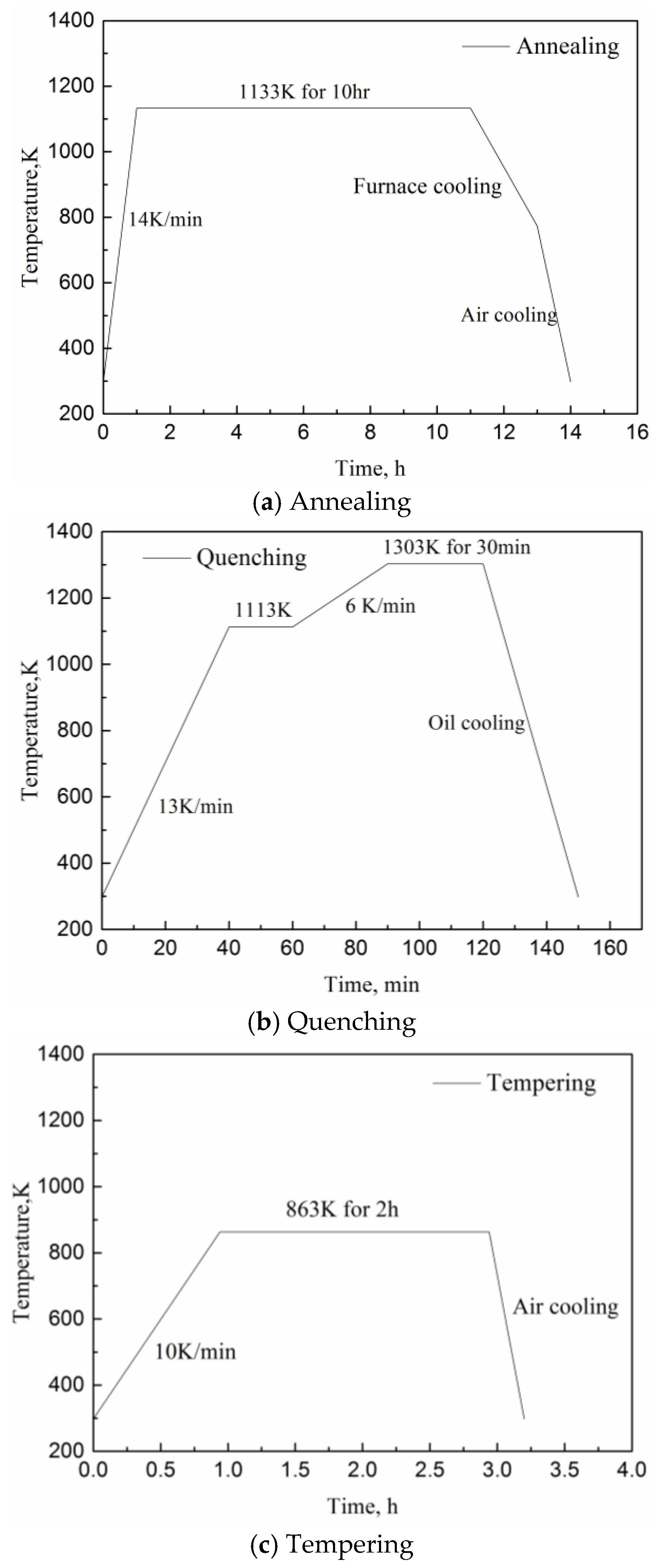

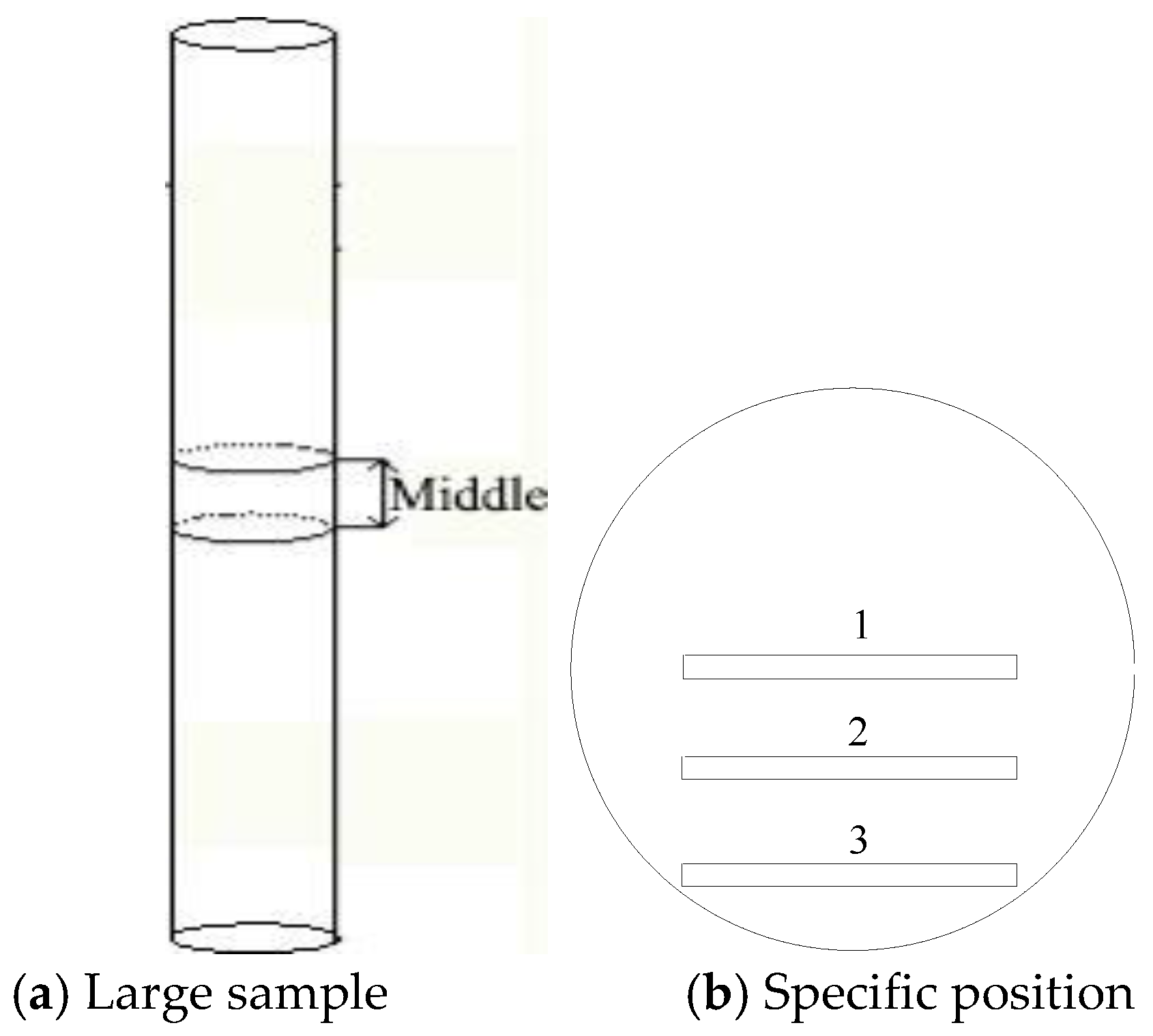

2. Experimental Materials and Methods

3. Experimental Results

3.1. Metallographic Structure after Tempering

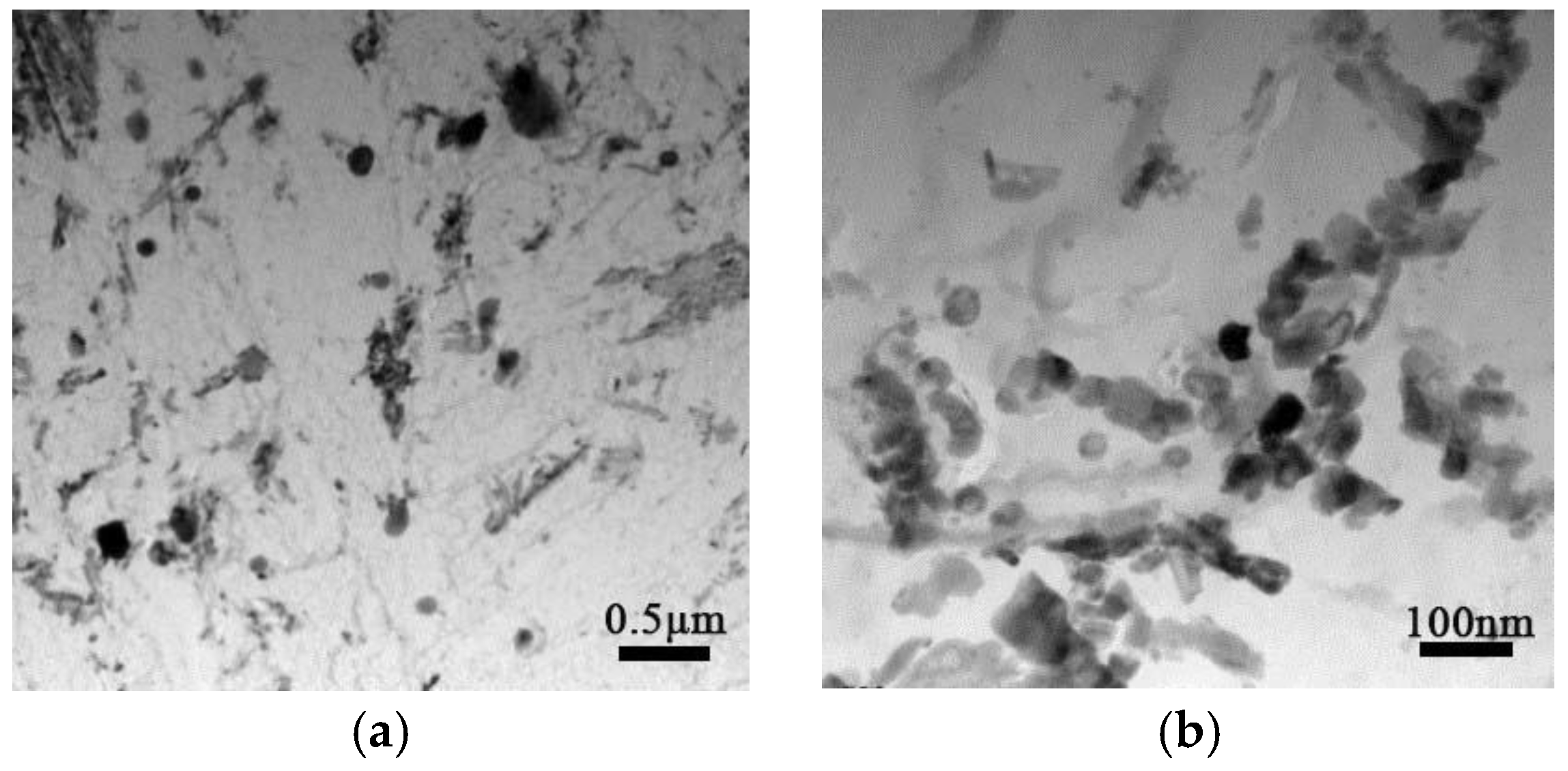

3.2. Types of Precipitates during Tempering

3.3. Analysis of the Size and Volume of Precipitate Carbides

- (1)

- The carbides less than 150 nm in size precipitate most frequently at the half-radius of the H13 ingot. Therefore, the quantity of precipitates at this position is the largest.

- (2)

- The greatest number of carbides are of sizes less than 50 nm, occurring near the surface of the ingot. Therefore, the average size is smallest at this position.

- (3)

- The particle size distribution deviates from a Gaussian distribution, possibly because short-time tempering leads to insufficient growth of the precipitates and a large number of small newly-formed carbides precipitate during tempering.

4. Discussion

4.1. Thermodynamic Calculation of Carbides during Tempering

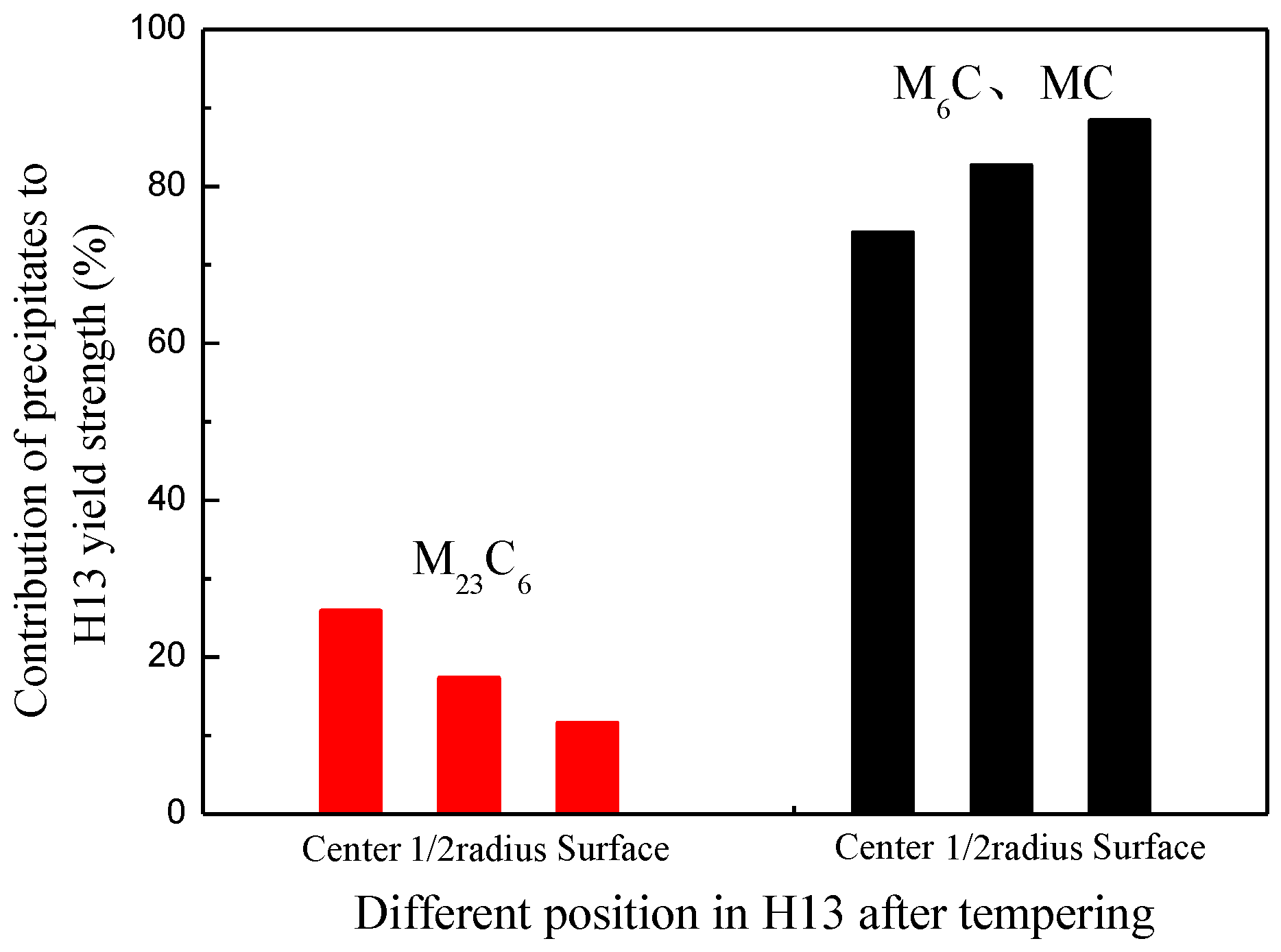

4.2. Effect of Precipitates in H13 during Tempering on Mechanical Properties

5. Conclusions

- Microstructures near the surface of the H13 ingot are homogeneous and have the narrowest martensite laths.

- V-rich MC, Mo-rich M6C, and Cr-rich M23C6 are the main kinds of carbides that precipitate in H13 during tempering. The shapes of MC and M6C are approximately square or elongated and their sizes are less than 200 nm. The shape of M23C6 is irregularly spherical and its size is greater than 200 nm. From thermodynamic calculations, the precipitation sequence is MC > M23C6.

- Carbide size and volume fraction decrease from the center to the periphery of H13 during tempering. There are more precipitates at the half-radius of H13 than that at the center. The surface of the H13 ingot has the fewest precipitates.

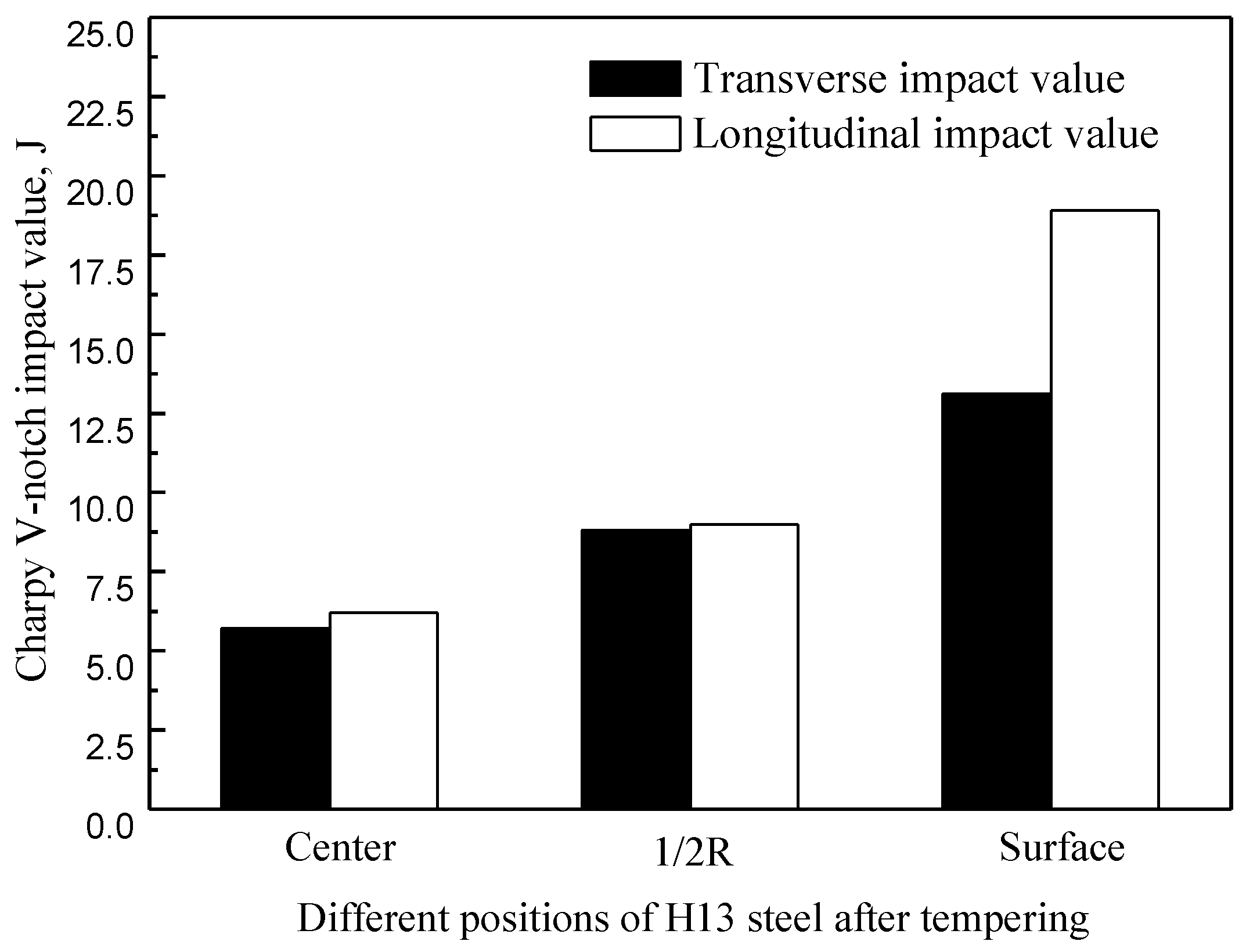

- The strength and plasticity after tempering are almost independent of the sample position. However, the hardness seems to be lower from the center to the surface, showing that the ingot was heated unevenly. The impact values after tempering become better from the center of the ingot to its outer surface, because the compositions and structures are uniform near the surface of the ingot, and the precipitates are uniformly dispersed with the finest size.

- The contribution of precipitation strengthening to yield strength increases from the center to the outer surface of the H13 ingot. The fraction of yield strength attributable to precipitation strengthening is 19.2%–22.4% after tempering. With a decreased contribution of M23C6 to precipitation strengthening, the contribution of MC and M2C increases from the center to the surface. MC and M6C have the main effect on precipitation strengthening in H13 after tempering, increasing the strength by up to 74.2%–88.4%.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Feng, X.Z. Mold Steel and Heat Treatment; Machinery Industry Press: Beijing, China, 1984. [Google Scholar]

- Sjöström, J.; Bergström, J. Thermal fatigue testing of chromium martensitic hot-work tool steel after different austenitizing treatments. J. Mater. Process. Technol. 2004, 153–154, 1089–1096. [Google Scholar] [CrossRef]

- Pan, X.H.; Zhu, Z.C. The study of chemical composition and improvement and development for the H13 hot work die & mold steel. Mold Manuf. 2006, 4, 78–85. [Google Scholar]

- Fuchs, K.D. Hot-work tool steels with improved properties for die casting applications, The use of tool steels: Experience research. In Proceedings of the 6th International Tooling Conference, Karlstad, Sweden, 10–13 September 2002; pp. 15–22.

- Kheirandish, S.; Noorian, A. Effect of niobium on microstructure of cast AISI H13 hot work tool steel. J. Iron Steel Res. Int. 2008, 15, 61–66. [Google Scholar] [CrossRef]

- Ma, D.S.; Zhou, J.; Chen, Z.Z.; Zhang, Z.K.; Chen, Q.A.; Li, D.H. Influence of thermal homogenization treatment on structure and impact toughness of H13 ESR steel. J. Iron Steel Res. Int. 2009, 16, 56–60. [Google Scholar] [CrossRef]

- Hu, X.B.; Li, L. Changes of morphology and composition of carbides in H13 steel after thermal fatigue. Trans. Mater. Heat Treat. 2007, 28, 82–87. [Google Scholar]

- Mebarki, N.; Delagnes, D.; Lamesle, P.; Delmas, F.; Levaillant, C. Relationship between microstructure and mechanical properties of a 5% Cr tempered martensitic tool steel. Mater. Sci. Eng. A 2004, 387–389, 171–175. [Google Scholar] [CrossRef]

- Song, W.W.; Min, Y.A.; Wu, X.C. Study on carbides and their evolution in H13 hot work steel. Trans. Mater. Heat Treat. 2009, 30, 122–126. [Google Scholar]

- Zhang, K.; Yong, Q.L.; Sun, X.J.; Li, Z.D.; Zhao, P.L.; Chen, S.D. Effect of tempering temperature on microstructure and mechanical properties of high Ti microalloyed directly quenched high strength steel. Acta Metall. Sin. 2014, 50, 913–920. [Google Scholar]

- Fu, J.; Li, G.Q.; Mao, X.P.; Fang, K.M. Nanoscale cementite precipitates and comprehensive strengthening mechanism of steel. Metall. Mater. Trans. A 2011, 42A, 3797–3812. [Google Scholar] [CrossRef]

- Mao, W.; Ning, A.; Guo, H. Nanoscale precipitates and comprehensive strengthening mechanism in AISI H13 steel. Int. J. Miner. Metall. Mater. 2016, 23, 1056–1064. [Google Scholar] [CrossRef]

- Zhou, J.; Ma, D.S.; Liu, B.S.; Kang, A.J.; Li, X.Y. Research of band segregation evolution of H13 steel. J. Iron Steel Res. 2012, 24, 47–57. [Google Scholar]

- Li, Z.B. Electroslag Metallurgy Equipment and Technology; Metallurgical Industry Press: Beijing, China, 2012. [Google Scholar]

- Guo, K.X.; Ye, H.Q.; Wu, Y.K. Application of Electron Diffraction Pattern in Crystallography; Science Press: Beijing, China, 1983. [Google Scholar]

- Gong, X.M. Fundamentals and Applications of Phase Transition Theory; Wuhan University of Technology Press: Wuhan, China, 2004. [Google Scholar]

- Ning, A.G.; Guo, H.J.; Chen, X.C.; Sun, X.L. Precipitation behaviors of carbides in H13 steel during ESR, forging and tempering. J. Univ. Sci. Technol. Beijing 2014, 36, 895–902. [Google Scholar]

- Ning, A.G.; Mao, W.W.; Guo, H.J.; Chen, X.C. Precipitation behaviors and strengthening of carbides in H13 steel during quenching. Chin. J. Process Eng. 2014, 14, 86–92. [Google Scholar]

- Ye, D.L.; Hu, J.H. Practical Inorganic Thermodynamic Data Manual, 2nd ed.; Metallurgical Industry Press: Beijing, China, 2002. [Google Scholar]

- Chen, J.X. Steelmaking Common Chart Data Manual, 2nd ed.; Metallurgical Industry Press: Beijing, China, 2010. [Google Scholar]

- Yong, Q.L. The Second Phase of the Steel Materials; Metallurgical Industry Press: Beijing, China, 2006. [Google Scholar]

- Klimiankou, M.; Lindau, R.; Moslang, A. Direct correlation between morphology of (Fe,Cr)23C6 precipitates and impact behavior of ODS steels. J. Nucl. Mater. 2007, 367–370, 173–178. [Google Scholar] [CrossRef]

- Oikawa, T.; Zhang, J.J.; Enomoto, M.; Adachi, Y. Influence of carbide particles on the grain growth of ferrite in an Fe-0.1C-0.09V alloy. ISIJ Int. 2013, 53, 1245–1252. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G.; Andres, C.G.D. Influence of V precipitates on acicula ferrite transformation Part 1: The role of nitrogen. ISIJ Int. 2008, 48, 1270–1275. [Google Scholar] [CrossRef]

- Cui, Z.Q.; Chun, Q.Y. Metal Science and Heat Treatment; Machinery Industry Press: Beijing, China, 2007. [Google Scholar]

- Seher, R.J.; James, H.M.; Maniar, G.N. Stereology and Quantitative Metallography, West Conshohocken; Pellissier, G.E., Purdy, S.M., Eds.; ASTM International: West Conshohocken, PA, USA, 1972; pp. 119–137. [Google Scholar]

- Kneissl, A.C.; Garcia, C.I.; Deardo, A.J. HSLA Steels: Processing, Properties, and Applications; Geoffrey, T., Zhang, S., Eds.; The Minerals, Metals and Materials Society: San Diego, CA, USA, 1992; pp. 99–102. [Google Scholar]

- McCall, J.L.; Boyd, J.E. Proceedings International Metallographic Society, PIMTB. In Proceedings of the 1968 Annual Meeting, Boston, MA, USA, 21 July 1968.

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Al | N | T [O] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.39 | 0.88 | 0.34 | 0.0064 | 0.0005 | 5.13 | 0.086 | 0.054 | 1.5 | 0.99 | 0.047 | 0.0015 | 0.0017 |

| Sample Number | Visual Field Area/μm2 | Field Number | Number of Precipitates | Average Size/nm |

|---|---|---|---|---|

| 1 | 3.8 × 3.8 | 15 | 711 | 82.6 |

| 0.8 × 0.8 | 15 | 394 | ||

| 2 | 3.8 × 3.8 | 15 | 815 | 81.6 |

| 0.8 × 0.8 | 15 | 327 | ||

| 3 | 3.8 × 3.8 | 15 | 683 | 60.7 |

| 0.8 × 0.8 | 15 | 261 |

| Austenite Region | ||||

|---|---|---|---|---|

| Carbides | V8C7 | MoC | VC | Cr23C6 |

| Temperature | 1553.5 K | 1499.0 K | 1331.8 K | 1058.2 K |

| Sample Number | Tensile Strength, Rm (MPa) | Yield Strength, Rp (MPa) | Elongation, A (%) | Area Reduction Rate, Z (%) | HRC |

|---|---|---|---|---|---|

| Center, #1 | 1764.6 | 1456.0 | 7.0 | 30.6 | 49.2 |

| Half-radius, #2 | 1743.1 | 1426.4 | 8.9 | 28.9 | 47.5 |

| Surface, #3 | 1750.2 | 1436.0 | 8.0 | 35.1 | 46.2 |

| Size (nm) | Amount | Average Diameter, D (nm) | Volume Fraction, f | Average Radius, r (nm) | Yield Strength Increment, τP (MPa) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1# | 2# | 3# | 1# | 2# | 3# | 1# | 2# | 3# | 1# | 2# | 3# | 1# | 2# | 3# | |

| 10–30 | 197 | 172 | 231 | 21.79 | 21.73 | 21.74 | 0.00015 | 0.00013 | 0.00035 | 10.90 | 10.87 | 10.87 | 26.78 | 25.01 | 40.88 |

| 30–50 | 233 | 238 | 262 | 40.27 | 40.44 | 39.31 | 0.00061 | 0.00063 | 0.0013 | 20.14 | 20.22 | 19.66 | 33.86 | 34.25 | 50.36 |

| 50–70 | 174 | 209 | 167 | 59.22 | 59.12 | 58.66 | 0.00099 | 0.0012 | 0.0019 | 29.61 | 29.56 | 29.33 | 31.82 | 34.87 | 43.89 |

| 70–90 | 128 | 141 | 109 | 79.67 | 79.1 | 79.67 | 0.0013 | 0.0014 | 0.0022 | 39.84 | 39.55 | 39.84 | 28.99 | 30.38 | 37.73 |

| 90–110 | 98 | 102 | 64 | 98.43 | 99.01 | 99.86 | 0.0015 | 0.0016 | 0.0021 | 49.22 | 49.51 | 49.93 | 26.42 | 26.99 | 30.20 |

| 110–130 | 74 | 76 | 38 | 118.74 | 118.15 | 120.02 | 0.0017 | 0.0017 | 0.0018 | 59.37 | 59.08 | 60.01 | 23.77 | 24.07 | 24.08 |

| 130–150 | 54 | 48 | 29 | 139.54 | 138.94 | 139.2 | 0.0017 | 0.0015 | 0.0018 | 69.77 | 69.47 | 69.60 | 20.91 | 19.70 | 21.60 |

| 150–170 | 38 | 53 | 17 | 160.42 | 159.11 | 157.63 | 0.0016 | 0.0022 | 0.0014 | 80.21 | 79.56 | 78.82 | 17.97 | 21.19 | 16.90 |

| 170–190 | 26 | 35 | 9 | 178.54 | 177.69 | 180.89 | 0.0013 | 0.0018 | 0.00095 | 89.27 | 88.85 | 90.45 | 15.14 | 17.55 | 12.59 |

| 190–210 | 24 | 26 | 6 | 200.26 | 198.01 | 199.23 | 0.0016 | 0.0017 | 0.00077 | 100.13 | 99.01 | 99.62 | 14.83 | 15.41 | 10.45 |

| 210–230 | 15 | 11 | 4 | 218.68 | 220.87 | 222.11 | 0.0012 | 0.00087 | 0.00064 | 109.34 | 110.44 | 111.06 | 11.90 | 10.20 | 8.69 |

| 230–250 | 11 | 11 | 4 | 242.57 | 239.75 | 238.34 | 0.0011 | 0.0010 | 0.00074 | 121.29 | 119.88 | 119.17 | 10.36 | 10.34 | 8.79 |

| 250–270 | 12 | 9 | 1 | 260.18 | 259.54 | 254.88 | 0.0013 | 0.00099 | 0.00021 | 130.09 | 129.77 | 127.44 | 10.94 | 9.47 | 4.44 |

| 270–290 | 5 | 6 | 2 | 275.09 | 278.86 | 278.88 | 0.00062 | 0.00076 | 0.00050 | 137.55 | 139.43 | 139.44 | 7.13 | 7.82 | 6.37 |

| 290–310 | 5 | 1 | 0 | 294.86 | 307.76 | 0 | 0.00071 | 0.00015 | 0 | 147.43 | 153.88 | 0 | 7.21 | 3.24 | 0 |

| 310–330 | 4 | 1 | 1 | 320.86 | 316.7 | 313.36 | 0.00067 | 0.00016 | 0.00032 | 160.43 | 158.35 | 156.68 | 6.53 | 3.26 | 4.59 |

| 330–350 | 5 | 2 | 0 | 340.15 | 334.18 | 0 | 0.00094 | 0.00036 | 0 | 170.08 | 167.09 | 0 | 7.37 | 4.65 | 0 |

| 350–370 | 2 | 1 | 0 | 357.39 | 353.43 | 0 | 0.00042 | 0.00020 | 0 | 178.70 | 176.72 | 0 | 4.69 | 3.31 | 0 |

| Total | 1105 | 1142 | 944 | 0.0193 | 0.0184 | 0.0169 | 279.84 | 301.72 | 321.56 | ||||||

| Item | Center (1#) | Half-Radius (2#) | Surface (3#) |

|---|---|---|---|

| Average size (nm) | 82.6 | 81.6 | 60.7 |

| Volume fraction (%) | 1.9 | 1.8 | 1.7 |

| Contribution to the yield strength (MPa) | 279.8 | 301.7 | 321.6 |

| Actual yield strength (MPa) | 1456.0 | 1426.4 | 1436.0 |

| The proportion of yield strength attributable to precipitation strengthening (%) | 19.2 | 21.2 | 22.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, A.; Mao, W.; Chen, X.; Guo, H.; Guo, J. Precipitation Behavior of Carbides in H13 Hot Work Die Steel and Its Strengthening during Tempering. Metals 2017, 7, 70. https://doi.org/10.3390/met7030070

Ning A, Mao W, Chen X, Guo H, Guo J. Precipitation Behavior of Carbides in H13 Hot Work Die Steel and Its Strengthening during Tempering. Metals. 2017; 7(3):70. https://doi.org/10.3390/met7030070

Chicago/Turabian StyleNing, Angang, Wenwen Mao, Xichun Chen, Hanjie Guo, and Jing Guo. 2017. "Precipitation Behavior of Carbides in H13 Hot Work Die Steel and Its Strengthening during Tempering" Metals 7, no. 3: 70. https://doi.org/10.3390/met7030070

APA StyleNing, A., Mao, W., Chen, X., Guo, H., & Guo, J. (2017). Precipitation Behavior of Carbides in H13 Hot Work Die Steel and Its Strengthening during Tempering. Metals, 7(3), 70. https://doi.org/10.3390/met7030070