Effect of Preparation Parameter on Microstructure and Grain Refining Behavior of In Situ AlN-TiN-TiB2/Al Composite Inoculants on Pure Aluminum

Abstract

:1. Introduction

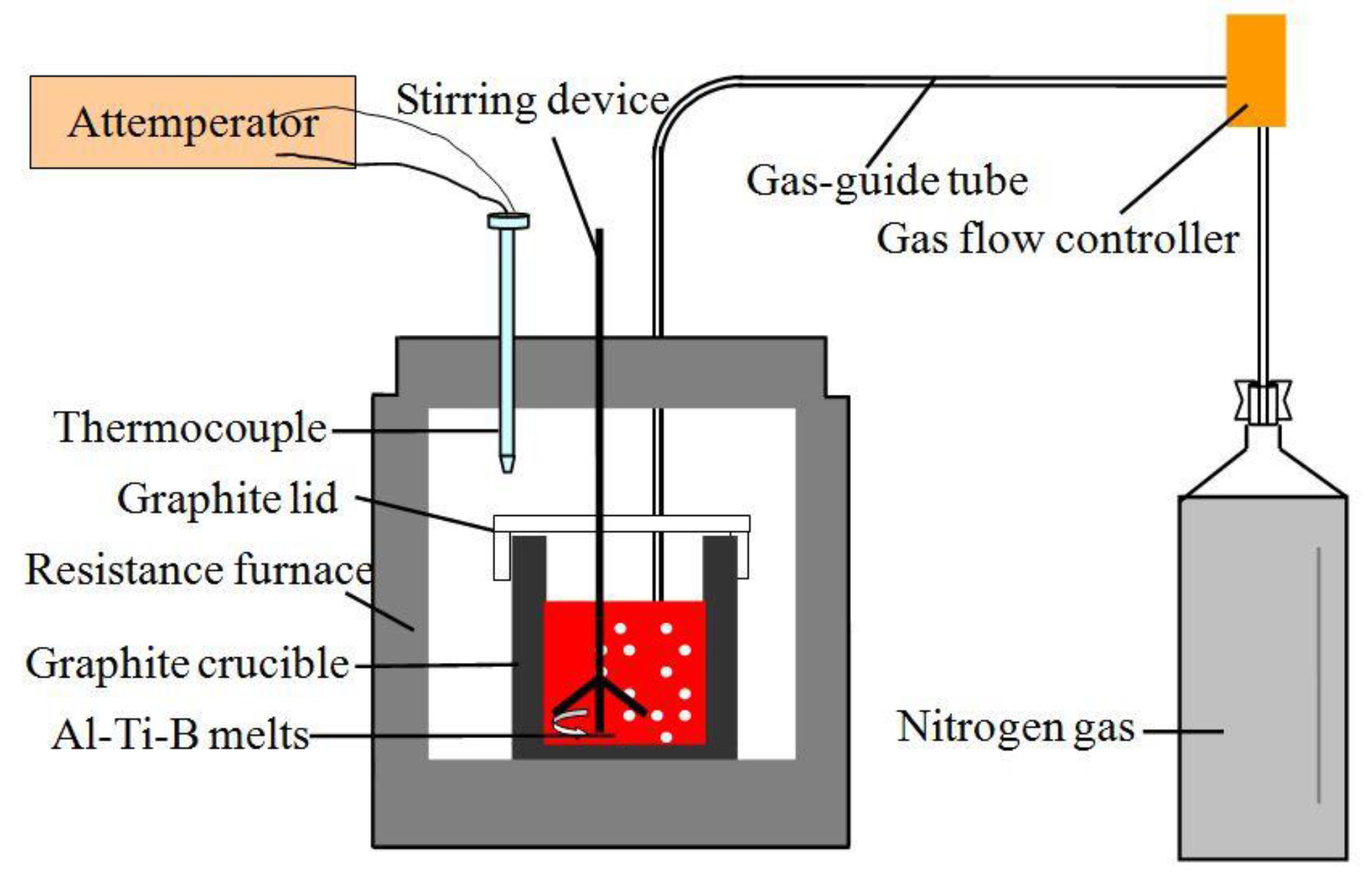

2. Experimental Procedures

3. Results and Discussion

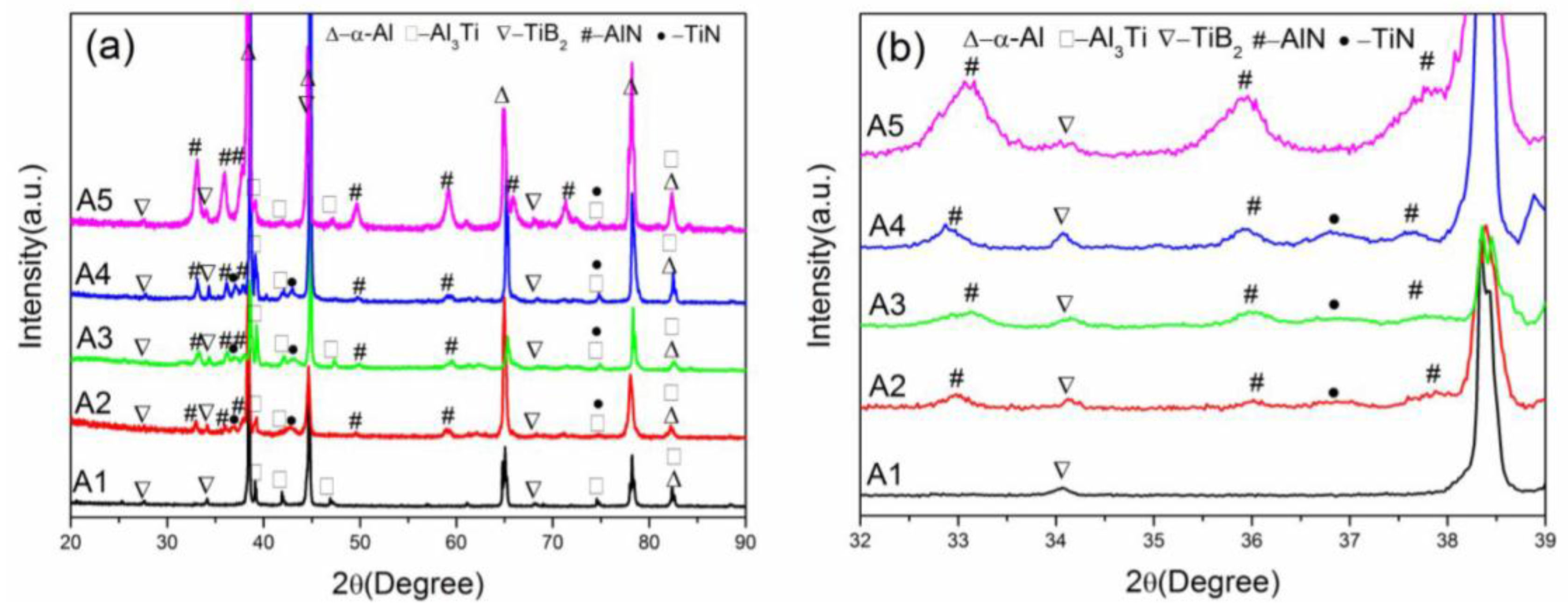

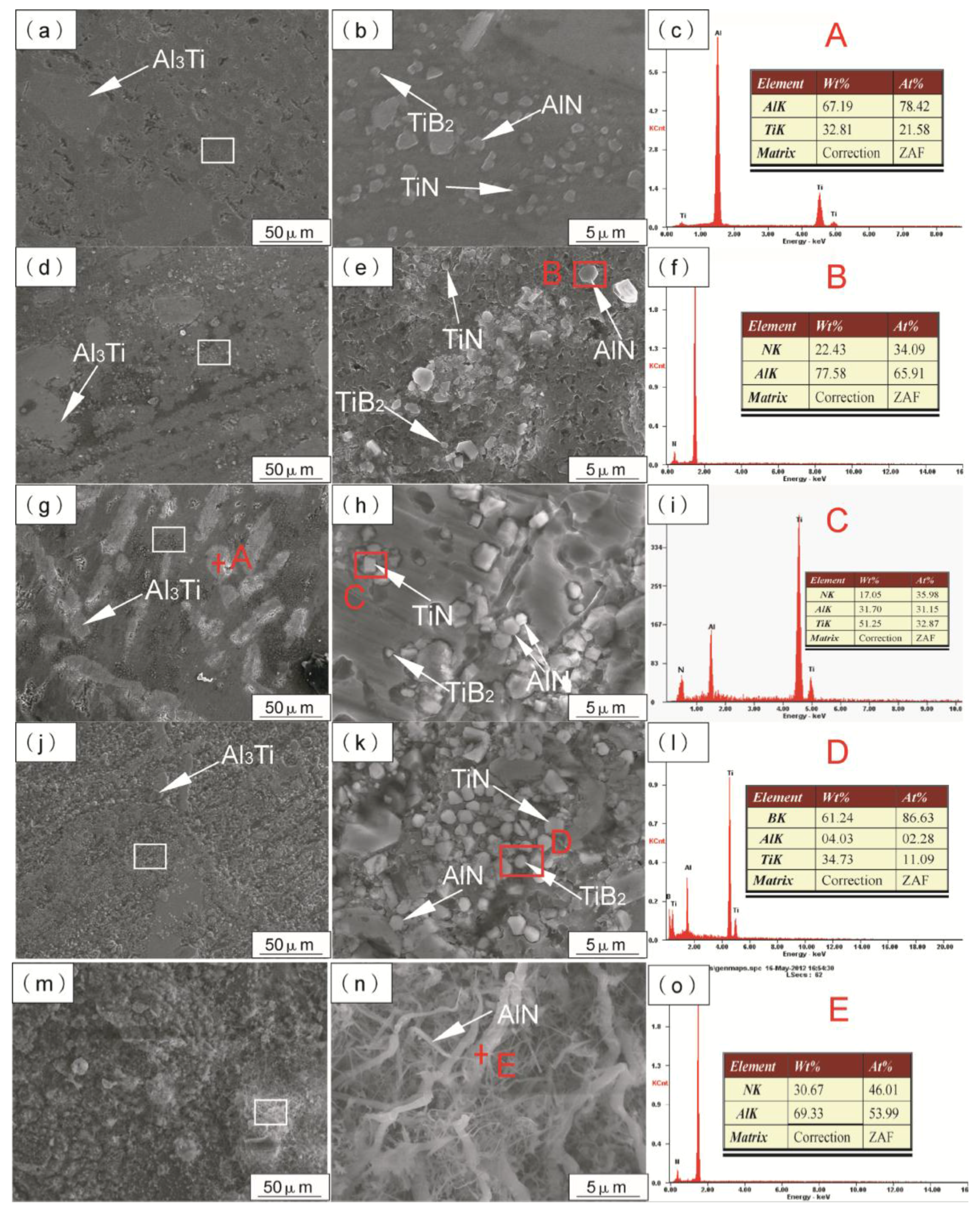

3.1. Effects of Nitriding Temperature, Nitriding Time, Composition, and Stirring Device on the Formation of In Situ AlN-TiN-TiB2/Al Composites

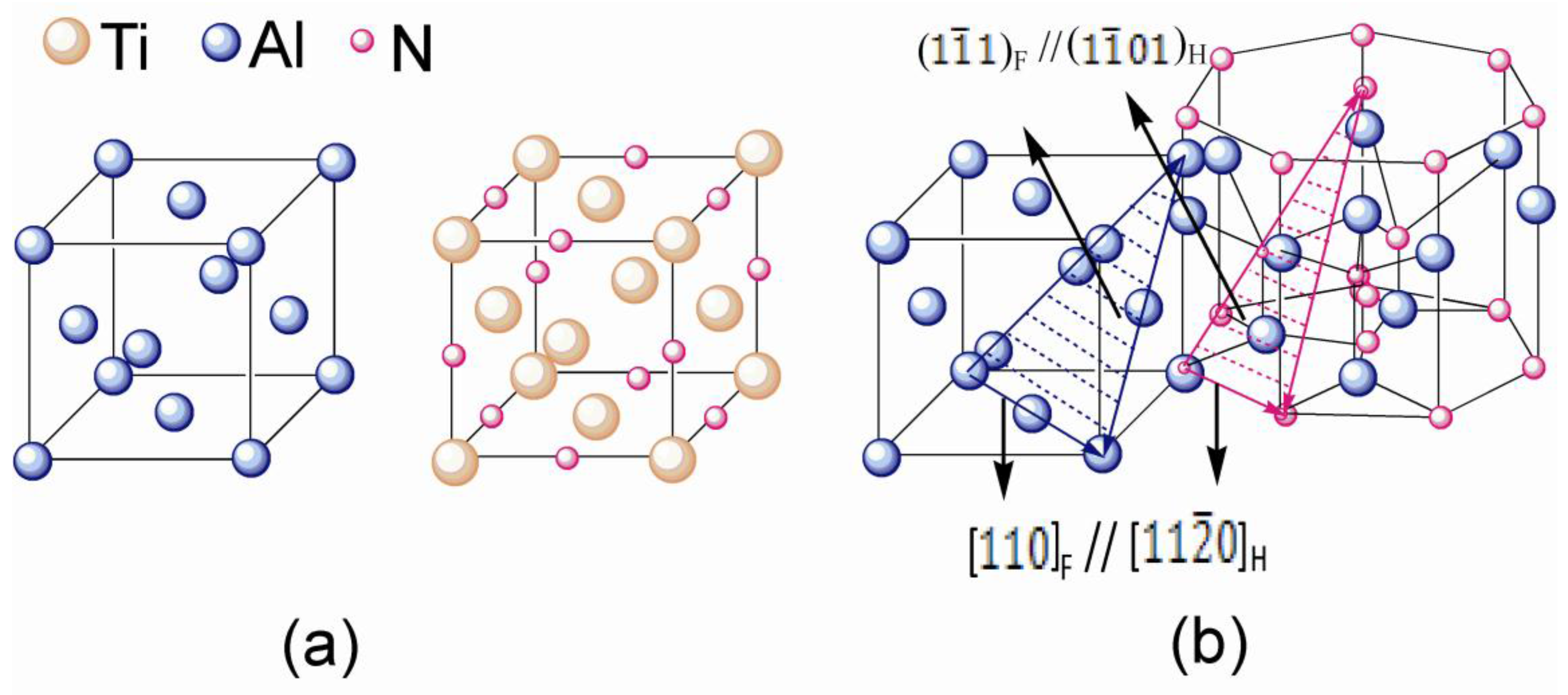

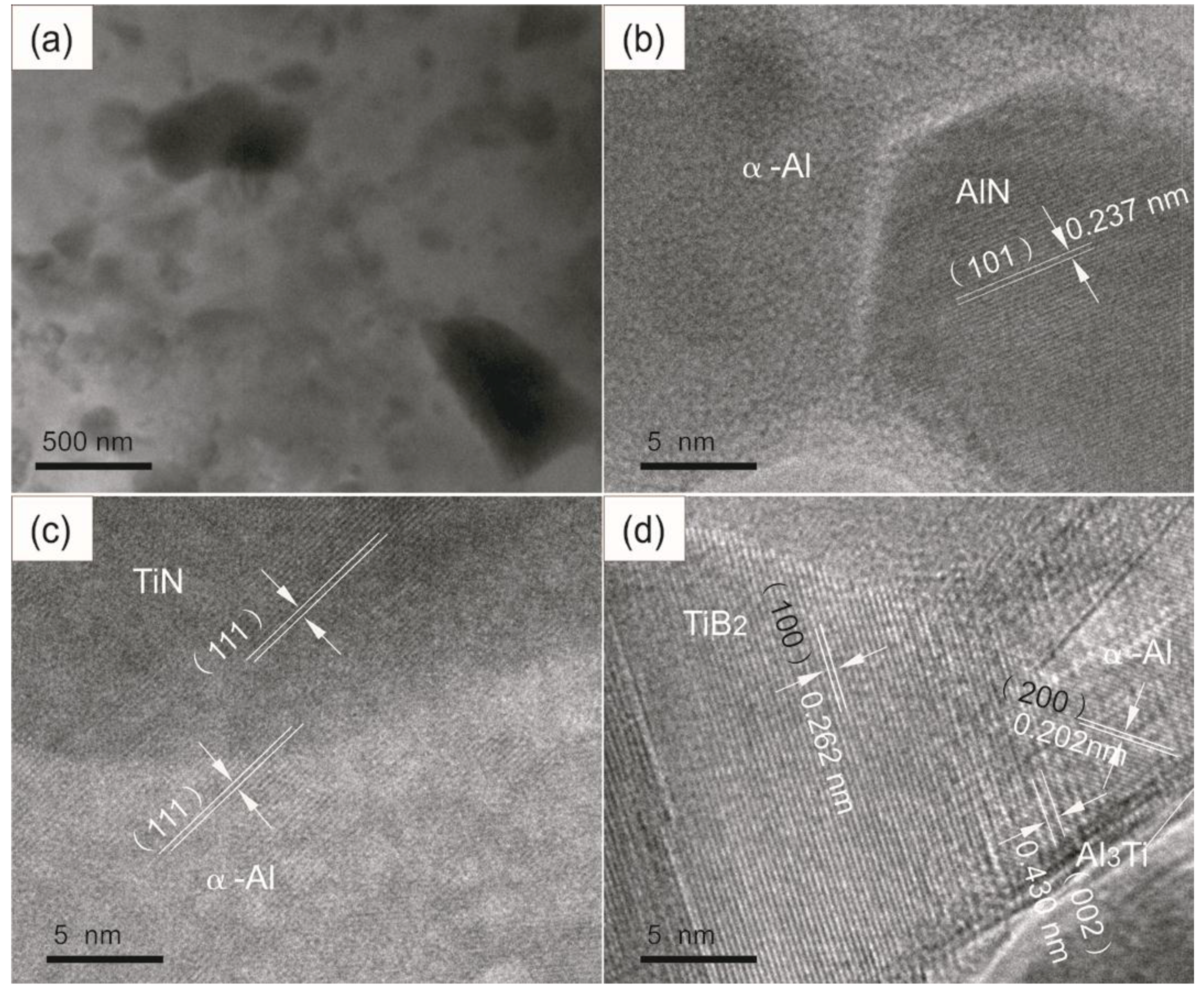

3.2. Thermodynamics Analysis and the Formation Mechanism

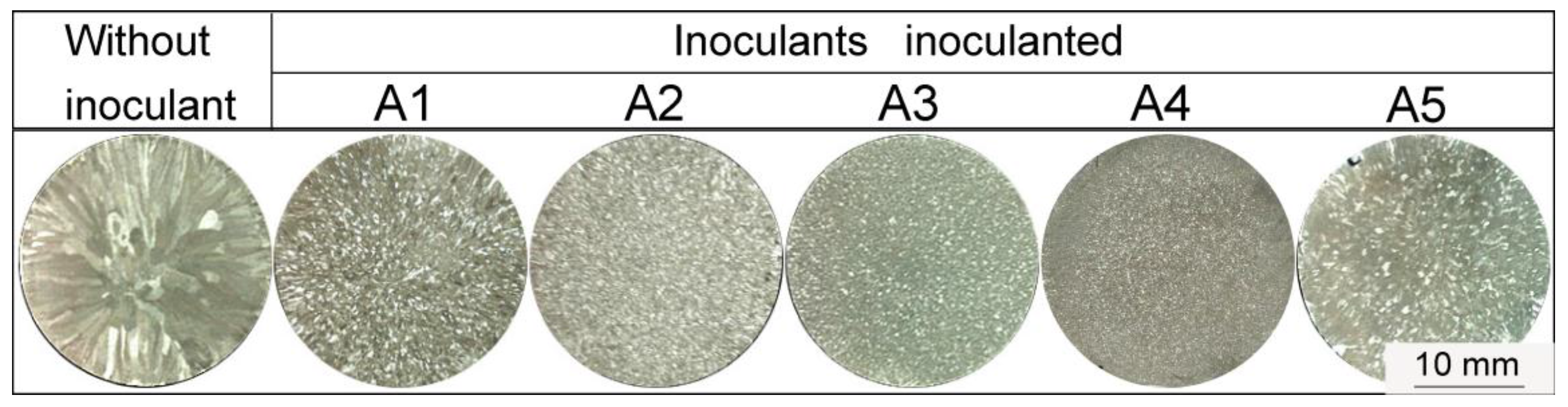

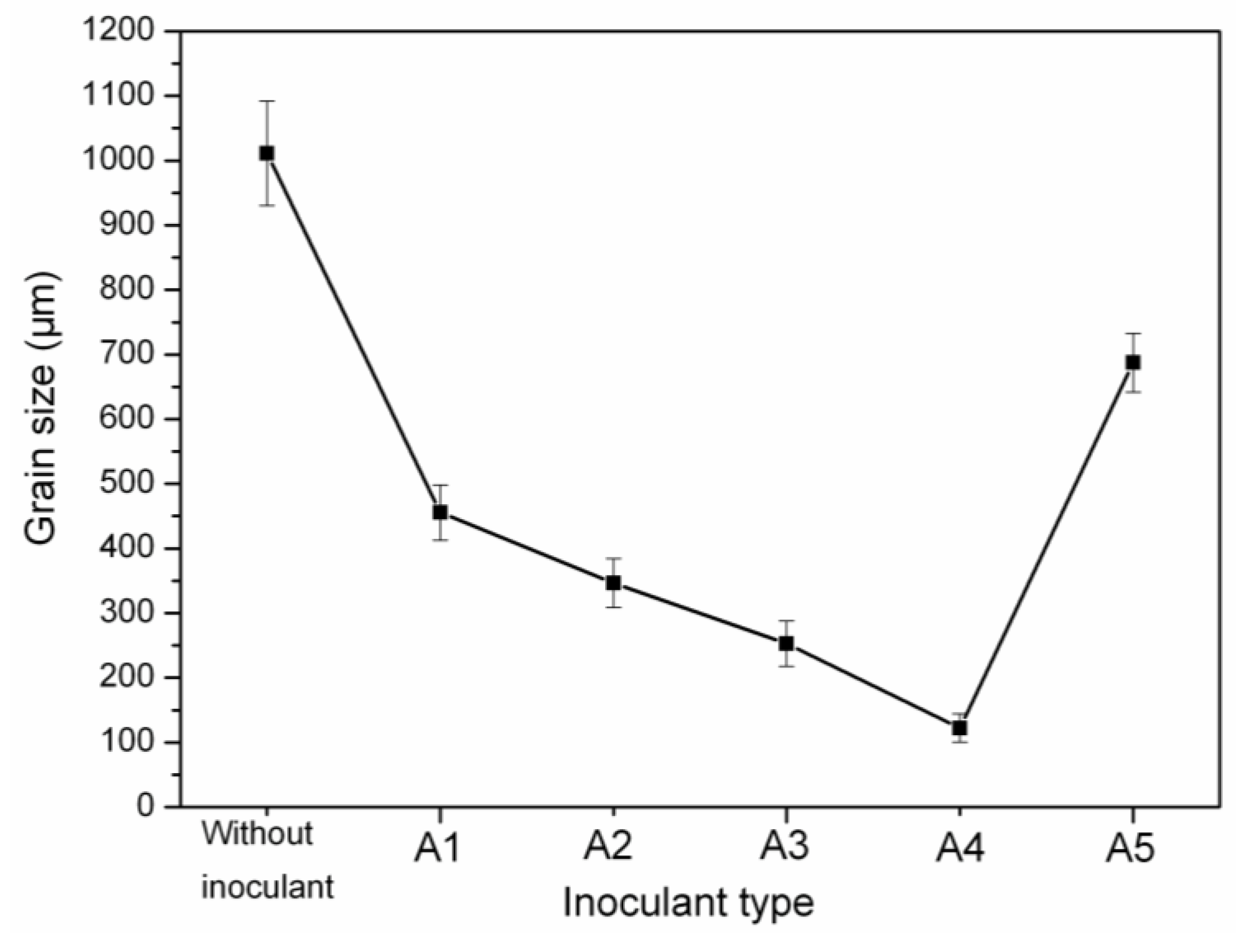

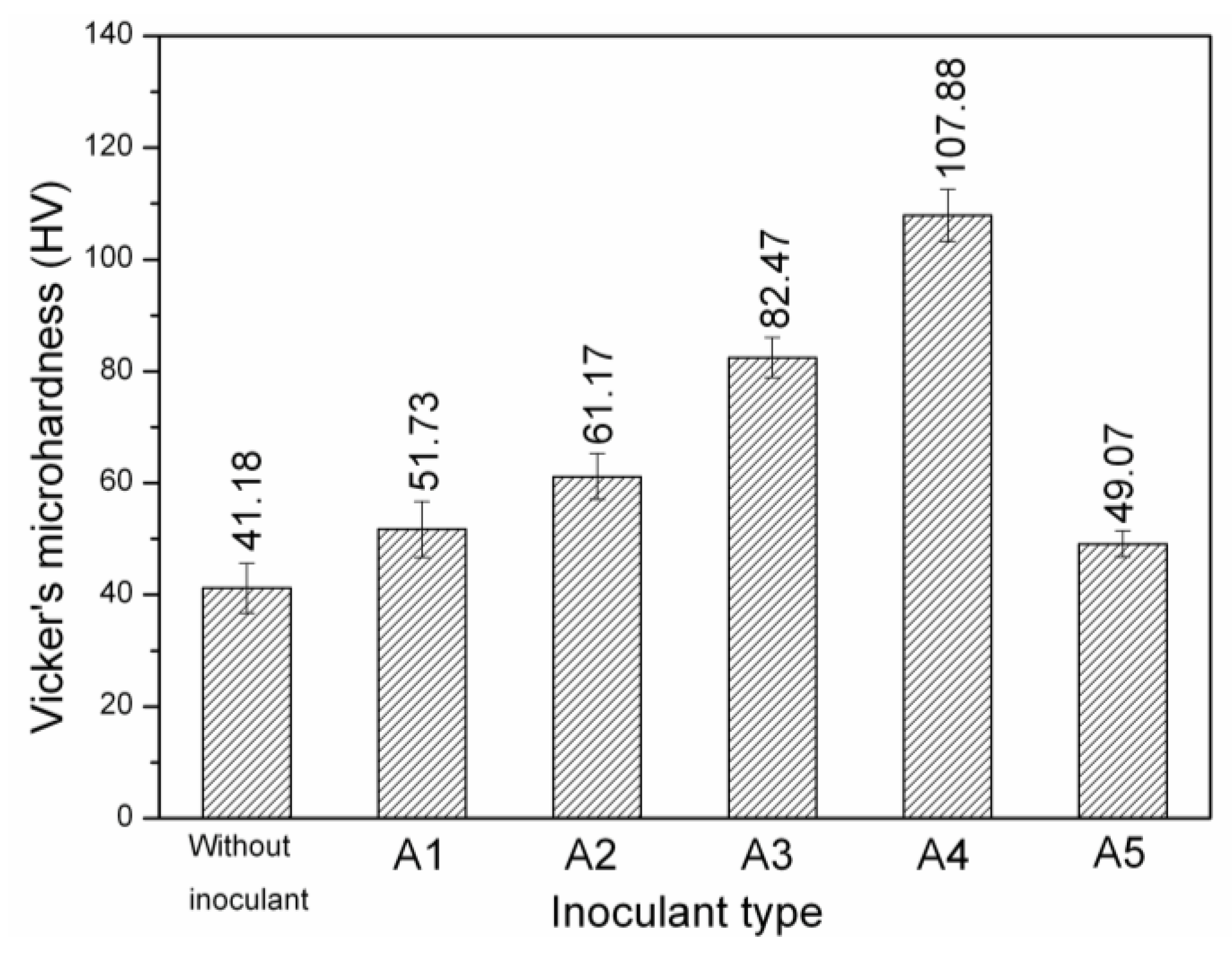

3.3. Refining and Reinforcing Effects of the Inoculants on Pure Aluminum

4. Conclusions

- (1)

- A multiple phase inoculant, the in situ AlN-TiN-TiB2/Al composite containing AlN, TiN, TiB2, Al3Ti and α-Al, was successfully prepared by nitrogen gas injection. The volume fraction, size, and distribution of TiN and AlN particles can be controlled by tuning the preparation parameters, such as nitriding temperature, nitriding time, Ti content in melt, and stirring.

- (2)

- The refining effect of in situ AlN-TiN-TiB2/Al composite inoculants increases with the increase of the content of TiB2, AlN, and TiN particles and the decrease of the size of the Al3Ti phase. The average grain size of the pure aluminum can be reduced to 122 ± 22 μm from 1010 ± 80 μm by adding of 0.3 wt % A4.

- (3)

- The excellent grain refining effect of in situ AlN-TiN-TiB2/Al composites is attributed to the miniaturization of Al3Ti phase, the diversification and homogeneous distribution of ceramic particles, such as AlN, TiN, and TiB2 particles caused by nitridation and stirring.

- (4)

- The mechanical properties of the pure aluminum have been obviously improved by the addition of in situ AlN-TiN-TiB2/Al composite inoculants. The tensile strength, yield strength, and microhardness of the pure aluminum are increased from 41.9 MPa, 28.5 MPa, and 41.18 HV to 109.7 MPa, 77.2 MPa, and 107.88 HV.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, H.L.; Song, Y.; Li, M.; Guan, S.K. Grain refining efficiency and microstructure of Al-Ti-C-RE master alloy. J. Alloy. Compd. 2010, 508, 206–211. [Google Scholar] [CrossRef]

- Wearing, D.; Horsfield, A.P.; Xu, W.W.; Lee, P.D. Which wets TiB2 inoculant particles: Al or Al3Ti? J. Alloy. Compd. 2016, 664, 460–468. [Google Scholar] [CrossRef]

- Greer, A.L. Grain refinement of alloys by inoculation of melt. Phil. Trans. R. Soc. Lond. A 2003, 361, 479–495. [Google Scholar] [CrossRef]

- Li, P.T.; Liu, S.D.; Zhang, L.L.; Liu, X.F. Grain refinement of A356 alloy by Al-Ti-B-C master alloy and its effect on mechanical properties. Mater. Des. 2013, 47, 522–528. [Google Scholar] [CrossRef]

- Birol, Y. Grain refining efficiency of Al-Ti-C alloys. J. Alloy. Compd. 2006, 422, 128–131. [Google Scholar] [CrossRef]

- Xu, C.; Xiao, W.L.; Zhao, W.T.; Wang, W.H. Microstructure and formation mechanism of grain-refining particles in Al-Ti-C-RE grain refiners. J. Rare Earths 2015, 33, 553–560. [Google Scholar] [CrossRef]

- Limmaneevichitra, C.; Eidhed, W. Fading mechanism of grain refinement of aluminum-silicon alloy with Al-Ti-B grain refiners. Mater. Sci. Eng. A 2003, 349, 197–206. [Google Scholar] [CrossRef]

- Liu, S.Q.; Wang, X.; Cui, C.X.; Zhao, L.C.; Liu, S.J.; Chen, C. Fabrication, microstructure and refining mechanism of in situ CeB6/Al inoculant in aluminum. Mater. Des. 2015, 65, 432–437. [Google Scholar] [CrossRef]

- Li, P.T.; Tian, W.J.; Wang, D.; Liu, X.F. Grain refining potency of LaB6 on aluminum alloy. J. Rare Earths 2012, 30, 1172–1176. [Google Scholar] [CrossRef]

- Li, X.W.; Cai, Q.Z.; Zhao, B.Y.; Li, B.; Liu, B.; Ma, W.L. Grain refining mechanism in pure aluminum with nanosized TiN/Ti composite refiner addition. J. Alloy. Compd. 2017, 699, 283–290. [Google Scholar] [CrossRef]

- Li, X.W.; Cai, Q.Z.; Zhao, B.Y.; Xiao, Y.T.; Li, B. Effect of nano TiN/Ti refiner addition content on the microstructure and properties of as-cast Al-Zn-Mg-Cu alloy. J. Alloy. Compd. 2016, 675, 201–210. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Khayyam, H.; Abdizadeh, H.; Karbalaei Akbari, M.; Pakseresht, A.H.; Abdi, F.; Abbasi, A.; Naebe, M. Effect of B4C, TiB2 and ZrSiO4 ceramic particles on mechanical properties of aluminium matrix composites: Experimental investigation and predictive modeling. Ceram. Int. 2016, 42, 6206–6220. [Google Scholar] [CrossRef]

- Wang, K.; Cui, C.X.; Wang, Q.; Qi, Y.M.; Wang, C. Fabrication of in situ AlN-TiN/Al inoculant and its refining efficiency and reinforcing effect on pure aluminum. J. Alloy. Compd. 2013, 547, 5–10. [Google Scholar] [CrossRef]

- Liu, S.Q.; Wang, X.; Cui, C.X.; Zhao, L.C.; Li, N.; Zhang, Z.; Ding, J.; Sha, D. Enhanced grain refinement of in situ CeB6/Al composite inoculant on pure aluminum by microstructure control. J. Alloy. Compd. 2017, 701, 926–934. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Cui, C.X.; Zhao, L.C.; Liu, S.J. Refining and Reinforcing Effects of In-situ AlN-TiN-TiB2/Al Composite Refiner on Aluminum. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Cheng, L.Z.; Han, S.G. Physical Chemistry; Shanghai Science and Technology Press: Shanghai, China, 1980; pp. 278–281. [Google Scholar]

- Frage, N.; Polak, M.; Dariel, M.P.; Frumin, N.; Levin, L. High-temperature phase equilibria in the Al-rich corner of the Al-Ti-C system. Metall. Mater. Trans. A 1998, 29, 1341–1345. [Google Scholar] [CrossRef]

- Li, P.J.; Kandalova, E.G.; Nikitin, V.I. Grain refining performance of Al-Ti master alloys with different microstructures. Mater. Lett. 2005, 59, 723–727. [Google Scholar] [CrossRef]

- Han, Y.F.; Li, K.; Wang, J.; Shu, D.; Sun, B.D. Influence of high-intensity ultrasound on grain refining performance of Al-5Ti-1B master alloy on aluminium. Mater. Sci. Eng. A 2005, 405, 306–312. [Google Scholar] [CrossRef]

- Bramfittt, B.L. The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall. Trans. 1970, 1, 1987–1995. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. Edge-to-edge matching and its applications: Part I. Application to the simple HCP/BCC system. Acta Mater. 2005, 53, 1073–1084. [Google Scholar] [CrossRef]

- Cao, Y.; Zhong, N.; Wang, X.D.; Huang, B.X.; Rong, Y.H. An edge-to-edge matching model and its application to the HCP/ FCC system. J. Shanghai Jiaotong Univ. 2007, 41, 586–591. [Google Scholar]

- Cui, C.X.; Wu, R.J.; Xue, B.Y.; Li, Y.C. Study of microstructure of AlN/Al interface on in situ TiCp-AlN/Al composite. J. Chin. Electron Microsc. Soc. 1998, 17, 59–63. [Google Scholar]

- Fan, Z.; Wang, Y.; Zhang, Y.; Qin, T.; Zhou, X.R.; Thompson, G.E.; Pennycook, T.; Hashimoto, T. Grain refining mechanism in the Al/Al-Ti-B system. Acta Mater. 2015, 84, 292–304. [Google Scholar] [CrossRef]

- Buban, J.P.; Matsunaga, K.; Chen, J.; Shibata, N.; Ching, W.Y.; Yamamoto, T.; Ikuhara, Y. Grain boundary strengthening in alumina by rare impurities. Science 2006, 311, 212–215. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.X.; He, L.J.; Mi, G.B.; Li, P.J. Two direction microstructure and effects of nanoscale dispersed Si parciles on microhardness and tensile properties of AlSi7Mg melt-spun alloy. J. Alloy. Compd. 2015, 618, 609–614. [Google Scholar] [CrossRef]

| Alloys No. | Composition | Nitridation Temperature (K) | Nitridation Time (h) | Whether the Stirring |

|---|---|---|---|---|

| A1 | Al5Ti1B | 1173 | 1 | Stirring |

| A2 | Al5Ti1B | 1373 | 1 | Stirring |

| A3 | Al8Ti1B | 1373 | 1 | Stirring |

| A4 | Al8Ti1B | 1373 | 2 | Stirring |

| A5 | Al5Ti1B | 1373 | 1 | Without Stirring |

| Number | TiN | Al | δ/% | ||

|---|---|---|---|---|---|

| d/nm | (hkl) | d/nm | (hkl) | ||

| 1 | 0.2440 | 111 | 0.2330 | 111 | 4.72 |

| 2 | 0.2120 | 200 | 0.2020 | 200 | 4.95 |

| 3 | 0.1496 | 220 | 0.1430 | 220 | 4.61 |

| 4 | 0.1227 | 311 | 0.1220 | 311 | 0.57 |

| 5 | 0.1223 | 320 | 0.1170 | 222 | 4.53 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Cui, C.; Wang, X.; Zhao, L.; Li, N.; Liu, S. Effect of Preparation Parameter on Microstructure and Grain Refining Behavior of In Situ AlN-TiN-TiB2/Al Composite Inoculants on Pure Aluminum. Metals 2017, 7, 56. https://doi.org/10.3390/met7020056

Wang Q, Cui C, Wang X, Zhao L, Li N, Liu S. Effect of Preparation Parameter on Microstructure and Grain Refining Behavior of In Situ AlN-TiN-TiB2/Al Composite Inoculants on Pure Aluminum. Metals. 2017; 7(2):56. https://doi.org/10.3390/met7020056

Chicago/Turabian StyleWang, Qian, Chunxiang Cui, Xin Wang, Lichen Zhao, Nuo Li, and Shuiqing Liu. 2017. "Effect of Preparation Parameter on Microstructure and Grain Refining Behavior of In Situ AlN-TiN-TiB2/Al Composite Inoculants on Pure Aluminum" Metals 7, no. 2: 56. https://doi.org/10.3390/met7020056

APA StyleWang, Q., Cui, C., Wang, X., Zhao, L., Li, N., & Liu, S. (2017). Effect of Preparation Parameter on Microstructure and Grain Refining Behavior of In Situ AlN-TiN-TiB2/Al Composite Inoculants on Pure Aluminum. Metals, 7(2), 56. https://doi.org/10.3390/met7020056