The Pseudo-Eutectic Microstructure and Enhanced Properties in Laser-Cladded Hypereutectic Ti–20%Si Coatings

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

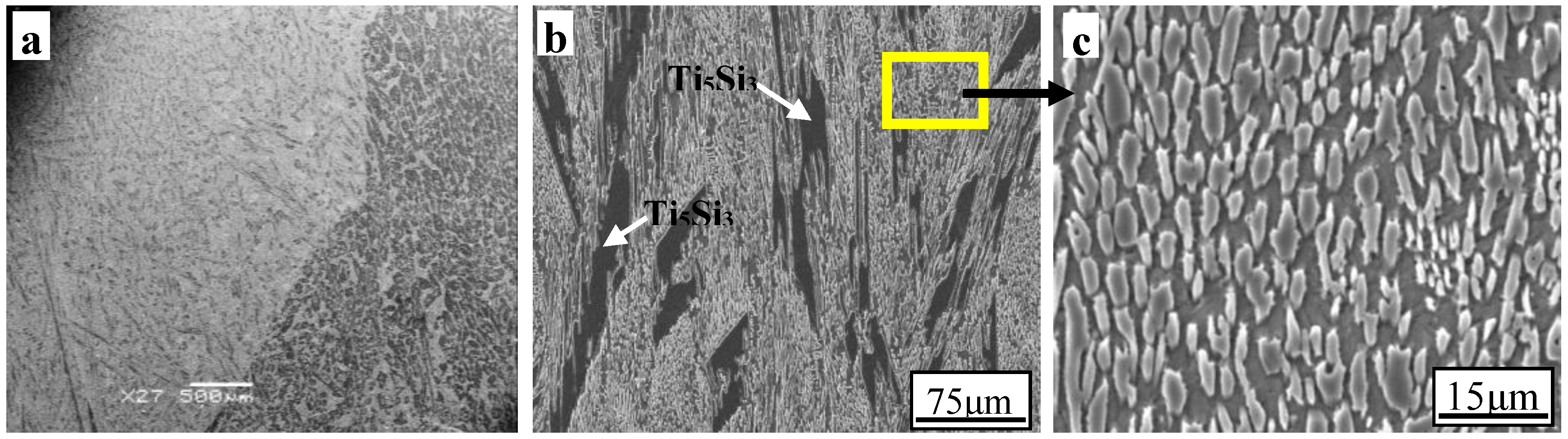

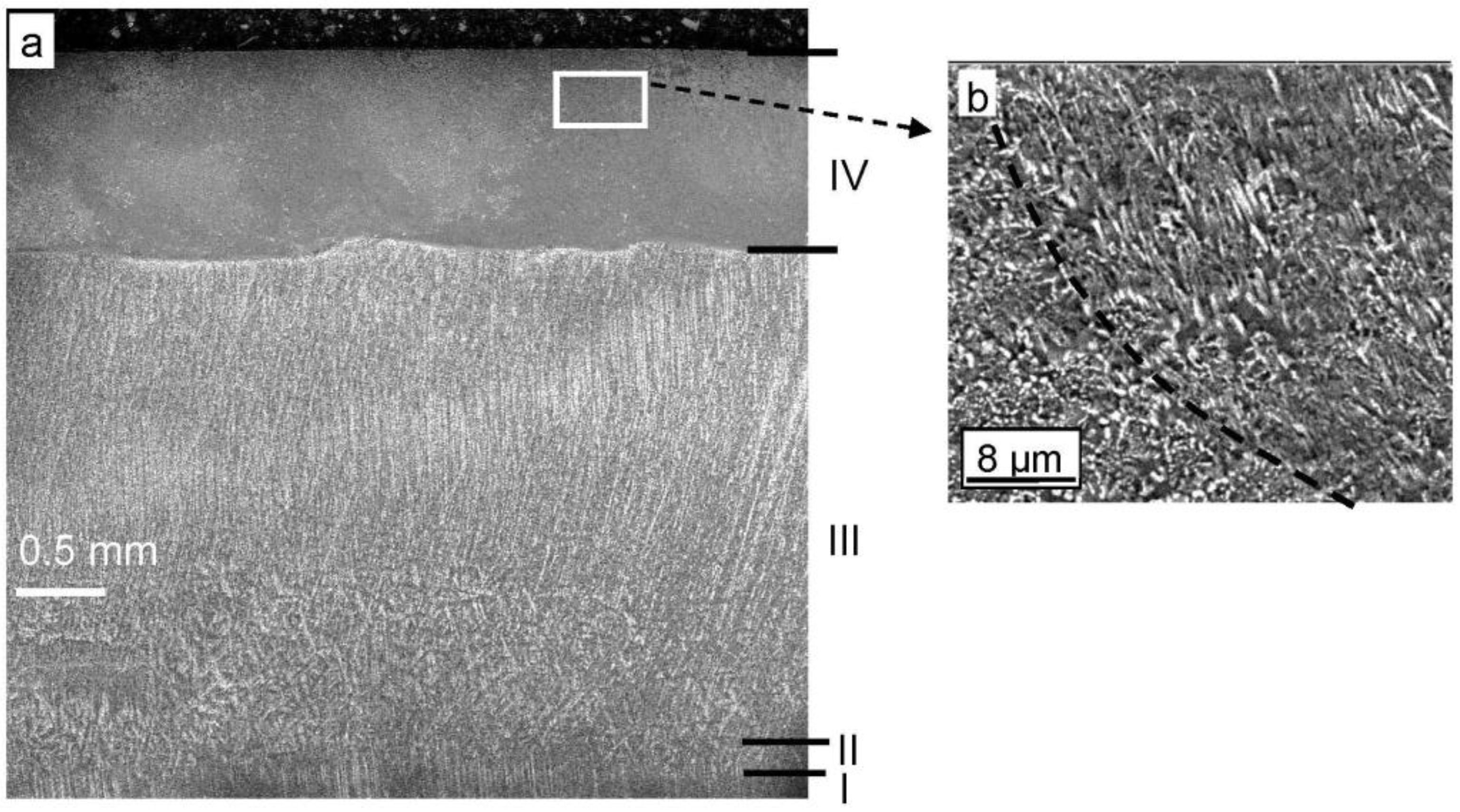

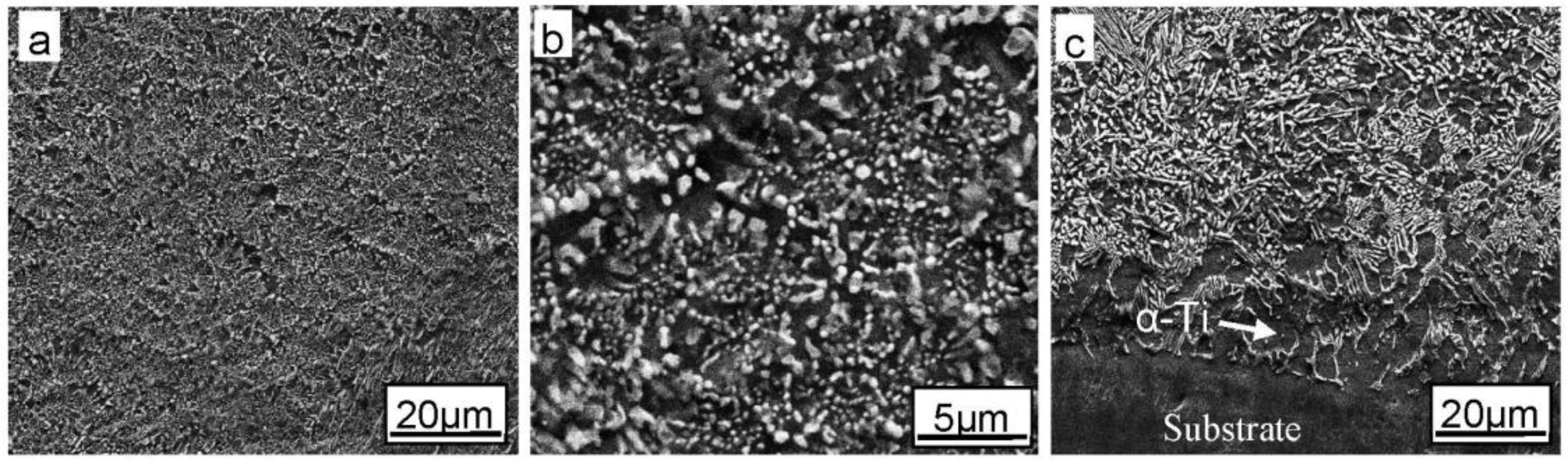

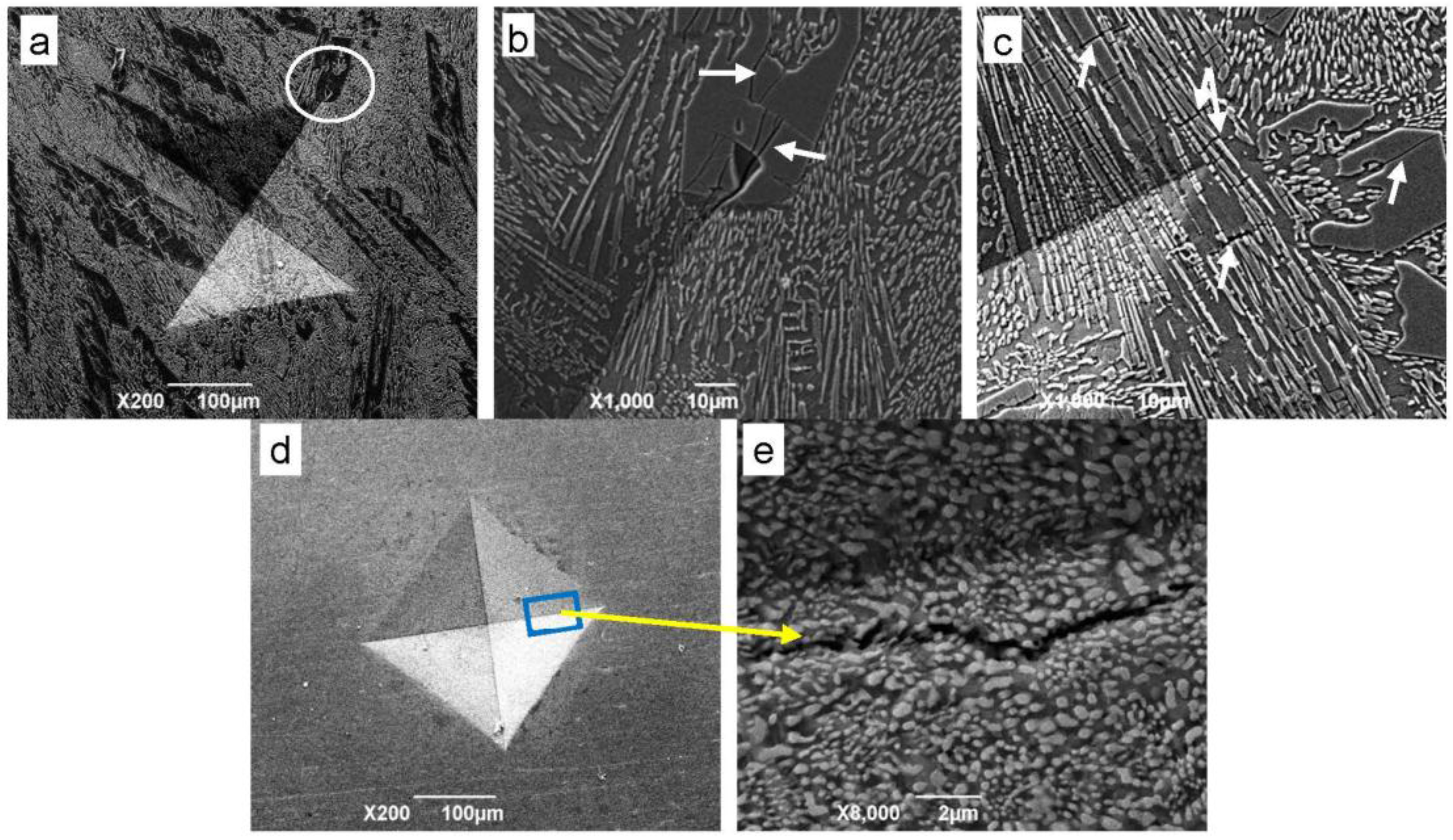

3.1. Characterization of Microstructure and Phases

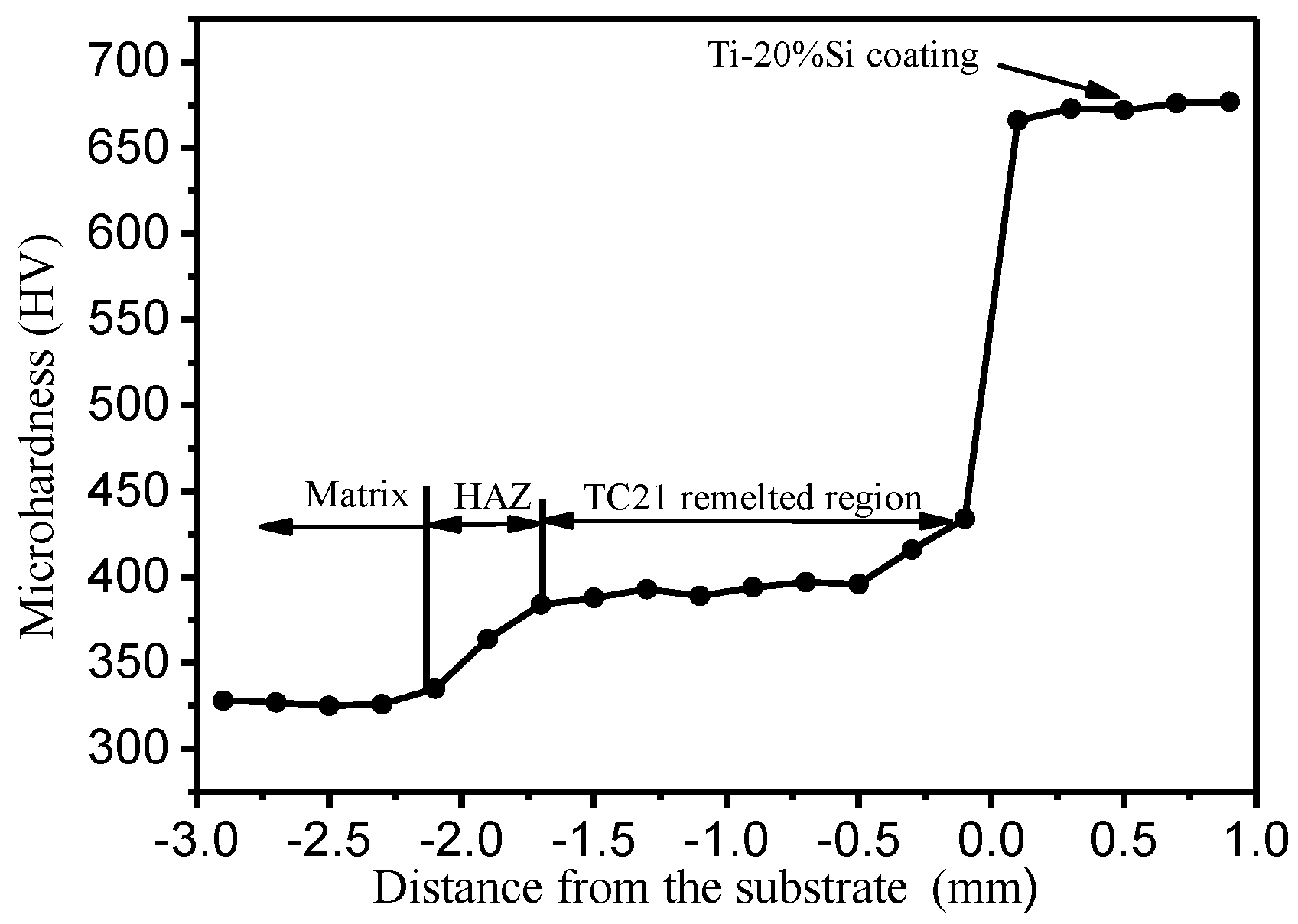

3.2. Hardness and Fracture Resistance

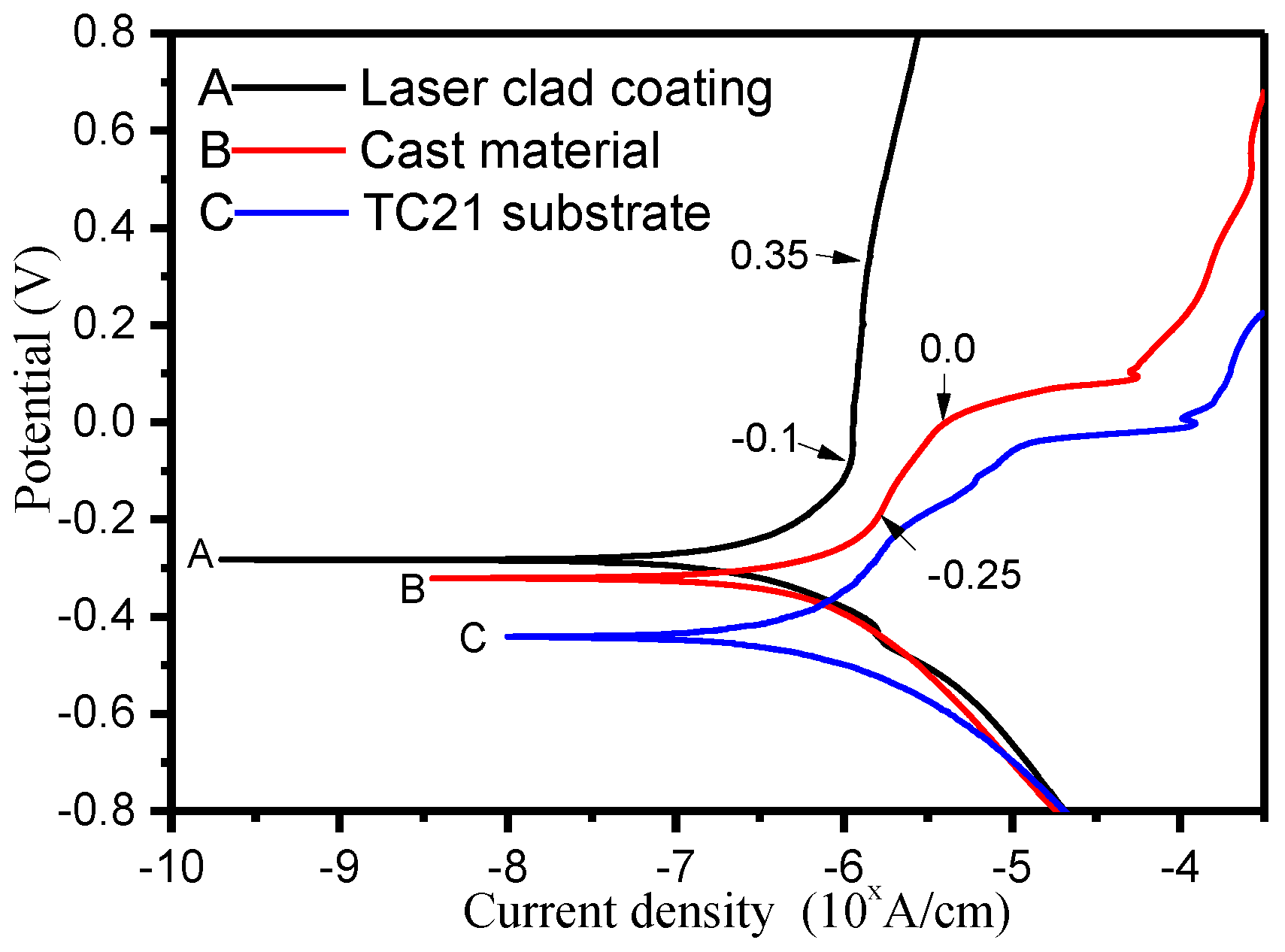

3.3. Corrosion Resistance in the Simulated Body Fluid Solution

4. Conclusions

- (1)

- A pseudo-eutectic (α-Ti + Ti5Si3) microstructure was obtained in the hypereutectic Ti–20%Si coating produced by laser cladding. Unlike the metal cast material, coarse primary Ti5Si3 crystals are absent.

- (2)

- The fine and well dispersed eutectic Ti5Si3 phase of the laser-cladded material greatly improves the hardness, corrosion resistance, and fracture resistance of the hypereutectic Ti–20%Si when compared with the same alloy prepared by the conventional metal mold casting method.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, X.; Wang, L.; Wang, Q.J.; Wu, Y.D.; Si, J.J.; Hui, X.D. Enhanced mechanical properties and structure stability induced by Si in Ti–8.5Al–1.5Mo alloys. Mater. Eng. Sci. A 2016, 676, 304–311. [Google Scholar] [CrossRef]

- Alhammad, M.; Esmaeili, S.; Toyserkani, E. Surface modification of Ti–6Al–4V alloy using laser-assisted deposition of a Ti–Si compound. Surf. Coat. Technol. 2008, 203, 1–8. [Google Scholar] [CrossRef]

- Hu, Z.H.; Zhan, Y.Z.; She, J. The role of Nd on the microstructural evolution and compressive behavior of Ti–Si alloys. Mater. Eng. Sci. A 2013, 560, 583–588. [Google Scholar] [CrossRef]

- Kishida, K.; Fujiwara, M.; Adachi, H.; Tanaka, K.; Inui, H. Plastic deformation of single crystals of Ti5Si3 with the hexagonal D88 structure. Acta Mater. 2010, 58, 846–857. [Google Scholar] [CrossRef] [Green Version]

- Riley, D.P. Synthesis and characterization of SHS bonded Ti5Si3 on Ti substrates. Intermetallics 2006, 14, 770–775. [Google Scholar] [CrossRef]

- Murray, J.L. Phase Diagrams of Binary Titanium Alloys; ASM International: Materials Park, OH, USA, 1987; p. 289. [Google Scholar]

- Zhang, Q.; Chen, J.; Zhao, Z.; Tan, H.; Lin, X.; Huang, W.D. Microstructure and anisotropic tensile behavior of laser additive manufactured TC21 titanium alloy. Mater. Eng. Sci. A. 2016, 673, 204–212. [Google Scholar] [CrossRef]

- Tancret, F.; Osterstock, F. The Vickers indentation technique used to evaluate thermal shock resistance of brittle materials. Scr. Mater. 1997, 37, 443–447. [Google Scholar] [CrossRef]

- Herlach, D.M. Non-equilibrium solidification of undercooled metallic melts. Mater. Eng. Sci. R 1994, 12, 177–272. [Google Scholar] [CrossRef]

- Zhang, H.; He, Y.Z.; Pan, Y. Enhanced hardness and fracture toughness of the laser-solidified FeCoNiCrCuTiMoAlSiB0.5 high-entropy alloy by martensite strengthening. Scr. Mater. 2013, 69, 342–345. [Google Scholar] [CrossRef]

- Si, S.H.; Zhang, H.; He, Y.Z.; Li, M.X.; Guo, S. Liquid Phase Separation and the Aging Effect on Mechanical and Electrical Properties of Laser Rapidly Solidified Cu100−xCrx Alloys. Metals 2015, 5, 2119–2127. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, J. Ti5Si3 and Ti5Si3-based alloys: Alloying behavior, microstructure and mechanical property evaluation. Acta Mater. 1998, 46, 3535–3546. [Google Scholar] [CrossRef]

- Frommeyer, G.; Rosenkranz, R.; Smarsly, W. Microstructure and properties of high melting point intermetallic Ti5Si3 and TiSi2 compounds. Mater. Sci. Eng. A 1992, 152, 288–294. [Google Scholar]

- Counihan, P.J.; Crawford, A.; Thadhani, N.N. Influence of dynamic densification on nanostructure formation in Ti5Si3 intermetallic alloy and its bulk properties. Mater. Sci. Eng. A 1999, 267, 26–35. [Google Scholar] [CrossRef]

- Xu, J.; Liu, L.; Li, Z.; Munroe, P.; Xie, Z.H. Niobium addition enhancing the corrosion resistance of nanocrystalline Ti5Si3 coating in H2SO4 solution. Acta Mater. 2014, 63, 245–260. [Google Scholar] [CrossRef]

- Xu, J.; Liu, L.L.; Xie, Z.H.; Munroe, P. Nanocomposite bilayer film for resisting wear and corrosion damage of a Ti–6Al–4V alloy. Surf. Coat. Technol. 2012, 206, 4156–4165. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, A.H.; Zhang, Z.; Zheng, R.R.; Xia, H.B.; Wang, Y.N. Laser alloying of Ti–Si compound coating on Ti–6Al–4V alloy for the improvement of bioactivity. Appl. Surf. Sci. 2014, 305, 16–23. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zhang, Z.; Yue, T.M. The Pseudo-Eutectic Microstructure and Enhanced Properties in Laser-Cladded Hypereutectic Ti–20%Si Coatings. Metals 2017, 7, 33. https://doi.org/10.3390/met7020033

Zhang H, Zhang Z, Yue TM. The Pseudo-Eutectic Microstructure and Enhanced Properties in Laser-Cladded Hypereutectic Ti–20%Si Coatings. Metals. 2017; 7(2):33. https://doi.org/10.3390/met7020033

Chicago/Turabian StyleZhang, Hui, Zhonghong Zhang, and T. M. Yue. 2017. "The Pseudo-Eutectic Microstructure and Enhanced Properties in Laser-Cladded Hypereutectic Ti–20%Si Coatings" Metals 7, no. 2: 33. https://doi.org/10.3390/met7020033

APA StyleZhang, H., Zhang, Z., & Yue, T. M. (2017). The Pseudo-Eutectic Microstructure and Enhanced Properties in Laser-Cladded Hypereutectic Ti–20%Si Coatings. Metals, 7(2), 33. https://doi.org/10.3390/met7020033