Entropy Change Caused by Martensitic Transformations of Ferromagnetic Shape Memory Alloys

Abstract

:1. Introduction

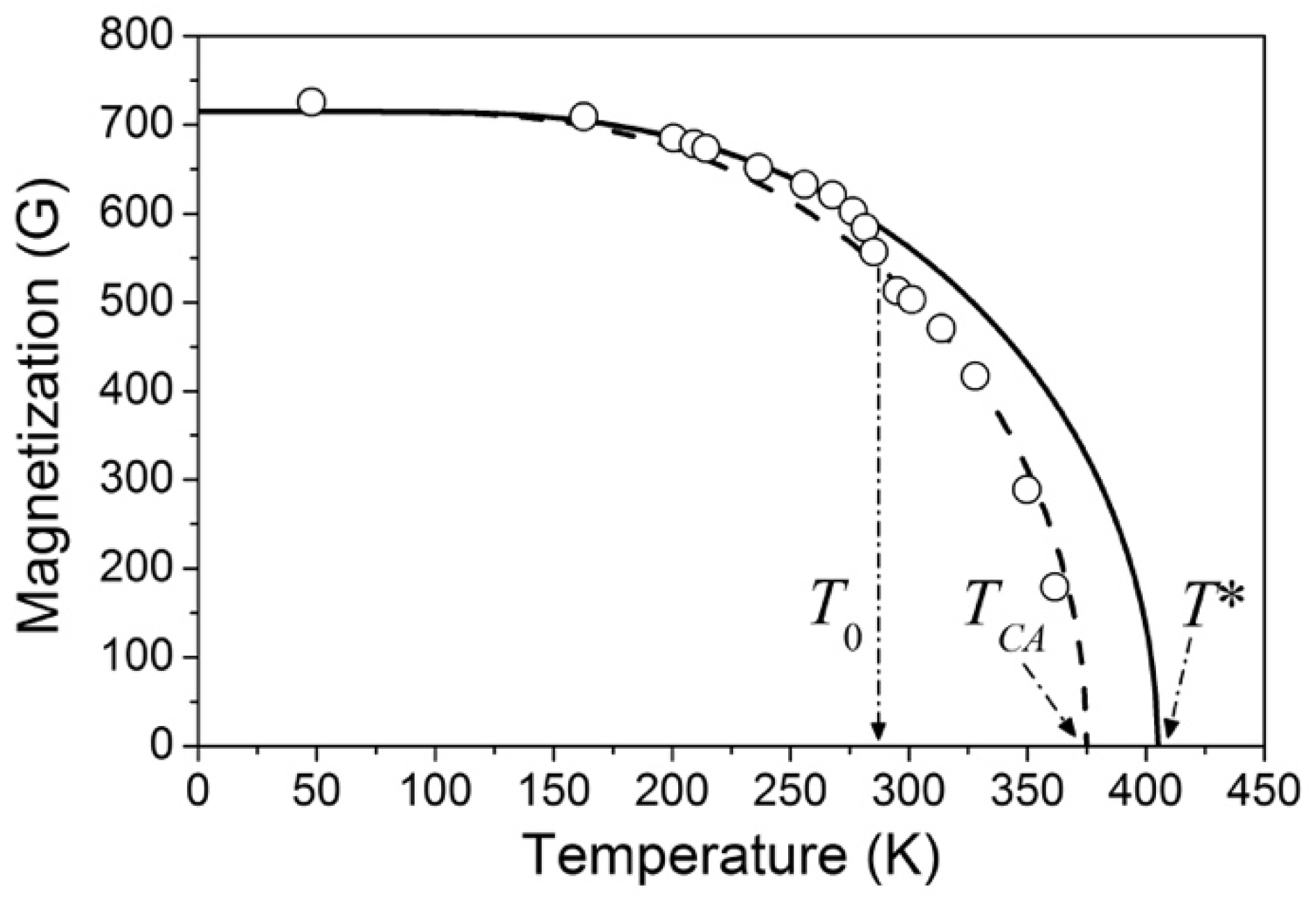

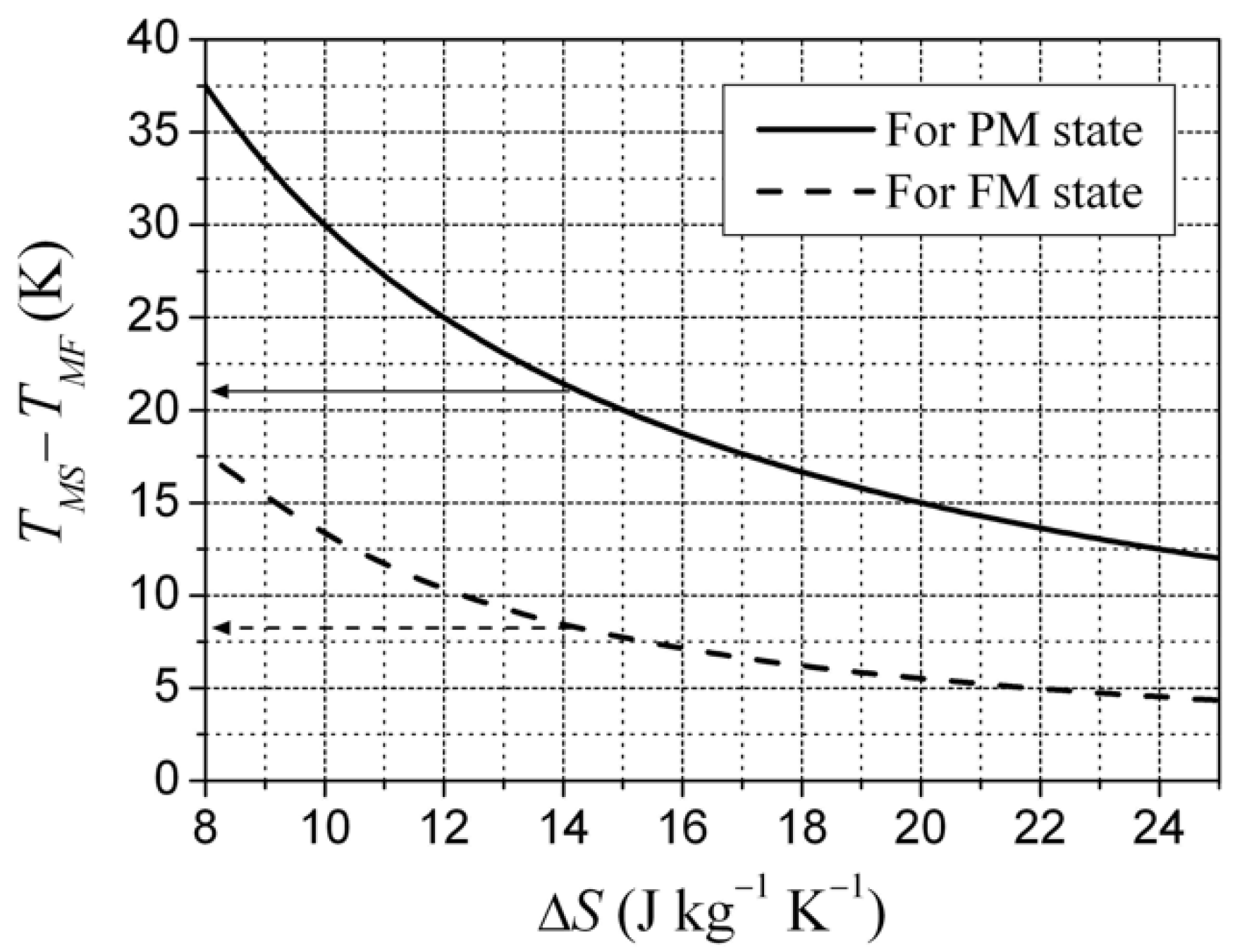

2. Influence of Ferromagnetic Order on the Transformational Properties of FSMAs

3. Evaluation of Magnetic and Non-Magnetic Contributions to ∆S and Q

4. Concluding Remarks

- (a)

- Experiments carried out for different alloy compositions confirm the linear dependence of on . This shows that the product weakly depends on the composition of the alloy.

- (b)

- It is worth noting that a shear modulus value of 1 GPa gives the correct theoretical estimation for . The value is a lower value than that resulting from numerous experiments; given that the choices for and m = 8 g·cm−3 are properly defined, choosing a higher value for would lead to non-realistic differences. However, a pronounced tendency takes place: the experimental values of the elastic moduli of different FSMAs reported in the recent works are lower than the values measured previously. For example, the values of elastic modulus ~2 GPa were registered in Ni29Mn48Ga23 single crystal using dynamic mechanical analysis [29]; a linear decrease of shear modulus on approaching the temperature of Fe3Pt alloy was reported very recently, the extrapolation of the experimental line to resulted in the estimation [30].

- (c)

- A strong increase of with () was observed in metamagnetic alloys such as Ni-Mn-In and Ni-Mn-(In,Sn)-Co, see Figure 4. Nevertheless, the inverse relationship, as predicted by Equation (6), was found to be fulfilled only for transformations under magnetic field.

- (d)

- The entropy changes caused by the MTs of different FSMAs were previously estimated from the results of experimental stress–strain tests performed at different temperatures, or from the measurements of elastic moduli (that is, from the experimental values and , respectively). For the correct interpretation of experimental results, it should be remembered that, in cases where MT occurs in the ferromagnetic phase of alloy, the estimated entropy change is the sum of and .

- (e)

- A thermodynamic analysis of existing experimental data was carried out above, without taking into account the five-layered and seven-layered modulation of crystal lattice inherent to Ni-Mn-Ga martensites. The equations, which include the temperature derivative of the stress value initiating the MT, were used. As far as we know, the theoretical analysis of the influence of lattice modulation on this derivative is an open problem.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- O’Handley, R.C.; Murray, S.J.; Marioni, M.; Nembach, H.; Allen, S.M. Phenomenology of giant magnetic-field-induced strain in ferromagnetic shape-memory materials (invited). J. Appl. Phys. 2000, 87, 4712–4717. [Google Scholar] [CrossRef]

- Sozinov, A.; Likhachev, A.A.; Lanska, N.; Ullakko, K. Giant magnetic-field-induced strain in NiMnGa seven-layered martensitic phase. Appl. Phys. Lett. 2002, 80, 1746–1748. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Giri, S.; Majundar, S.; De, S.K. Giant magnetoresistance and large inverse magnetocaloric effect in Ni2Mn1.36Sn0.64 alloy. J. Phys. D Appl. Phys. 2009, 42. [Google Scholar] [CrossRef]

- Karaca, E.; Karaman, I.; Basaran, B.; Ren, Y.; Chumlyakov, Y.I.; Maier, H.J. Magnetic field-induced phase transformation in NiMnCoIn magnetic shape-memory alloys—A new actuation mechanism with large work output. Adv. Funct. Mater. 2009, 19, 983–998. [Google Scholar] [CrossRef]

- L’vov, V.A.; Cesari, E.; Recarte, V.; Perez-Landazabal, J.I. Entropy change of martensitic transformation in ferromagnetic shape memory alloys. Acta Mater. 2013, 61, 1764–1772. [Google Scholar] [CrossRef]

- Ito, W.; Imano, Y.; Kainuma, R.; Sutou, Y.; Oikawa, K.; Ishida, K. Martensitic and magnetic transformation behaviors in heusler-type NiMnIn and NiCoMnIn metamagnetic shape memory alloys. Metall. Mater. Trans. A 2007, 38, 759–766. [Google Scholar] [CrossRef]

- Kustov, S.; Corró, M.L.; Pons, J.; Cesari, E. Entropy change and effect of magnetic field on martensitic transformation in a metamagnetic Ni-Co-Mn-In shape memory alloy. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Pérez-Sierra, A.M.; Bruno, N.M.; Pons, J.; Cesari, E.; Karaman, I. Atomic order and martensitic transformation entropy change in Ni-Co-Mn-In metamagnetic shape memory alloys. Scr. Mater. 2016, 110, 61–64. [Google Scholar] [CrossRef]

- Chernenko, V.A.; L’vov, V.A.; Cesari, E.; Kosogor, A.; Barandiaran, J.M. Transformation volume effects on shape memory alloys. Metals 2013, 3, 237–282. [Google Scholar] [CrossRef]

- Kosogor, A.; L’vov, V.A.; Cesari, E. Influence of volume magnetostriction on the thermodynamic properties of Ni-Mn-Ga shape memory alloys. J. Appl. Phys. 2015, 118. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Pons, J.; Seguí, C.; Cesari, E. Premartensitic phenomena and other phase transformations in Ni–Mn–Ga alloys studied by dynamical mechanical analysis and electron diffraction. Acta Mater. 2002, 50, 53–60. [Google Scholar] [CrossRef]

- Danilevich, A.G.; L’vov, V.A. Strong influence of ferromagnetic ordering and internal pressure on the elastic modulus of shape memory alloy. J. Magn. Magn. Mater. 2013, 333, 108–113. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Cesari, E.; Kokorin, V.V.; Vitenko, I.N. The development new ferromagnetic shape memory alloys in Ni-Mn-Ga system. Scr. Metall. Mater. 1995, 33, 1239–1244. [Google Scholar] [CrossRef]

- Fabricci, S.; Karamad, J.; Arnold, Z.; Casoli, F.; Palouzi, A.; Bolzoni, F.; Cabassi, R.; Solzi, M.; Porcari, G.; Pernechele, C.; Albertini, F. From direct to inverse giant magnetocaloric effect in Co-doped NiMnGa multifunctional alloys. Acta Mater. 2011, 59, 412–419. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Cesari, E.; Pons, J.; Segui, C. Phase transformations in rapidly quenched Ni-Mn-Ga alloys. J. Mater. Res. 2000, 15, 1496–1504. [Google Scholar] [CrossRef]

- Webster, P.J.; Ziebeck, K.R.A.; Town, S.L.; Peak, M.S. Magnetic order and phase transformation in Ni2MnGa. Philos. Mag. B 1984, 49, 295–310. [Google Scholar] [CrossRef]

- Chernenko, V.A.; L’vov, V.A.; Zagorodnyuk, S.P.; Takagi, T. Ferromagnetism of thermoelastic martensites: Theory and experiment. Phys. Rev. B 2003, 67, 064407. [Google Scholar] [CrossRef]

- Chernenko, V.A.; L’vov, V.A. Magnetoelastic nature of ferromagnetic shape memory effect. Mater. Sci. Forum 2008, 583, 1–20. [Google Scholar] [CrossRef]

- Kokorin, V.V.; Chemenko, V.A.; Val’kov, V.I.; Konoplyuk, S.M.; Khapaliuk, E.A. Magnetic transitions in Ni2MnGa. Phys. Solid State 1995, 37, 2049–2051. [Google Scholar]

- Chernenko, V.A.; Kokorin, V.V.; Babiy, O.M.; Zasimchuk, I.K. Phase diagrams in the Ni-Mn-Ga system under compression. Intermetallics 1998, 6, 29–34. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Amengual, A.; Cesari, E.; Kokorin, V.V.; Zasimchuk, I.K. Thermal and magnetic properties of stress-induced martensites in Ni-Mn-Ga alloys. J. Phys. IV Fr. 1995, 5, C2-95–C2-98. [Google Scholar] [CrossRef]

- Fukuda, T.; Maeda, H.; Yasui, M.; Kakeshita, T. Influence of magnetocrystalline anisotropy on martensitic transformation under magnetic field of single-crystalline Ni2MnGa. Scr. Mater. 2009, 60, 261–263. [Google Scholar] [CrossRef]

- Seguí, C.; Chernenko, V.A.; Pons, J.; Cesari, E. Low-temperature-induced intermartensitic phase transformations in Ni-Mn-Ga single crystal. J. Magn. Magn. Mater. 2005, 290, 811–815. [Google Scholar] [CrossRef]

- Seguí, C.; Chernenko, V.A.; Pons, J.; Cesari, E. Two-step martensitic transformation in Ni-Mn-Ga alloys. J. Phys. IV Fr. 2003, 112, 903–906. [Google Scholar] [CrossRef]

- Khovailo, V.V.; Takagi, T.; Tani, J.; Levitin, R.Z.; Cherechukin, A.A.; Matsumoto, M.; Note, R. Magnetic properties of Ni2.18Mn0.82Ga Heusler alloys with a coupled magnetostructural transition. Phys. Rev. B 2002, 65. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Landazábal, J.I.; Sánchez-Alarcos, V.; Zablotskii, V.; Cesari, E.; Kustov, S. Entropy change linked to the martensitic transformation in metamagnetic shape memory alloys. Acta Mater. 2012, 60, 3168–3175. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Villa, E.; Salazar, D.; Barandiaran, J.M. Large tensile superelasticity from intermartensitic transformations in Ni49Mn28Ga23 single crystal. Appl. Phys. Lett. 2016, 108. [Google Scholar] [CrossRef]

- Fukuda, T.; Kakeshita, T. Lattice softening in Fe3Pt exhibiting three types of martensitic transformations. Metals 2017, 7, 156. [Google Scholar] [CrossRef]

- Lázpita, P.; Sasmaz, M.; Cesari, E.; Barandiarán, J.M.; Gutierrez, J.; Chernenko, V.A. Martensitic transformation and magnetic field induced effects in Ni42Co8Mn39Sn11 metamagnetic shape memory alloy. Acta Mater. 2016, 109, 170–176. [Google Scholar] [CrossRef]

- Barandiarán, J.M.; Chernenko, V.A.; Cesari, E.; Salas, D.; Gutierrez, J.; Lázpita, P. Magnetic field and atomic order effect on the martensitic transformation of a metamagnetic alloy. J. Phys. Condens. Matter 2013, 25, 484005. [Google Scholar] [CrossRef] [PubMed]

| No. | Alloy | Q (J/g) DSC | Qcalc (J/g) | ΔS/m (J/kg·K) | ΔScalc/m (J/kg·K) |

|---|---|---|---|---|---|

| 1 | Ni51Mn24Ga25 a) case | 2.6 | 2.6 | 10.7 | 10.7 |

| 2 | Ni49.4Mn27.7Ga22.9 b) case | 3.6 | 4.6 | 13.14 | 16.6 |

| Ni49.4Mn27.7Ga22.9 a) case | 3.6 | 4.8 | 13.14 | 17.7 | |

| 3 | Ni51.5 Mn24.9Ga23.6 b) case | 3.8 | 4.2 | 13.1 | 14.6 |

| 4 | Ni52.6Mn23.6Ga23.8 b) case | 4.0 | 5.3 | 14.3 | 18.8 |

| 5 | Ni52.6 Mn23.9Ga23.5 b) case | 4.2 | 4.9 | 14.4 | 16.8 |

| 6 | Ni52.0Mn24.4Ga23.6 b) case | 5.0 | 5.1 | 16.1 | 16.3 |

| Ni52.0Mn24.4Ga23.6 a) case | 5.0 | 8.1 | 16.1 | 26.3 | |

| 7 | Ni57.5Mn22.5Ga20 | 10 | 15.9 | 16.5 | 26.2 |

| 8 | Ni53.1Mn26.6Ga20.3 | 11 | 11.38 | 29.3 | 31.5 |

| 9 | Ni51.2Mn31.1Ga17.7 | 13 | 20.3 | 30.2 | 47 |

| Alloy | Qmag (J/g) | Q–Qmag (J/g) | Qcalc–Qmag (J/g) |

|---|---|---|---|

| 1 | 2.5 | 0.1 | 0.1 |

| 2 a) case | 3.5 | 0.1 | 1.1 |

| b) case | 3.5 | 0.1 | 1.3 |

| 3 | 5.3 | −1.5 | −1.1 |

| 4 | 5.1 | −1.1 | 0.2 |

| 5 | 5.4 | −1.2 | −0.5 |

| 6 a) case | 6.3 | −1.3 | −1.2 |

| b) case | 6.3 | −1.3 | 1.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

L’vov, V.A.; Cesari, E.; Kosogor, A.; Torrens-Serra, J.; Recarte, V.; Pérez-Landazábal, J.I. Entropy Change Caused by Martensitic Transformations of Ferromagnetic Shape Memory Alloys. Metals 2017, 7, 509. https://doi.org/10.3390/met7110509

L’vov VA, Cesari E, Kosogor A, Torrens-Serra J, Recarte V, Pérez-Landazábal JI. Entropy Change Caused by Martensitic Transformations of Ferromagnetic Shape Memory Alloys. Metals. 2017; 7(11):509. https://doi.org/10.3390/met7110509

Chicago/Turabian StyleL’vov, Victor A., Eduard Cesari, Anna Kosogor, Joan Torrens-Serra, Vicente Recarte, and José Ignacio Pérez-Landazábal. 2017. "Entropy Change Caused by Martensitic Transformations of Ferromagnetic Shape Memory Alloys" Metals 7, no. 11: 509. https://doi.org/10.3390/met7110509

APA StyleL’vov, V. A., Cesari, E., Kosogor, A., Torrens-Serra, J., Recarte, V., & Pérez-Landazábal, J. I. (2017). Entropy Change Caused by Martensitic Transformations of Ferromagnetic Shape Memory Alloys. Metals, 7(11), 509. https://doi.org/10.3390/met7110509