A Case Study for the Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir Welding

Abstract

:1. Introduction

2. Friction Stir Welding

3. Materials and Methods

4. Results and Discussion

4.1. Macrostructure and Microstructure Investigations

4.2. Mechanical Properties

5. Conclusions

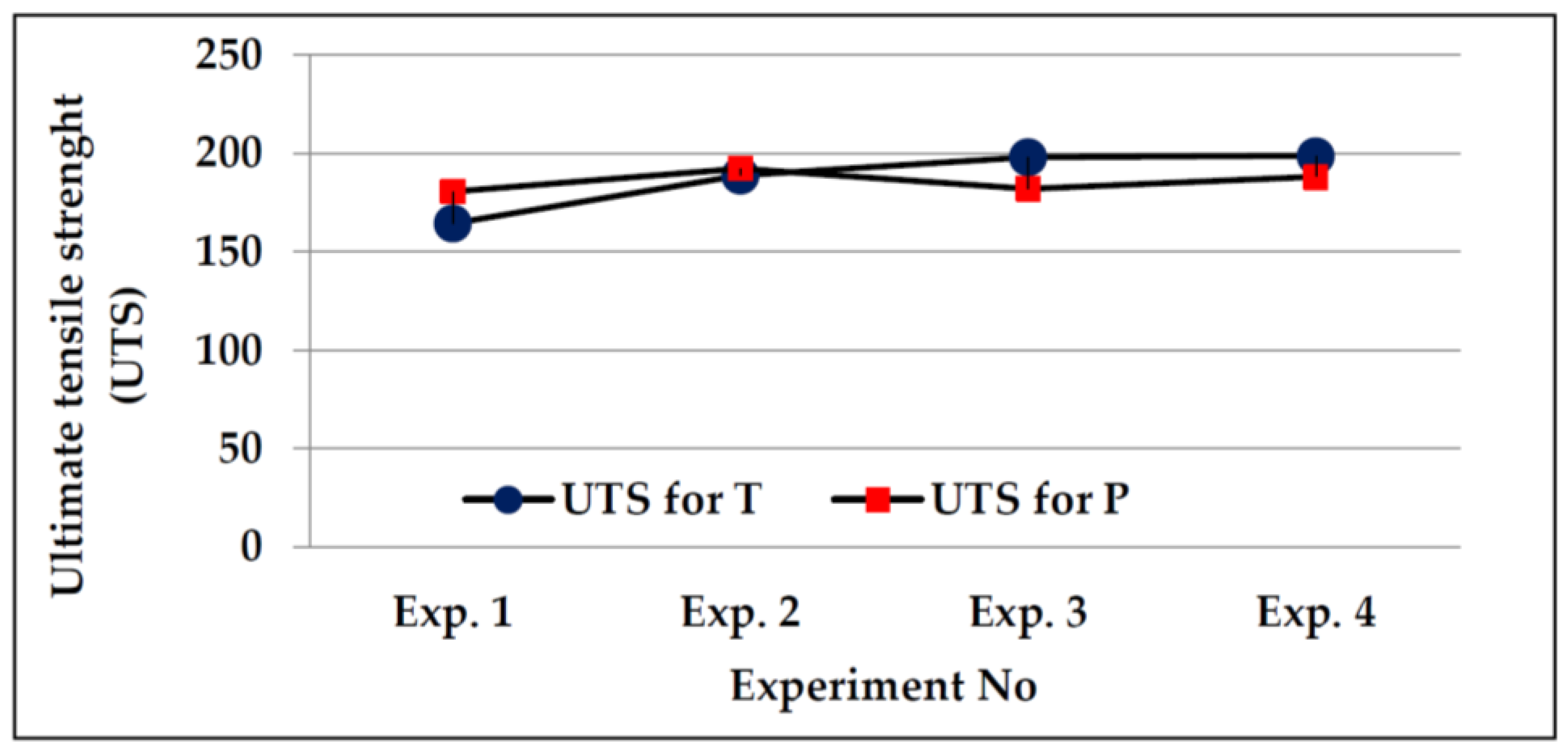

- The pin shape has a significant effect on the tensile properties and microstructure. The strengths of the weld joint fabricated by the pentagonal-shaped pin was smaller than those of triangular-shaped pin for Exp. 7 and Exp. 8.

- The highest tensile strength was obtained from the weld joint fabricated with a triangular-shaped pin and the UTS and ε values were 198.48 MPa and 4.26%, respectively.

- The efficiency for joint strength is ranged from 55% to 68%. The variation trend changes depending on both defects in the weld joint and the strength of the base material.

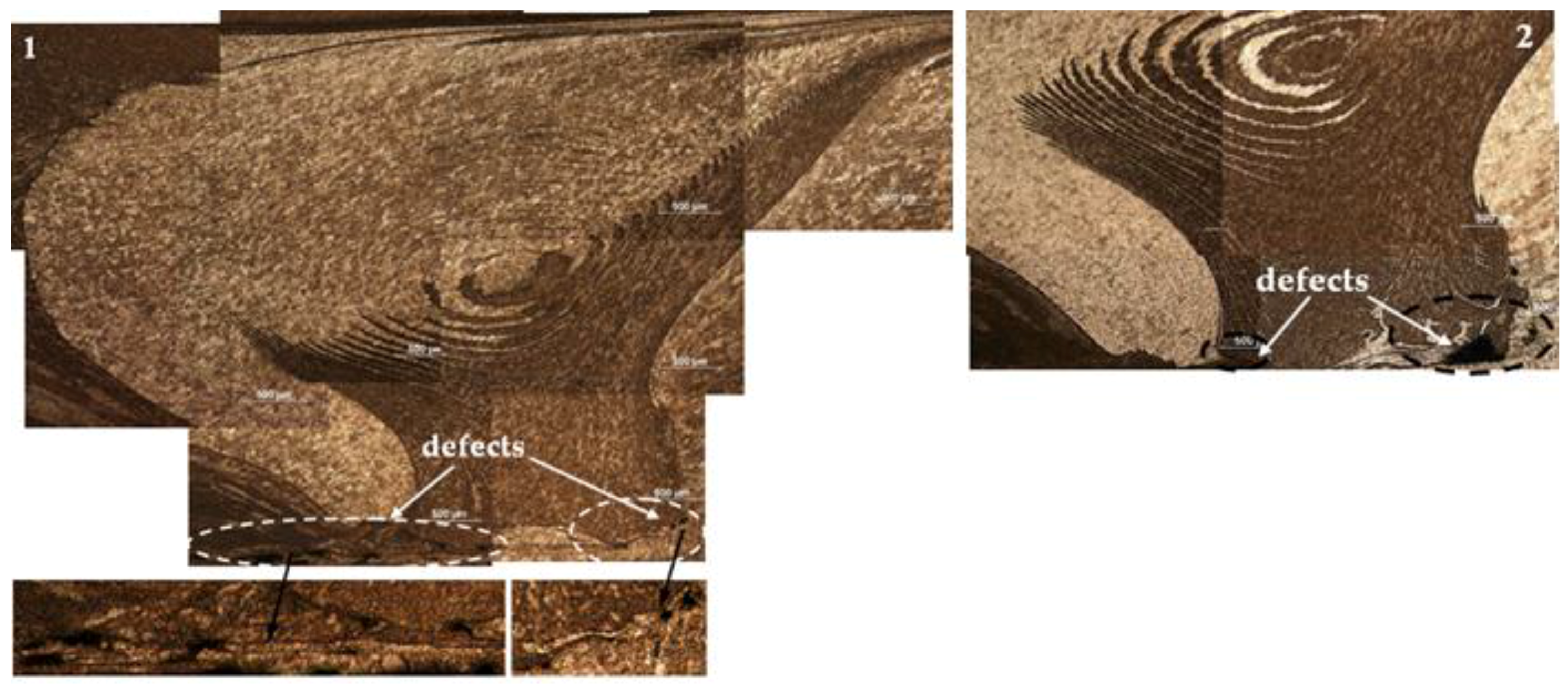

- Except for the fourth weld joint, the others contained small cavity and tunnel defects.

- The fracture of each joint except in Exp. 1 and Exp. 7 was located at the side of EN AW6082.

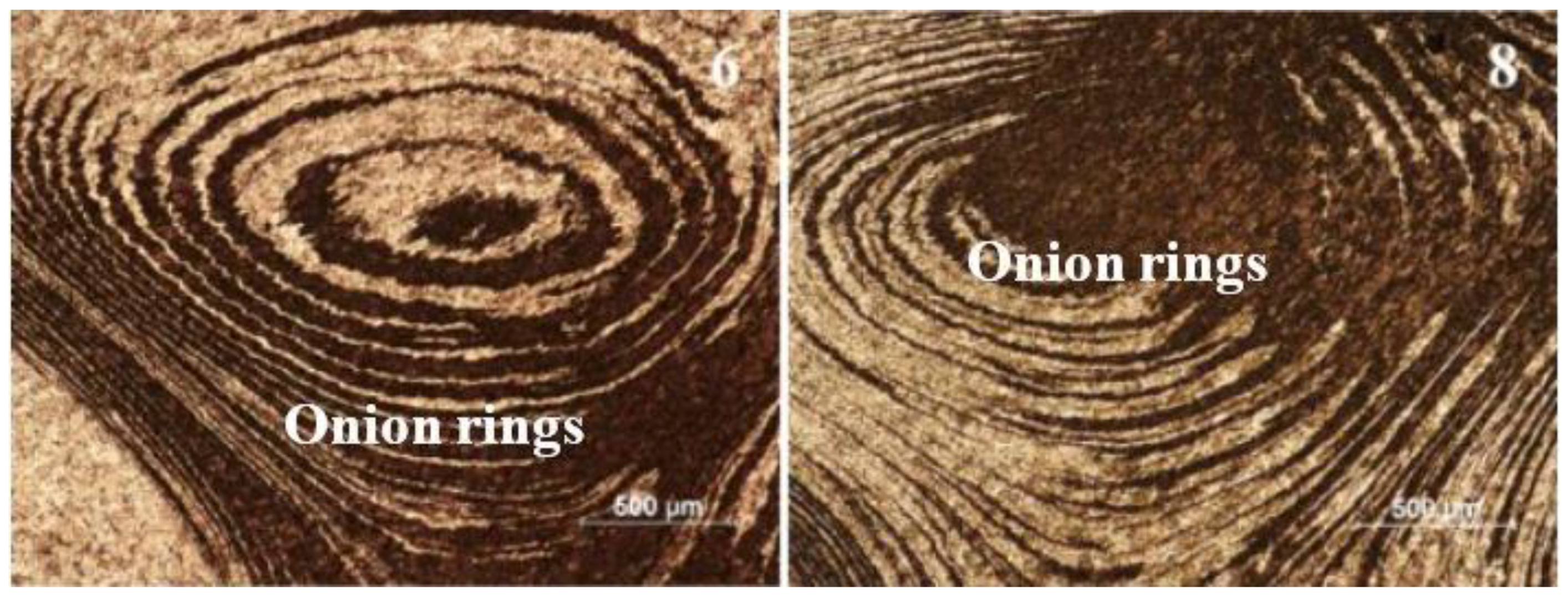

- The nugget zone profile was affected by the pin shape. The nugget zone of each weld contained onion rings. The shape of the onion rings was dependent on the value of the tool rotational speed and welding speed.

- The effect of a constant υ ratio on the profile and structure of the nugget zone is dependent on both the welding speed and tool rotational speed.

- At a lower tool rotational speed and welding speed for each tool pin shape, lower UTS values were obtained. The UTS increased as the tool rotational speed and the welding speed increased, while keeping the υ ratio constant for the triangular-shaped pin.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- DebRoy, T.; Bhadeshia, H.K.D.H. Friction stir welding of dissimilar alloys—A perspective. Sci. Technol. Weld. Join. 2010, 15, 266–270. [Google Scholar] [CrossRef]

- Aalco Metal Limited, Aluminium Alloys. Available online: www.aalco.co.uk/datasheets/Aalco-Metals-Ltd_Aluminium-Alloy-5083–0-H111-Sheet-and-Plate_149.pdf.ashx (accessed on 9 November 2016).

- Aalco Metal Limited, Aluminium Alloys. Available online: www.aalco.co.uk/datasheets/Aalco-Metals-Ltd_Aluminium-Alloy-6082-T6T651-Plate_148.pdf.ashx (accessed on 9 November 2016).

- Peel, M.J.; Steuwer, A.; Withers, P.J. Dissimilar Friction Stir Welds in EN AW5083-EN AW6082, Part II: Process Parameter Effects on Microstructure. Metall. Mater. Trans. A 2006, 37, 2195–2206. [Google Scholar] [CrossRef]

- Donatus, U.; Thompson, G.E.; Zhou, X.; Wang, J.; Cassell, A.; Beamish, K. Corrosion susceptibility of dissimilar friction stir welds of EN AW5083 and EN AW6082 alloys. Mater. Charact. 2015, 107, 85–97. [Google Scholar] [CrossRef]

- Donatus, U.; Thompson, G.E.; Zhou, X.; Wang, J.; Beamish, K. Flow patterns in friction stir welds of EN AW5083 and EN AW6082 alloys. Mater. Des. 2015, 83, 203–213. [Google Scholar]

- Steuwer, A.; Peel, M.J.; Withers, P.J. Dissimilar friction stir welds in EN AW5083-EN AW6082: The effect of process parameters on residual stress. Mater. Sci. Eng. A 2006, 441, 187–196. [Google Scholar] [CrossRef]

- Leitão, C.; Louro, R.; Rodrigues, D.M. Analysis of high temperature plastic behaviour and its relation with weldability in friction stir welding for aluminium alloys AA5083-H111 and AA6082-T6. Mater. Des. 2012, 37, 402–409. [Google Scholar] [CrossRef]

- Sun, Y.; Tsuji, N.; Fujii, H. Microstructure and mechanical properties of dissimilar friction stir welding between ultrafine grained 1050 and 6061-t6 aluminum alloys. Metals 2016, 6, 249. [Google Scholar] [CrossRef]

- Aval, H.J.; Serajzadeh, S.; Kokabi, A.H. Thermo-mechanical and microstructural issues in dissimilar friction stir welding of AA5086-AA6061. J. Mater. Sci. 2011, 46, 3258–3268. [Google Scholar] [CrossRef]

- Hao, H.L.; Ni, D.R.; Huang, H.; Wang, D.; Xiao, B.L.; Nie, Z.R.; Ma, Z.Y. Effect of welding parameters on microstructure and mechanical properties of friction stir welded Al-Mg-Er alloy. Mater. Sci. Eng. A 2013, 559, 889–896. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

| Alloy/Elements | Cu | Si | Mg | Mn | Zn | Ti | Cr | Fe | Al |

|---|---|---|---|---|---|---|---|---|---|

| EN AW6082-T6 | 0.23 | 0.98 | 1.02 | 0.6 | 0.21 | 0.01 | 0.03 | 0.6 | Bal. |

| EN AW5083-H111 | 0.056 | 0.093 | 4.19 | 0.53 | 0.09 | 0.007 | 0.083 | 0.243 | Bal. |

| Alloy | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| EN AW6082-T6 | 293.21 | 8.12 |

| EN AW5083-H111 | 325 | 17.6 |

| Parameters (Unit) | Symbol | Levels | |||

|---|---|---|---|---|---|

| Tool Rotational Speed (rpm) | TRS | 400 | 500 | 630 | 800 |

| Welding Speed (mm·min−1) | WS | 40 | 50 | 63 | 80 |

| Tool Rotational Speed-to-Welding Speed | υ | 10 | |||

| Pin shape | PS | T | P | ||

| Fixed parameters | |||||

| Tool shoulder diameter (mm) | D | 20 | |||

| Tool tilt angle (°) | α | 2 | |||

| Dwell time (s) | t | 20 | |||

| Exp. No. | Process Parameters | Welding Performance | |||||||

|---|---|---|---|---|---|---|---|---|---|

| PS | TRS | WS | υ | UTS (MPa) | ε (%) | Efficiency | Defect | ||

| TRS/WS | 6082 | 5083 | |||||||

| 1 | T | 400 | 40 | 10 | 164.36 | 0.49 | 56.06 | 50.57 | Defective |

| 2 | T | 500 | 50 | 188.68 | 4.6 | 64.35 | 58.06 | Defective | |

| 3 | T | 630 | 63 | 198 | 4.7 | 67.53 | 60.92 | Defective | |

| 4 | T | 800 | 80 | 198.48 | 4.26 | 67.69 | 61.07 | Sound weld | |

| 5 | P | 400 | 40 | 180.59 | 4.14 | 61.59 | 55.57 | Defective | |

| 6 | P | 500 | 50 | 192.27 | 4.312 | 65.57 | 59.16 | Defective | |

| 7 | P | 630 | 63 | 181.96 | 0.39 | 62.06 | 55.99 | Defective | |

| 8 | P | 800 | 80 | 187.85 | 4.24 | 64.07 | 57.80 | Defective | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasman, S.; Kahraman, F.; Emiralioğlu, A.; Kahraman, H. A Case Study for the Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir Welding. Metals 2017, 7, 6. https://doi.org/10.3390/met7010006

Kasman S, Kahraman F, Emiralioğlu A, Kahraman H. A Case Study for the Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir Welding. Metals. 2017; 7(1):6. https://doi.org/10.3390/met7010006

Chicago/Turabian StyleKasman, Sefika, Fatih Kahraman, Anıl Emiralioğlu, and Haydar Kahraman. 2017. "A Case Study for the Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir Welding" Metals 7, no. 1: 6. https://doi.org/10.3390/met7010006