Study on the Tribological Properties of Porous Titanium Sliding against Tungsten Carbide YG6

Abstract

:1. Introduction

2. Experimental Procedures

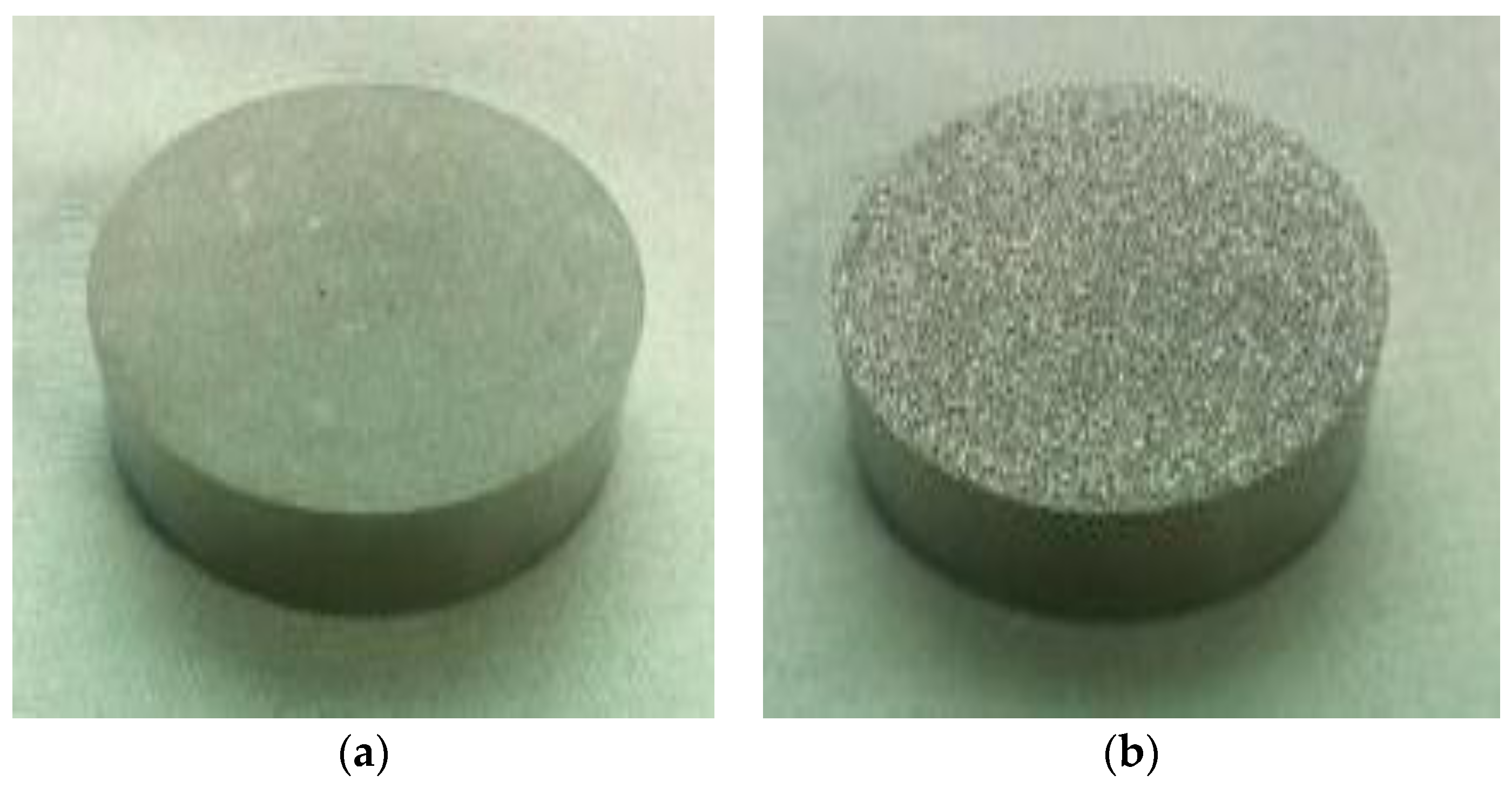

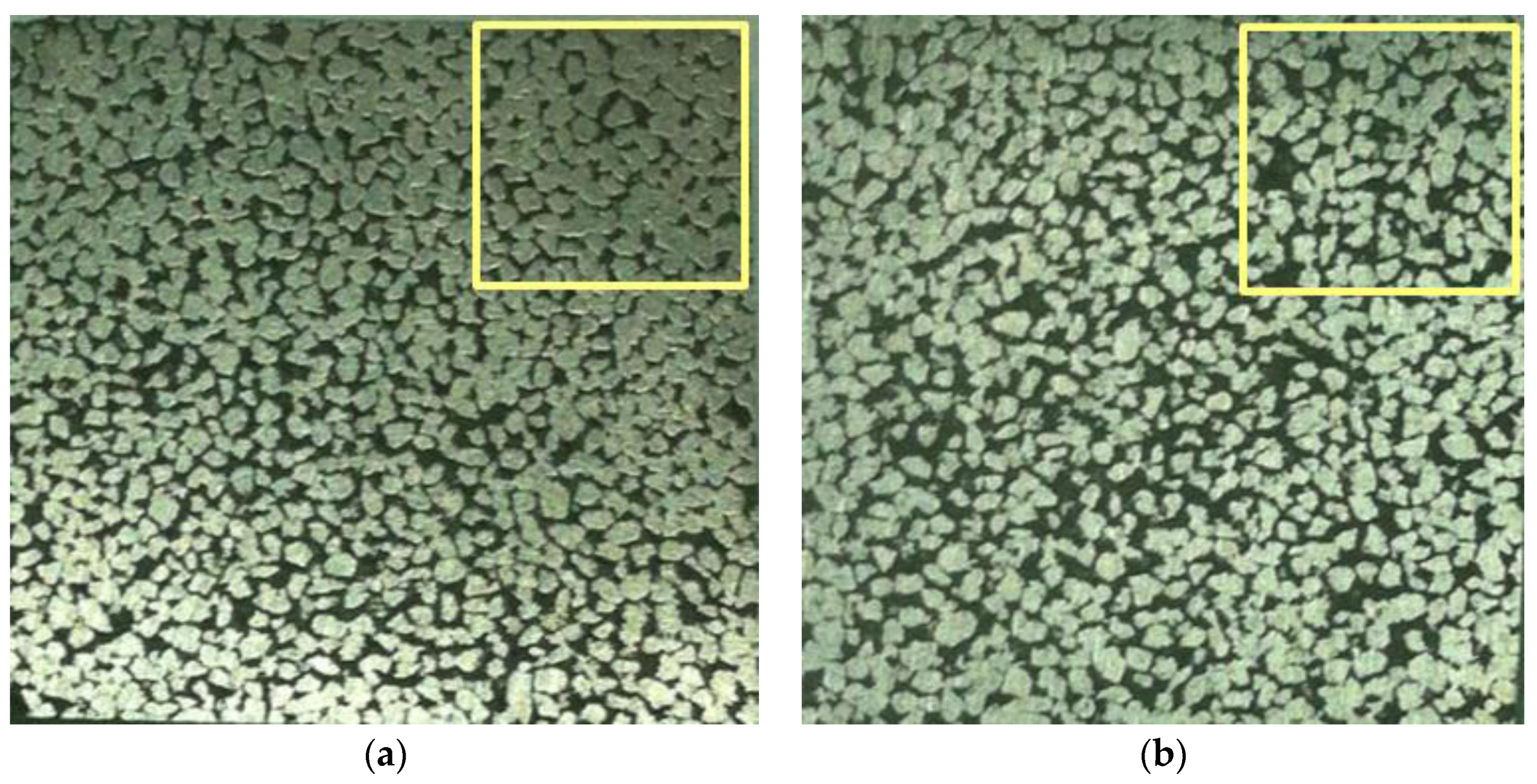

2.1. Materials

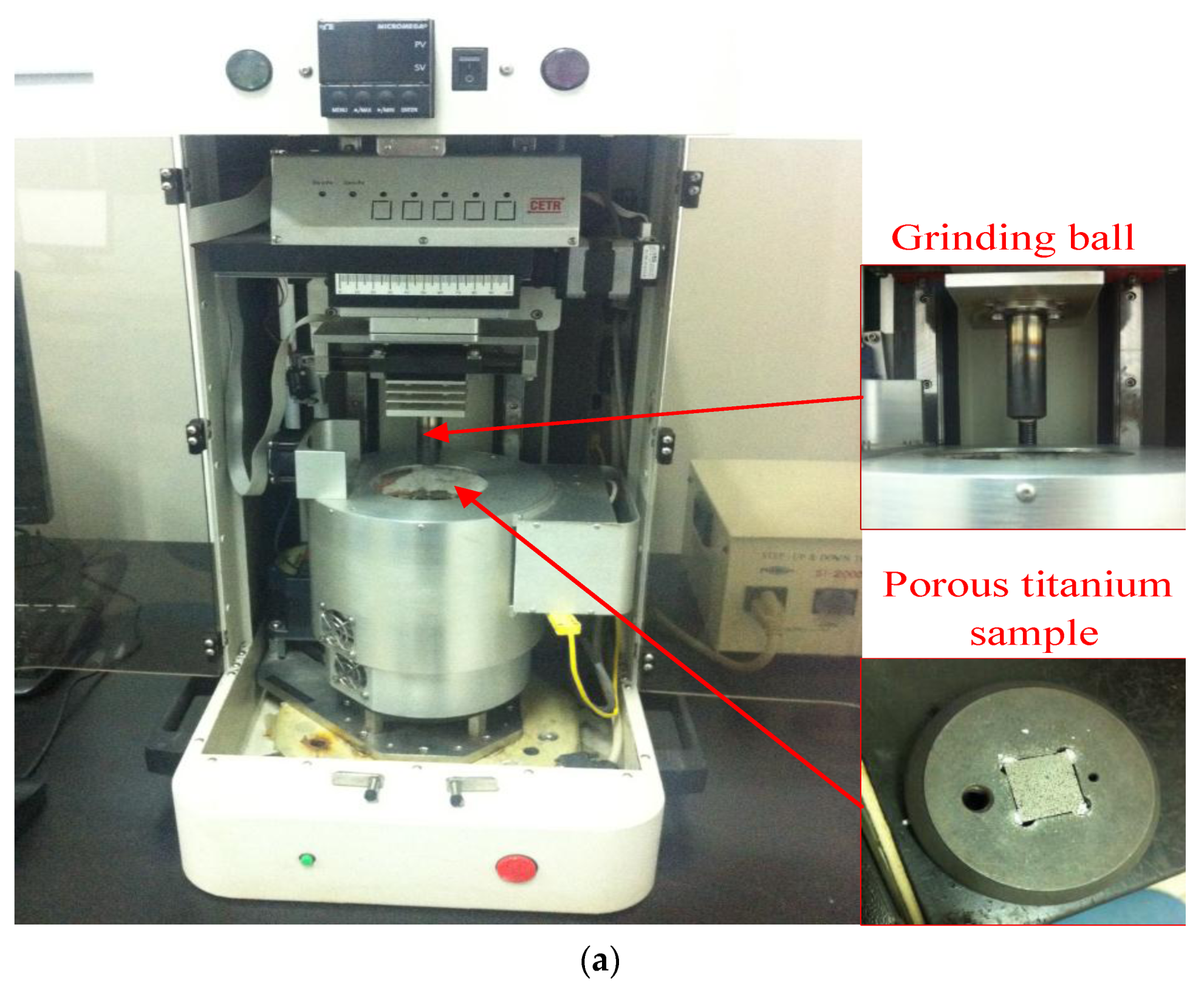

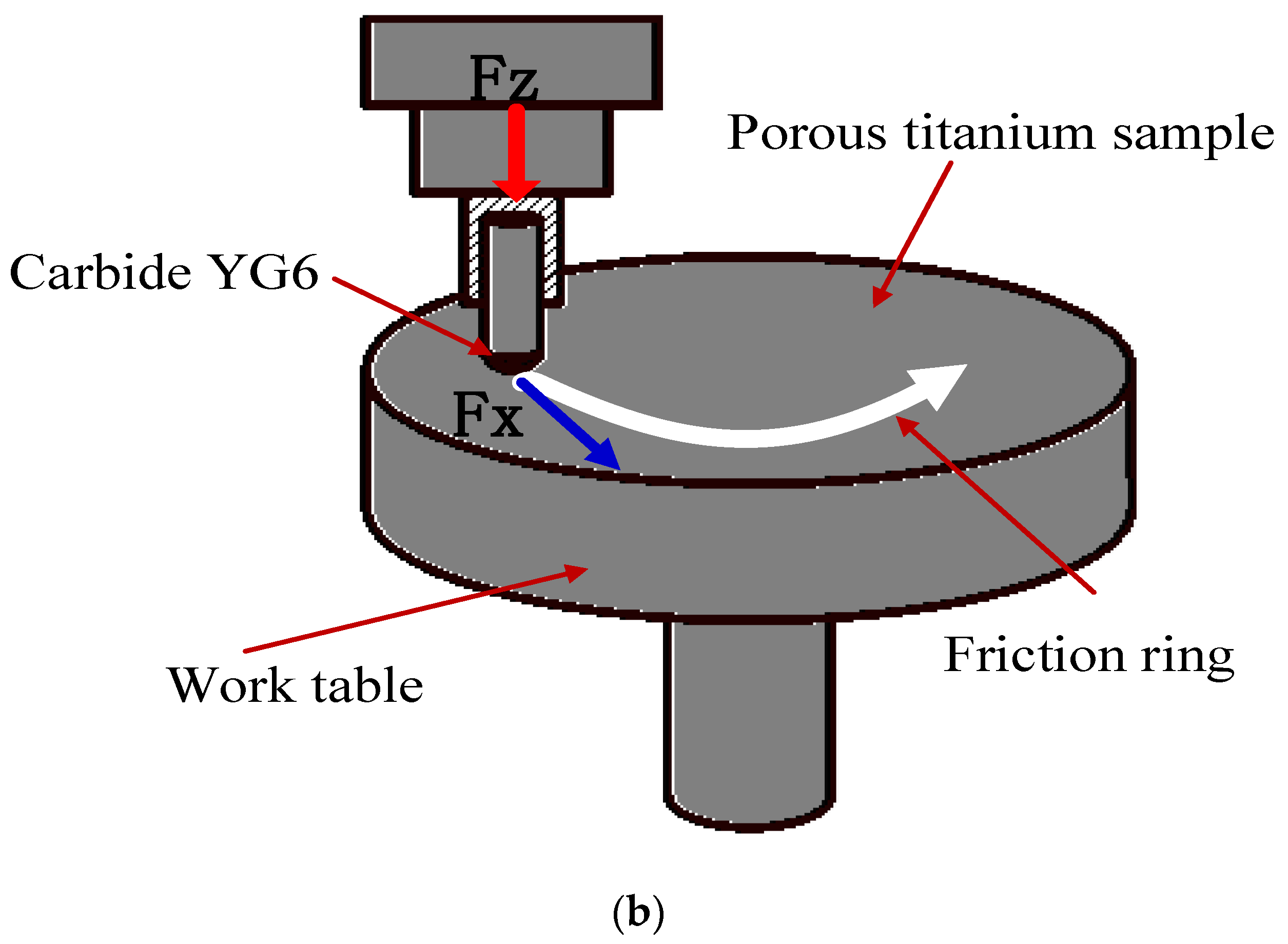

2.2. Friction and Wear Tests

3. Results and Discussion

3.1. Friction Coefficient and Wear Rate Curve

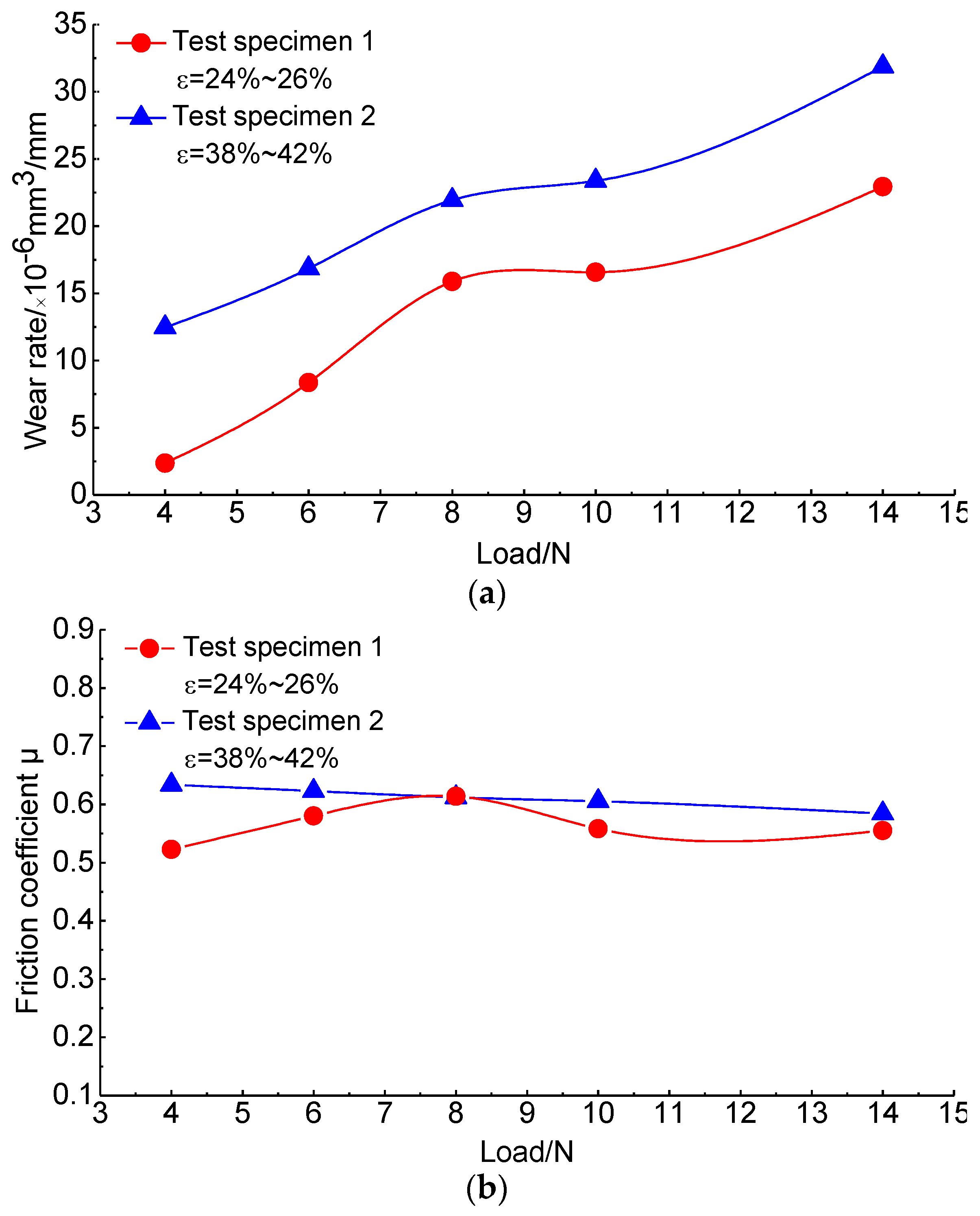

3.1.1. Effects of Load on Friction Coefficient and Wear Rate

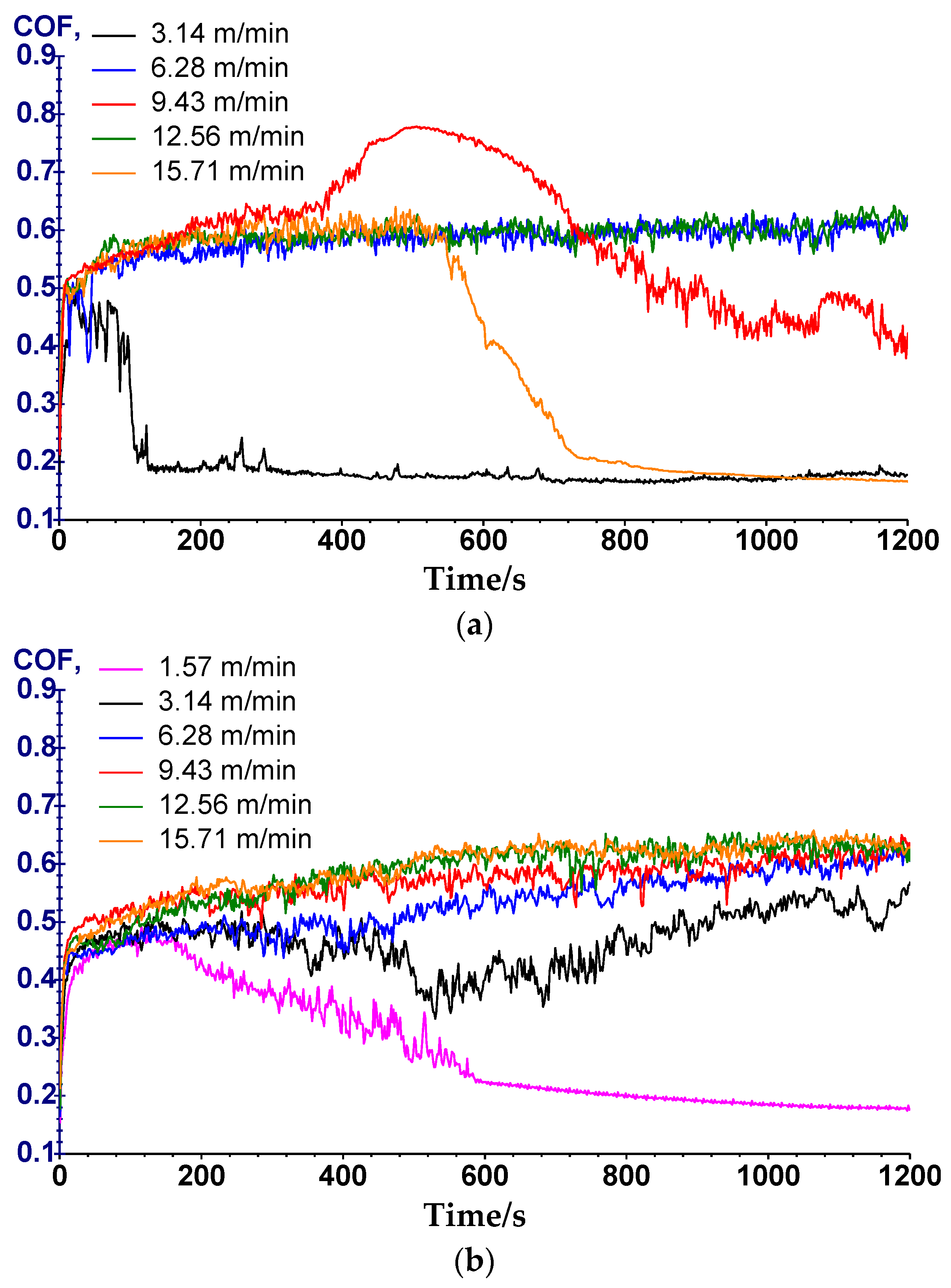

3.1.2. Effects of Sliding Speed on Friction Coefficient and Wear Rate

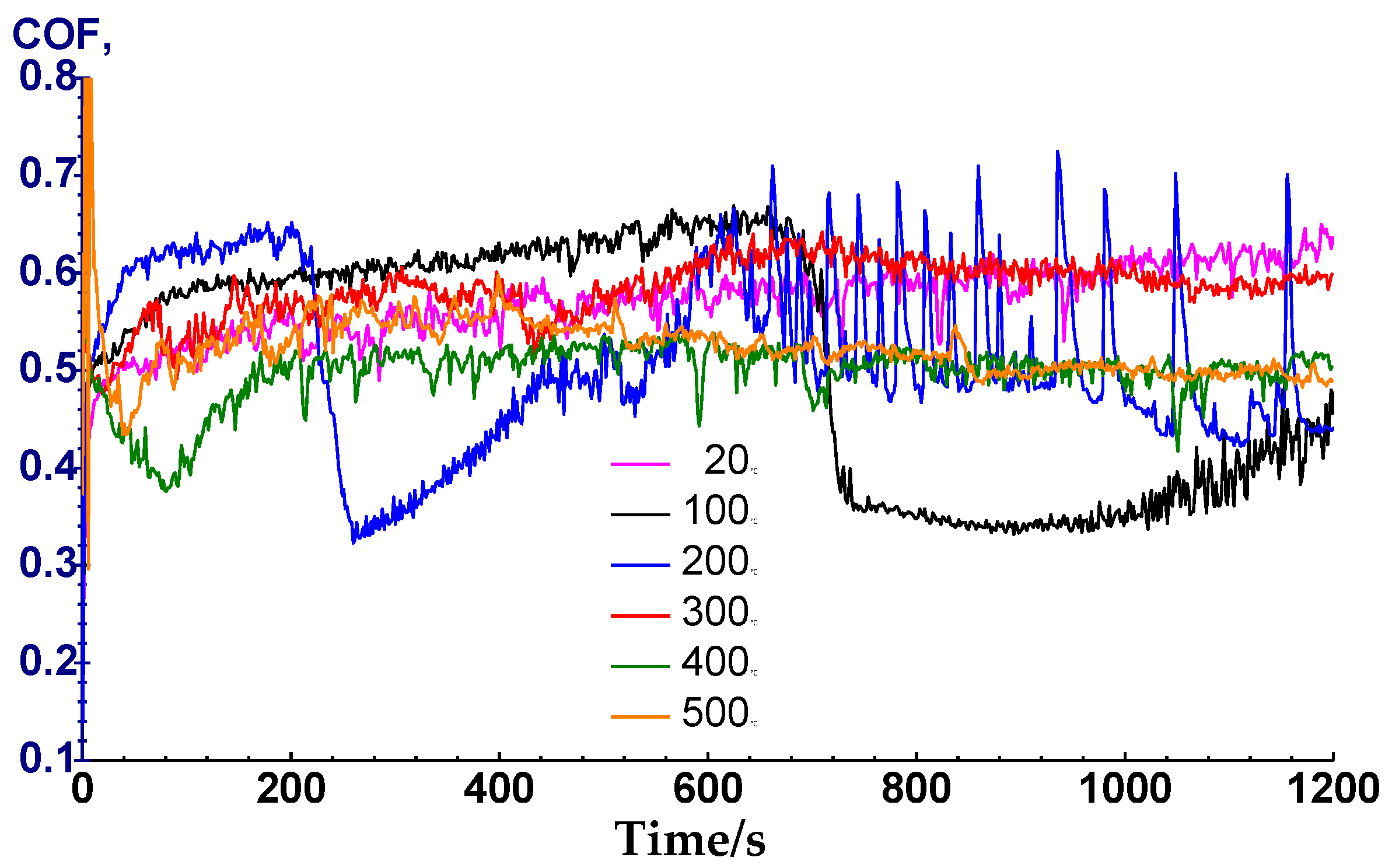

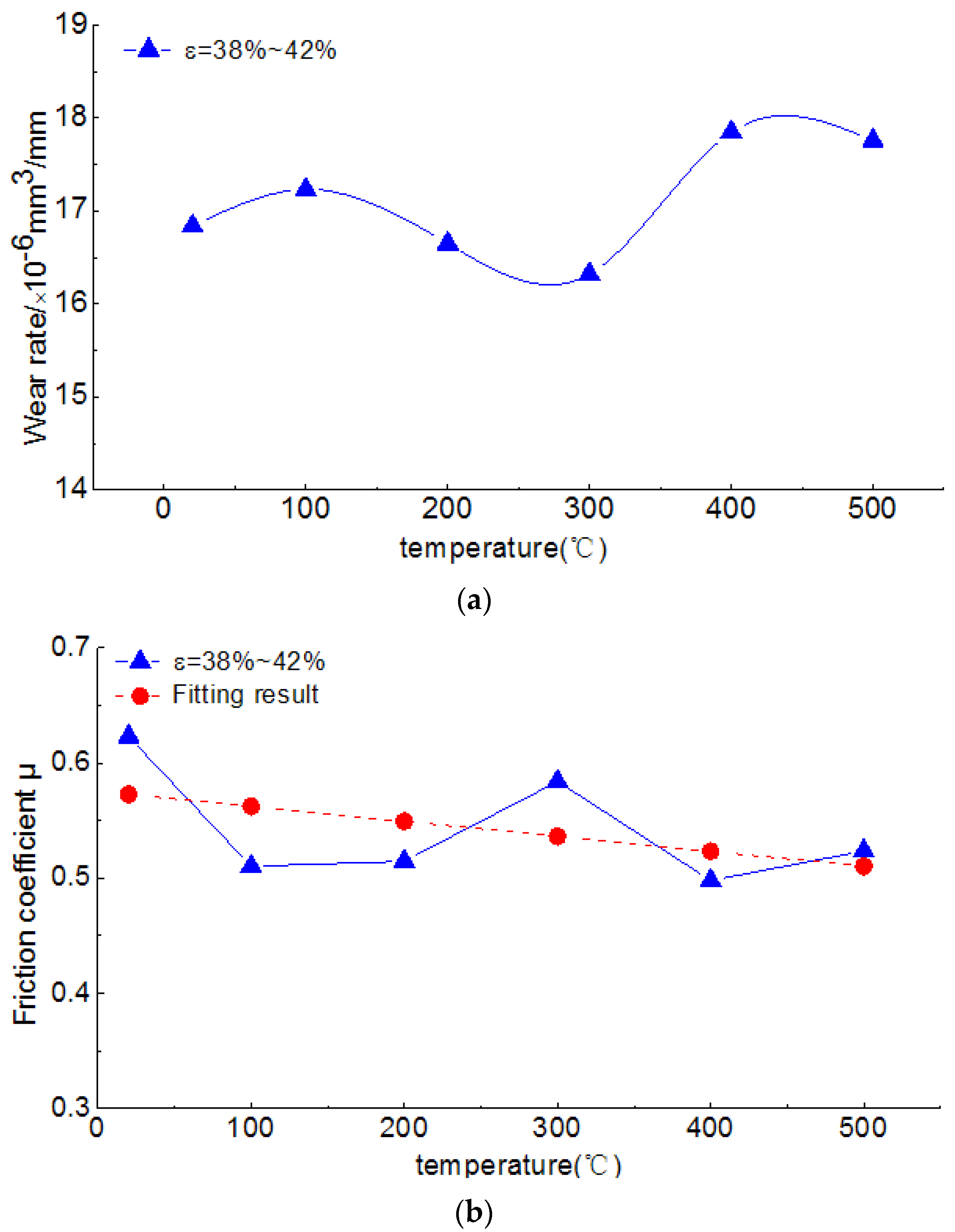

3.1.3. Effects of Temperature on Friction Coefficient and Wear Rate

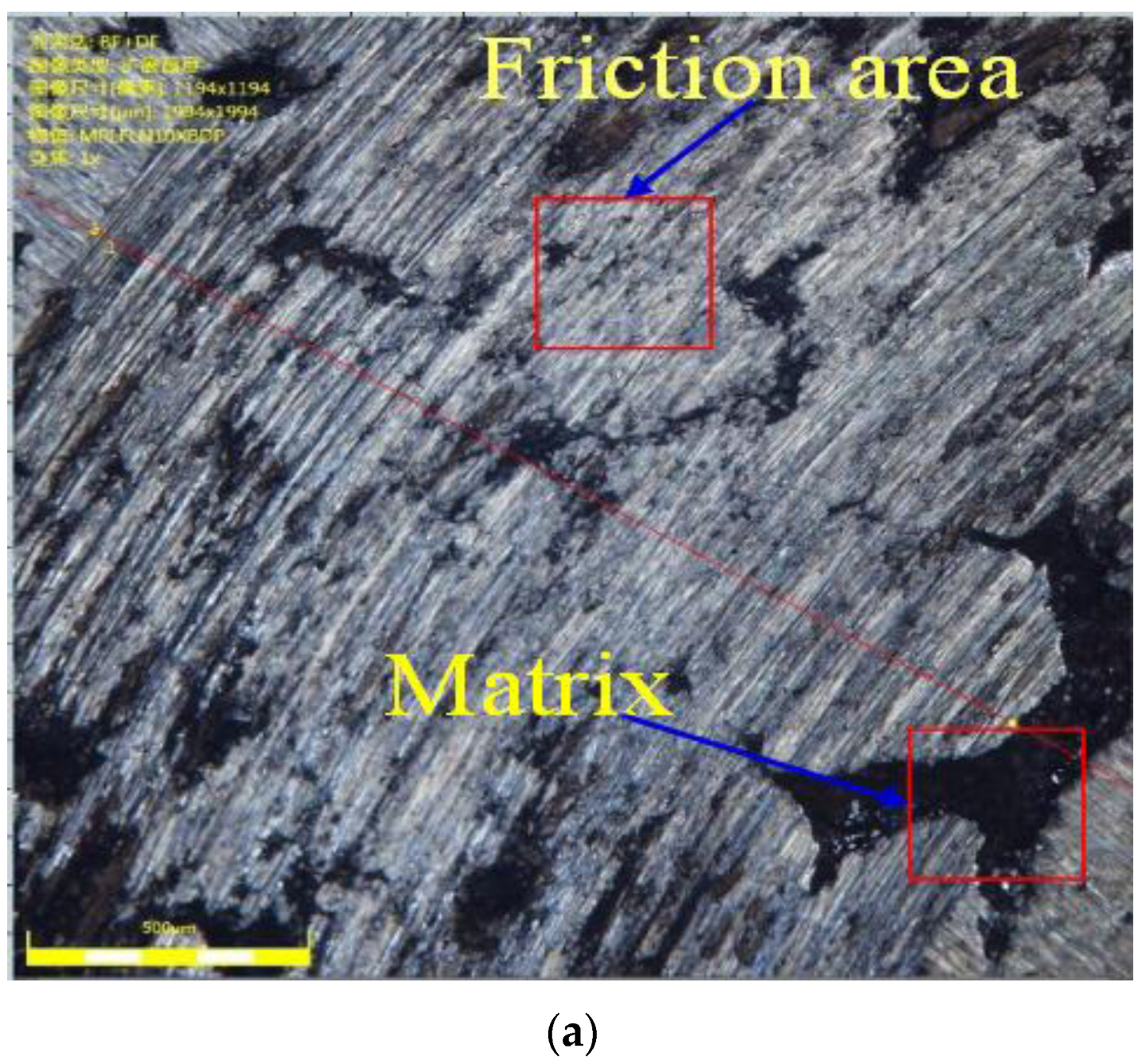

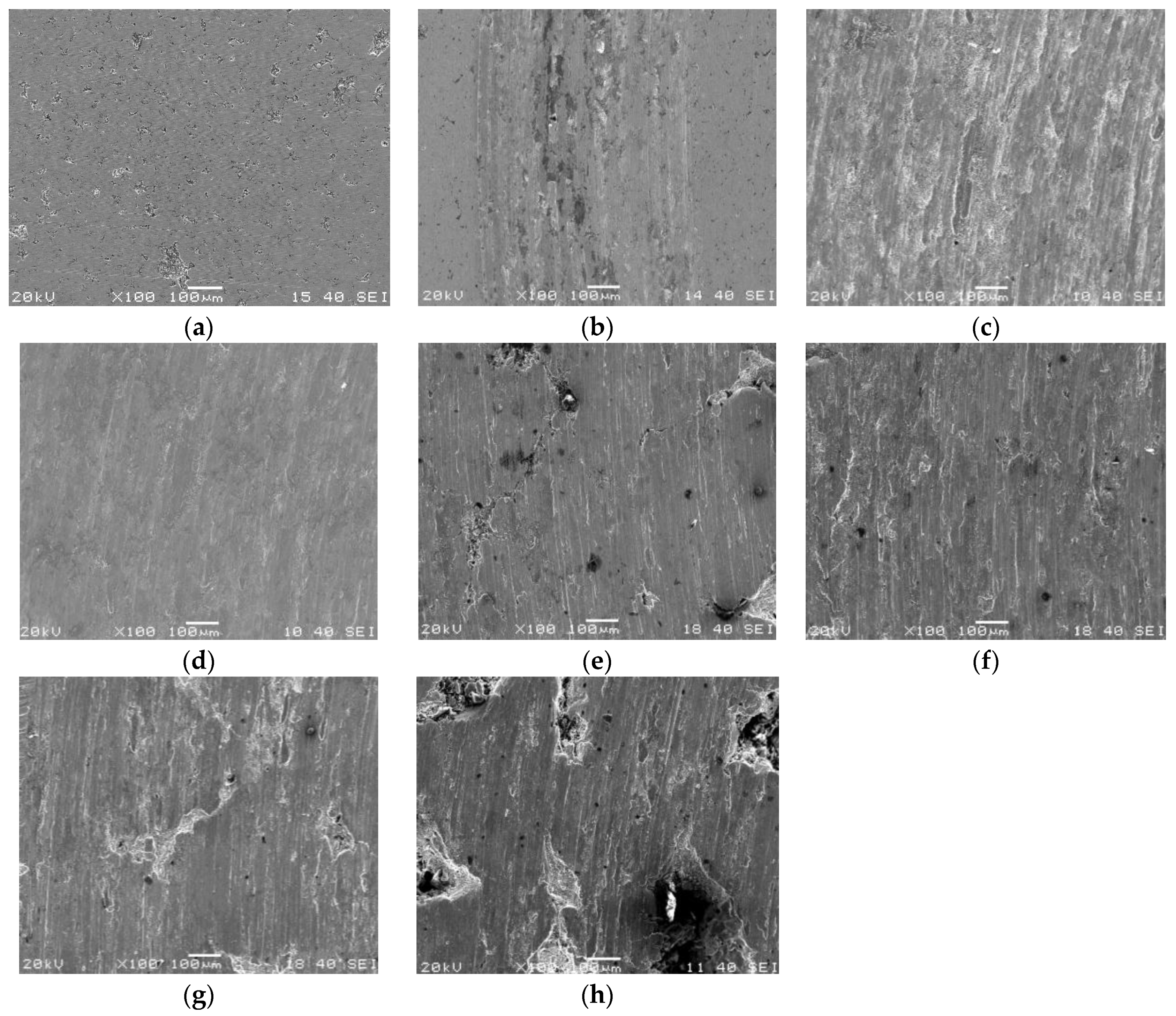

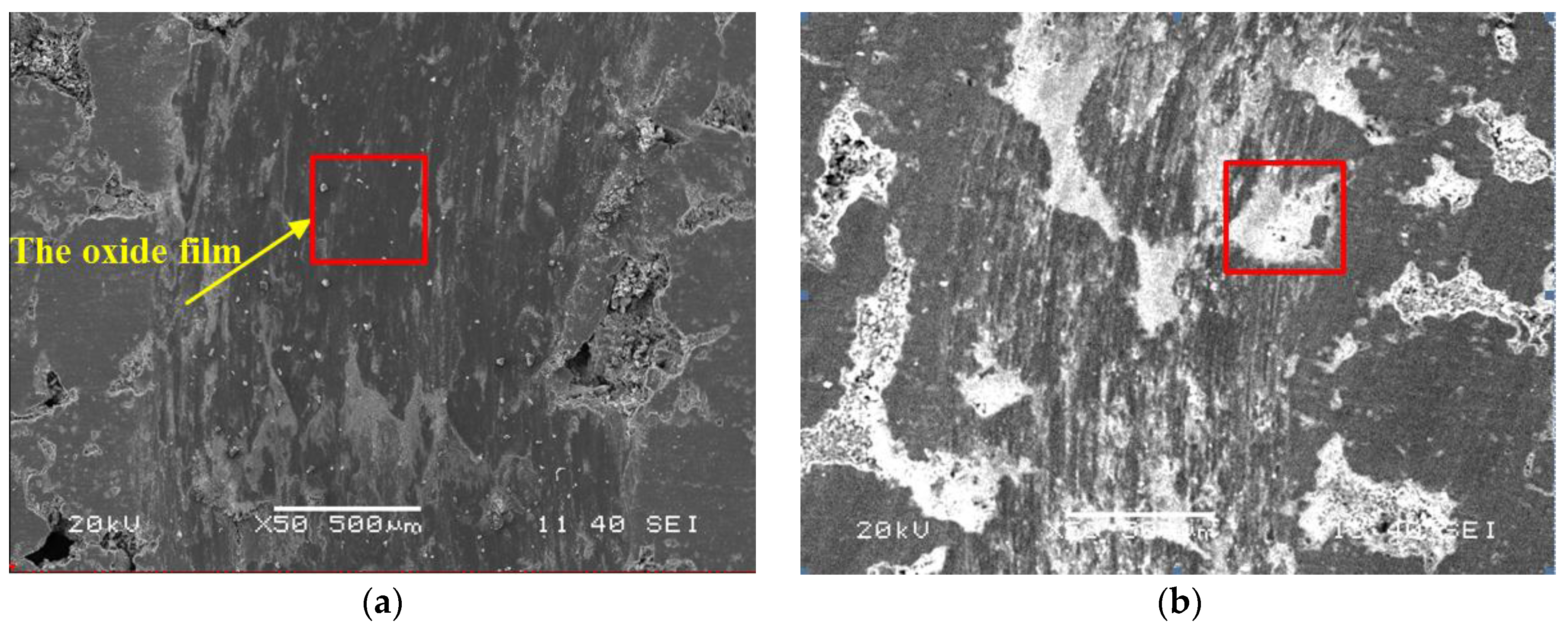

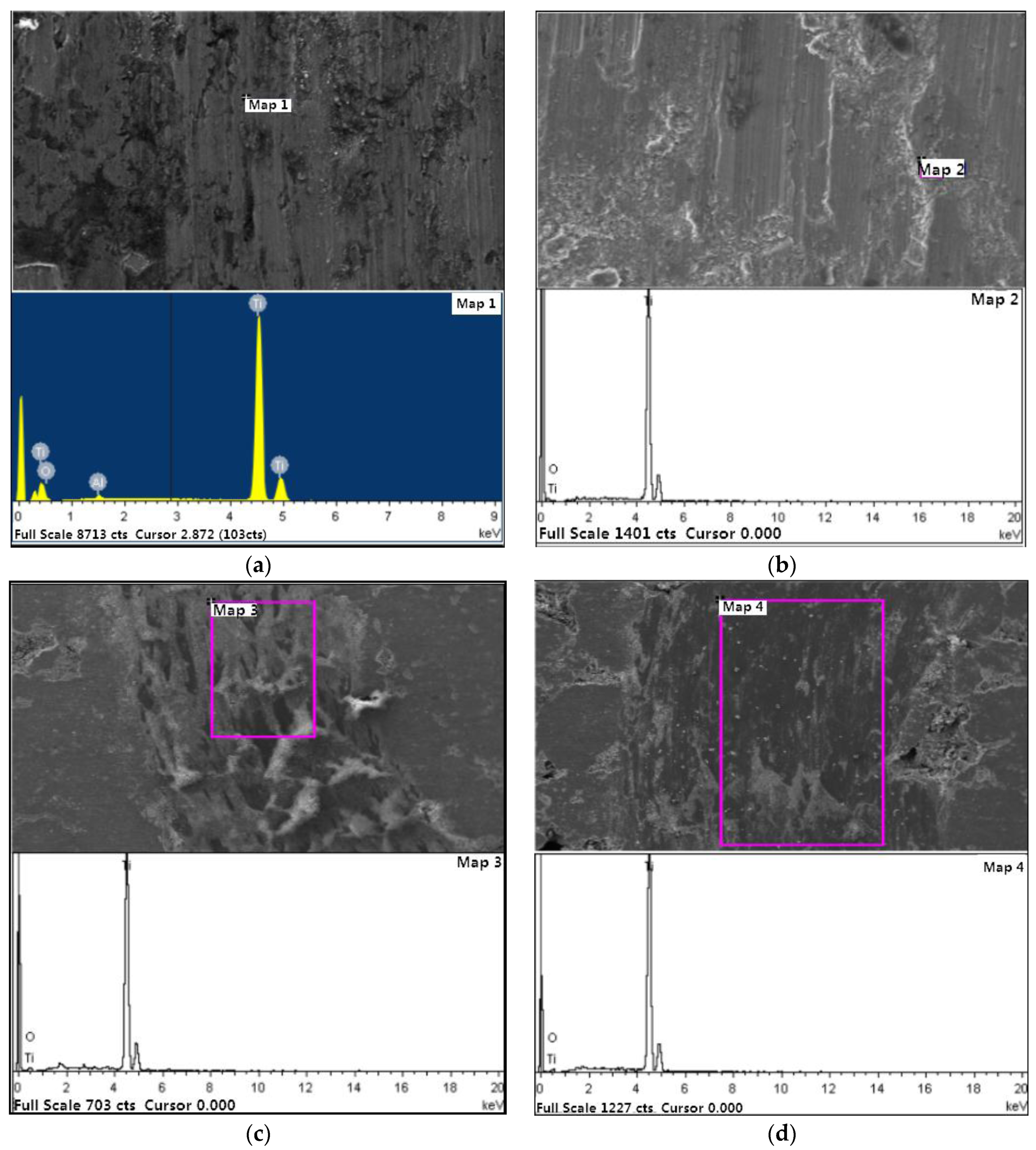

3.2. Wear Morphology and Mechanism of Porous Titanium Materials

4. Conclusions

- (1)

- In the micro-cutting process of porous titanium alloys, the best choice of machining parameters for different porosity materials are as follows: the load is about 8 N, the sliding speed is about 400 r/min and the temperature is about 300 °C. This choice can satisfy the requirements that the material’s friction coefficient and wear rate should be kept at a relatively stable value to the maximum extent possible, to improve the quality of the machined surface and the service life of the cutter.

- (2)

- The wear mechanism of porous titanium material is abrasive wear and slight oxidation wear at room temperature. However, the mechanism will change to severe oxidation wear and abrasive wear if the temperature is high. In addition, the main wear mechanism in the contact area of the YG6 carbide grinding ball is abrasive wear.

- (3)

- Among the parameters of porosity, load, sliding velocity and temperature, the main factor that influences the friction coefficient and wear rate is the porosity. Porosity reduces the wear resistance of the material. In addition, due to the existence of the porosity, the abrasive wear mainly occurs between the friction pair, while the oxidation wear occurs only under large load.

- (4)

- Under the micro-cutting condition, the contact surface of the friction pair is mainly plastic contact. The black oxide film formed on the surface of the processed surface at high speed or high temperature is mainly compounds of titanium and oxygen.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, G.F.; He, G. Enhancement of entangled porous titanium by BisGMA for load-bearing biomedical applications. Mater. Sci. Eng. C 2016, 61, 37–41. [Google Scholar] [CrossRef] [PubMed]

- Yetim, A.F. Investigation of wear behavior of titanium oxide films, produced by anodic oxidation, on commercially pure titanium in vacuum conditions. Surf. Coat. Technol. 2010, 205, 1757–1763. [Google Scholar] [CrossRef]

- Sui, X.D.; Li, G.J.; Qin, X.S. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN conposite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Ayed, Y.; Germain, G.; Ammar, A. Tool wear analysis and improvement of cutting conditions using the high-pressure water-jet assistance when machining the Ti17 titanium alloy. Mater. Lett. 2015, 42, 294–301. [Google Scholar] [CrossRef]

- Zhao, X.X.; Ke, W.; Zhang, S.S. Potential failure cause analysis of tungsten carbide end mills for titanium alloy machining. Eng. Fail. Anal. 2016, 66, 321–327. [Google Scholar] [CrossRef]

- Dearnley, P.A.; Grearson, A.N.; Aucote, J. Wear mechanisms of cemented carbides and ceramics used for machining titanium alloys. High Technol. Ceram. 1987, 38, 2699–2712. [Google Scholar]

- Corduan, N.; Hirnbert, T.; Poulachon, G. Wear mechanisms of new tool materials for Ti-6Al-4V high performance machining. CIRP Ann. 2003, 52, 73–76. [Google Scholar] [CrossRef]

- Igor, V.; Florian, A.; Stefan, K. The influence of temperature on friction and wear of unlubricated steel/steel contacts in different gaseous atmospheres. Tribol. Int. 2016, 98, 155–171. [Google Scholar]

- Dai, J.J.; Zhu, J.Y.; Chen, C.Z. High temperature oxidation behavior and research status of modification on improving high temperature oxidation resistance of titanium alloy and titanium aluminides: A review. J. Alloy. Compd. 2016, 685, 784–798. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, J.; Chen, J.M. Improvement of the oxidation and wear resistance of pure Ti by laser cladding at elevated temperature. Surf. Coat. Technol. 2010, 205, 2142–2151. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Friction and surface behavior of selected titanium alloys during reciprocating-sliding motion. Wear 2001, 249, 157–167. [Google Scholar] [CrossRef]

- Matikas, T.E.; Nicolaou, P.D. Prediction of contact temperature distribution during fretting fatigue in titanium alloys. Tribol. Trans. 2009, 52, 346–353. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.H.; Wang, Y. Friction and wear performance of titanium alloy against tungsten carbide lubricated with phosphate ester. Tribol. Int. 2016, 95, 27–34. [Google Scholar] [CrossRef]

- Wang, X.H.; Li, J.S.; Hu, R. Mechianical properties and pore structure deformation buhaviour of biomedical porous titanium. Trans. Nonferr. Met. Soc. China 2015, 25, 1543–1550. [Google Scholar] [CrossRef]

- Wang, G.; Rahman, M.; Wong, Y.S. Study on orthogonal turning of titanium alloys with different coolant supply strategies. Int. J. Adv. Manuf. Technol. 2009, 42, 621–632. [Google Scholar] [CrossRef]

- Quan, H.X.; Gao, S.S.; Zhu, M.H.; Yu, H.Y. Comparison of the torsional fretting behavior of three porous titanium coatings for biomedical applications. Tribol. Int. 2015, 192, 29–37. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Tesi, B.; Baccai, T. Dry sliding wear mechanism of the Ti6Al4V alloy. Wear 1997, 208, 105–112. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Z.Q. Surface topography analysis and cutting parameters optimization for peripheral milling titanium alloy Ti-6Al-4V. Int. J. Refract. Met. Hard Mater. 2015, 51, 192–200. [Google Scholar] [CrossRef]

- Tutunea Fatan, O.R.; Fakhri, M.A.; Bordatchev, E.V. Porosity and cutting forces: From macroscale to microscale machining correlations. Proc. Inst. Mech. Eng. 2011, 255, 619–630. [Google Scholar] [CrossRef]

- Lauro, C.H.; Filho, S.L.M.R.; Brandão, L.C.; Davim, J.P. Analysis of behaviour biocompatible titanium alloy (Ti-6Al-7Nb) in the micro-cutting. Measurement 2016, 93, 529–540. [Google Scholar] [CrossRef]

- Attanasio, A.; Gelfi, M.; Giardini, C.; Remino, C. Minimum quantity lubrication in turning. Wear 2006, 160, 333–338. [Google Scholar] [CrossRef]

- Farokhzadeh, K.; Edrisy, A. Transition between mild and severe wear in titanium alloys. Tribol. Int. 2016, 94, 98–111. [Google Scholar] [CrossRef]

- Fakhri, M.A.; Bordatchev, E.V.; Tutunea Fatan, O.R. An image-based methodology to establish correlations between porosity and cutting force in micromilling of porous titanium foams. Int. J. Adv. Manuf. Technol. 2012, 60, 841–851. [Google Scholar] [CrossRef]

| Type | Ti | Fe | Cu | C | O | N |

|---|---|---|---|---|---|---|

| 500# | ≥99.7% | ≤0.02% | ≤0.005% | ≤0.02% | ≤0.06% | ≤0.02% |

| 200# | ≥99.7% | ≤0.03% | ≤0.006% | ≤0.02% | ≤0.02% | ≤0.03% |

| Type | Porosity (%) | Equivalent Aperture (mm) |

|---|---|---|

| 200# | ~24–26 | 0.015 |

| 500# | ~38–42 | 0.25 |

| Material | Diameter (mm) | Hardness (HAR) | Roughness (μm) |

|---|---|---|---|

| Carbide YG6 | 9.53 | ~89–92 | 0.01 |

| Experimental Condition | Speed of Revolution (r/min) | Load (N) | Temperature (K) |

|---|---|---|---|

| Range | 50–500 | 4–14 | 293–773 |

| Test Scheme | Speed of Revolution () | Load (N) | Temperature (°C) |

|---|---|---|---|

| 1 | 300 | 6 | 20 |

| 300 | 6 | 100 | |

| 300 | 6 | 200 | |

| 300 | 6 | 300 | |

| 300 | 6 | 400 | |

| 300 | 6 | 500 | |

| 2 | 50 (1.57 m/min) | 6 | 20 |

| 100 (3.14 m/min) | 6 | 20 | |

| 200 (6.28 m/min) | 6 | 20 | |

| 300 (9.43 m/min) | 6 | 20 | |

| 400 (12.56 m/min) | 6 | 20 | |

| 500 (15.71 m/min) | 6 | 20 | |

| 3 | 300 | 4 | 20 |

| 300 | 6 | 20 | |

| 300 | 8 | 20 | |

| 300 | 10 | 20 | |

| 300 | 14 | 20 |

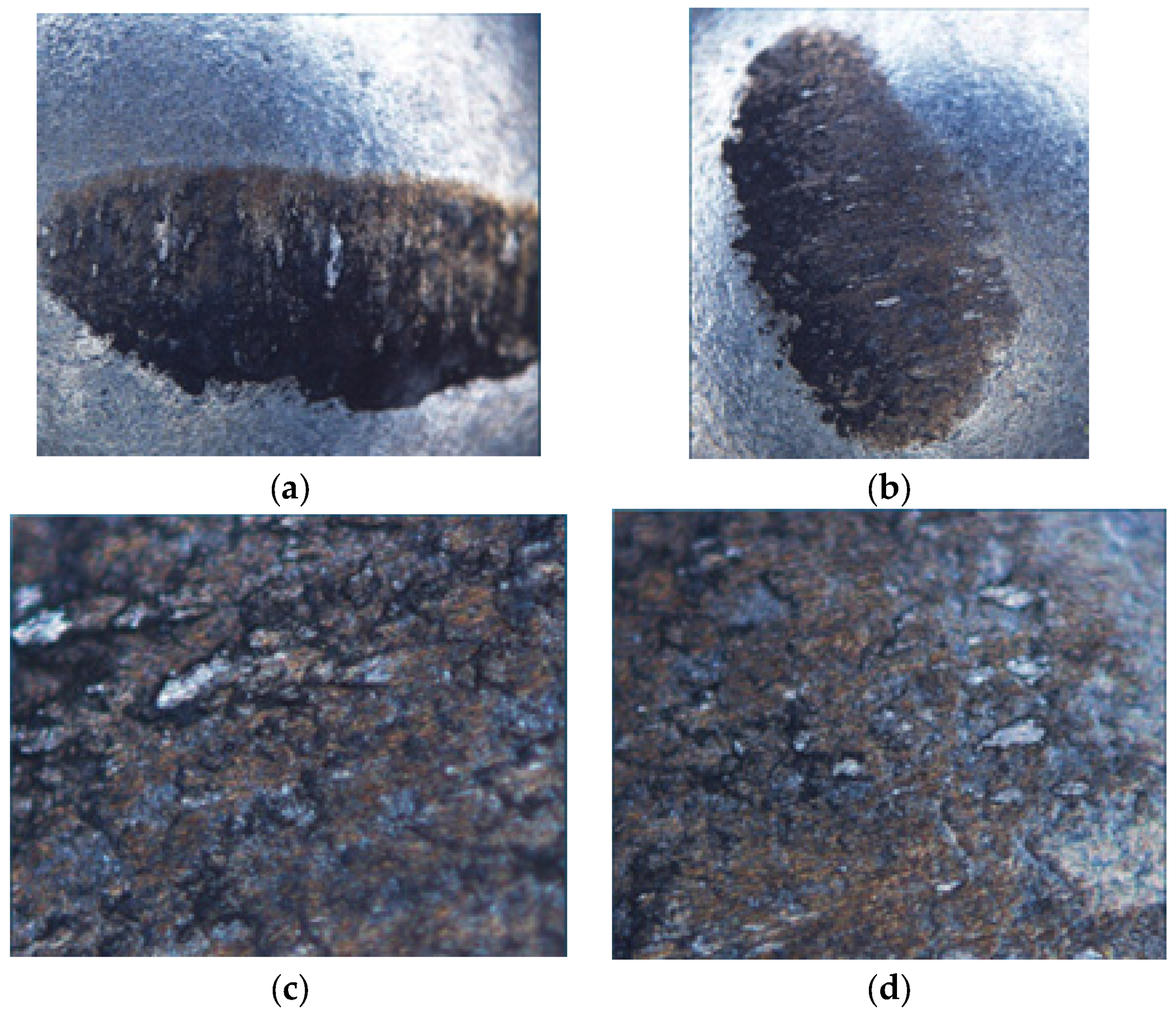

| Number | Porosity (%) | Load (N) | Temperature (°C) | Element | Weight (%) | Atom (%) |

|---|---|---|---|---|---|---|

| a | ~24–26 | 10 | 20 | O | 2.26 | 6.43 |

| Al | 1.03 | 1.74 | ||||

| Ti | 96.71 | 91.83 | ||||

| b | ~38–42 | 10 | 20 | O | 6.40 | 17.00 |

| Ti | 93.60 | 83.00 | ||||

| c | ~38–42 | 6 | 200 | O | 10.77 | 26.55 |

| Ti | 89.23 | 73.45 | ||||

| d | ~38–42 | 6 | 300 | O | 11.89 | 28.77 |

| Ti | 88.11 | 71.23 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Ji, F.; Wang, M.; Zhu, T. Study on the Tribological Properties of Porous Titanium Sliding against Tungsten Carbide YG6. Metals 2017, 7, 28. https://doi.org/10.3390/met7010028

Liu Z, Ji F, Wang M, Zhu T. Study on the Tribological Properties of Porous Titanium Sliding against Tungsten Carbide YG6. Metals. 2017; 7(1):28. https://doi.org/10.3390/met7010028

Chicago/Turabian StyleLiu, Zhiqiang, Feifei Ji, Mingqiang Wang, and Tianyu Zhu. 2017. "Study on the Tribological Properties of Porous Titanium Sliding against Tungsten Carbide YG6" Metals 7, no. 1: 28. https://doi.org/10.3390/met7010028

APA StyleLiu, Z., Ji, F., Wang, M., & Zhu, T. (2017). Study on the Tribological Properties of Porous Titanium Sliding against Tungsten Carbide YG6. Metals, 7(1), 28. https://doi.org/10.3390/met7010028