Effects of Austenitizing Conditions on the Microstructure of AISI M42 High-Speed Steel

Abstract

:1. Introduction

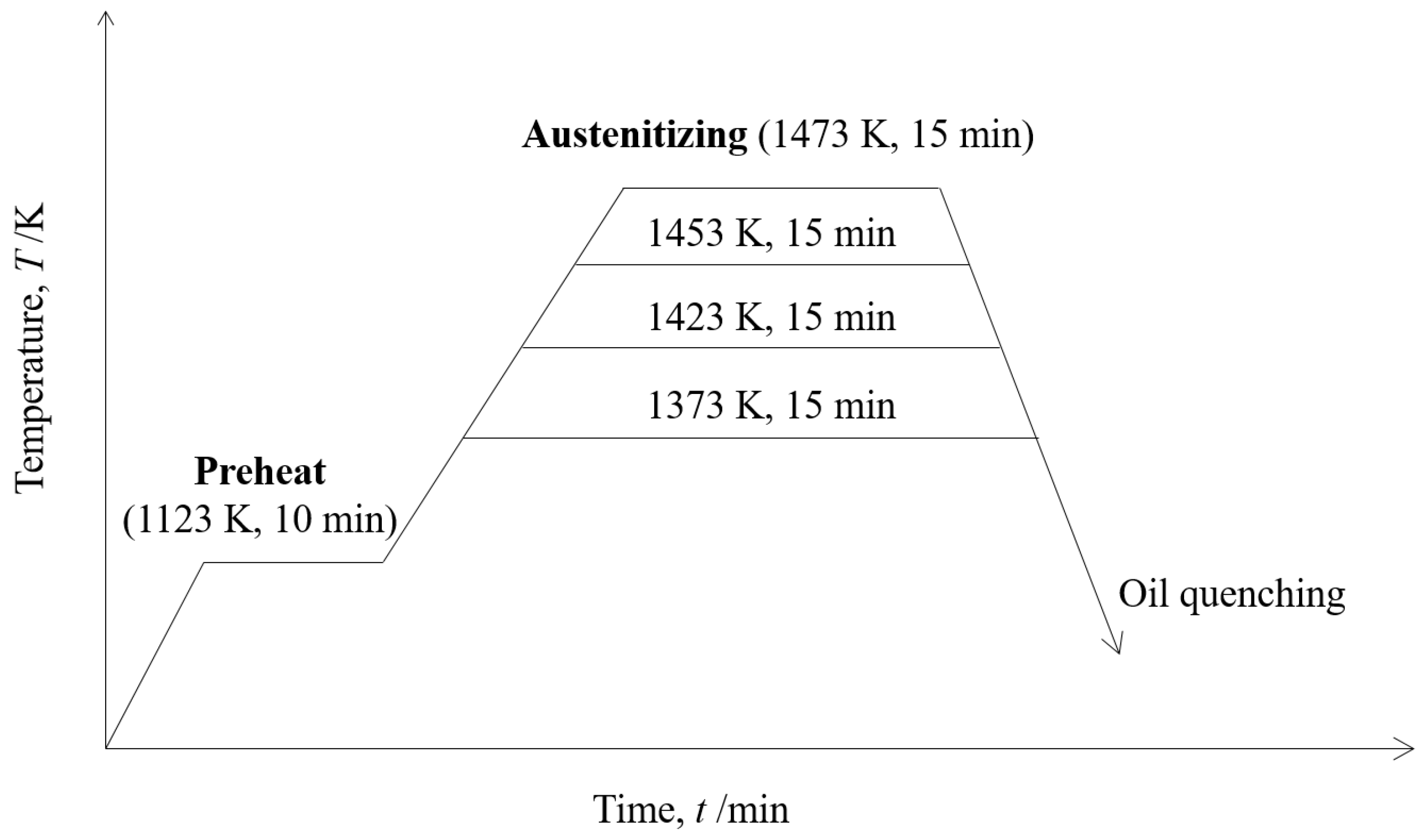

2. Materials and Methods

3. Results and Discussion

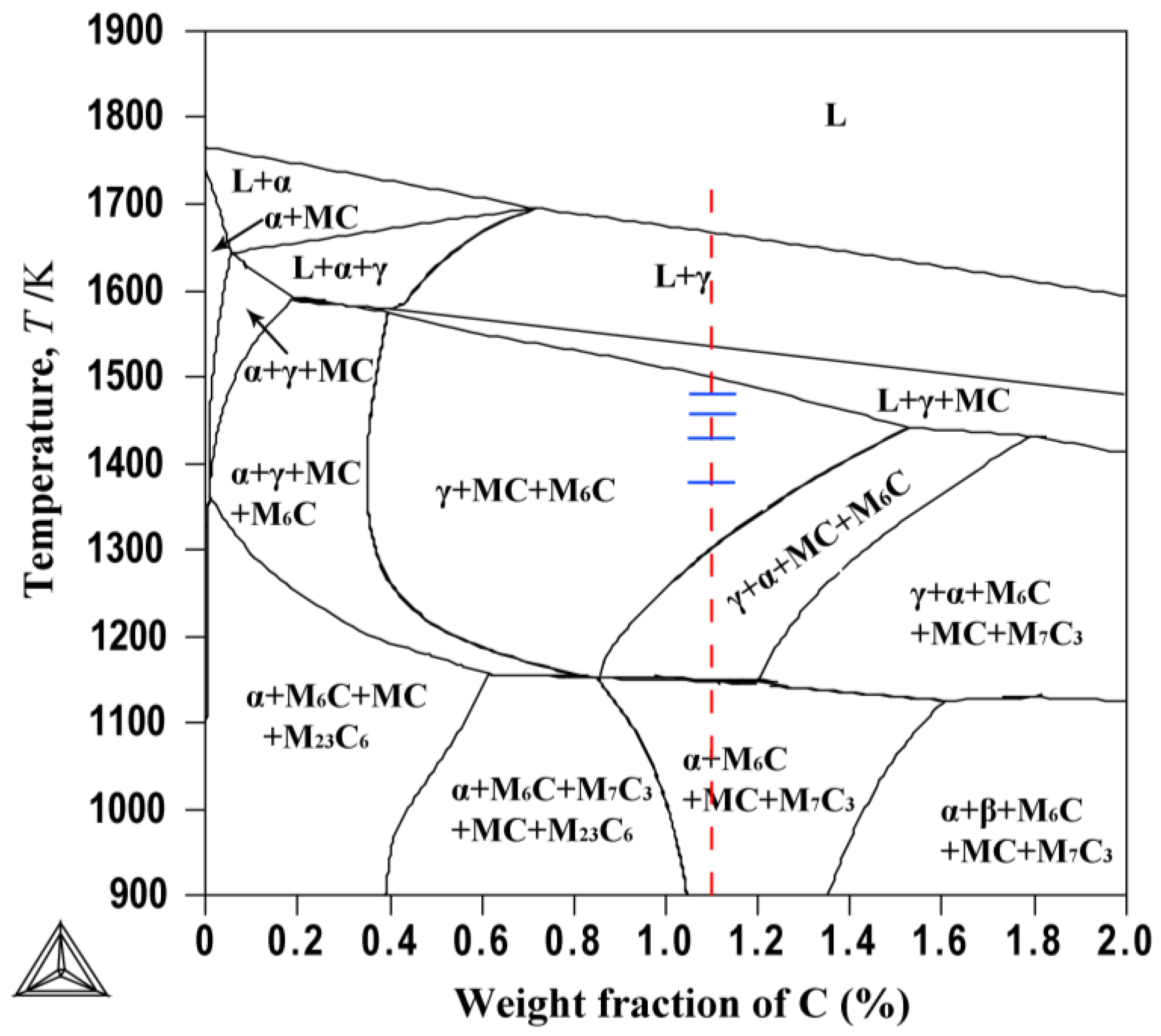

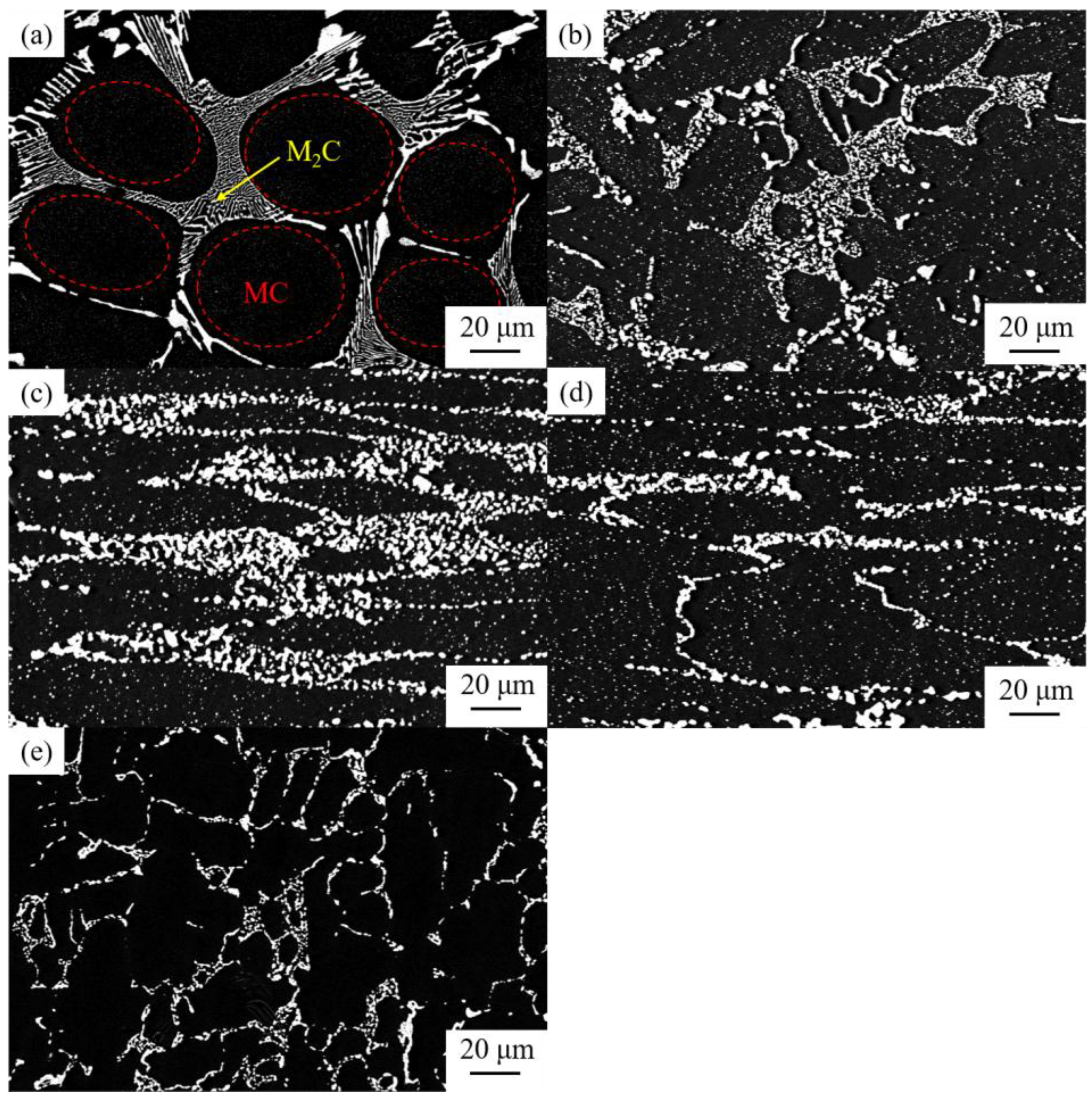

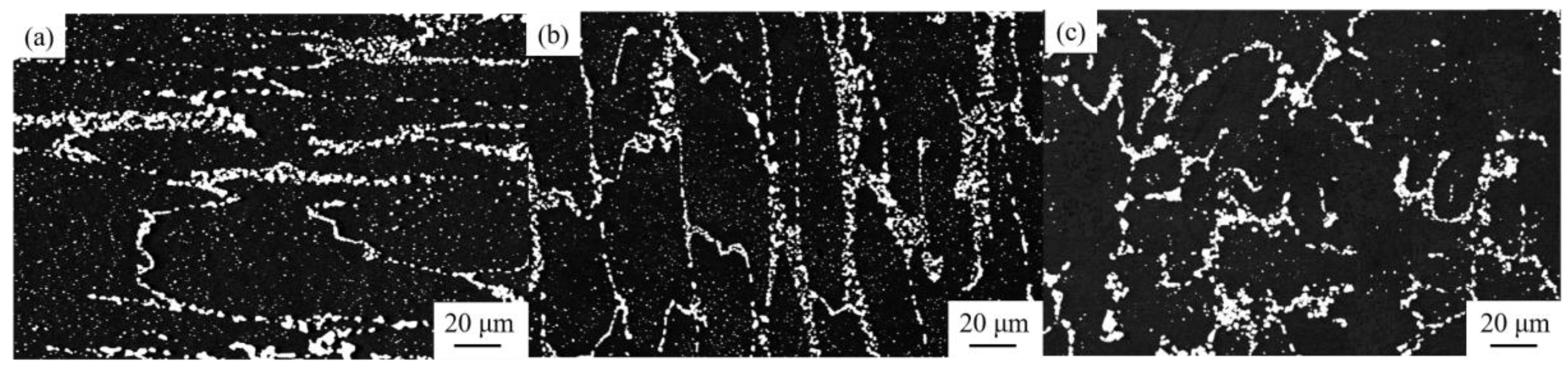

3.1. Phase Transformation and Precipitation Behavior of Carbides

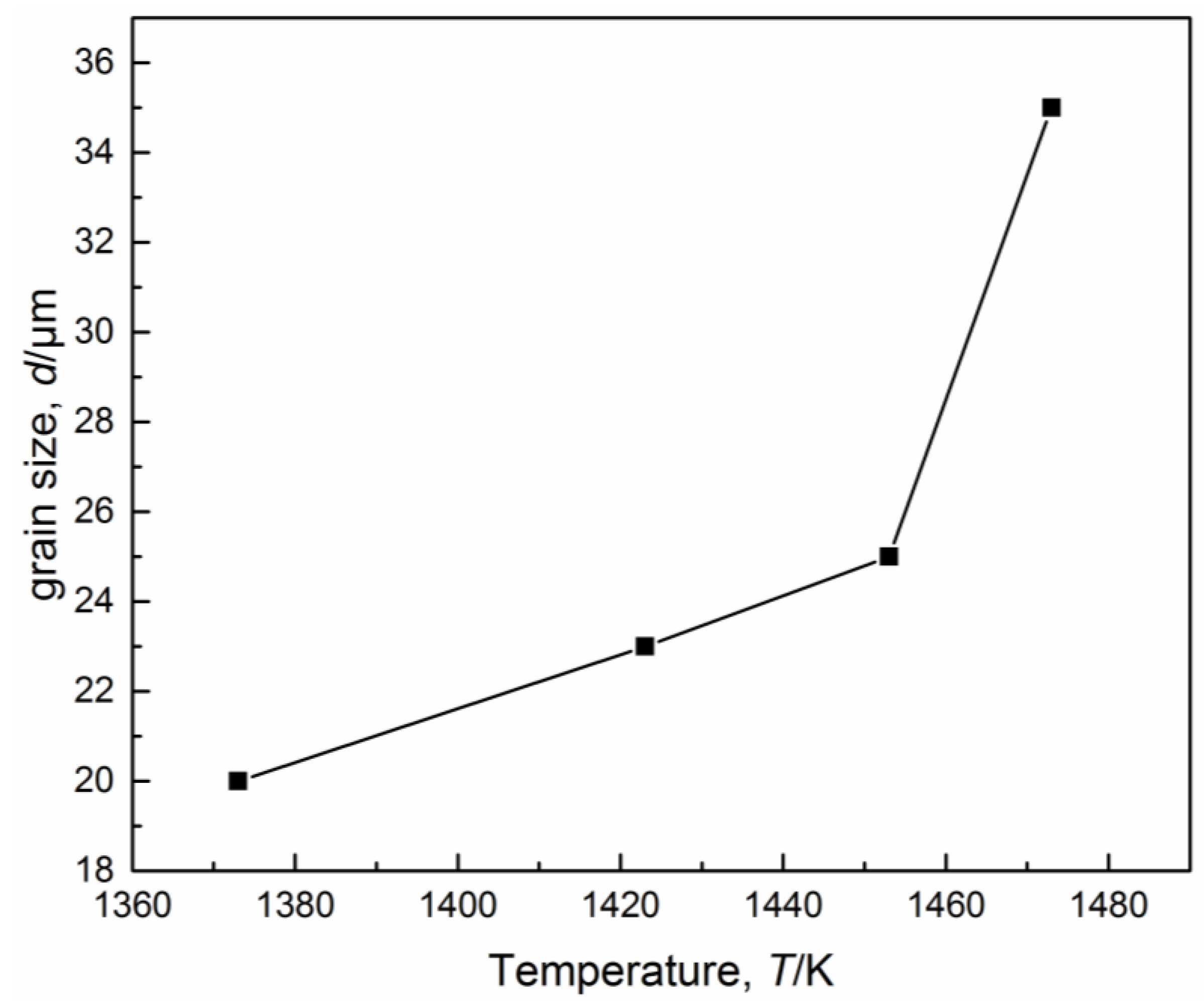

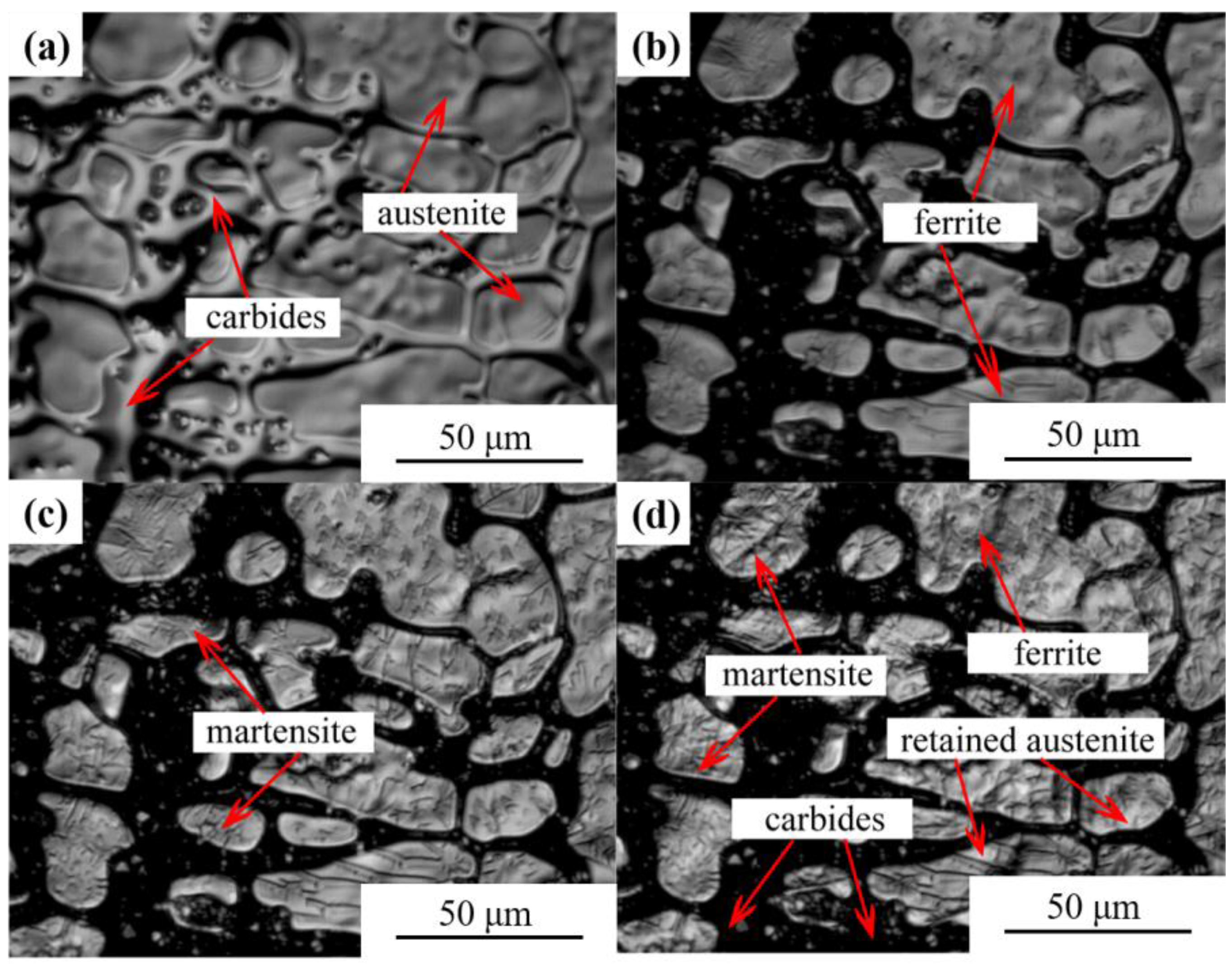

3.2. Effects of Austenitizing Temperature on Microstructure and Properties

3.3. Effects of Austenitizing Time on Microstructure and Properties

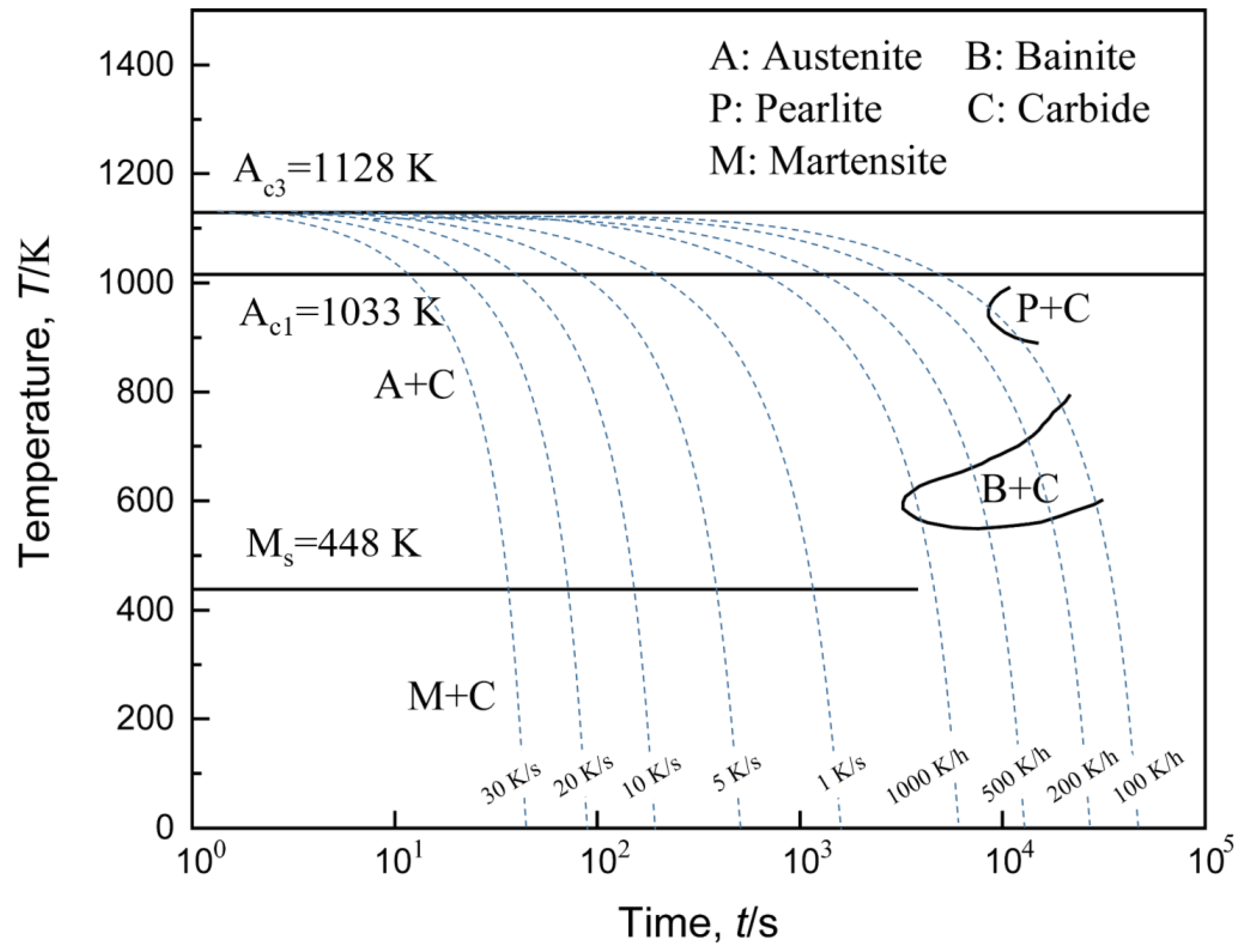

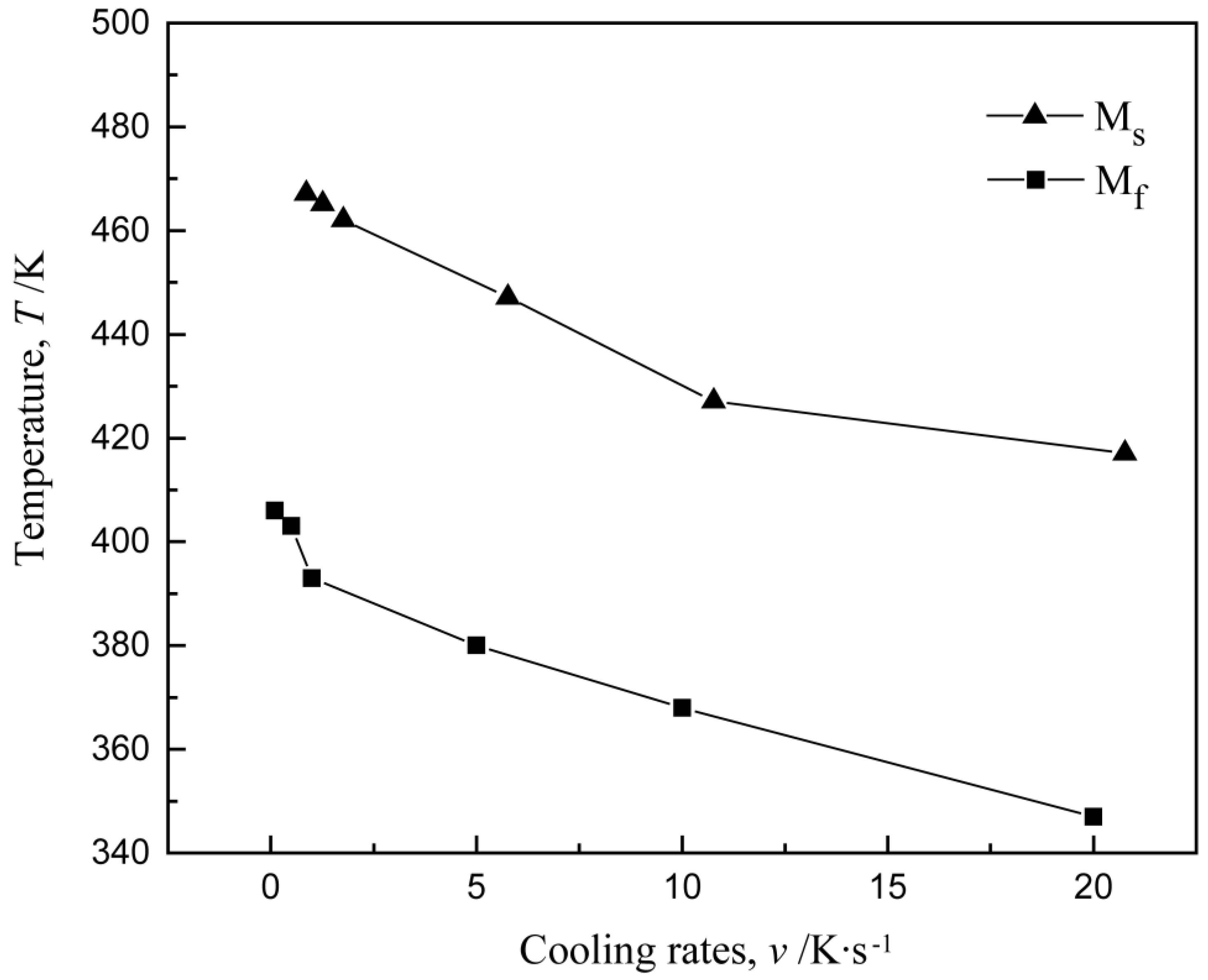

3.4. Effects of Cooling Rate on Microstructure and Properties

4. Conclusions

- When the austenitizing temperature is 1373 K, the network morphology of carbides could not dissolve completely and distribute equably. When the austenitizing temperature reaches 1473 K, the excessive increase in temperature leads to increased carbide dissolution and unwanted grain growth. 1453 K gives the best austenitizing condition on temperature for AISI M42 HSS.

- The amount of hardness increases with the increase of austenitizing temperature between 1373 and 1453 K, but decreases when the austenitizing temperature reaches 1473 K. The hardness of the AISI M42 HSS does not change much when the holding time is less than 30 min, but decreases when the holding time reaches 45 min because of Ostwald ripening. The impact toughness of the specimens increases with the increase of austenitizing temperature and holding time.

- The value of Ms and Mf decrease with the increase of cooling rate. High cooling rate can depress the martensitic transformation and increase the content of retained austenite, which prevents less retained austenite, better microstructure, and higher hardness in AISI M42 HSS.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, C.K.; Park, J.I.; Lee, S.; Kim, Y.C.; Kim, N.J.; Yang, J.S. Effects of alloying elements on microstructure, hardness, and fracture toughness of centrifugally cast high-speed steel rolls. Metall. Mater. Trans. A 2005, 36, 87–97. [Google Scholar] [CrossRef]

- Sano, Y.; Hattori, T.; Haga, M. Characteristics of high-carbon high speed steel rolls for hot strip mill. ISIJ Int. 1992, 32, 1194–1201. [Google Scholar] [CrossRef]

- Zhou, X.F.; Fang, F.; Li, F.; Jiang, J.Q. Morphology and microstructure of M2C carbide formed at different cooling rates in AISI M2 high speed steel. J. Mater. Sci. 2011, 46, 1196–1202. [Google Scholar] [CrossRef]

- Yu, T.H.; Yang, J.R. Effect of retained austenite on GPM A30 high-speed steel. J. Mater. Eng. Perform. 2007, 16, 500–507. [Google Scholar] [CrossRef]

- Cambronero, L.E.G.; Gordo, E.; Torralba, J.M.; Ruiz-Prieto, J.M. Comparative study of high speed steels obtained through explosive compaction and hot isostatic pressing. Mater. Sci. Eng. A 1996, 207, 36–45. [Google Scholar] [CrossRef]

- Xu, L.; Xing, J.; Wei, S.; Chen, H.; Long, R. Comparative investigation to rolling wear properties between high-vanadium high-speed steel and high-chromium cast iron. J. Xi’an Jiaotong Univ. 2006, 40, 275–278. [Google Scholar]

- Himuro, Y.; Kainuma, R.; Ishida, K. Martensitic transformation and shape memory effect in ausaged Fe-Ni-Si alloys. ISIJ Int. 2002, 42, 184–190. [Google Scholar] [CrossRef]

- Durlu, T.N. Effects of high austenitizing temperature and austenite deformation on formation of martensite in Fe-Ni-C alloys. J. Mater. Sci. 2001, 36, 5665–5671. [Google Scholar] [CrossRef]

- Sarafianos, N. The effect of the austenitizing heat-treatment variables on the fracture toughness of high-speed steel. Metall. Mater. Trans. A 1997, 28, 2089–2099. [Google Scholar] [CrossRef]

- Hashimoto, M.; Kubo, O.; Matsubara, Y. Analysis of carbides in multi-component white cast iron for hot rolling mill rolls. ISIJ Int. 2004, 44, 372–380. [Google Scholar] [CrossRef]

- Fu, H.; Qu, Y.; Xing, J.; Zhi, X.; Jiang, Z.; Li, M.; Zhang, Y. Investigations on heat treatment of a high-speed steel roll. J. Mater. Eng. Perform. 2008, 17, 535–542. [Google Scholar] [CrossRef]

- Kang, M.; Lee, Y.K. The effects of austenitizing conditions on the microstructure and wear resistance of a centrifugally cast high-speed steel roll. Metall. Mater. Trans. A 2016, 47, 3365–3374. [Google Scholar] [CrossRef]

- Zhou, X.; Fang, F.; Li, G.; Jiang, J. Morphology and properties of M2C eutectic carbides in AISI M2 steel. ISIJ Int. 2010, 50, 1151–1157. [Google Scholar] [CrossRef]

- Hwang, K.C.; Lee, S.; Lee, H.C. Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls part I: Microstructural analysis. Mater. Sci. Eng. A 1998, 254, 282–295. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kucheev, Y.O.; Efron, L.I.; Petelin, A.L.; Majumdar, J.D.; Manna, I. Complete and incomplete wetting of ferrite grain boundaries by austenite in the low-alloyed ferritic steel. J. Mater. Eng. Perform. 2012, 21, 667–670. [Google Scholar] [CrossRef]

- Modica, L. Critical point wetting. J. Chem. Phys. 1977, 66, 359–361. [Google Scholar]

- Straumal, B.B.; Baretzky, B.; Kogtenkova, O.A.; Straumal, A.B.; Sidorenko, A.S. Wetting of grain boundaries in Al by the solid Al3Mg2 phase. J. Mater. Sci. 2010, 45, 2057–2061. [Google Scholar] [CrossRef]

- Straumal, B.B.; Gornakova, A.S.; Kucheev, Y.O.; Baretzky, B.; Nekrasov, A.N. Grain boundary wetting by a second solid phase in the Zr-Nb alloys. J. Mater. Eng. Perform. 2012, 21, 721–724. [Google Scholar] [CrossRef]

- Zhou, B.; Shen, Y.; Chen, J.; Cui, Z.S. Evolving mechanism of eutectic carbide in as-cast AISI M2 high-speed steel at elevated temperature. J. Shanghai Jiaotong Univ. Sci. 2010, 15, 463–471. [Google Scholar] [CrossRef]

- Deng, Y.K.; Chen, J.R.; Wang, S.Z. High Speed Tool Steel; Guo, G.C., Ed.; Metallurgical Industry Press: Beijing, China, 2002; pp. 199–200. [Google Scholar]

- Yamamoto, K.; Kogin, T.; Harakawa, T.; Murai, N.; Kuwano, M.; Ogi, K. Effects of alloying elements in hardenability for high C high speed steel type alloy. J. Jpn. Foundry Eng. Soc. 2000, 72, 90–95. [Google Scholar]

- Barlow, L.D.; Toit, M.D. Effect of austenitizing heat treatment on the microstructure and hardness of martensitic stainless steel AISI 420. J. Mater. Eng. Perform. 2012, 21, 1327–1336. [Google Scholar] [CrossRef]

- Snyder, V.A.; Akaiwa, N.; Alkemper, J.; Voorhees, P.W. The influence of temperature gradients on Ostwald ripening. Metall. Mater. Trans. A 1999, 30, 2341–2348. [Google Scholar] [CrossRef]

- Garay-Reyes, C.G.; Hernandez-Santiago, F.; Cayetano-Castro, N.; Martinez-Sanchez, R.; Hernandez-Rivera, J.L.; Dorantes-Rosales, H.J.; Cruz-Rivera, J. Analysis of Ostwald ripening in Ni-rich Ni-Ti alloys by diffusion couples. J. Bull. Mater. Sci. 2014, 37, 823–829. [Google Scholar] [CrossRef]

- Alvarado-Meza, M.A.; Garcia-Sanchez, E.; Covarrubias-Alvarado, O.; Salinas-Rodriguez, A.; Guerrero-Mata, M.P.; Colas, R. Effect of the high-temperature deformation on the Ms temperature in a low C martensitic stainless steel. J. Mater. Eng. Perform. 2013, 22, 345–350. [Google Scholar] [CrossRef]

- Morito, S.; Yoshida, H.; Maki, T.; Huang, X. Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng. A 2006, 438–440, 237–240. [Google Scholar] [CrossRef]

- Nogueira, R.A.; Riberiro, O.C.S.; Das-Neves, M.D.M.; de Lima, L.F.C.P.; Filho, F.A.; Friedrich, D.N.; Boehs, L. Influence of the heat treatment on the microstructure of AISI T15 high speed steel. Mater. Sci. Forum 2003, 416–418, 89–94. [Google Scholar] [CrossRef]

- Hwang, K.C.; Lee, S.; Lee, H.C. Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls part II: Fracture behavior. Mater. Sci. Eng. A 1998, 254, 296–304. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | W | Mo | V | Co |

|---|---|---|---|---|---|---|---|---|---|

| 1.11 | 0.7 | 0.39 | 0.016 | 0.002 | 4.58 | 1.39 | 9.46 | 1.37 | 8.04 |

| Austenitizing Temp. (K) | Holding Time (min) | Hardness (HRc) | Impact Toughness (J) |

|---|---|---|---|

| 1373 | 15 | 58.5 | 8.7 |

| 1423 | 15 | 59.8 | 10.4 |

| 1453 | 15 | 65.5 | 10.9 |

| 1453 | 30 | 65.7 | 11.2 |

| 1453 | 45 | 64.8 | 11.9 |

| 1473 | 15 | 63.7 | 12.5 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Guo, H.; Sun, X.; Mao, M.; Guo, J. Effects of Austenitizing Conditions on the Microstructure of AISI M42 High-Speed Steel. Metals 2017, 7, 27. https://doi.org/10.3390/met7010027

Luo Y, Guo H, Sun X, Mao M, Guo J. Effects of Austenitizing Conditions on the Microstructure of AISI M42 High-Speed Steel. Metals. 2017; 7(1):27. https://doi.org/10.3390/met7010027

Chicago/Turabian StyleLuo, Yiwa, Hanjie Guo, Xiaolin Sun, Mingtao Mao, and Jing Guo. 2017. "Effects of Austenitizing Conditions on the Microstructure of AISI M42 High-Speed Steel" Metals 7, no. 1: 27. https://doi.org/10.3390/met7010027