Microstructure and Properties of Spark Plasma Sintered Aluminum Containing 1 wt.% SiC Nanoparticles

Abstract

:1. Introduction

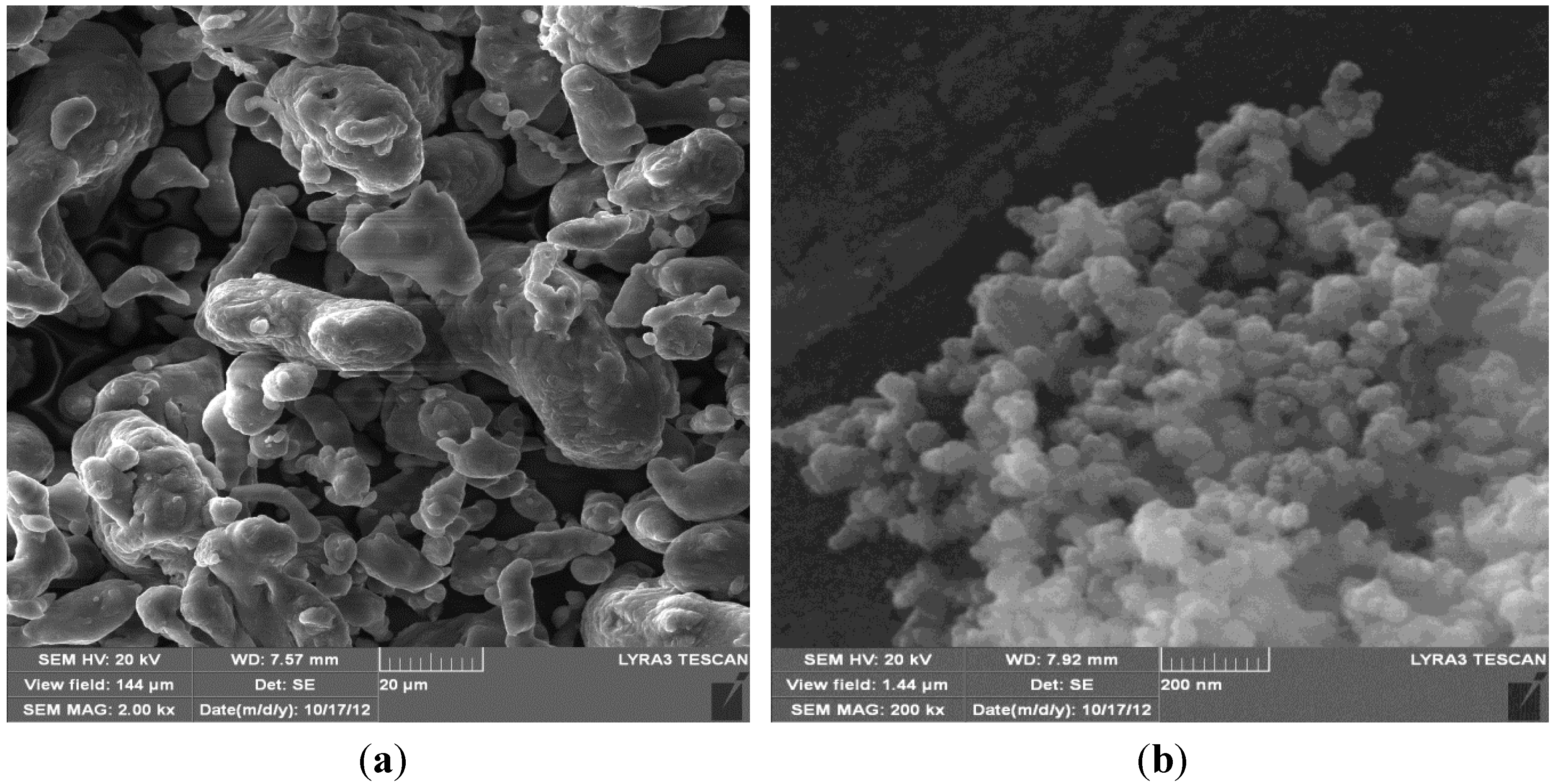

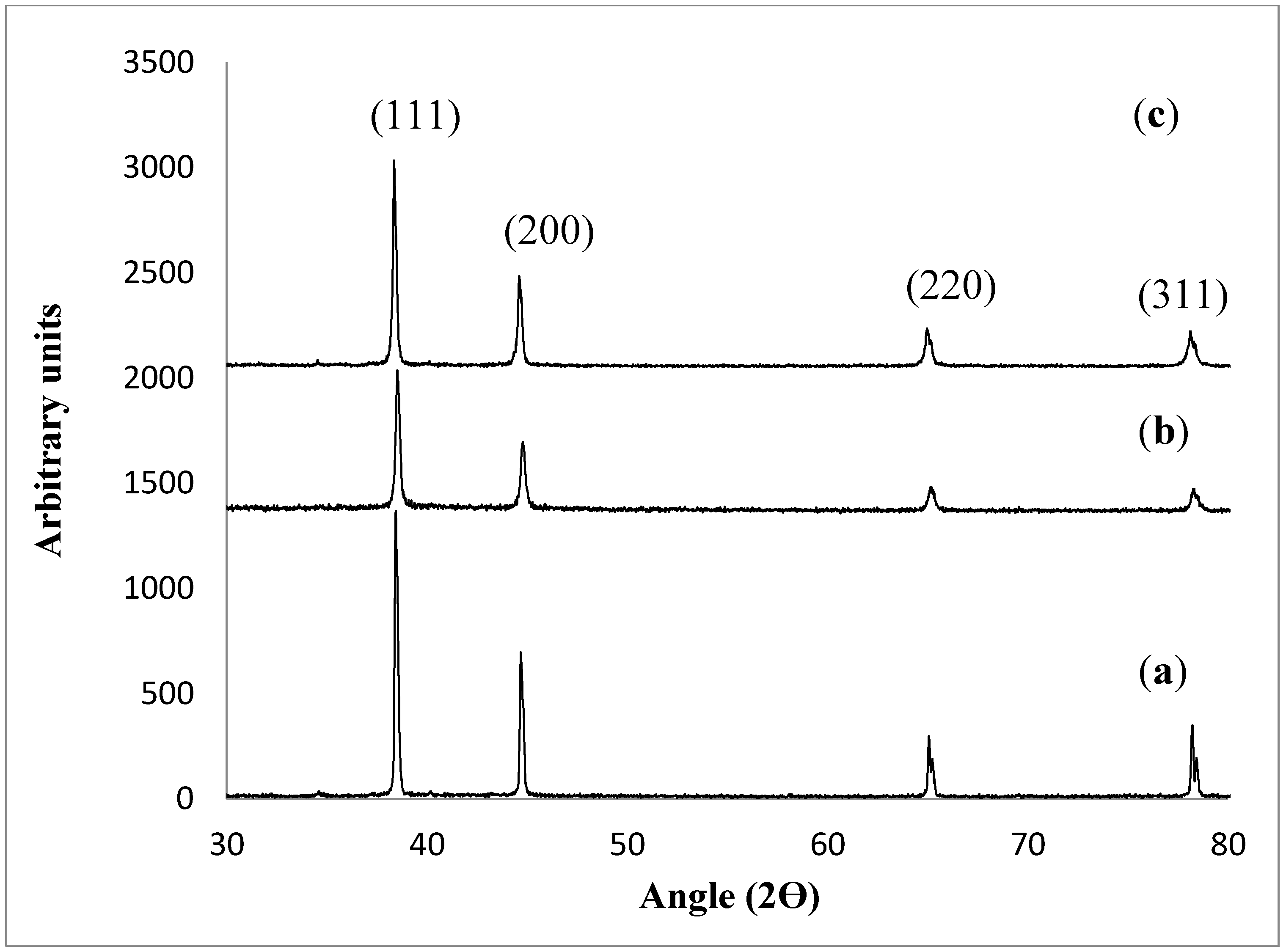

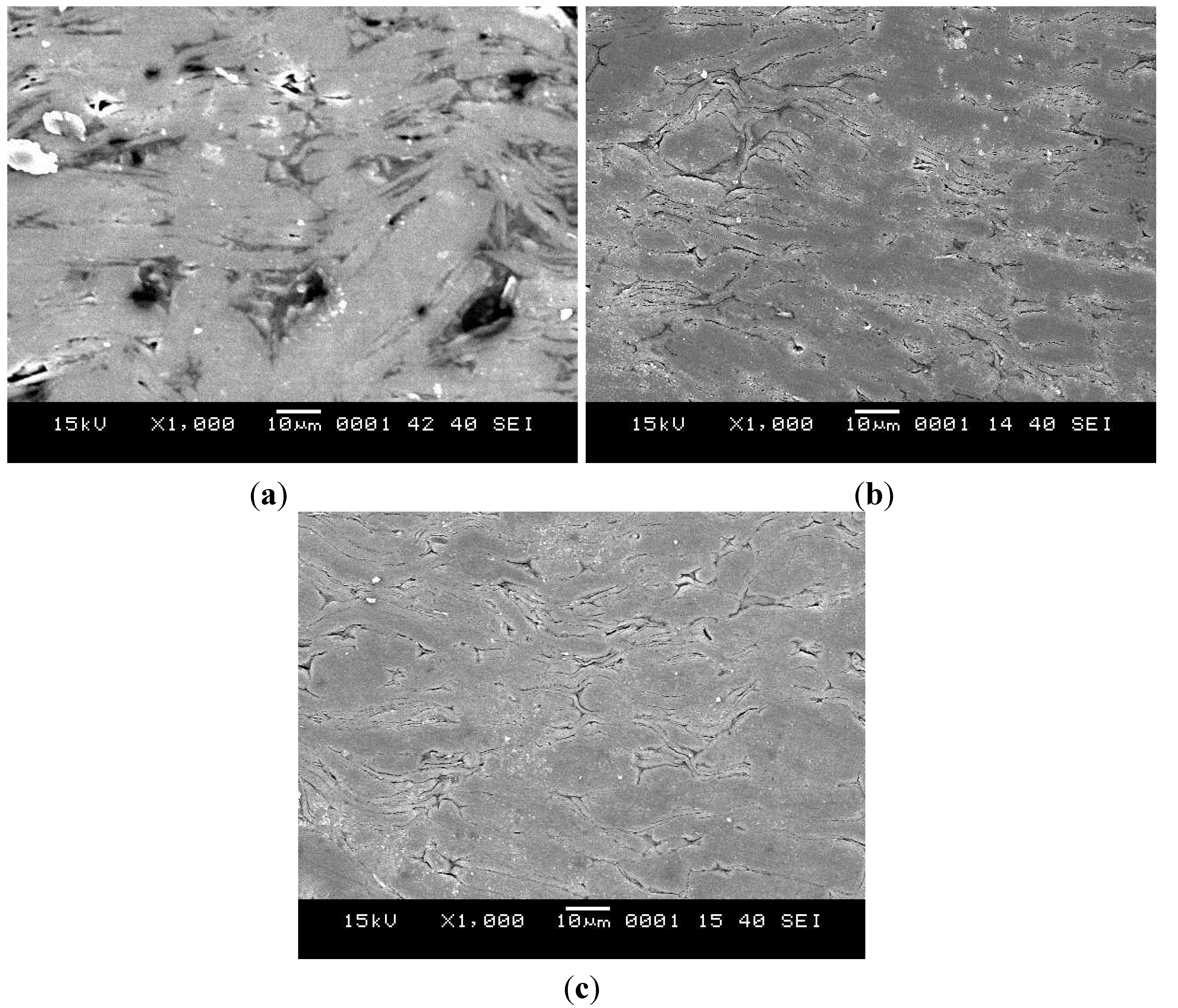

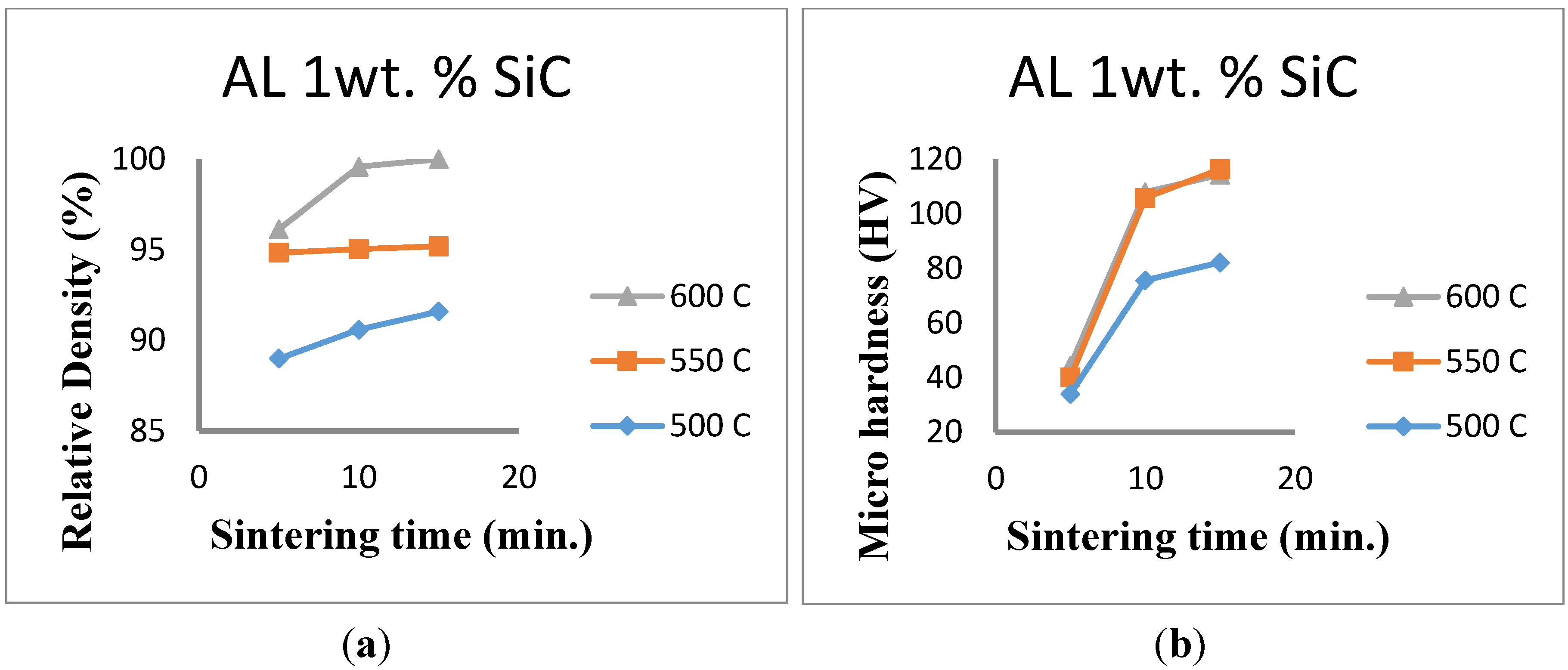

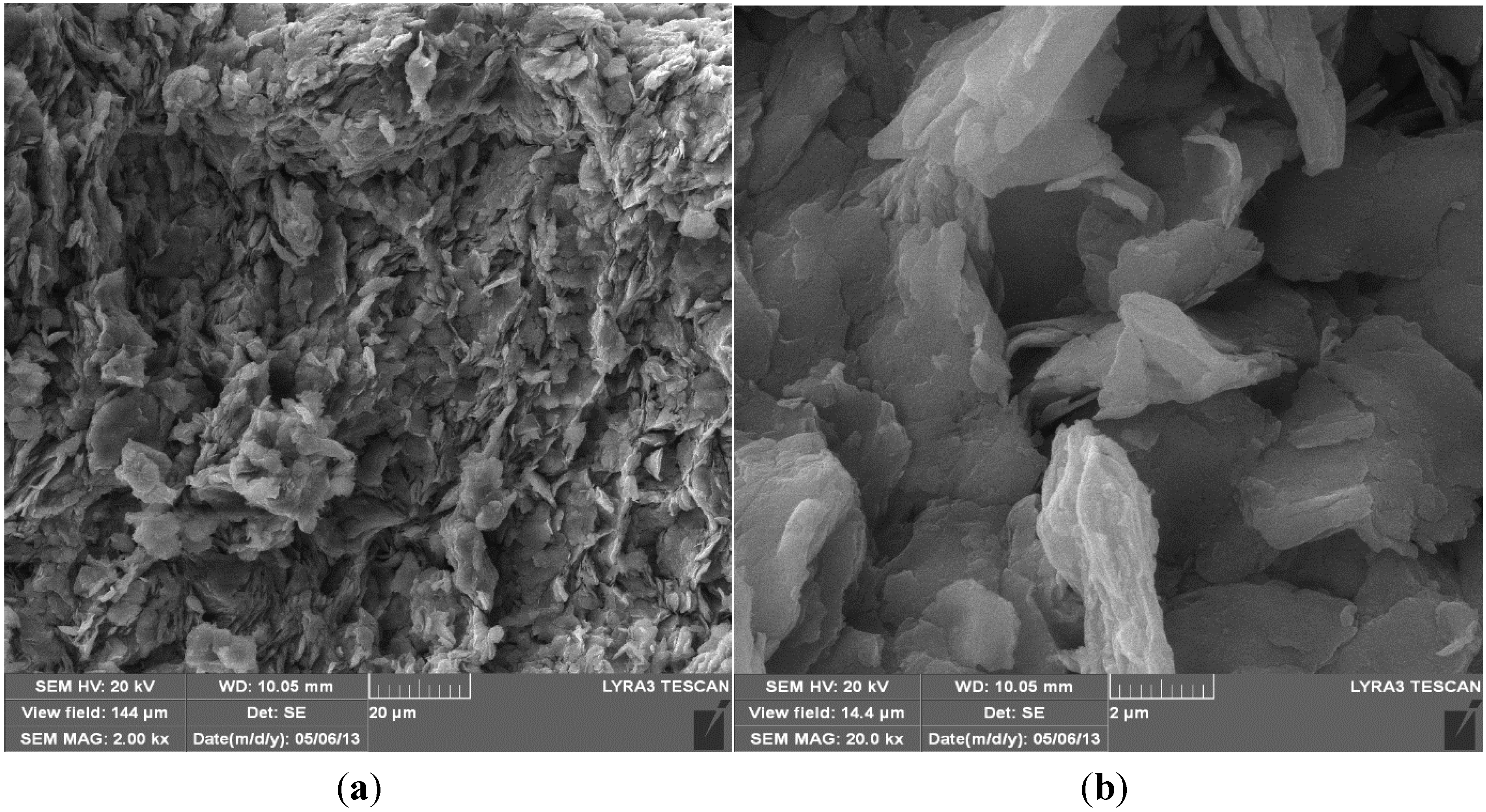

2. Results and Discussion

3. Materials and Experimental Procedures

| SAMPLE | Pressure (MPa) | H.R (K/min) | Temperature (°C) | Time (min) |

|---|---|---|---|---|

| Al-1 wt% SiC-1 | 20 | 100 | 550 | 5 |

| Al-1 wt% SiC-2 | 35 | 100 | 550 | 5 |

| Al-1 wt% SiC-3 | 50 | 100 | 550 | 5 |

| Al-1 wt% SiC-4 | 20 | 200 | 550 | 5 |

| Al-1 wt% SiC-5 | 35 | 200 | 550 | 5 |

| Al-1 wt% SiC-6 | 50 | 200 | 550 | 5 |

| Al-1 wt% SiC-7 | 20 | 300 | 550 | 5 |

| Al-1 wt% SiC-8 | 35 | 300 | 550 | 5 |

| Al-1 wt% SiC-9 | 50 | 300 | 550 | 5 |

| SAMPLE | Temperature (°C) | Time (min) | Pressure (MPa) | H.R (K/min) |

|---|---|---|---|---|

| Al-1 wt% SiC-1 | 500 | 5 | 50 | 200 |

| Al-1 wt% SiC-2 | 550 | 5 | 50 | 200 |

| Al-1 wt% SiC-3 | 600 | 5 | 50 | 200 |

| Al-1 wt% SiC-4 | 500 | 10 | 50 | 200 |

| Al-1 wt% SiC-5 | 550 | 10 | 50 | 200 |

| Al-1 wt% SiC-6 | 600 | 10 | 50 | 200 |

| Al-1 wt% SiC-7 | 500 | 15 | 50 | 200 |

| Al-1 wt% SiC-8 | 550 | 15 | 50 | 200 |

| Al-1 wt% SiC-9 | 600 | 15 | 50 | 200 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bakshi, S.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Rosso, M. Ceramic and metal matrix composites: Routes and properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Saheb, N.; Aliyu, I.; Hassan, S.; Al-Aqeeli, N. Matrix structure evolution and nanoreinforcement distribution in mechanically milled and spark plasma sintered Al-SiC nanocomposites. Materials 2014, 7, 6748–6767. [Google Scholar] [CrossRef]

- Rohatgi, P.; Schultz, B. Lightweight metal matrix nanocomposites-stretching the boundaries of metals. Mater. Matters 2007, 2, 16–19. [Google Scholar]

- Rostamzadeh, T.; Shahverdi, H.R.; Shanaghi, A.; Shahrabi, T. EIS study of bulk Al-SiC nanocomposite prepared by mechanical alloying and the hot press method. Adv. Mater. Res. 2009, 83–86, 1297–1305. [Google Scholar] [CrossRef]

- Sadeghian, Z.; Lotfi, B.; Enayati, M.H.; Beiss, P. Microstructural and mechanical evaluation of Al–TiB2 nanostructured composite fabricated by mechanical alloying. J. Alloy. Compd. 2011, 509, 7758–7763. [Google Scholar] [CrossRef]

- Suryanarayana, C. Synthesis of nanocomposites by mechanical alloying. J. Alloy. Compd. 2011, 509, S229–S234. [Google Scholar] [CrossRef]

- Yu, H. Processing Routes for Aluminum Based Nano-Composites. Master Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2010. [Google Scholar]

- Lan, J.; Yang, Y.; Li, X. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method. Mater. Sci. Eng. A 2004, 386, 284–290. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, J.; Li, X. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Saheb, N.; Qadir, N.U.; Siddiqui, M.U.; Arif, A.F.M.; Akhtar, S.S.; Al-Aqeeli, N. Characterization of nanoreinforcement dispersion in inorganic nanocomposites: A Review. Materials 2014, 7, 4148–4181. [Google Scholar] [CrossRef]

- Yadav, V. Spark plasma sintering of aluminum matrix composites. Master Thesis, Oklahoma State University, Stillwater, OK, USA, 2011. [Google Scholar]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al Aqeeli, N.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark plasma sintering of metals and metal matrix nanocomposites: A review. J. Nanomater. 2012, 2012. [Google Scholar] [CrossRef]

- Singla, M.; Dwivedi, D.D.; Singh, L.; Chawla, V. Development of aluminium based silicon carbide particulate metal matrix composite. J. Miner. Mater. Charact. Eng. 2009, 8, 455–467. [Google Scholar]

- Saberi, Y.; Zebarjad, S.; Akbari, G. On the role of nano-size SiC on lattice strain and grain size of Al/SiC nanocomposite. J. Alloy. Compd. 2009, 484, 637–640. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Sadeghi, M.; Mahmoudi, J. Experimental and theoretical studies on the effect of die temperature on the quality of the products in high-pressure die-casting process. Adv. Mater. Sci. Eng. 2012, 2012. [Google Scholar] [CrossRef]

- Borgonovo, C.; Apelian, D.; Makhlouf, M. Aluminum nanocomposites for elevated temperature applications. JOM J. Miner. Metals Mater. Soc. 2011, 63, 57–64. [Google Scholar]

- Rostamzadeh, T.; Shahverd, H. Microstructure study on AL-5% SiC nanocomposite powders. Iranian J. Mater. Sci. Eng. 2011, 8, 32–39. [Google Scholar]

- Benjamin, J.; Volin, T. The mechanism of mechanical alloying. Metall. Trans. 1974, 5, 1929–1934. [Google Scholar] [CrossRef]

- Gujba, K.A. Development and Characterization of Carbon Nanotubes (CNTs) and Silicon Carbide (SiC) Reinforced Al-Based Nanocomposites. Master Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 2012. [Google Scholar]

- Anselmi-Tamburini, U.; Garay, J.; Munir, Z.; Tacca, A.; Maglia, F.; Spinolo, G. Spark plasma sintering and characterization of bulk nanostructured fully stabilized zirconia: Part I. Densification studies. J. Mater. Res. 2004, 19, 3255–3262. [Google Scholar] [CrossRef]

- Khalil, A. Synthesis and Wear Behaviour of Aluminium 6061 Alloy Reinforced with CNT. Master Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 2012. [Google Scholar]

- Al-Aqeeli, N.; Abdullahi, K.; Hakeem, A.; Suryanarayana, C.; Laoui, T.; Saheb, N. Synthesis, characterisation and mechanical properties of SiC reinforced Al based nanocomposites processed by MA and SPS. Powder Metall. 2012, 56, 149–157. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K.; Sayed, A.; Taher, M.; Lanka, S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminium composites. Compos. Sci. Technol. 2010, 70, 2237–2241. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Shi, L.; Jiang, W.; Chen, L. Rapid fabrication of Ti3SiC2–SiC nanocomposite using the spark plasma sintering-reactive synthesis (SPS-RS) method. Scripta Mater. 2007, 56, 241–244. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, T.; Wang, L.; Jiang, W.; Chen, L. Microstructure and properties of Ti3SiC2/SiC nanocomposites fabricated by spark plasma sintering. Compos. Sci. Technol. 2008, 68, 499–505. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X. Ultrasonic cavitation-based nanomanufacturing of bulk aluminum matrix nanocomposites. J. Manuf. Sci. Eng. 2007, 129, 252–255. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, H.; Cai, M.; Liu, L.; Zhai, P. The dynamic properties of SiCp/Al composites fabricated by spark plasma sintering with powders prepared by mechanical alloying process. Mater. Sci. Eng. A 2009, 527, 218–224. [Google Scholar] [CrossRef]

- El-Daly, A.; Abdelhameed, M.; Hashish, M.; Daoush, W.M. Fabrication of silicon carbide reinforced aluminum matrix nanocomposites and characterization of its mechanical properties using non-destructive technique. Mater. Sci. Eng. A 2013, 559, 384–393. [Google Scholar] [CrossRef]

- Bathula, S.; Anandani, R.C.; Dhar, A.; Srivastava, A.K. Microstructural features and mechanical properties of Al 5083/SiCp metal matrix nanocomposites produced by high energy ball milling and spark plasma sintering. Mater. Sci. Eng. A 2012, 545, 97–102. [Google Scholar] [CrossRef]

- Daly, R.; Khitouni, M.; Kolsi, A.W.; Njah, N. The studies of crystallite size and microstrains in aluminum powder prepared by mechanical milling. Phys. Status Solid. 2006, 3, 3325–3331. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Kandukuri, S.; Froyen, L. Consolidation enhancement in spark-plasma sintering: Impact of high heating rates. J. Appl. Phys. 2007, 102. [Google Scholar] [CrossRef]

- Bathula, S.; Anandani, R.; Dhar, A.; Srivastava, A. Synthesis and characterization of Al-alloy/SiCp nanocomposites employing high energy ball milling and spark plasma sintering. Adv. Mater. Res. 2012, 410, 224–227. [Google Scholar] [CrossRef]

- Ohser-Wiedemann, R.; Martin, U.; Seifert, H.J.; Müller, A. Densification behaviour of pure molybdenum powder by spark plasma sintering. Int. J. Refract. Metals Hard Mater. 2010, 28, 550–557. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Kwon, H.; Park, D.H.; Park, Y.; Silvain, J.F.; Kawasaki, A.; Park, Y. Spark plasma sintering behavior of pure aluminum depending on various sintering temperatures. Metals Mater. Int. 2010, 16, 71–75. [Google Scholar] [CrossRef]

- Kwon, H.; Cho, S.; Leparoux, M.; Kawasaki, A. Dual-nanoparticulate-reinforced aluminum matrix composite materials. Nanotechnology 2012, 23, 225704. [Google Scholar] [CrossRef] [PubMed]

- Khalil, A.; Hakeem, A.S.; Saheb, N. Optimization of process parameters in spark plasma sintering Al6061 and Al2124 aluminum alloys. Adv. Mater. Res. 2011, 328–330, 1517–1522. [Google Scholar] [CrossRef]

- Saheb, N. Spark plasma sintering of Al6061 and Al2124 alloys. Adv. Mater. Res. 2011, 284, 1656–1660. [Google Scholar]

- Garay, J.E. Current-activated, pressure-assisted densification of materials. Annu. Rev. Mater. Res. 2010, 40, 445–468. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, W.; Chen, L.; Bai, S. Rapid reactive synthesis and sintering of submicron TiC/SiC composites through spark plasma sintering. J. Am. Ceram. Soc. 2004, 87, 1157–1160. [Google Scholar] [CrossRef]

- Munoz-Morris, M.; Garcia Oca, C.; Morris, D. An analysis of strengthening mechanisms in a mechanically alloyed, oxide dispersion strengthened iron aluminide intermetallic. Acta Mater. 2002, 50, 2825–2836. [Google Scholar] [CrossRef]

- Dai, L.; Ling, Z.; Bai, Y. A strain gradient-strengthening law for particle reinforced metal matrix composites. Scripta Mater. 1999, 41, 245–252. [Google Scholar] [CrossRef]

- Chawla, N.; Shen, Y.-L. Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles-a review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Aliyu, I.K. Effect of Process Parameters on Microstructure and Properties of Spark Plasma Sintered Al-SiC Nanocomposites. Master Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 2013. [Google Scholar]

- Le, G.; Godfrey, A.; Hansen, N. Structure and strength of aluminium with sub-micrometer/micrometer grain size prepared by spark plasma sintering. Mater. Des. 2013, 49, 360–367. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aliyu, I.K.; Saheb, N.; Hassan, S.F.; Al-Aqeeli, N. Microstructure and Properties of Spark Plasma Sintered Aluminum Containing 1 wt.% SiC Nanoparticles. Metals 2015, 5, 70-83. https://doi.org/10.3390/met5010070

Aliyu IK, Saheb N, Hassan SF, Al-Aqeeli N. Microstructure and Properties of Spark Plasma Sintered Aluminum Containing 1 wt.% SiC Nanoparticles. Metals. 2015; 5(1):70-83. https://doi.org/10.3390/met5010070

Chicago/Turabian StyleAliyu, Ismaila Kayode, Nouari Saheb, Syed Fida Hassan, and Nasser Al-Aqeeli. 2015. "Microstructure and Properties of Spark Plasma Sintered Aluminum Containing 1 wt.% SiC Nanoparticles" Metals 5, no. 1: 70-83. https://doi.org/10.3390/met5010070

APA StyleAliyu, I. K., Saheb, N., Hassan, S. F., & Al-Aqeeli, N. (2015). Microstructure and Properties of Spark Plasma Sintered Aluminum Containing 1 wt.% SiC Nanoparticles. Metals, 5(1), 70-83. https://doi.org/10.3390/met5010070