Grain Refinement and High-Performance of Equal-Channel Angular Pressed Cu-Mg Alloy for Electrical Contact Wire

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

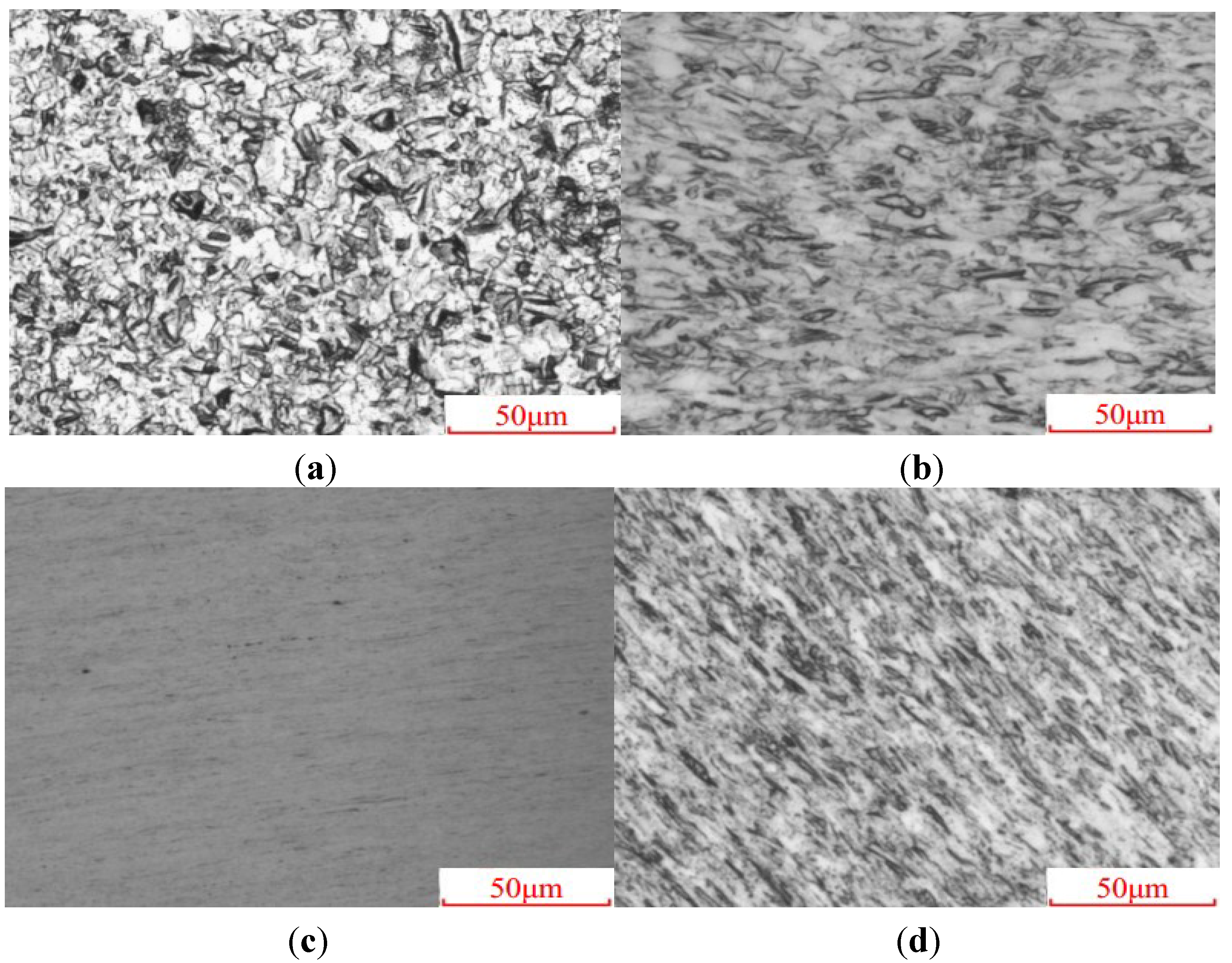

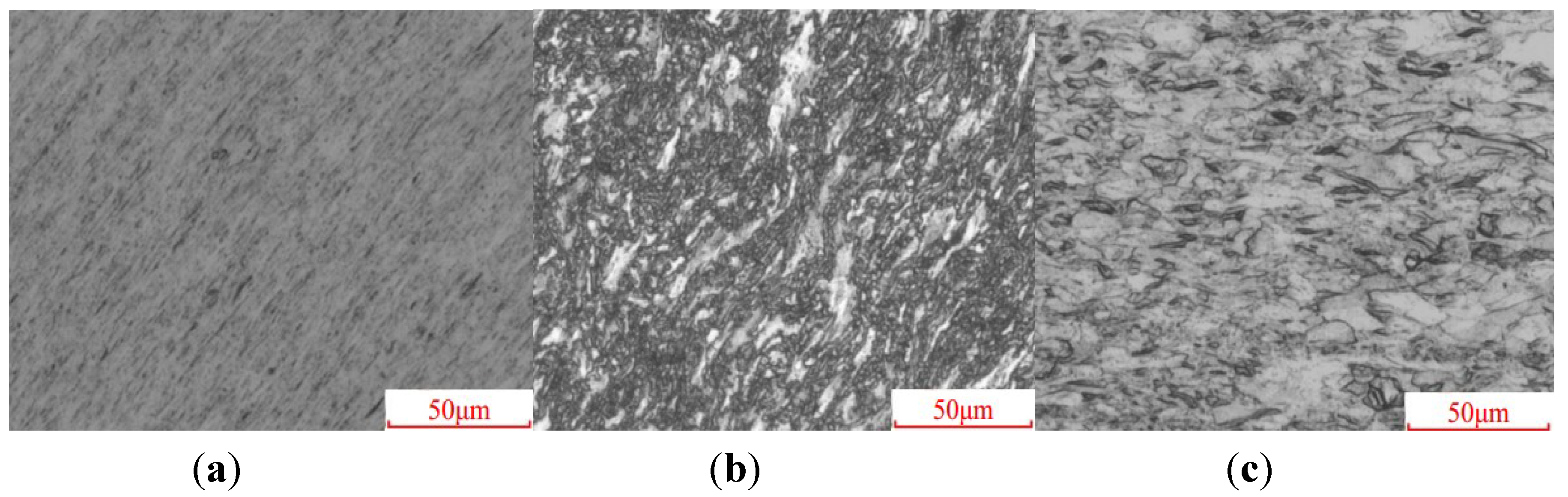

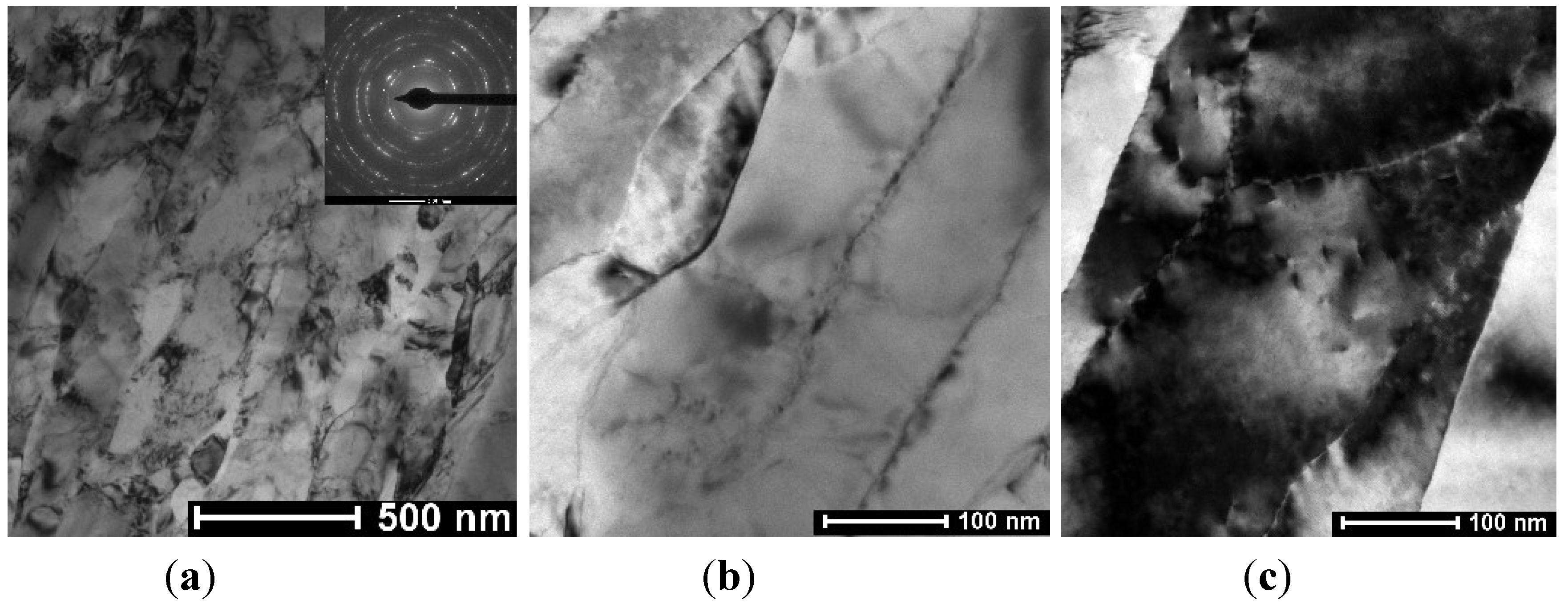

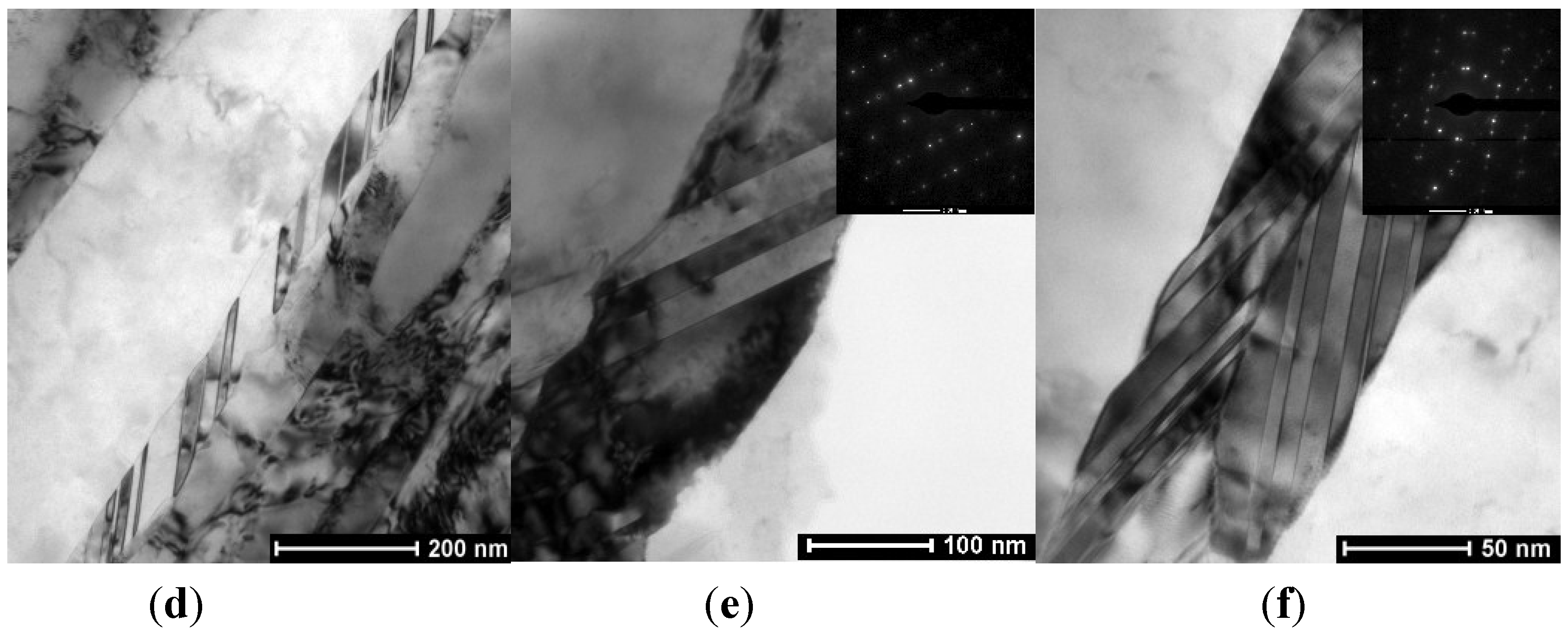

3.1. Microstructure

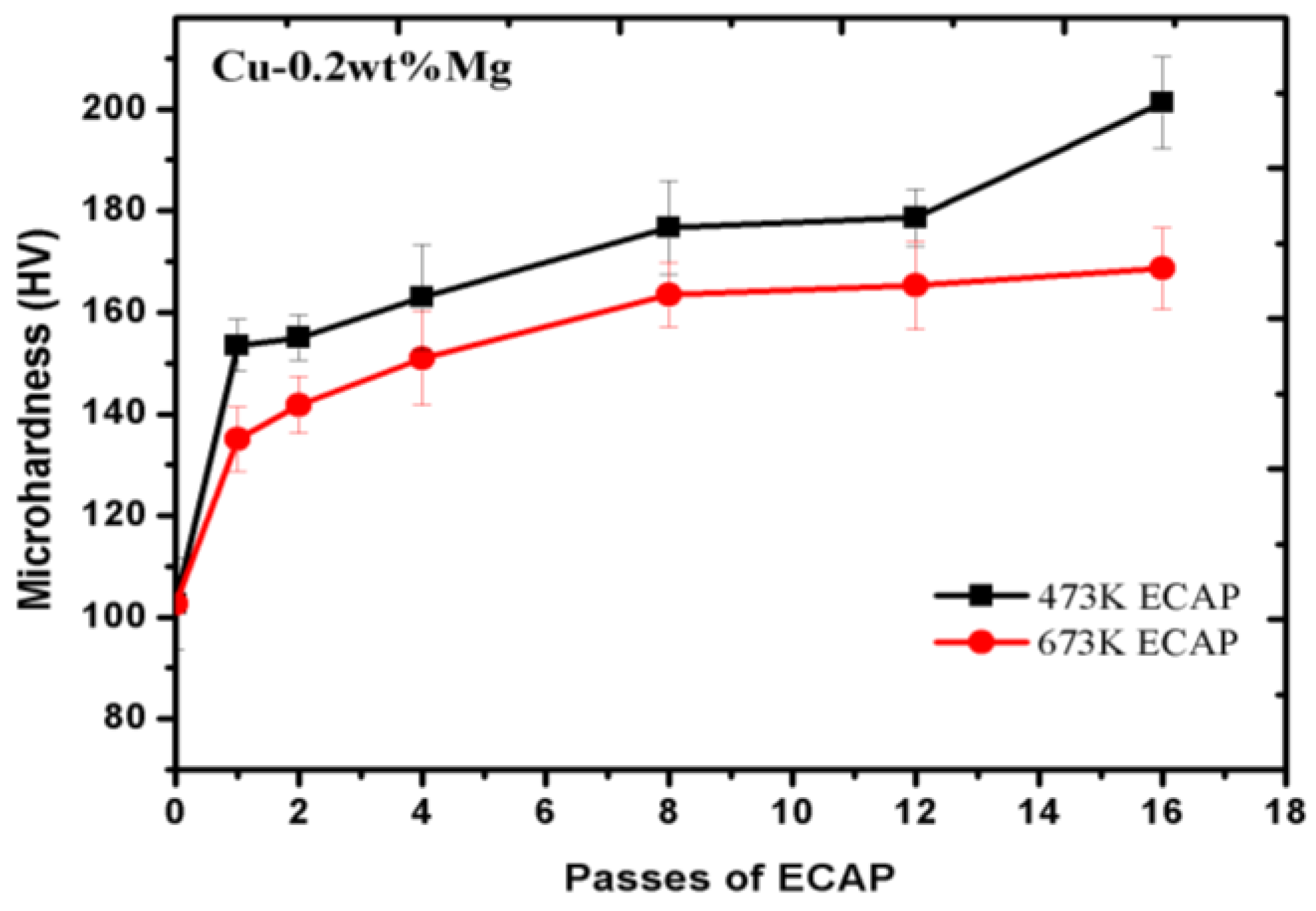

3.2. Microhardness

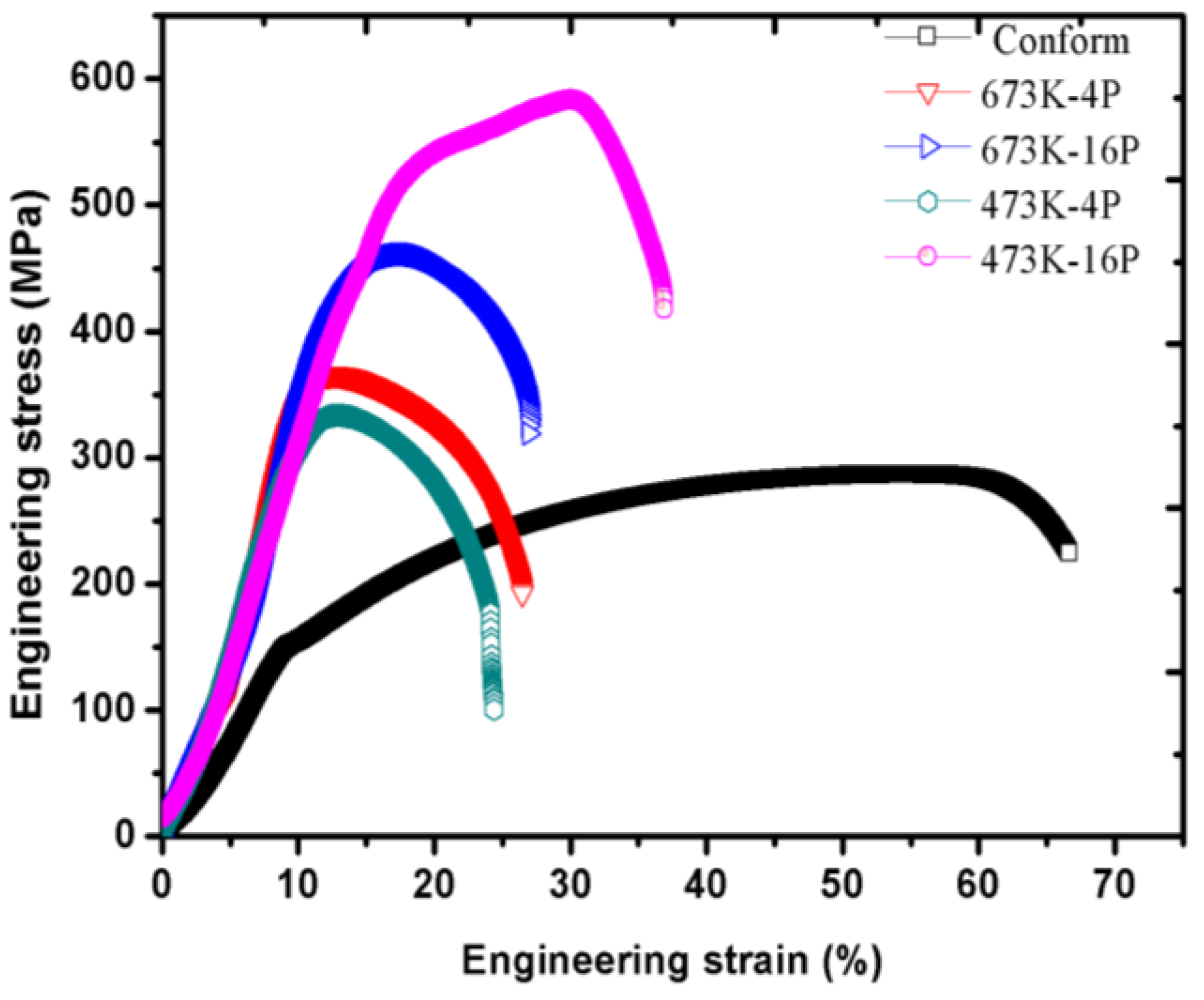

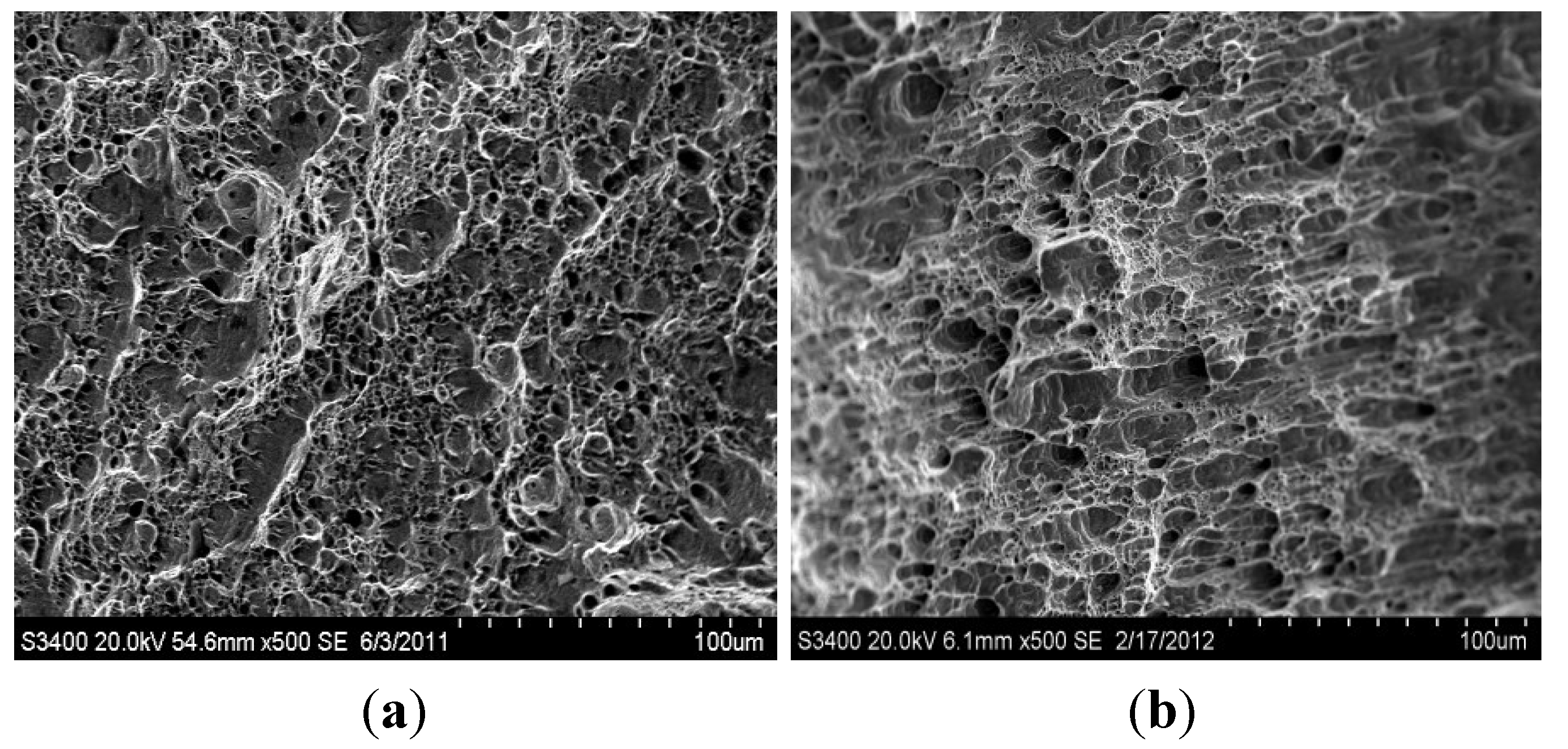

3.3. Tensile Properties

| Sample | Microhardness (HV) | Ultimate tensile stress (MPa) | Total elongation (%) |

|---|---|---|---|

| Conform | 102.6 | 286.4 | 66.7 |

| 473 K-4 P | 162.9 | 333.2 | 24.7 |

| 473 K-16 P | 201.2 | 583.4 | 37.9 |

| 673 K-4 P | 150.9 | 365.5 | 22.5 |

| 673 K-16 P | 168.6 | 461.1 | 26.9 |

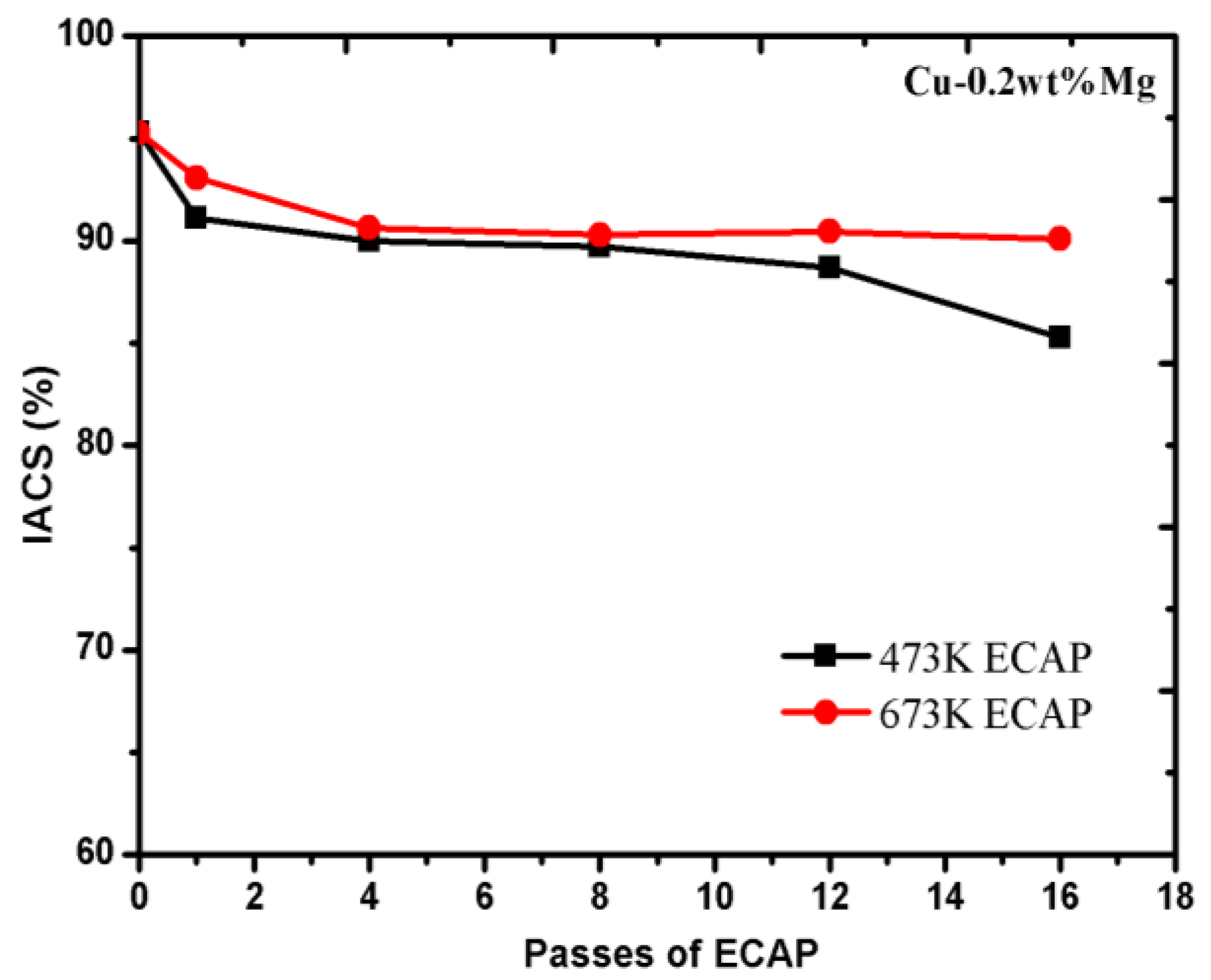

3.4. Conductivity

4. Conclusions

- (1)

- Multi-pass ECAP processing, compared with cold drawing, improves grain refinement effect of the Conformed Cu-0.2wt%Mg alloy. More passes of ECAP leads to finer grains, and the grain size of the 16-pass sample ECAPed at 473 K is about 200 nm.

- (2)

- Compared with the as-achieved sample in Conform state, the ones after multi-pass ECAP exhibit much higher strength with adequate ductility. The ECAPed samples for 16 passes have much higher strength and better ductility than those for less passes.

- (3)

- With increasing the ECAP pass, hardness and strengthen of the ECAPed samples increased obviously but the conductivity decreased gradually. However, the conductivity of the Cu-0.2wt%Mg alloy after Conform plus ECAP is still much higher than that of the current Cu-0.4wt%Mg product processed by Conform plus cold drawing.

- (4)

- Conform plus ECAP provides a simple and effective procedure to obtain high strength and good conductivity Cu-Mg alloy, in comparison with current Conform plus cold drawing. After Conform plus ECAP for 16 passes at 473 K, Cu-0.2wt%Mg alloy exhibits superior tensile strength (583.4 MPa), adequate total elongation (37.9%), good conductivity (84.5% IACS), and high hardness (201.2 HV).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [PubMed]

- Han, K.; Walsh, R.P.; Ishmaku, A.; Toplosky, V.; Brandao, L.; Embury, J.D. High strength and high electrical conductivity bulk Cu. Pilos. Mag. A 2004, 84, 3705–3716. [Google Scholar]

- Wei, K.X.; Wei, W.; Wang, F.; Du, Q.B.; Alexandrov, I.V.; Hu, J. Microstructure, mechanical properties and electrical conductivity of industrial Cu-0.5% Cr alloy processed by severe plastic deformation. Mater. Sci. Eng. A 2011, 528, 1478–1484. [Google Scholar] [CrossRef]

- Sakai, Y.; Schneider-Muntau, H.J. Ultra-high strength, high conductivity Cu-Ag alloy wires. Acta Mater. 1997, 45, 1017–1023. [Google Scholar] [CrossRef]

- Saarivirta, M.J. High conductivity copper-rich Cu-Zr alloys. Trans. Metall. Soc. AIME 1960, 218, 431–437. [Google Scholar]

- Embury, J.D.; Han, K. Conductor materials for high field magnets. Curr. Opin. Solid State Mater. Sci. 1998, 3, 304–308. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed]

- Reiss, G.; Vancea, J.; Hoffmann, H. Grain-boundary resistance in polycrystalline metals. Phys. Rev. Lett. 1986, 56, 2100–2103. [Google Scholar] [CrossRef] [PubMed]

- Fernee, H.; Nairn, J.; Atrens, A. Cold worked Cu-Fe-Cr alloys. J. Mater. Sci. 2001, 36, 5497–5510. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Torre, F.D.; Lapovok, R.; Sandlin, J.; Thomson, P.F.; Davies, C.H.J.; Pereloma, E.V. Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Wang, J.; Horita, Z.; Nemoto, M.; Langdon, T.G. Principles of equal-channel angular pressing for the processing of ultra-fine grained materials. Script. Mater. 1996, 35, 143–146. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Yamashita, A.; Yamaguchi, D.; Horita, Z.; Langdon, T.G. Influence of pressing temperature on microstructural development in equal-channel angular pressing. Mater. Sci. Eng. A 2000, 287, 100–106. [Google Scholar] [CrossRef]

- Huang, J.Y.; Zhu, Y.T.; Jiang, H.; Lowe, T.C. Microstructure and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater. 2001, 49, 1497–1505. [Google Scholar] [CrossRef]

- Shaarbaf, M.; Toroghinejad, M.R. Nano-grained copper strip produced by accumulative roll bonding process. Mater. Sci. Eng. A 2008, 473, 28–33. [Google Scholar] [CrossRef]

- Habibi, A.; Ketabchi, M.; Eskandarzade, M. Nano-grained pure copper with high-strength and high-conductivity produced by equal channel angular rolling process. J. Mater. Process. Technol. 2011, 6, 1085–1090. [Google Scholar] [CrossRef]

- Dannenberg, R.; King, A.H. Behavior of grain boundary resistivity in metals predicted by a two-dimensional model. J. Appl. Phys. 2000, 88, 2623–2633. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, A.; Zhu, C.; Chen, J.; Jiang, J.; Song, D.; Ni, S.; He, Q. Grain Refinement and High-Performance of Equal-Channel Angular Pressed Cu-Mg Alloy for Electrical Contact Wire. Metals 2014, 4, 586-596. https://doi.org/10.3390/met4040586

Ma A, Zhu C, Chen J, Jiang J, Song D, Ni S, He Q. Grain Refinement and High-Performance of Equal-Channel Angular Pressed Cu-Mg Alloy for Electrical Contact Wire. Metals. 2014; 4(4):586-596. https://doi.org/10.3390/met4040586

Chicago/Turabian StyleMa, Aibin, Chengcheng Zhu, Jianqing Chen, Jinghua Jiang, Dan Song, Shizhan Ni, and Qing He. 2014. "Grain Refinement and High-Performance of Equal-Channel Angular Pressed Cu-Mg Alloy for Electrical Contact Wire" Metals 4, no. 4: 586-596. https://doi.org/10.3390/met4040586