1. Introduction

There are several known methods, by which one can reduce the grain size of a casting, including: addition of inoculants/grain refining agents, increasing solidification rate, and by controlling the pouring temperature. Ning

et al. [

1], and recently Ferguson

et al. [

2] have shown that for several aluminum alloys of commercial significance, reducing the pouring temperature leads to a reduction in grain size; the degree of which depends on the superheat and the solidification rate. In addition to the above effects, it has also been demonstrated that vibration of liquid melts during solidification can result in grain refinement [

3,

4]. This grain refinement effect has been shown to result from “grain multiplication,” where dendrites separate from the cool surfaces of the mold as they form due to convection or vibrational forces in the melt that cause remelting, or bending and breaking of dendrite roots [

3,

4,

5,

6,

7,

8,

9].

One method of inducing vibration in liquid melts, ultrasonic treatment (UST), has received particular attention for nearly 80 years [

10,

11,

12] as a potential means to induce grain refinement. Numerous researchers have proposed that vibrating a liquid metal at ultrasonic frequencies (typically ~20 kHz) causes cavitation, which can reduce the grain size by (a) inducing local changes in the melting temperature due to the collapse of bubbles (Clapeyron equation) [

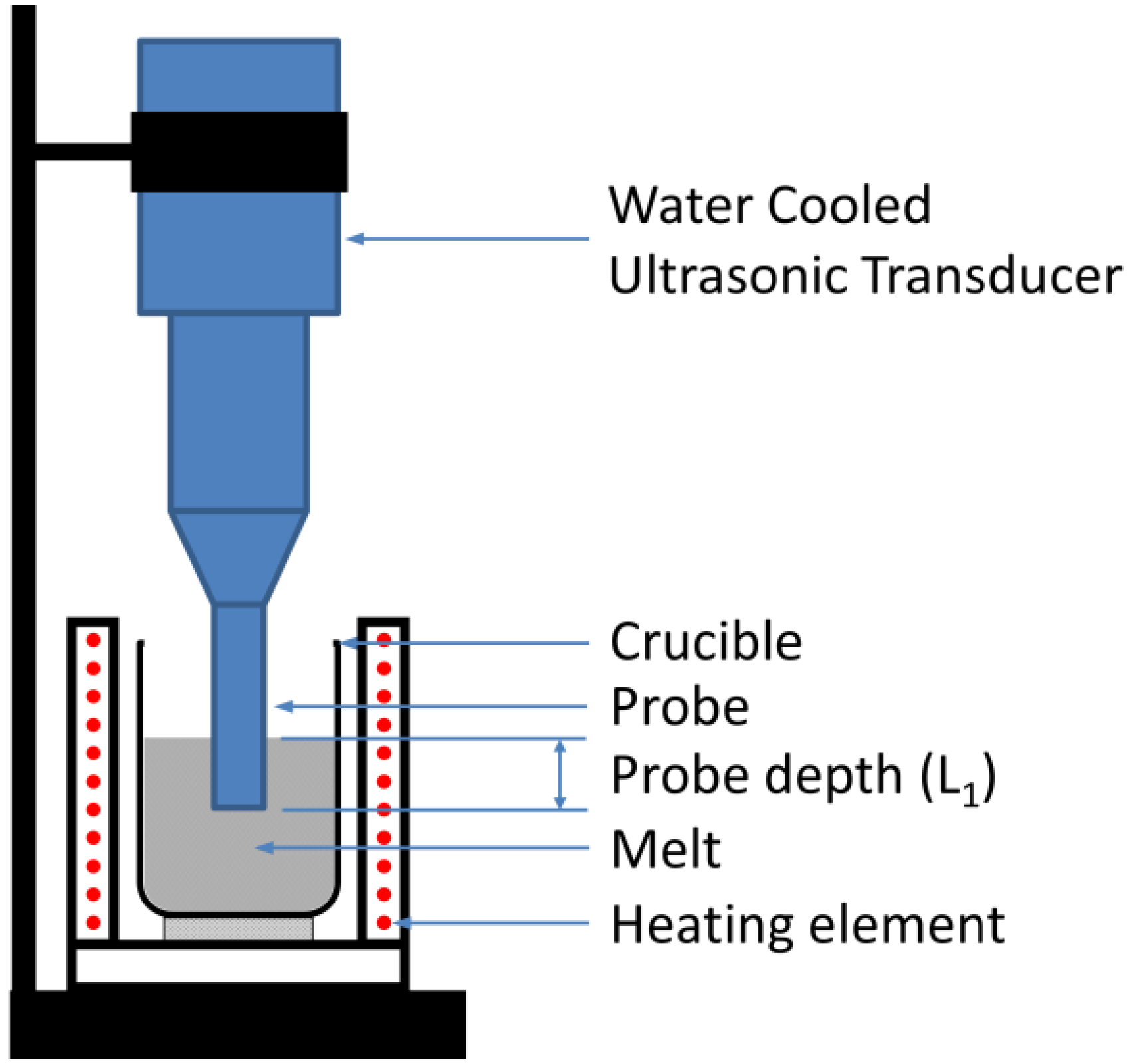

13]; (b) improving wetting of insoluble nucleant particles; and (c) breakage of crystals as they form caused by flow from acoustic streaming or vibration of the horn. Typical experiments involve dipping a water-cooled waveguide (a.k.a. probe or horn) into the liquid metal that is contained in a crucible as shown in

Figure 1. Following treatment, the melt is cast in a mold or left to solidify in the crucible. Many experimental studies omit representative controls as the effects that the UST apparatus has on the cast microstructure are considered to be negligible. It is generally assumed that, while there is no experimental means to directly confirm that either of the cavitation induced mechanisms previously described have occurred [

14], cavitation effects are solely responsible for grain refinement.

Figure 1.

Schematic of typical setup for ultrasonic irradiation of liquid metal melts.

What seems to have been universally overlooked in these studies is the effect that the immersion of a cooled horn has on the liquid melt temperature and eventual pouring temperature. To function at high temperatures, ultrasonic probe systems must be water-cooled. Even if preheated to the temperature of the liquid on the end to be immersed, the probe still acts as a chill with the water-cooled end extracting heat from molten liquid via the immersed end. This heat flow produces a cold region surrounding the horn and leads to localized solidification and a lower average liquid temperature.

As mentioned earlier, it has been shown that the grain size of the liquid metal is intimately connected with the pouring temperature of the liquid, the temperature of the mold and the cooling rate of the entire system. In order to gauge any effect of UST, the pouring/casting temperature (at a minimum) must be measured. The following critical review of the current literature on ultrasonic processing of liquid metals examines the reports of improved grain refinement when UST is conducted via a horn inserted in the liquid as shown in

Figure 1, then casting the melt in a separate mold. An experimental study is then presented which attempts to separate the effects of ultrasonic cavitation from the effects of pouring/casting temperature.

Critique on Effects of Ultrasonic Irradiation on Grain Size of Metals

Khalifa

et al. [

15] studied the effect of UST on the microstructure of Al alloy A356 at different treatment temperatures and times. The alloy charge (230–245 g) was first heated to 650–660 °C in an alumina crucible (dimensions not provided), and then the crucible containing the melt was transferred to a separate furnace modified such that a water-cooled MoB/CoCr coated hot worked tool steel ultrasound horn (diameter not provided) can be inserted into the melt to a depth of 5–10 mm through the top of the furnace. UST was applied at 19.5 kHz and 26 W/cm

2 (amplitude not provided) in seven effective temperature ranges (608–609, 610–613, 614–615, 617–623, 619–623, 622–625, 626–628) for periods of 15, 30, 90, and 180 s. After treatment, the ultrasound was turned off and the melt was cast in a steel mold heated to 90–100 °C. For comparison, specimens were cast at temperatures of 620 and 614 °C. Above the liquidus temperature (619 °C), grain size was found to decrease with decreasing treatment temperature, but typically coarsened slightly with increasing UST time. As a result of their study, the researchers claim that in the temperature regime above the liquidus temperature, UST produces finer grains for the same cooling rate as a result of the activation of inclusions. This conclusion is questionable, because (a) cooling rate depends somewhat on the pouring temperature and (b) Ning

et al. [

1] and Ferguson

et al. [

2] have shown that for consistent mold conditions, grain size increases significantly with increasing pour temperature in A356 from 625 to 725 °C; thus the refinement could potentially be due to the pouring temperature with only a minor potential contribution of grain refining from UST. Unfortunately, the researchers did not cast samples untreated by ultrasound at the same pouring/casting temperatures as those that did receive a treatment to try to isolate any effect of UST in refining the grains and therefore cannot definitively prove any effect of UST.

At temperatures near (when longer treatment times are examined) or below the liquidus temperature, the grain size was found to first jump above the grain size obtained in 620 °C castings that were sonicated, but then decreased with decreasing temperature with a mixture of coarse and fine-grained material. The researchers claim that UST is not effective in grain refining in a semi-solid below the liquidus, possibly because fewer inclusions are activated or because the dendrites are not effectively broken in this temperature range. However, they fail to consider that the rate of cooling from the melt temperature to hold temperature will affect the number and size of nuclei present in the melt when the liquid finally reaches a temperature below the liquidus. Thus, when the semi-solid is cast, the final grain size of the solid will derive partially from the quantity and size of nuclei already present that may have formed on the water-cooled probe. This is a fundamentally different situation than what is occurring when a liquid is cast, as nuclei are not formed until solidification has begun in the mold. Given that the rate of cooling is significantly higher in the mold than in the slowly cooled crucible in which the UST was applied, the larger grain size in the semi-solid casting is likely a result of the nuclei already present in the crucible and that the grain refinement at the lower temperature is due to lower pouring temperature. Also, nuclei created in the semi-solid after it has been poured into the mold will be smaller and result in finer structure. Therefore, the mix of grain sizes results from the mix of nuclei formed in the crucible (large) and nuclei formed in the mold (small).

Zhang

et al. [

16] studied the effects of cooling rate and UST on the microstructures of a variety of aluminum alloys as shown in

Table 1. Different cooling rates were achieved by treating the specimens with ultrasound (amplitude of 40 µm, frequency, intensity, horn dimensions and depth were not reported) in a certain temperature range, then pouring the melt in either a graphite mold (0.8 K/s), copper mold (2.0 K/s), through a launder to a steel mold (2.0 K/s), or by direct chill (DC) casting (6.0 K/s). In the case of the graphite crucible and copper mold experiments, ultrasound was supplied directly to the alloy in the crucible until the target pouring temperature was reached; then the alloy was poured in the appropriate mold. In the case of the launder and the DC casting methods, the ultrasound was supplied in a launder that fed a mold, rather than in the crucible. It can be seen from

Table 1 that UST can result in either a refinement in the grain size or a coarsening in grain size, depending on the alloy and the mold type or cooling rate. For example, in the case of the Al-0.4Zr-0.12Ti, the size of Al

3Zr intermetallics decreased from 50–100 to 5–10 μm after UST, however the grain size increased from 115 to 185 μm. In a similar work published by the same group [

17], Al-Zr-Ti alloys treated with ultrasound and then cast into a copper mold had a finer grain size than the alloy cast without UST. The authors attribute these seemingly contradictory results to the need for a critical undercooling to be reached to nucleate grains from intermetallics of a given size. The UST process results in a refinement of the first formed intermetallics in the liquid (as shown in

Table 1), which causes the critical undercooling to increase. Casting the alloy in a graphite crucible does not provide a sufficient undercooling to achieve grain refinement, while casting in a copper mold does provide sufficient undercooling. A similar argument is given to explain the results when UST is performed on AA2024, AA7075 and Al-3.9Cu alloys containing TiB

2 intermetallics. The DC casting method (cooling rate of 6 K/s) results in an undercooling sufficient to nucleate grains on the UST refined TiB

2 particles, while the 2 K/s cooling rate (and resulting undercooling) for the AA7075 and AA2024 alloys was not sufficient. Moreover, there is little evidence from this work that UST directly affects the grain size, as equivalent control specimens were not produced.

Table 1.

Processing parameters and grain size of UST and non-UST aluminum alloys (adapted from [16]).

| Alloy | Additive | State | UST start Temp. (°C) | UST Stop/Pouring Temp. (°C) | Mold | Cooling Rate (K/s) | Temp of Phase formation (°C) | Phase size (μm) | Grain size (µm) |

|---|

| Al-0.4Zr-0.12Ti | - | UST | 790 | 750 | graphite | 0.8 | 790 (Al3Zr); 662 (Al) | 5–10 | 185 |

| Al-0.4Zr-0.12Ti | - | NO UST | - | 790 | graphite | 0.8 | 790 (Al3Zr); 662 (Al) | 50–100 | 115 |

| Al-0.4Ti | - | UST | 720 | 680 | copper | 2 | 766 (Al3Ti); 660 (Al) | 3–8 | 65 |

| Al-0.4Ti | - | NO UST | - | 720 | copper | 2 | 766 (Al3Ti); 660 (Al) | 20–80 | 90 |

| AA2024 | Al3Ti1B | UST | 750 | 700 | copper | 2 | 646 (Al) | - | 138 |

| AA2024 | Al3Ti1B | NO UST | - | 720 | copper | 2 | 646 (Al) | - | 116 |

| AA7075 | 0.2Zr-0.07Ti | UST | 720 | 640 | Launder to steel mold | 2 | 765 (Al3Zr); 639 (Al) | - | 45 |

| AA7075 | 0.2Zr-0.07Ti | NO UST | - | Unknown | Launder to steel mold | 2 | 765 (Al3Zr); 639 (Al) | - | 350 |

| AA7075 | Al3Ti1B | UST | 720 | 640 | Launder to steel mold | 2 | 765 (Al3Zr); 639 (Al) | - | 155 |

| AA7075 | Al3Ti1B | NO UST | - | Unknown | Launder to steel mold | 2 | 765 (Al3Zr); 639 (Al) | - | 135 |

| Al-3.9Cu | Al3Ti1B | UST | 693 | Unknown | DC Casting | 6 | 650 (Al) | - | 30 |

| Al-3.9Cu | Al3Ti1B | NO UST | - | Unknown | DC Casting | 6 | 650 (Al) | - | 60 |

Aghayani and Niroumand [

18] studied the effect of UST with a water-cooled probe (frequency of 20 kHz, insertion depth 5 mm, amplitude, and horn dimensions were not reported) on the microstructure of Mg alloy AZ91 cast in a sodium silicate bonded sand mold. The melt temperature was brought to 700 °C in an electric muffle furnace; then the Ultrasound horn was inserted in the melt and held in place for 5 min to treat the sample at intensities of 0% (ultrasound horn not turned on), 20%, 40% and 60% of the maximum power (600 W). The melt was then removed from the furnace and cast in the sand mold. The size of the intermetallics identified in the castings decreased with increasing UST power. The tensile strength was also shown to increase with increasing UST intensity, indicative of the presence of grain refinement. Several possible mechanisms for the refinement of the various intermetallics formed, based on cavitation are posited by the authors, however as the pouring temperature was not measured, the refinement could also be attributed to differences in casting temperature. While the authors did insert the water-cooled horn in the melt without applying ultrasound for the same period of time, the resulting temperature of the melt is likely not as homogenous as in the sonicated melts, where solids forming on the probe will be knocked off when the waveguide is removed and mixed into the surrounding liquid.

In an interesting study by Nie

et al. [

19], an Mg alloy AZ91 melt was sonicated at 700 °C for 20 min (20 kHz, frequency, 350 W power, 20 mm probe depth; amplitude, and probe dimensions not provided) and cast in a preheated (450 °C) steel mold capable of pressurizing the melt to 100 MPa. Prior to casting, the melt temperature was elevated to 720 °C, to match the casting temperature of their control specimen which did not receive UST. Selected specimens were heat treated to the T4 condition. UST had no observable effect on the grain size when compared to the control specimen. The yield stress of the as-cast specimens was un-effected by UST, as would be expected due to the similar grain size, however some improvement in the ultimate tensile strength (UTS) and percentage elongation was shown in the UST specimens. The authors attribute this improvement to the formation of larger lamellar Mg

17Al

12 phases in the UST specimens compared to the more continuous plate-like Mg

17Al

12 phases that formed in the control specimens. It is possible that the mixing effect of UST resulted in a more uniform melt composition prior to casting, which has been shown to alter the intermetallic morphology and solubility of Al and Zn in the Mg matrix in the case of electromagnetically stirred Mg-AZ91 [

20]. The T4 heat-treated UST specimens showed no observable change in the yield stress, UTS and percent elongation, compared to the control specimen.

From the above review of data, it seems clear that UST is able to produce mixing of the liquid and thereby reduce or eliminate thermal and compositional gradients. However, it is unclear whether the evidence is strong enough to support either of the proposed cavitation-induced mechanisms. Rather, the results seem to be explained equally well by cooling rate and casting temperature influences. In the following sections, experiments designed to isolate thermal effects from cavitation-induced effects are described to help clarify the effects of UST on grain size in aluminum alloy A356.

2. Results and Discussion

Table 2 shows the results of grain size measurements for the different conditions tested. In this table the term “casting time” refers to the time at which the crucible was removed from the furnace and the metal was poured in the mold (further explanation of the experiments conducted are provided in

Section 3 of this manuscript). Note that in the cases of 750 °C melting temperature where the horn was immersed but no UST was applied, there was a considerable amount of solid metal around the horn and therefore the amount of liquid was insufficient to fill the mold.

Table 2.

Experimental parameters and measured grain size at 25.4, 76.2, and 127.0 mm from bottom of casting.

| Tmelt (°C) | UST | Contact Time (s) | Hold Time (s) | Casting Time (s) | Tcast (°C) | Grain Size (mm) |

|---|

| Horn | Applied | 25.4 | 76.2 | 127 |

|---|

| 610 | No | No | 0 | 0 | 0 | 610 | 0.11 | 0.13 | 0.16 |

| 750 | No | No | 0 | 0 | 0 | 750 | 0.65 | 0.69 | 0.91 |

| Yes | 30 | 0 | 30 | 630 | 0.31 | 0.37 | -- |

| Yes | 60 | 0 | 60 | 626 | 0.19 | 0.24 | -- |

| Yes | Yes | 30 | 0 | 30 | 608 | 0.09 | 0.15 | 0.18 |

| Yes | 30 | 60 | 90 | 611 | 0.11 | 0.13 | 0.16 |

| Yes | 30 | 120 | 150 | 616 | 0.12 | 0.16 | 0.18 |

| Yes | Yes | 60 | 0 | 60 | 609 | 0.11 | 0.14 | 0.17 |

| Yes | 60 | 60 | 120 | 606 | 0.09 | 0.11 | 0.12 |

| Yes | 60 | 120 | 180 | 606 | 0.09 | 0.10 | 0.12 |

| 850 | No | No | 0 | 0 | 0 | 850 | 0.83 | >2 | >2 |

| 950 | No | No | 0 | 0 | 0 | 950 | 1.35 | >2 | >2 |

| Yes | 30 | 0 | 30 | 688 | 1.15 | 1.35 | >2 |

| Yes | 60 | 0 | 60 | 654 | 0.72 | 0.88 | 1.26 |

| Yes | Yes | 30 | 0 | 30 | 681 | 0.27 | 0.34 | 0.44 |

| Yes | 30 | 60 | 90 | 726 | 0.49 | 0.58 | 0.71 |

| Yes | 30 | 120 | 150 | 739 | 0.50 | 0.66 | 0.82 |

| Yes | Yes | 60 | 0 | 60 | 682 | 0.28 | 0.38 | 0.41 |

| Yes | 60 | 60 | 120 | 722 | 0.49 | 0.55 | 0.74 |

| Yes | 60 | 120 | 180 | 754 | 0.61 | 0.68 | 0.83 |

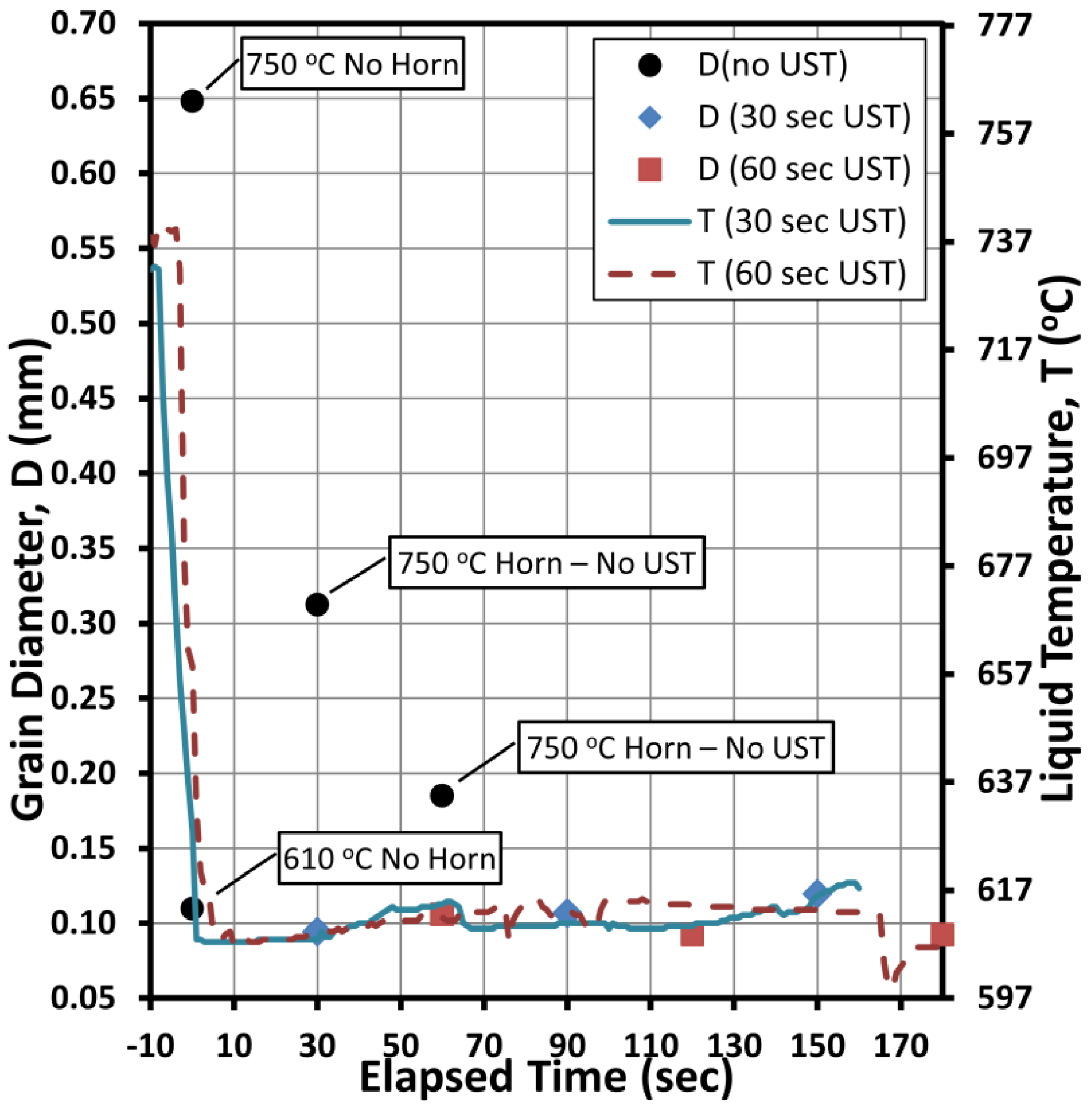

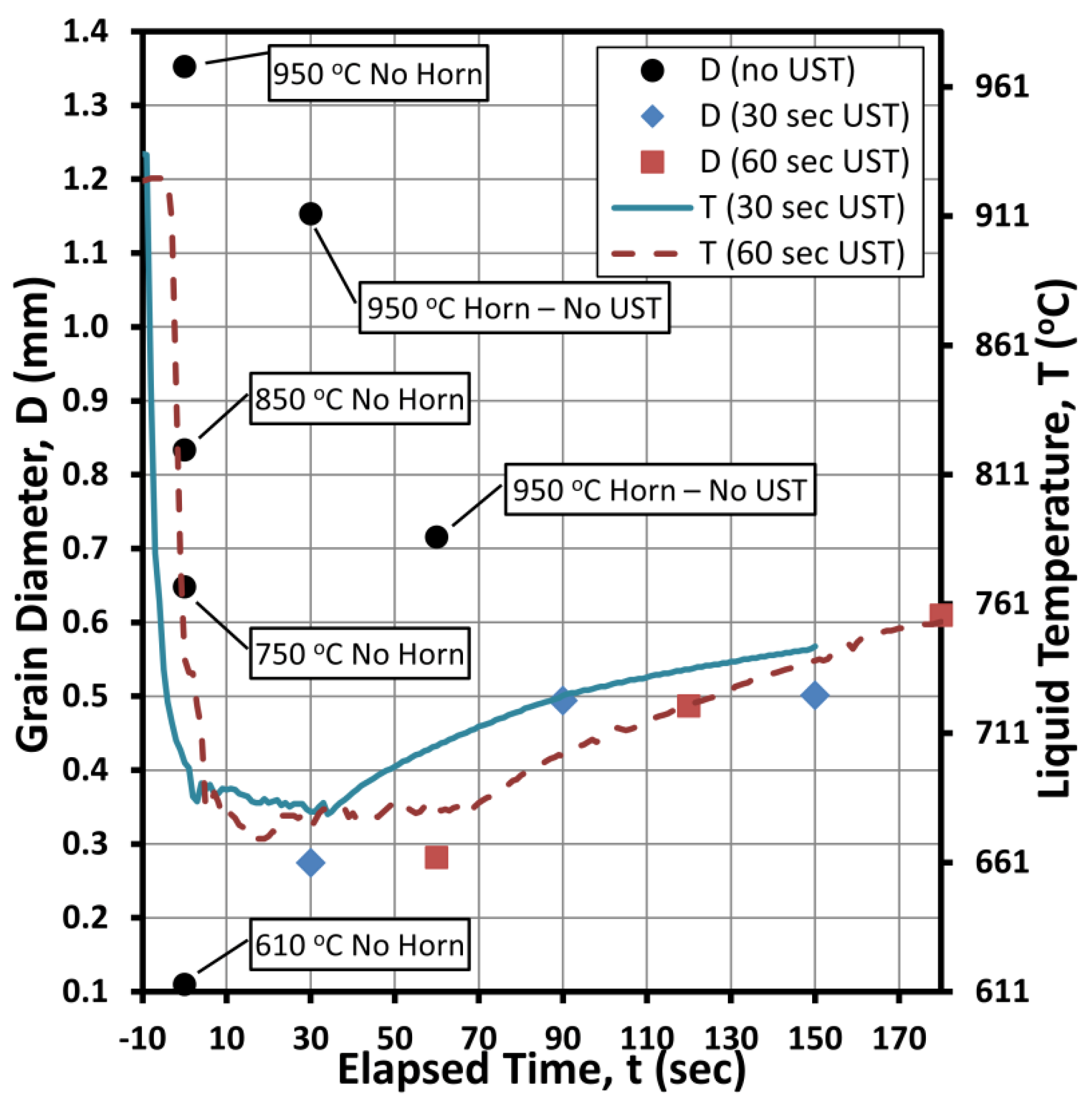

Figure 2 and

Figure 3 clearly show that for untreated samples, lower melt/casting temperature causes a significant decrease in grain size. The figures also show that immersion of the horn alone (without UST) produces smaller grains with increasing horn immersion time, which is undoubtedly a result of the chill effect of the un-preheated horn, especially in light of the large pucks of solid metal that formed around the horn at 750 °C and the smaller pucks that formed around the horn at 950 °C.

Immersion coupled with UST left very little solid metal on the horn and resulted in significantly smaller grains as can be seen in

Figure 2 and

Figure 3.

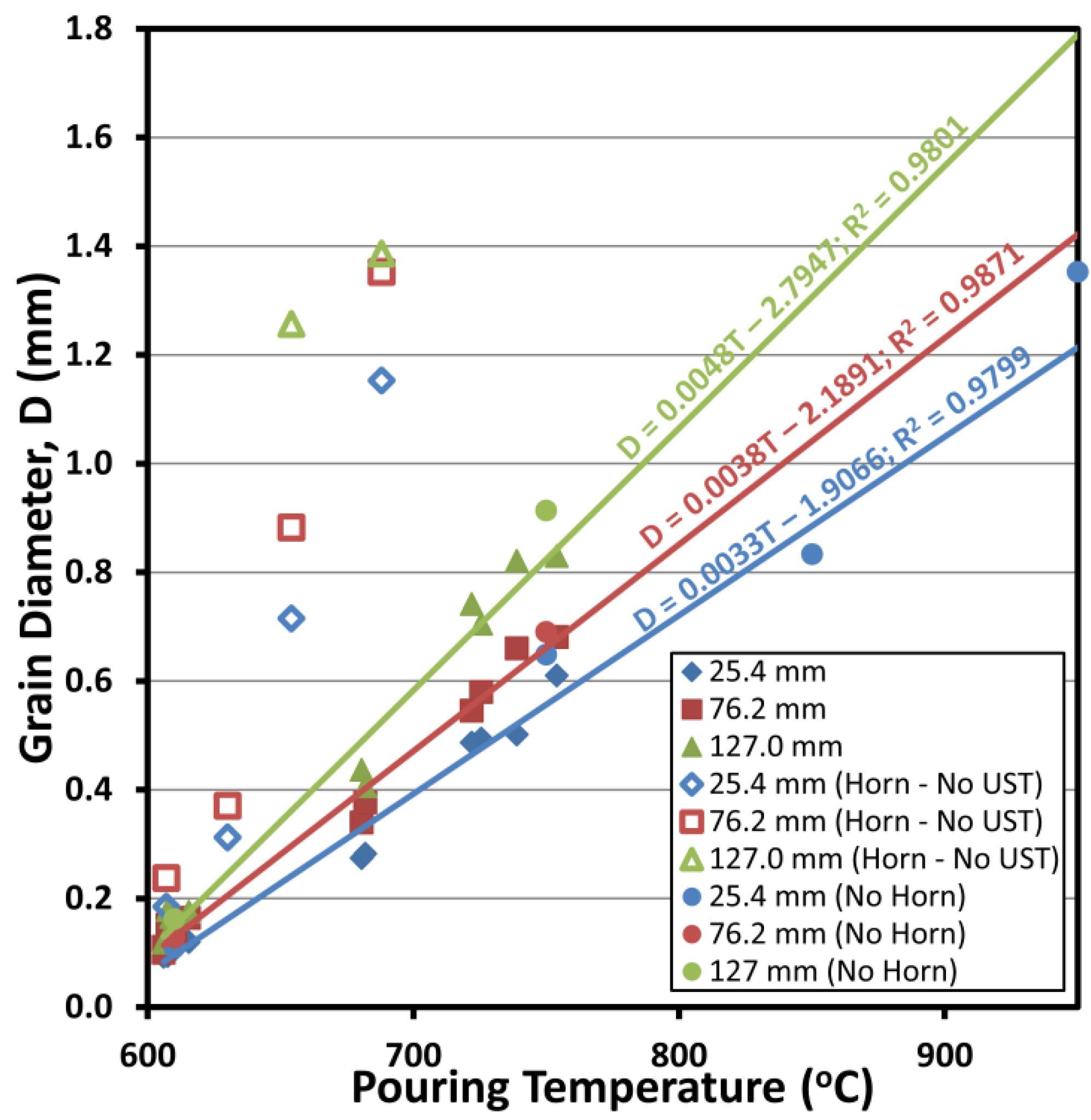

Figure 4, which was obtained by plotting the grain size against the pouring temperature for each experiment, shows an approximately linear dependence of grain size on casting temperature. Superimposing the sonicated liquid temperature history onto

Figure 2 and

Figure 3 using this linear scaling shows that there is very good agreement between grain size and liquid temperature at the time of pouring/casting. Also, for the specimens subjected to UST at 750 °C, UST resulted in lowering the temperature to approximately 610 °C, which is well below the liquidus. Heat input by the furnace was insufficient to significantly increase the temperature even after the horn was removed, resulting in a relatively constant temperature near 610 °C under both sonication times and all hold times. Since all 750 °C UST experiments were essentially cast at about 610 °C and all grain sizes are roughly the same as the grain sizes of the sample that was not treated and cast at 610 °C, it must be concluded that UST did not enhance nucleation by either of the theoretical cavitation-induced schemes. The grain size of the UST experiments at 950 °C also seems to follow the cooling curves equally well, leading to the same conclusion.

Figure 2.

Variation of grain diameter at 25.4 mm from bottom of casting and liquid temperature with elapsed time for Al-A356 melted at 750 °C for various ultrasonic treatments.

Figure 3.

Variation of grain diameter at 25.4 mm from bottom of casting and liquid temperature with elapsed time for Al-A356 melted at 950 °C for various ultrasonic treatments.

Figure 4.

Variation of grain diameter at 25.4, 76.2, and 127.0 mm from bottom of casting with pouring temperature.

While UST does not appear to enhance nucleation, it is clear that the application of ultrasound has an effect on the measured melt temperature. It was previously observed that the “Horn-No UST” specimens had finer grains than the “No Horn” specimens poured at the same start temperature (750 or 950 °C), indicative of a lower pouring temperature. However, the measured grain sizes in the “Horn-No UST” specimens were larger than what would be predicted for the sonicated specimens at equivalent treatment times as shown in

Figure 4. Considering the behavior of these experiments, it has already been stated that solid formed around the horn and therefore the casting was made from whatever liquid remained. In these cases, solidification begins rapidly at the surface of the unheated horn. Vigorous mixing is absent as UST was not applied and the chill therefore retards convection. Owing to this a thermal gradient develops with temperature near 750 or 950 °C at the crucible wall, and approximately the liquidus temperature (620 °C) in the mushy zone of the solid/liquid interface. The average liquid temperature must be somewhere between these extreme values with the average liquid temperature being high when there is little solid and decreasing as solid is formed. Though composition of the liquid becomes richer in solute with increasing solid fraction, this change in composition can be considered relatively small initially and it can be assumed that the average liquid temperature should always remain above the liquidus but decrease with longer immersion times.

Table 2 shows that the measured temperature of the liquid immediately after removing the horn was always above the liquidus and decreased with increasing immersion time, as expected.

In the experiments conducted at a starting temperature of 750 °C, where the horn was immersed without applying ultrasound, there was considerably less liquid to be cast as a result of the solid left on the horn. The grains that formed in those castings were large and columnar rather than fine and equiaxed as there was less time for grain multiplication by dendrite shear or stem remelting to occur. In the same experiments conducted at 950 °C, there was far less solid left on the horn and the pouring temperature was considerably higher than the liquidus, which could lead one to expect grain sizes to be commensurate with the sonicated specimens or the specimens cast at similar temperatures. However, despite the higher starting temperature, the chill quickly creates columnar grains on its surface. Due to reduced convection at the chill surface, there is less grain multiplication and any dendrites that are dislodged by natural convection will likely be larger than in sonicated melts. Also, some of the grains at the solidification front, which are relatively large, would be expected to be dislodged when removing the horn. Therefore, the remaining liquid in this case contains large grains and nuclei which continue to grow after the liquid is poured into the mold, thus resulting in a larger grain size or a mixture of small and large grain sizes as reported by Khalifa

et al. [

9] in their samples treated below the liquidus.

When UST was applied, it is likely that roughly the same amount of solid formed as when it was not applied. However, mixing from the vibration of the horn causes considerably more nuclei to form as fine dendrites, rather than columnar grains. Due to vibration of the horn, the dendrites that form at the horn become dislodged at the solidification front and are distributed throughout the liquid, thereby forming a semi-solid slurry. Because mixing destroys temperature and concentration gradients, the average temperature of the metal in the crucible is that of the semi-solid, which is between the liquidus and solidus temperatures. As a result, the average temperature of the pourable material in the sonicated specimens (semi-solid at 610 °C) is lower than that of the pourable material that was not sonicated (liquid between 620 and 750 °C) resulting in finer grains.