Particle Stimulated Nucleation Effect for Al-Mg-Zr-Sc Alloys with Ni Addition during Multidirectional Forging

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure of Alloys before MDF

3.2. Stress–Strain Behavior during MDF

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Kawasaki, M.; Ahn, B.; Kumar, P.; Jang, J.I.; Langdon, T.G. Nano- and Micro-Mechanical Properties of UltrafineGrained Materials Processed by Severe Plastic Deformation. Adv. Eng. Mater. 2017, 19, 1600578. [Google Scholar] [CrossRef]

- Murashkin, M.; Medvedev, A.; Kazykhanov, V.; Krokhin, A.; Raab, G.; Enikeev, N.; Valiev, R.Z. Enhanced Mechanical Properties and Electrical Conductivity in Ultrafine-Grained Al 6101 Alloy Processed via ECAP-Conform. Metals 2015, 5, 2148–2164. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-Five Years of Ultrafine-Grained Materials: Achieving Exceptional Properties through Grain Refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons Inc.: New York, NY, USA, 2014. [Google Scholar]

- Avtokratova, E.; Sitdikov, O.; Mukhametdinova, O.; Markushev, M.; Murty, S.N.; Prasad, M.J.N.V.; Kashyap, B.P. Microstructural Evolution in Al–Mg–Sc–Zr Alloy during Severe Plastic Deformation and Annealing. J. Alloys Compd. 2016, 673, 182–194. [Google Scholar] [CrossRef]

- Zayed, E.M.; Shazly, M.; El-Sabbagh, A.; El-Mahallawy, N.A. Deformation Behavior and Properties of Severe Plastic Deformation Techniques for Bulk Materials: A Review. Heliyon 2023, 9, e16700. [Google Scholar] [CrossRef] [PubMed]

- Asadi, S.; Kazeminezhad, M. Multi Directional Forging of 2024 Al Alloy After Different Heat Treatments: Microstructural and Mechanical Behavior. Trans. Indian Inst. Met. 2017, 70, 1707–1719. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mikhaylovskaya, A.V.; Kotov, A.D.; Mosleh, A.O.; AbuShanab, W.S.; Portnoy, V.K. Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al-Mg-Mn Alloy. Materials 2018, 11, 2166. [Google Scholar] [CrossRef] [PubMed]

- Markushev, M.V.; Avtokratova, E.V.; Sitdikov, O.S. Effect of the Initial State on Nanostructuring and Strengthening of Middle- and High-Strength Age-Hardenable Aluminum Alloys under Severe Plastic Deformation (Review). Lett. Mater. 2017, 7, 459–464. [Google Scholar] [CrossRef]

- Buranova, Y.; Kulitskiy, V.; Peterlechner, M.; Mogucheva, A.; Kaibyshev, R.; Divinski, S.V.; Wilde, G. Al3(Sc,Zr)-Based Precipitates in Al–Mg Alloy: Effect of Severe Deformation. Acta Mater. 2017, 124, 210–224. [Google Scholar] [CrossRef]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured Aluminium Alloys Produced by Severe Plastic Deformation: New Horizons in Development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Sabirov, I.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Metals for Innovative Applications. JOM 2012, 64, 1134–1142. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural Evolutions of Metallic Materials Processed by Severe Plastic Deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Sakai, T.; Miura, H.; Goloborodko, A.; Sitdikov, O. Continuous Dynamic Recrystallization during the Transient Severe Deformation of Aluminum Alloy 7475. Acta Mater. 2009, 57, 153–162. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Goloborodko, A.; Miura, H.; Kaibyshev, R. Effect of Pass Strain on Grain Refinement in 7475 Al Alloy during Hot Multidirectional Forging. Mater. Trans. 2004, 45, 2232–2238. [Google Scholar] [CrossRef]

- Mulyukov, R.R.; Imayev, R.M.; Nazarov, A.A. Production, Properties and Application Prospects of Bulk Nanostructured Materials. J. Mater. Sci. 2008, 43, 7257–7263. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kotov, A.D.; Kishchik, M.S.; Prosviryakov, A.S.; Portnoy, V.K. The Effect of Isothermal Multi-Directional Forging on the Grain Structure, Superplasticity, and Mechanical Properties of the Conventional Al–Mg-Based Alloy. Metals 2019, 9, 33. [Google Scholar] [CrossRef]

- Aoba, T.; Kobayashi, M.; Miura, H. Effects of Aging on Mechanical Properties and Microstructure of Multi-Directionally Forged 7075 Aluminum Alloy. Mater. Sci. Eng. A 2017, 700, 220–225. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, L.; Ban, C.; Zhao, Z.; Zuo, Y.; Cui, J. Structure Uniformity and Limits of Grain Refinement of High Purity Aluminum during Multi-Directional Forging Process at Room Temperature. Trans. Nonferrous Met. Soc. China 2014, 24, 1301–1306. [Google Scholar] [CrossRef]

- Padap, A.K.; Chaudhari, G.P.; Nath, S.K.; Pancholi, V. Ultrafine-Grained Steel Fabricated Using Warm Multiaxial Forging: Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2009, 527, 110–117. [Google Scholar] [CrossRef]

- Sitdikov, O.; Garipova, R.; Avtokratova, E.; Mukhametdinova, O.; Markushev, M. Effect of Temperature of Isothermal Multidirectional Forging on Microstructure Development in the Al-Mg Alloy with Nano-Size Aluminides of Sc and Zr. J. Alloys Compd. 2018, 746, 520–531. [Google Scholar] [CrossRef]

- Miura, H.; Nakamura, W. Microstructure and Mechanical Properties of Mg–8Al Alloy Fabricated by Room-Temperature Multi-Directional Forging. Philos. Mag. Lett. 2013, 93, 601–607. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Cui, Z. Microstructures and Mechanical Properties of AZ61 Magnesium Alloy after Isothermal Multidirectional Forging with Increasing Strain Rate. Mater. Sci. Eng. A 2015, 643, 32–36. [Google Scholar] [CrossRef]

- Armstrong, P.E.; Hockett, J.E.; Sherby, O.D. Large Strain Multidirectional Deformation of 1100 Aluminum at 300 K. J. Mech. Phys. Solids 1982, 30, 37–58. [Google Scholar] [CrossRef]

- Rao, P.N.; Singh, D.; Jayaganthan, R. Mechanical Properties and Microstructural Evolution of Al 6061 Alloy Processed by Multidirectional Forging at Liquid Nitrogen Temperature. Mater. Des. 2014, 56, 97–104. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme Grain Refinement by Severe Plastic Deformation: A Wealth of Challenging Science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Mirzadeh, H. Grain Refinement of Magnesium Alloys by Dynamic Recrystallization (DRX): A Review. J. Mater. Res. Technol. 2023, 25, 7050–7077. [Google Scholar] [CrossRef]

- Buckingham, R.C.; Argyrakis, C.; Hardy, M.C.; Birosca, S. The Effect of Strain Distribution on Microstructural Developments during Forging in a Newly Developed Nickel Base Superalloy. Mater. Sci. Eng. A 2016, 654, 317–328. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Q.; Hu, N.; Huang, Y.; Langdon, T.G. Using an Al-Cu Binary Alloy to Compare Processing by Multi-Axial Compression and High-Pressure Torsion. Mater. Sci. Eng. A 2013, 588, 280–287. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Shiran, M.K.G.; Khalaj, G.; Shirazi, M. On the Effect of Non-Isothermal Annealing and Multi-Directional Forging on the Microstructural Evolutions and Correlated Mechanical and Electrical Characteristics of Hot-Deformed Al-Mg Alloy. Mater. Sci. Eng. A 2016, 657, 431–440. [Google Scholar] [CrossRef]

- Miura, H.; Nakao, Y.; Sakai, T. Enhanced Grain Refinement by Mechanical Twinning in a Bulk Cu-30mass%Zn during Multi-Directional Forging. Mater. Trans. 2007, 48, 2539–2541. [Google Scholar] [CrossRef]

- Ringeval, S.; Piot, D.; Desrayaud, C.; Driver, J.H. Texture and Microtexture Development in an Al–3Mg–Sc(Zr) Alloy Deformed by Triaxial Forging. Acta Mater. 2006, 54, 3095–3105. [Google Scholar] [CrossRef]

- Zolotorevskiy, V.S.; Dobrojinskaja, R.I.; Cheverikin, V.V.; Khamnagdaeva, E.A.; Pozdniakov, A.V.; Levchenko, V.S.; Besogonova, E.S. Evolution of the Structure and Mechanical Properties of Sheets of the Al—4.7 Mg—0.32 Mn—0.21 Sc—0.09 Zr Alloy Due to Deformation Accumulated upon Rolling. Phys. Met. Metallogr. 2016, 117, 1163–1169. [Google Scholar] [CrossRef]

- Zolotorevskiy, V.S.; Dobrozhinskaya, R.I.; Cheverikin, V.V.; Khamnagdaeva, E.A.; Pozdniakov, A.V.; Levchenko, V.S.; Besogonova, E.S. Strength and Substructure of Al–4.7Mg–0.32Mn–0.21Sc–0.09Zr Alloy Sheets. Phys. Met. Metallogr. 2017, 118, 407–414. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Portnoy, V.K.; Mochugovskiy, A.G.; Zadorozhnyy, M.Y.; Tabachkova, N.Y.; Golovin, I.S. Effect of Homogenisation Treatment on Precipitation, Recrystallisation and Properties of Al—3% Mg—TM Alloys (TM = Mn, Cr, Zr). Mater. Des. 2016, 109, 197–208. [Google Scholar] [CrossRef]

- Ning, J.L.; Jiang, D.M. Influence of Zr Addition on the Microstructure Evolution and Thermal Stability of Al–Mg–Mn Alloy Processed by ECAP at Elevated Temperature. Mater. Sci. Eng. A 2007, 452, 552–557. [Google Scholar] [CrossRef]

- Jones, M.J.; Humphreys, F.J. Interaction of Recrystallization and Precipitation: The Effect of Al3Sc on the Recrystallization Behaviour of Deformed Aluminium. Acta Mater. 2003, 51, 2149–2159. [Google Scholar] [CrossRef]

- Robson, J.D. A New Model for Prediction of Dispersoid Precipitation in Aluminium Alloys Containing Zirconium and Scandium. Acta Mater. 2004, 52, 1409–1421. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Ryazantseva, M.A.; Portnoy, V.K. Effect of Eutectic Particles on the Grain Size Control and the Superplasticity of Aluminium Alloys. Mater. Sci. Eng. A 2011, 528, 7306–7309. [Google Scholar] [CrossRef]

- Humphreys, F.J. The Nucleation of Recrystallization at Second Phase Particles in Deformed Aluminium. Acta Metall. 1977, 25, 1323–1344. [Google Scholar] [CrossRef]

- Song, X.; Rettenmayr, M. Modeling Recrystallization in a Material Containing Fine and Coarse Particles. Comput. Mater. Sci. 2007, 40, 234–245. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press: Cambridge, UK, 1997; ISBN 9780521561051. [Google Scholar]

- Khani, S.; Kazeminezhad, M.; Logé, R.; Khani Moghanaki, S.; Kazeminezhad, M.; Logé, R. Recrystallization Behavior of Multi-Directionally Forged over-Aged and Solution Treated Al-Cu-Mg Alloy during Non-Isothermal Annealing. Mater. Des. 2017, 132, 250–256. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Jiang, J.-T.; Li, G.-A.; Wang, X.-M.; Shao, W.-Z.; Zhen, L. Particle-Stimulated Nucleation and Recrystallization Texture Initiated by Coarsened Al2CuLi Phase in Al–Cu–Li Alloy. J. Mater. Res. Technol. 2021, 10, 643–650. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, Y.; Sun, J.; Bachmann, F.; Yang, X.; Sanders, R.E.; Juul Jensen, D. Particle Stimulated Nucleation Revisited in Three Dimensions: A Laboratory-Based Multimodal X-Ray Tomography Investigation. Mater. Res. Lett. 2021, 9, 65–70. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, S.; Kyeong, J.; Shin, S.; Kang, H. Effect of Geometrical Parameters of Microscale Particles on Particle-Stimulated Nucleation and Recrystallization Texture of Al-Si-Mg-Cu-Based Alloy Sheets. Materials 2022, 15, 7924. [Google Scholar] [CrossRef]

- Zang, Q.; Chen, H.; Lee, Y.-S.; Yu, H.; Kim, M.-S.; Kim, H.-W. Improvement of Anisotropic Tensile Properties of Al-7.9Zn-2.7Mg-2.0Cu Alloy Sheets by Particle Stimulated Nucleation. J. Alloys Compd. 2020, 828, 154330. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Kalu, P.N. The Plasticity of Particle-Containing Polycrystals. Acta Metall. Mater. 1990, 38, 917–930. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Pergamon Press: Oxford, UK, 1995. [Google Scholar]

- Humphreys, F.J.; Miller, W.S.; Djazeb, M.R. Microstructural Development during Thermomechanical Processing of Particulate Metal-Matrix Composites. Mater. Sci. Technol. 1990, 6, 1157–1166. [Google Scholar] [CrossRef]

- Wert, J.A.; Paton, N.E.; Hamilton, C.H.; Mahoney, M.W. Grain Refinement in 7075 Aluminum by Thermomechanical Processing. Metall. Trans. A 1981, 12, 1267–1276. [Google Scholar] [CrossRef]

- Kudo, T.; Goto, A.; Saito, K. High Strain Rate Blow Formability of Newly Developed Al-Mg-High-Mn Alloy. Mater. Sci. Forum 2012, 735, 271–277. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Barkov, R.Y.; Amer, S.M.; Levchenko, V.S.; Kotov, A.D.; Mikhaylovskaya, A.V. Microstructure, Mechanical Properties and Superplasticity of the Al–Cu–Y–Zr Alloy. Mater. Sci. Eng. A 2019, 758, 28–35. [Google Scholar] [CrossRef]

- Moore, D.M.; Morris, L.R. A New Superplastic Aluminum Sheet Alloy. Mater. Sci. Eng. 1980, 43, 85–92. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Mikhaylovskaya, A.V.; Bazlov, A.I.; Tsarkov, A.A.; Kotov, A.D.; Aksenov, S.A. Influence of Al 3 Ni Crystallisation Origin Particles on Hot Deformation Behaviour of Aluminium Based Alloys. Philos. Mag. 2017, 97, 572–590. [Google Scholar] [CrossRef]

- Taylor, S.; Janik, V.; Grimes, R.; Dashwood, R. Study on the Influence of Nickel Additions on AA7020 Formability Under Superplastic Forming Like Conditions. Met. Mater. Int. 2023, 29, 2597–2604. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Mikhaylovskaya, A.V.; Kotov, A.D.; Rofman, O.V.; Portnoy, V.K. Al-Mg-Fe-Ni Based Alloy for High Strain Rate Superplastic Forming. Mater. Sci. Eng. A 2018, 718, 190–197. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Kotov, A.D.; Rofman, O.V.; Tabachkova, N.Y. Precipitation Behavior and High Strain Rate Superplasticity in a Novel Fine-Grained Aluminum Based Alloy. Mater. Sci. Eng. A 2019, 760, 37–46. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Tabachkova, N.Y.; Kotov, A.D.; Cheverikin, V.V.; Bazlov, A.I. Microstructural Characterization and Tensile Properties of Al-Mg-Fe-Ce Alloy at Room and Elevated Temperatures. JOM 2020, 72, 1619–1626. [Google Scholar] [CrossRef]

- Zupanič, F.; Žist, S.; Albu, M.; Letofsky-Papst, I.; Burja, J.; Vončina, M.; Bončina, T. Dispersoids in Al-Mg-Si Alloy AA 6086 Modified by Sc and Y. Materials 2023, 16, 2949. [Google Scholar] [CrossRef] [PubMed]

- Amer, S.M.; Barkov, R.Y.; Prosviryakov, A.S.; Pozdniakov, A.V. Structure and Properties of New Wrought Al–Cu–Y- and Al–Cu–Er-Based Alloys. Phys. Met. Metallogr. 2021, 122, 915–922. [Google Scholar] [CrossRef]

- Liu, F.; Zhu, X.; Qin, J.; Zhou, W.; Ling, J.; Dong, Q.; Yu, J.; Nagaumi, H.; Zhang, B. Effect of Mn/Cr Ratio on Precipitation Behaviors of α-Al(FeMnCr)Si Dispersoids and Mechanical Properties of Al–Mg–Si–Cu Alloys. Mater. Sci. Eng. A 2022, 860, 144269. [Google Scholar] [CrossRef]

- Li, Q.; Huang, G.; Cao, Y.; Zhang, C.; He, J.; Jiang, H.; Lin, L.; Liu, Q. Microstructure Refinement, Strengthening and Ductilization Mechanisms in Al–Mg–Mn–Er–Zr Alloy with High Mn Content by Friction Stir Processing. Mater. Charact. 2022, 189, 111939. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, G.; Yang, Z.; Xu, G. Microstructure Characteristics and Mechanical Properties of New Aerospace Al-Mg-Mn Alloys with Al3(Sc1−xZrx) or Al3(Er1−xZrx) Nanoparticles. Mater. Charact. 2019, 153, 79–91. [Google Scholar] [CrossRef]

- Monastyrska, T.O.; Berezina, A.L.; Molebny, O.A.; Kotko, A.V. Effect of Alloying with Transition Metals on the Aging of Anomalously Supersaturated Solid Solution of Al–Mg Alloys. Appl. Nanosci. 2022, 12, 513–521. [Google Scholar] [CrossRef]

- Dorin, T.; Jiang, L.; Langan, T. Formation of Al3Sc Dispersoids and Associated Strengthening. In TMS Annual Meeting & Exhibition; Springer Nature: Cham, Switzerland, 2023; pp. 1207–1212. [Google Scholar]

- Croteau, J.R.; Jung, J.-G.; Whalen, S.A.; Darsell, J.; Mello, A.; Holstine, D.; Lay, K.; Hansen, M.; Dunand, D.C.; Vo, N.Q. Ultrafine-Grained Al-Mg-Zr Alloy Processed by Shear-Assisted Extrusion with High Thermal Stability. Scr. Mater. 2020, 186, 326–330. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.-C.; Zhang, X.-Y.; Huang, Y.-C. Understanding Grain Refinement of Sc Addition in a Zr Containing Al-Zn-Mg-Cu Aluminum Alloy from Experiments and First-Principles. Intermetallics 2020, 123, 106823. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V. Comparison of Precipitation Kinetics and Mechanical Properties in Zr and Sc-Bearing Aluminum-Based Alloys. Mater. Lett. 2020, 275, 128096. [Google Scholar] [CrossRef]

- Robson, J.D.; Prangnell, P.B. Dispersoid Precipitation and Process Modelling in Zirconium Containing Commercial Aluminum Alloys. Acta Mater. 2001, 49, 599–613. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Tabachkova, N.Y.; Ghayoumabadi, M.E.; Cheverikin, V.V.; Mikhaylovskaya, A.V. Joint Effect of Quasicrystalline Icosahedral and L12-Strucutred Phases Precipitation on the Grain Structure and Mechanical Properties of Aluminum-Based Alloys. J. Mater. Sci. Technol. 2021, 87, 196–206. [Google Scholar] [CrossRef]

- Xue, C.; Wang, S.; Zhang, Y.; Tian, G.; Yang, X.; Chang, X.; Ke, Y.; Xie, Z.; Wang, J. Uncovering the Kinetics of Li-Rich Clusters and Monodisperse Core–Shell Al3(Zr, Sc) Structures in Al–Li–Cu Alloys. Mater. Sci. Eng. A 2023, 881, 145393. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Wu, R.; Turakhodjaev, N.; Hou, L.; Zhang, J.; Betsofen, S. Coarsening Kinetics and Strengthening Mechanisms of Core-Shell Nanoscale Precipitates in Al-Li-Yb-Er-Sc-Zr Alloy. J. Mater. Sci. Technol. 2021, 61, 197–203. [Google Scholar] [CrossRef]

- Sitdikov, O.; Avtokratova, E.; Markushev, M. Development of Ultrafine Grain Structure in an Al–Mg–Mn–Sc–Zr Alloy During High-Temperature Multidirectional Isothermal Forging. Met. Mater. Int. 2021, 27, 2743–2755. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Avtokratova, E.; Apollonov, A.; Davies, R. High Strain Rate Superplasticity in an Al–Mg–Sc–Zr Alloy Subjected to Simple Thermomechanical Processing. Scr. Mater. 2006, 54, 2119–2124. [Google Scholar] [CrossRef]

- Sitdikov, O.; Avtokratova, E.; Markushev, M. Influence of Strain Rate on Grain Refinement in the Al-Mg-Sc-Zr Alloy during High-Temperature Multidirectional Isothermal Forging. Mater. Charact. 2019, 157, 109885. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Kishchik, M.S.; Tsarkov, A.A.; Aksenov, S.A.; Portnoy, V.K. Superplasticity of High-Strength Al-Based Alloys Produced by Thermomechanical Treatment. J. Alloys Compd. 2016, 688, 336–344. [Google Scholar] [CrossRef]

- Mochugovskiy, A.; Kotov, A.; Mikhaylovskaya, A.; Ghayoumabadi, M.E.; Yakovtseva, O. A High-Strain-Rate Superplasticity of the Al-Mg-Si-Zr-Sc Alloy with Ni Addition. Materials 2021, 14, 2028. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Aksenov, S.A.; Kishchik, M.S.; Demin, D.O.; Churyumov, A.Y.; Mikhailovskaya, A.V. The Microstructure and Mechanical Properties of an Al–Mg–Fe–Ni–Zr–Sc Alloy after Multidirectional Isothermal Forging. Phys. Met. Metallogr. 2023, 124, 540–549. [Google Scholar]

- Yakovtseva, O.; Sitkina, M.; Mosleh, A.O.; Mikhaylovskaya, A. High Strain Rate Superplasticity in Al-Zn-Mg-Based Alloy: Microstructural Design, Deformation Behavior, and Modeling. Materials 2020, 13, 2098. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Esmaeili Ghayoumabadi, M.; Mochugovskiy, A.G. Superplasticity and Mechanical Properties of Al–Mg–Si Alloy Doped with Eutectic-Forming Ni and Fe, and Dispersoid-Forming Sc and Zr Elements. Mater. Sci. Eng. A 2021, 817, 141319. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Mochugovskiy, A.G.; Levchenko, V.S.; Tabachkova, N.Y.; Mufalo, W.; Portnoy, V.K. Precipitation Behavior of L12 Al3Zr Phase in Al-Mg-Zr Alloy. Mater. Charact. 2018, 139, 30–37. [Google Scholar] [CrossRef]

- Alemdag, Y.; Karabiyik, S.; Mikhaylovskaya, A.V.; Kishchik, M.S.; Purcek, G. Effect of Multi-Directional Hot Forging Process on the Microstructure and Mechanical Properties of Al–Si Based Alloy Containing High Amount of Zn and Cu. Mater. Sci. Eng. A 2021, 803, 140709. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V.; Zadorognyy, M.Y.; Golovin, I.S. Effect of Heat Treatment on the Grain Size Control, Superplasticity, Internal Friction, and Mechanical Properties of Zirconium-Bearing Aluminum-Based Alloy. J. Alloys Compd. 2021, 856, 157455. [Google Scholar] [CrossRef]

- Michi, R.A.; Toinin, J.P.; Seidman, D.N.; Dunand, D.C. Ambient- and Elevated-Temperature Strengthening by Al3Zr-Nanoprecipitates and Al3Ni-Microfibers in a Cast Al-2.9Ni-0.11Zr-0.02Si-0.005Er (at.%) Alloy. Mater. Sci. Eng. A 2019, 759, 78–89. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Toinin, J.P.; Michi, R.A.; Pandee, P.; Dunand, D.C.; Limmaneevichitr, C. Strengthening Mechanisms in Al Ni Sc Alloys Containing Al3Ni Microfibers and Al3Sc Nanoprecipitates. Acta Mater. 2019, 164, 334–346. [Google Scholar] [CrossRef]

- Sotoudeh, K.; Bate, P.S. Diffusion Creep and Superplasticity in Aluminium Alloys. Acta Mater. 2010, 58, 1909–1920. [Google Scholar] [CrossRef]

- Li, H.; Huang, Y.; Liu, Y. Dynamic Recrystallization Mechanisms of As-Forged Al–Zn–Mg-(Cu) Aluminum Alloy during Hot Compression Deformation. Mater. Sci. Eng. A 2023, 878, 145236. [Google Scholar] [CrossRef]

| Alloy Designation | Mg | Ni | Zr | Sc | Fe | Si | Al |

|---|---|---|---|---|---|---|---|

| 1Ni | 4.70 | 1.1 | 0.21 | 0.10 | 0.13 | 0.14 | Bal. |

| 2Ni | 4.67 | 2.1 | 0.20 | 0.09 | 0.14 | 0.15 | Bal. |

| 4Ni | 4.65 | 4.3 | 0.19 | 0.10 | 0.13 | 0.15 | Bal. |

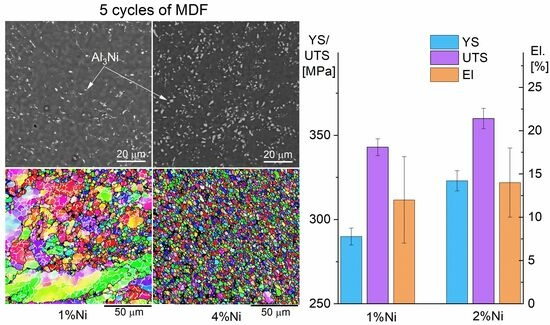

| Alloy | YS (MPa) | YTS (MPa) | El. (%) |

|---|---|---|---|

| 1Ni | 290 ± 5 | 343 ± 5 | 12 ± 3 |

| 2Ni | 323 ± 6 | 360 ± 6 | 14 ± 4 |

| 4Ni | 323 ± 6 | 353 ± 5 | 8 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kishchik, M.S.; Mochugovskiy, A.G.; Cuda, M.; Kishchik, A.A.; Mikhaylovskaya, A.V. Particle Stimulated Nucleation Effect for Al-Mg-Zr-Sc Alloys with Ni Addition during Multidirectional Forging. Metals 2023, 13, 1499. https://doi.org/10.3390/met13081499

Kishchik MS, Mochugovskiy AG, Cuda M, Kishchik AA, Mikhaylovskaya AV. Particle Stimulated Nucleation Effect for Al-Mg-Zr-Sc Alloys with Ni Addition during Multidirectional Forging. Metals. 2023; 13(8):1499. https://doi.org/10.3390/met13081499

Chicago/Turabian StyleKishchik, Mikhail S., Andrey G. Mochugovskiy, Maxence Cuda, Anna A. Kishchik, and Anastasia V. Mikhaylovskaya. 2023. "Particle Stimulated Nucleation Effect for Al-Mg-Zr-Sc Alloys with Ni Addition during Multidirectional Forging" Metals 13, no. 8: 1499. https://doi.org/10.3390/met13081499