A Study on the Influence of Zr on the Strengthening of the Al-10% Al2O3 Composite Obtained by Mechanical Alloying

Abstract

:1. Introduction

2. Materials and Methods

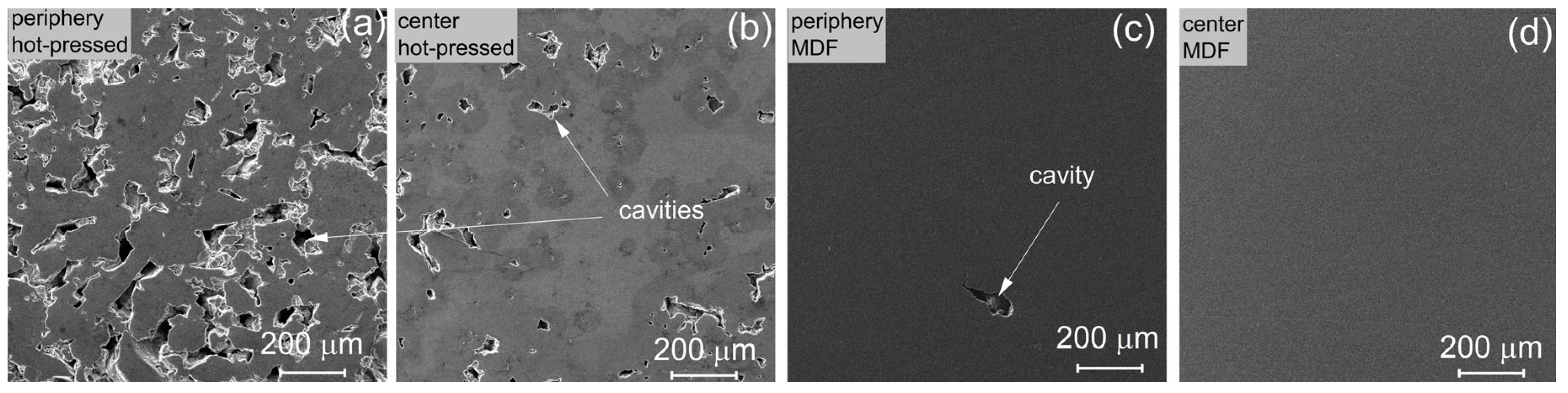

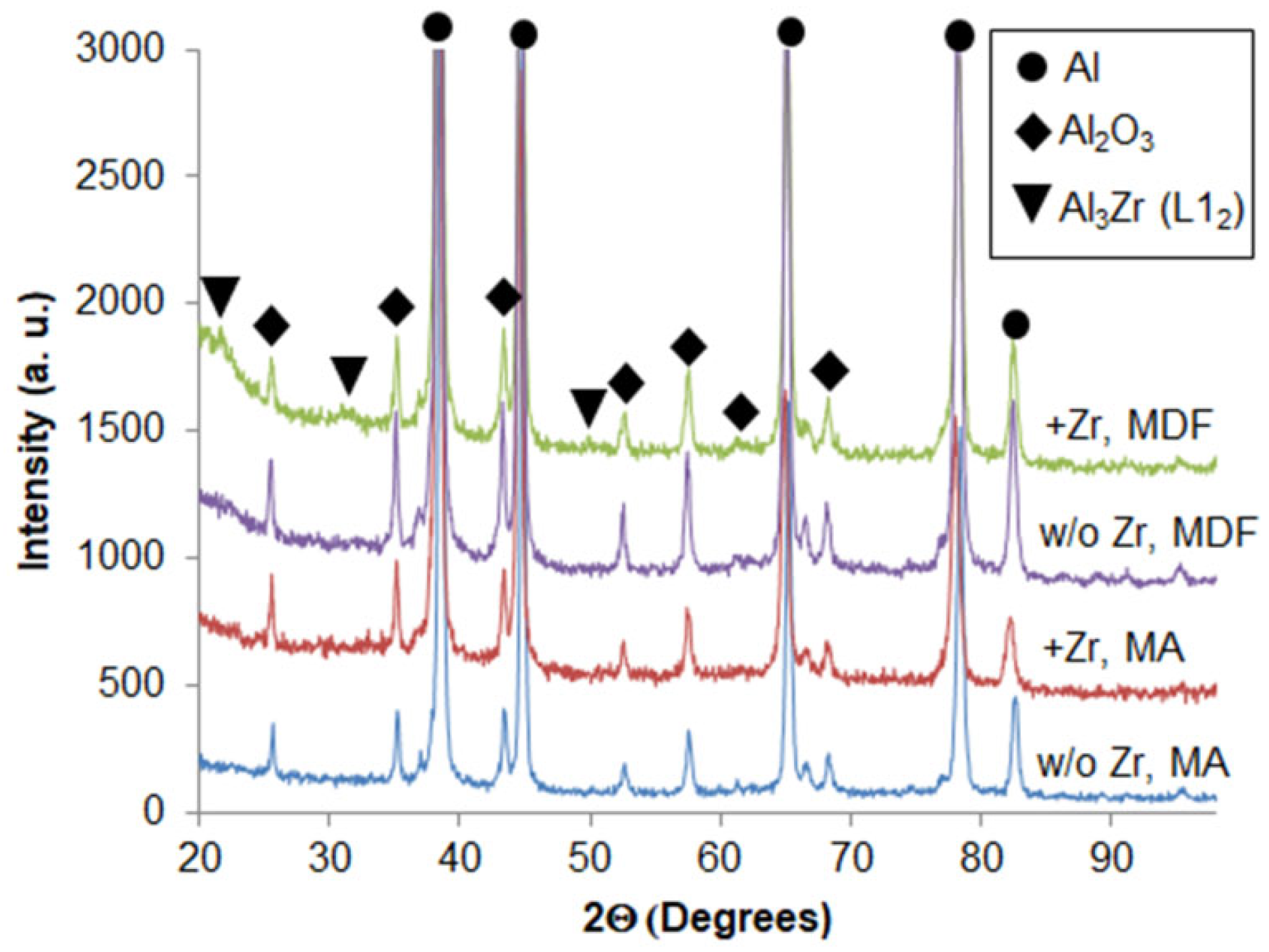

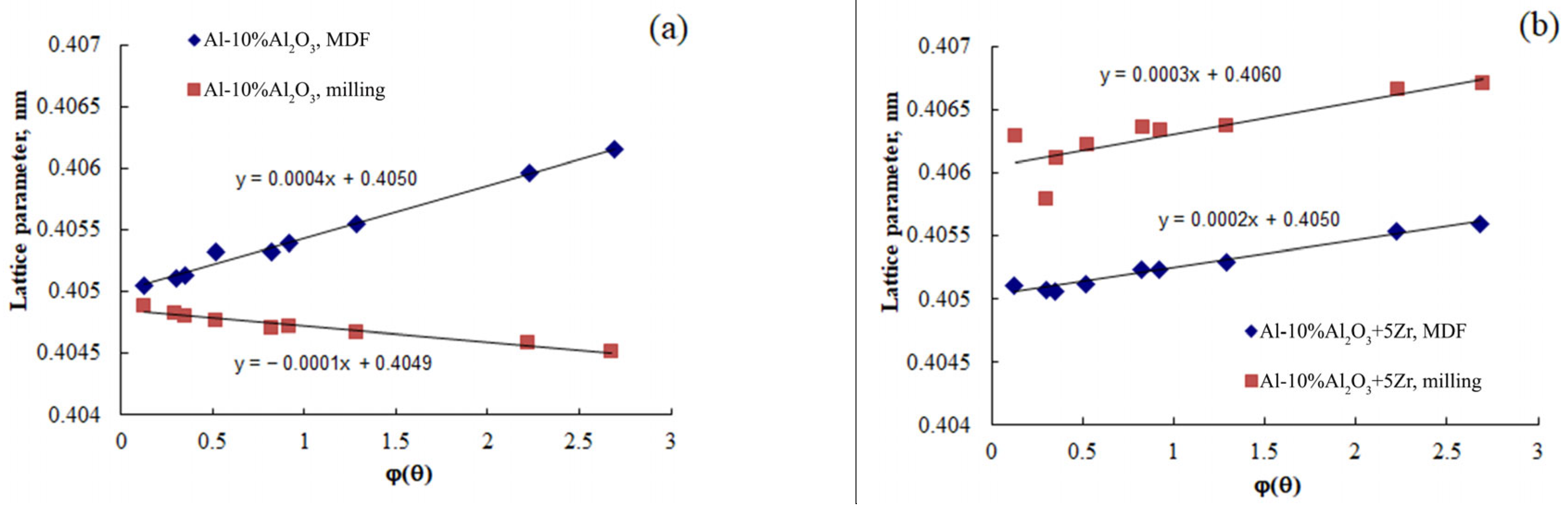

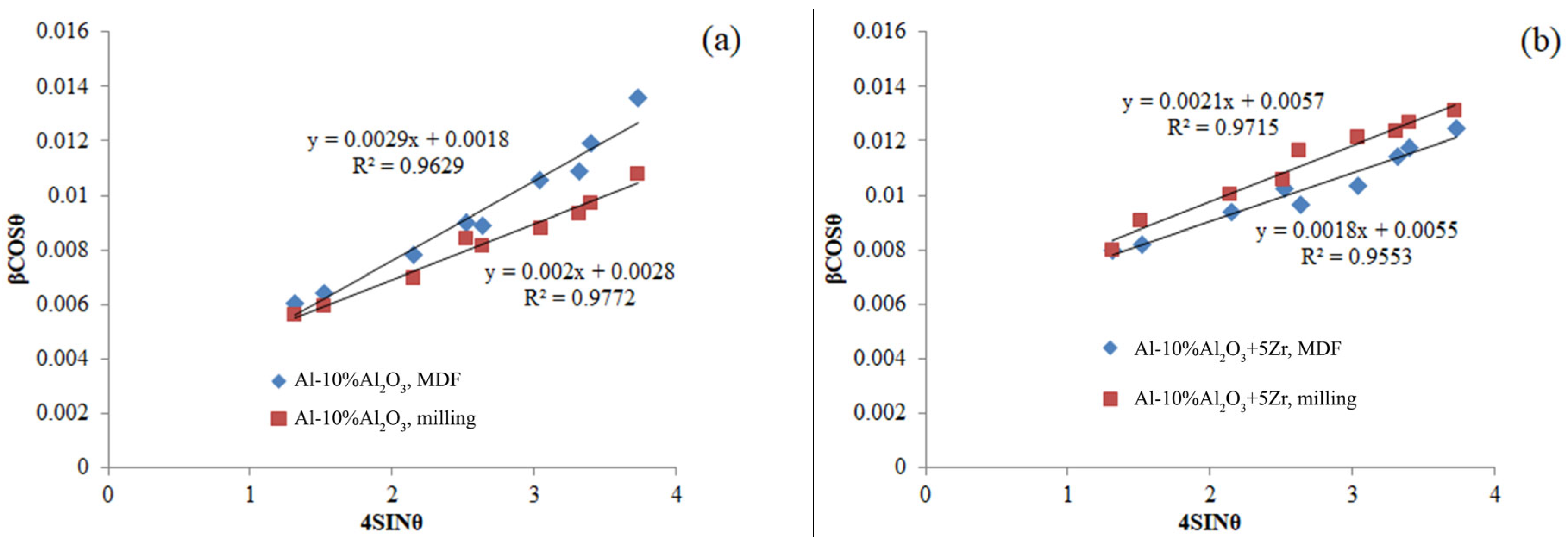

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Czerwinski, F. Thermal Stability of Aluminum Alloys. Materials 2020, 13, 3441. [Google Scholar] [CrossRef]

- Deng, S.-X.; Li, J.-F.; Ning, H.; Lu, D.-D.; Zeng, G.-J.; Liu, Z.-Z.; Xiang, H.; Que, J.-R.; Liu, D.-Y. Effect of Zr addition on the microstructure evolution and mechanical properties of extruded Al–Cu–Li–Mn alloys. Mater. Charact. 2023, 202, 113011. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, P.; Sui, Y.; Jiang, Y.; Zhou, R. Influence of Zr content on microstructure and mechanical properties of As-cast Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2021, 867, 158920. [Google Scholar] [CrossRef]

- Wu, S.; Yin, J.; Luo, Y.; Huang, J.; Wang, Y.; Liu, Y.; Zhong, Y. A high strength Al-Zr alloy with good electrical conductivity by combining gas-assisted continuous casting and extrusion with subsequent thermomechanical treatment. Mater. Today Commun. 2023, 37, 107194. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Singla, A.; Singh, Y. Fabrication methods of nano-based metal matrix composites: A review. AIP Conf. Proc. 2023, 2521, 020025. [Google Scholar] [CrossRef]

- Singh, H.; Singh, K.; Vardhan, S.; Mohan, S.; Singh, V. A comprehensive review of aluminium matrix composite reinforcement and fabrication methodologies. Funct. Compos. Struct. 2021, 3, 015007. [Google Scholar] [CrossRef]

- Ma, K.; Lavernia, E.J.; Schoenung, J.M. Particulate Reinforced Aluminum Alloy Matrix Composites–A Review on the Effect of Microconstituents. Rev. Adv. Mater. Sci. 2017, 48, 91–104. [Google Scholar]

- Prosviryakov, A.; Bazlov, A. The Study of Thermal Stability of Mechanically Alloyed Al-5 wt.% TiO2 Composites with Cu and Stearic Acid Additives. Appl. Sci. 2023, 13, 1104. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Shcherbachev, K.D.; Tabachkova, N.Y. Investigation of nanostructured Al-10 wt.% Zr material prepared by ball milling for high temperature applications. Mater. Charact. 2017, 123, 173–177. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Heydari Vini, M.; Daneshmand, S.; Patra, I.; Lafta, H.A.; Jawad Kadhim, Z. Effect of Al2O3 particles on the mechanical and wear properties of Al base composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 3063–3072. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, W.; Du, Y.; Wang, Y. High-performance Al-1.5 wt% Si-Al2O3 composite by vortex-free high-speed stir casting. J. Manuf. 2020, 56, 1126–1135. [Google Scholar] [CrossRef]

- Miserez, A.; Stucklin, S.; Rossoll, A.; San Marchi, C.; Mortensen, A. Influence of heat treatment and particle shape on mechanical properties of infiltrated Al2O3 particle reinforced Al–2 wt% Cu. Mater. Sci. Technol. 2002, 18, 1461–1470. [Google Scholar] [CrossRef]

- Travitzky, N.A. Effect of metal volume fraction on the mechanical properties of alumina/aluminum composites. J. Mater. Sci. 2001, 36, 4459–4463. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Shanu, C. A review on the employment of ultrasonic-assisted routes for synthesis of aluminium matrix composites. Mater. Today Proc. 2023, 72, 1170–1174. [Google Scholar] [CrossRef]

- Zhukov, I.A.; Kozulin, A.A.; Khrustalyov, A.P.; Kahidze, N.I.; Khmeleva, M.G.; Moskvichev, E.N.; Lychagin, D.V.; Vorozhtsov, A.B. Pure Aluminum Structure and Mechanical Properties Modified by Al2O3 Nanoparticles and Ultrasonic Treatment. Metals 2019, 9, 1199. [Google Scholar] [CrossRef]

- Luan, B.F.; Wu, G.H.; Liu, W.; Hansen, N.; Lei, T. High strength Al2O3p/2024Al composites—Effect of particles, subgrains and precipitates. Mater. Sci. Technol. 2005, 21, 1440–1443. [Google Scholar] [CrossRef]

- Qin, X.H.; Jiang, D.L.; Dong, S.M. Nanometer, submicron and micron sized aluminum powder prepared by semi-solid mechanical stirring method with addition of ceramic particles. Mater. Sci. Eng. A 2004, 385, 31–37. [Google Scholar] [CrossRef]

- Çalışkan, O.; Sunar, T.; Özyürek, D. Mechanical and wear performance of A356/Al2O3 aluminum nanocomposites by considering the mechanical milling time and microstructural properties. Ind. Lubr. Tribol. 2023, 75, 465–473. [Google Scholar] [CrossRef]

- Prabhu, B.; Suryanarayana, C.; An, L.; Vaidyanathan, R. Synthesis and characterization of high volume fraction Al–Al2O3 nanocomposite powders by high-energy milling. Mater. Sci. Eng. A 2006, 425, 192–200. [Google Scholar] [CrossRef]

- Hernández Rivera, J.L.; Cruz Rivera, J.J.; Paz del Ángel, V.; Garibay Febles, V.; Coreño Alonso, O.; Martínez-Sánchez, R. Structural and morphological study of a 2024 Al–Al2O3 composite produced by mechanical alloying in high energy mill. Mater. Des. 2012, 37, 96–101. [Google Scholar] [CrossRef]

- Prashanth, M.; Karunanithi, R.; Mohideen, S.R.; Sivasankaran, S.; Vlahović, M. A comparative study on X-ray peak broadening analysis of mechanically alloyed Al2O3 particles dispersion strengthened Al 7017 alloy. Mater. Chem. Phys. 2023, 294, 127015. [Google Scholar] [CrossRef]

- Zebarjad, S.M.; Sajjadi, S.A. Microstructure evaluation of Al–Al2O3 composite produced by mechanical alloying method. Mater. Des. 2006, 27, 684–688. [Google Scholar] [CrossRef]

- Zebarjad, S.M.; Sajjadi, S.A. Dependency of physical and mechanical properties of mechanical alloyed Al–Al2O3 composite on milling time. Mater. Des. 2007, 28, 2113–2120. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Matori, K.A.; Ostovan, F.; Abdul Aziz, S.; Mamat, M.S. Effect of Milling Time on the Microstructure, Physical and Mechanical Properties of Al-Al2O3 Nanocomposite Synthesized by Ball Milling and Powder Metallurgy. Materials 2017, 10, 1232. [Google Scholar] [CrossRef]

- Poirier, D.; Drew, R.A.L.; Trudeau, M.L.; Gauvin, R. Fabrication and properties of mechanically milled alumina/aluminum nanocomposites. Mater. Sci. Eng. A 2010, 527, 7605–7614. [Google Scholar] [CrossRef]

- Wagih, A. Synthesis of Nanocrystalline Al2O3 Reinforced Al Nanocomposites by High-Energy Mechanical Alloying: Microstructural Evolution and Mechanical Properties. Trans. Indian. Inst. Met. 2016, 69, 851–857. [Google Scholar] [CrossRef]

- Tavoosi, M.; Karimzadeh, F.; Enayati, M.H. Wear behaviour of Al–Al2O3 nanocomposites prepared by mechanical alloying and hot pressing. Mater. Sci. Technol. 2010, 26, 1114–1119. [Google Scholar] [CrossRef]

- Razavi Tousi, S.S.; Yazdani Rad, R.; Salahi, E.; Mobasherpour, I.; Razavi, M. Production of Al–20 wt.% Al2O3 composite powder using high energy milling. Powder Technol. 2009, 192, 346–351. [Google Scholar] [CrossRef]

- Benjamin, J.S.; Volin, T.E. The Mechanism of Mechanical Alloying. Metall. Trans. 1974, 5, 1929–1934. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying: A critical review. Mater. Res. Lett. 2022, 10, 619–647. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical Alloying and Milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Klassen, T.; Ivanov, E. Synthesis of nanocomposites and amorphous alloys by mechanical alloying. J. Mater. Sci. 2011, 46, 6301–6315. [Google Scholar] [CrossRef]

- Zhang, D.L. Processing of advanced materials using high-energy mechanical milling. Prog. Mater. Sci. 2004, 49, 537–560. [Google Scholar] [CrossRef]

- Shuai, C.; He, C.; Peng, S.; Qi, F.; Wang, G.; Min, A.; Yang, W.; Wang, W. Mechanical Alloying of Immiscible Metallic Systems: Process, Microstructure, and Mechanism. Adv. Eng. Mater. 2021, 23, 2001098. [Google Scholar] [CrossRef]

- Jia, Z.; Hu, G.; Forbord, B.; Solberg, J.K. Enhancement of recrystallization resistance of Al–Zr–Mn by two-step precipitation annealing. Mater. Sci. Eng. A 2008, 483–484, 195–198. [Google Scholar] [CrossRef]

- Al-Aqeeli, N.; Mendoza-Suarez, G.; Suryanarayana, C.; Drew, R.A.L. Development of new Al-based nanocomposites by mechanical alloying. Mater. Sci. Eng. A 2008, 480, 392–396. [Google Scholar] [CrossRef]

- Muthaiah, V.M.S.; Mula, S. Effect of zirconium on thermal stability of nanocrystalline aluminum alloy prepared by mechanical alloying. J. Alloys Compd. 2016, 688, 571–580. [Google Scholar] [CrossRef]

- Srinivasarao, B.; Suryanarayana, C.; Oh-ishi, K.; Hono, K. Microstructure and mechanical properties of Al–Zr nanocomposite materials. Mater. Sci. Eng. A 2009, 518, 100–107. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Shcherbachev, K.D. Strengthening of mechanically alloyed Al-based alloy with high Zr contents. Mater. Sci. Eng. A. 2018, 713, 174–179. [Google Scholar] [CrossRef]

- Kaveendran, B.; Wang, G.S.; Huang, L.J.; Geng, L.; Peng, H.X. In situ (Al3Zr + Al2O3np)/2024Al metal matrix composite with novel reinforcement distributions fabricated by reaction hot pressing. J. Alloys Compd. 2013, 581, 16–22. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kotov, A.D.; Kishchik, M.S.; Prosviryakov, A.S.; Portnoy, V.K. The Effect of Isothermal Multi-Directional Forging on the Grain Structure, Superplasticity, and Mechanical Properties of the Conventional Al–Mg-Based Alloy. Metals 2019, 9, 33. [Google Scholar] [CrossRef]

- Nelson, J.B.; Riley, D.P. An experimental investigation of extrapolation methods in the derivation of accurate unit-cell dimensions of crystals. Proc. Phys. Soc. 1945, 57, 160–177. [Google Scholar] [CrossRef]

- Belov, N.A. Aluminum casting alloys with high content of zirconium. Mater. Sci. Forum 1996, 217–222, 293–298. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Shcherbachev, K.D.; Tabachkova, N.Y. Microstructural characterization of mechanically alloyed Al–Cu–Mn alloy with zirconium. Mater. Sci. Eng. A 2015, 623, 109–113. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminum and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Shanmugasundaram, T.; Heilmaier, M.; Murty, B.S.; Subramanya Sarma, V. Microstructure and Mechanical Properties of Nanostructured Al-4Cu Alloy Produced by Mechanical Alloying and Vacuum Hot Pressing. Metall. Mater. Trans. A 2009, 40, 2798–2801. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Salahi, E.; Alikhani Hesari, F.; Simchi, A.; Kim, H.S. Fabrication, characterization and mechanical properties of hybrid composites of copper using the nanoparticulates of SiC and carbon nanotubes. Mater. Sci. Eng. A 2013, 572, 83–90. [Google Scholar] [CrossRef]

- Mohammadi, A.; Enikeev, N.A.; Murashkin, M.Y.; Arita, M.; Edalati, K. Examination of inverse Hall-Petch relation in nanostructured aluminum alloys by ultra-severe plastic deformation. J. Mater. Sci. Technol. 2021, 91, 78–89. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

| Material | , MPa | , MPa | , MPa | , MPa | |||

|---|---|---|---|---|---|---|---|

| k = 0.1 | k = 0.07 | k = 0.1 | k = 0.07 | ||||

| Al-10%Al2O3 | 354 | — | 143 | 22 | 529 | — | 572 |

| Al-10%Al2O3-5%Zr | 598 | 418 | 191 | 189 | 988 | 808 | 823 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prosviryakov, A.S.; Bazlov, A.I.; Churyumov, A.Y.; Mikhaylovskaya, A.V. A Study on the Influence of Zr on the Strengthening of the Al-10% Al2O3 Composite Obtained by Mechanical Alloying. Metals 2023, 13, 2008. https://doi.org/10.3390/met13122008

Prosviryakov AS, Bazlov AI, Churyumov AY, Mikhaylovskaya AV. A Study on the Influence of Zr on the Strengthening of the Al-10% Al2O3 Composite Obtained by Mechanical Alloying. Metals. 2023; 13(12):2008. https://doi.org/10.3390/met13122008

Chicago/Turabian StyleProsviryakov, Alexey S., Andrey I. Bazlov, Alexander Yu. Churyumov, and Anastasia V. Mikhaylovskaya. 2023. "A Study on the Influence of Zr on the Strengthening of the Al-10% Al2O3 Composite Obtained by Mechanical Alloying" Metals 13, no. 12: 2008. https://doi.org/10.3390/met13122008