Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility

Abstract

:1. Introduction

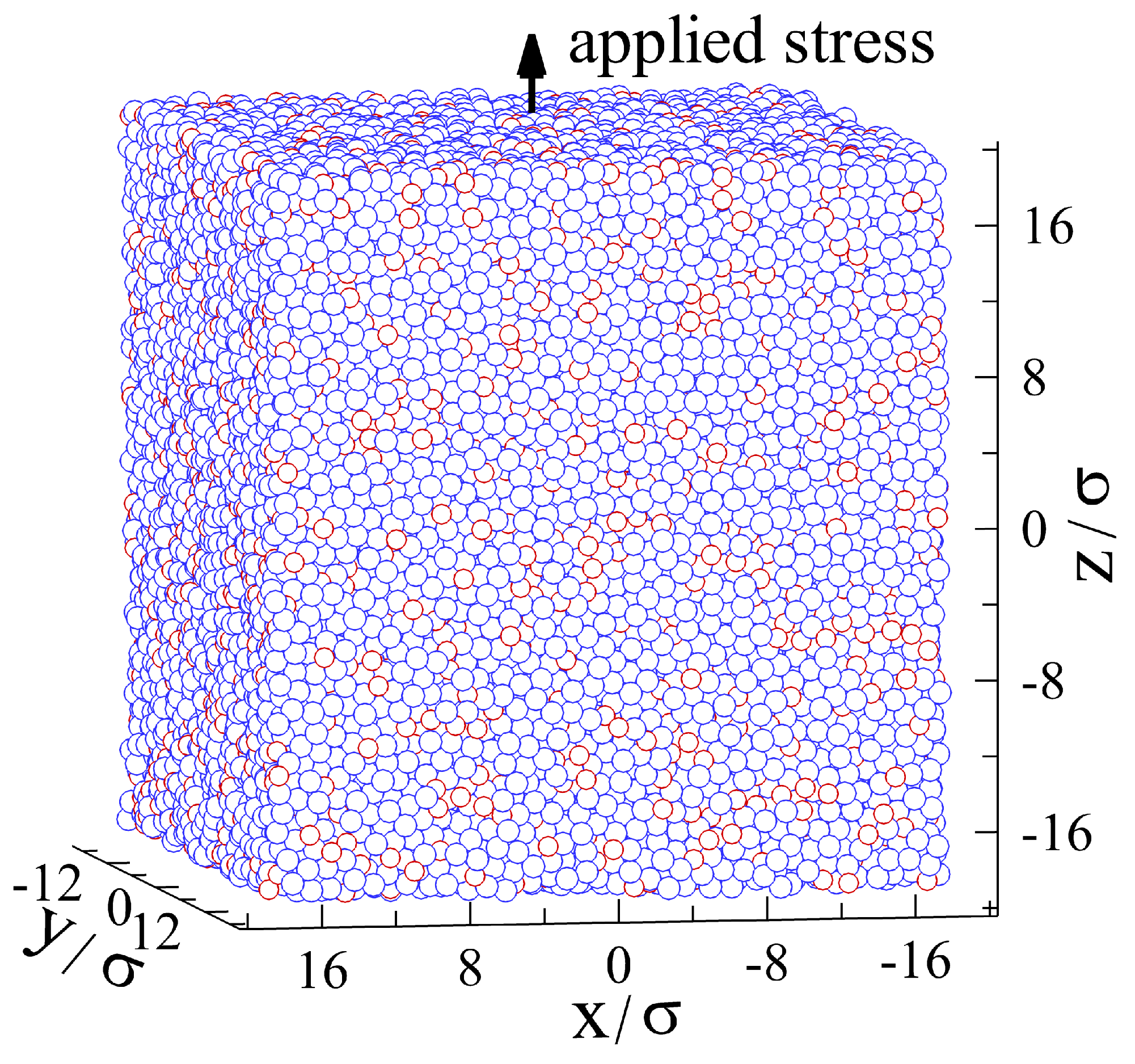

2. Molecular Dynamics Simulations

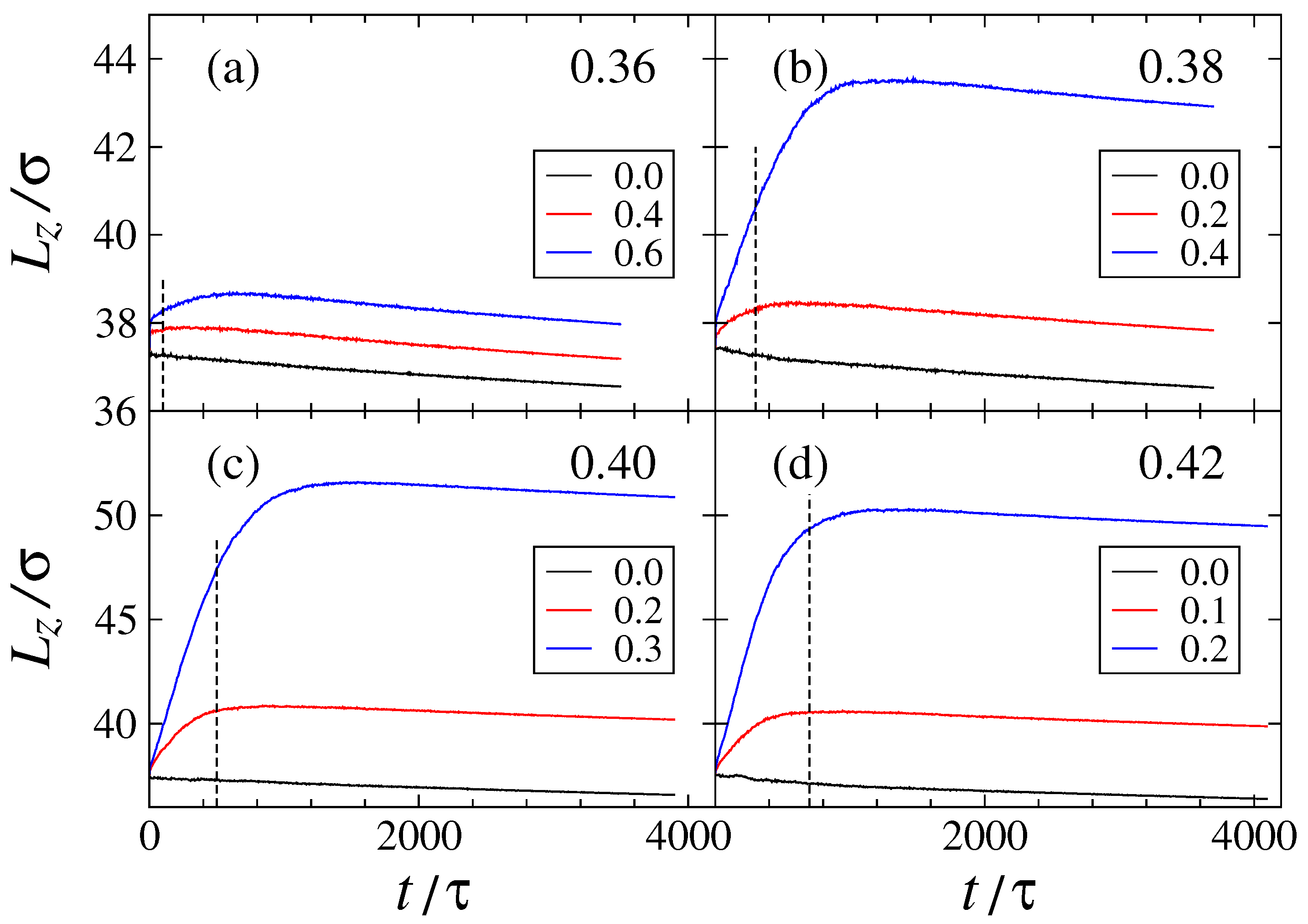

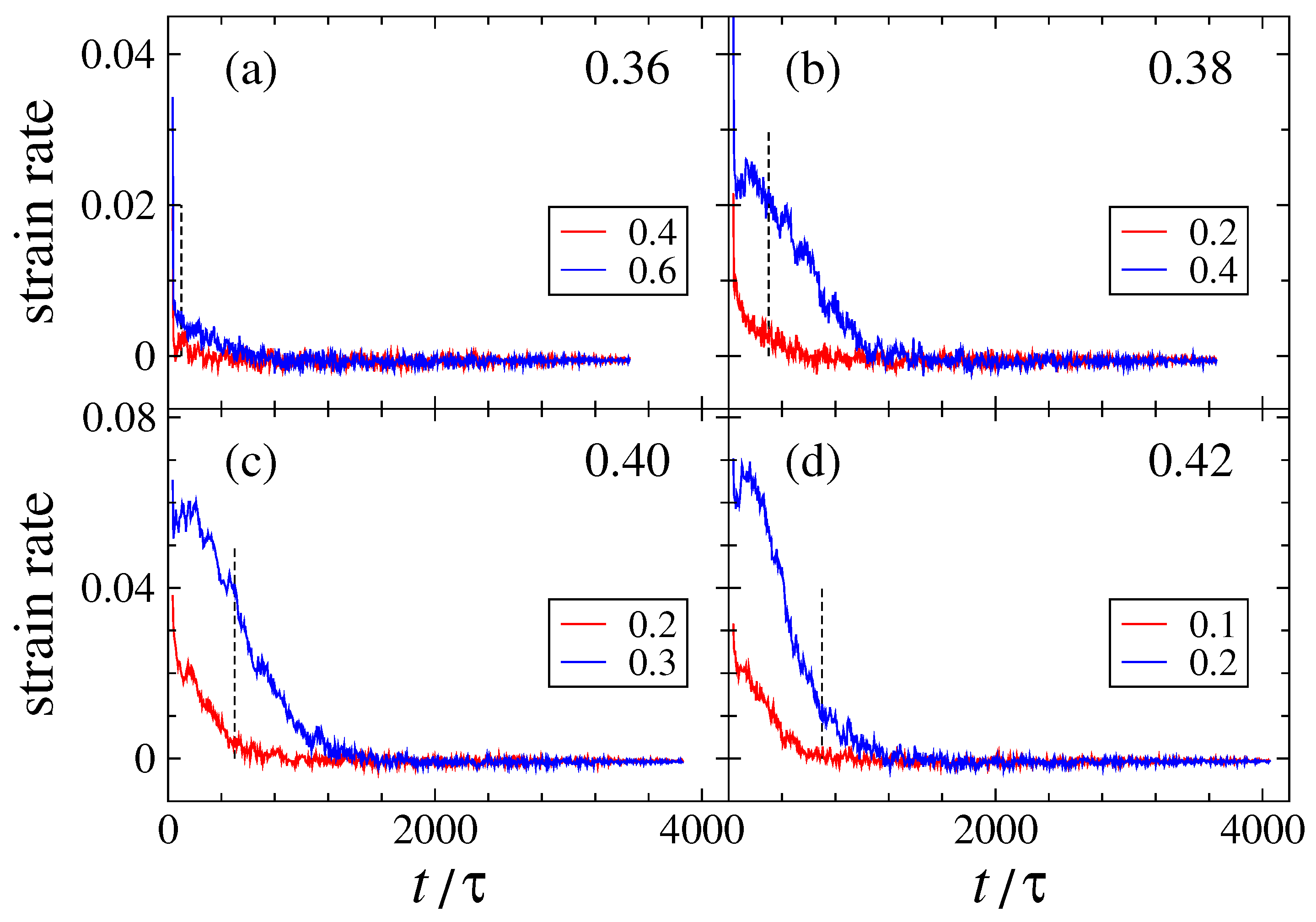

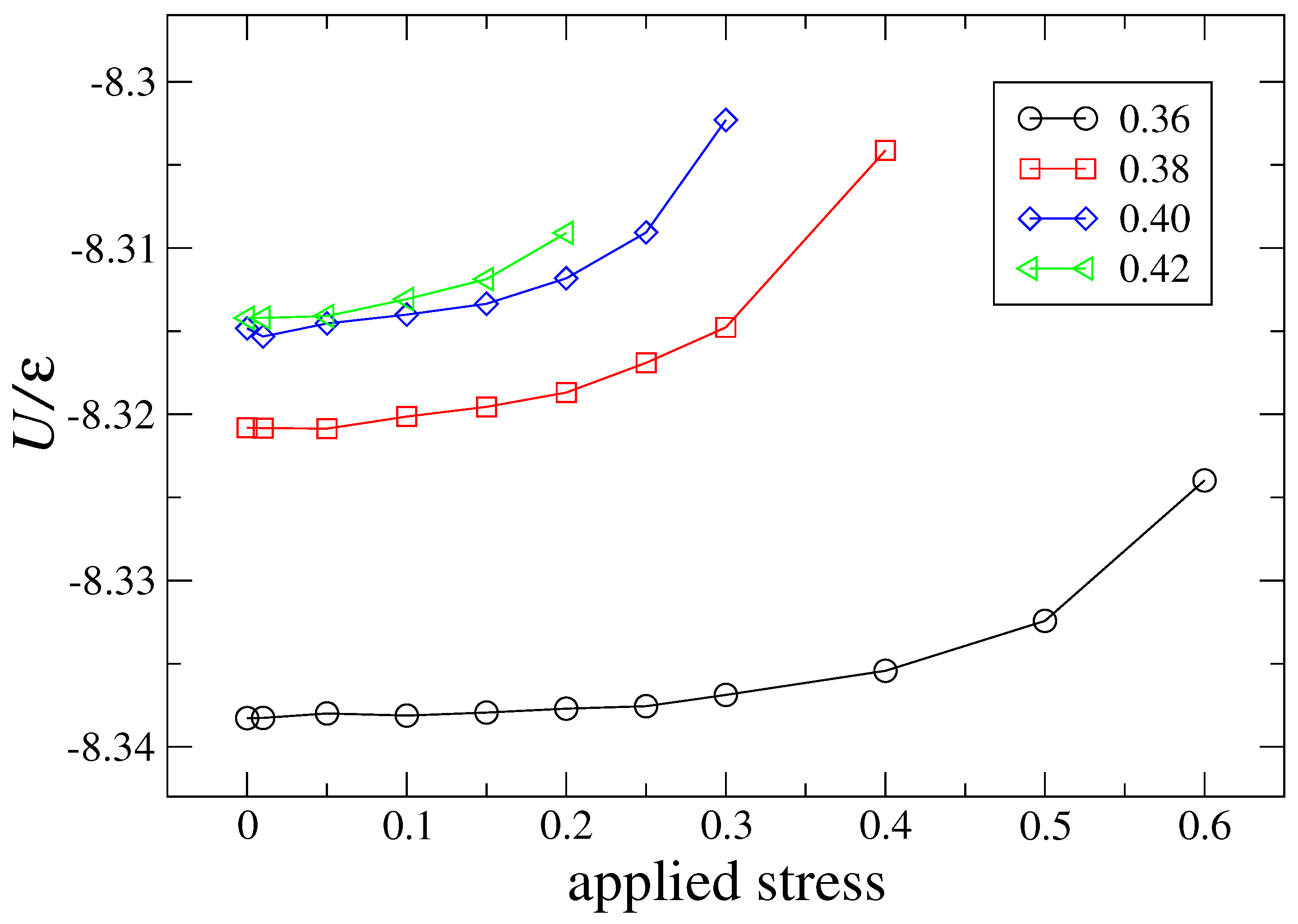

3. Results

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, M.M.; Nemati, A.; Rahman, Z.U.; Shah, U.H.; Asgar, H.; Haider, W. Recent advancements in bulk metallic glasses and their applications: A Review. Crit. Rev. Solid State Mater. Sci. 2018, 43, 233–268. [Google Scholar] [CrossRef]

- Li, H.F.; Zheng, Y.F. Recent advances in bulk metallic glasses for biomedical applications. Acta Biomater. 2016, 36, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Schuh, C.A.; Lund, A.C. Atomistic basis for the plastic yield criterion of metallic glass. Nat. Mater. 2003, 2, 449–452. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Cheng, Y.Q.; Ma, E. Correlating local structure with inhomogeneous elastic deformation in a metallic glass. Appl. Phys. Lett. 2012, 101, 121917. [Google Scholar] [CrossRef]

- Shang, B.S.; Li, M.Z.; Yao, Y.G.; Lu, Y.J.; Wang, W.H. Evolution of atomic rearrangements in deformation in metallic glasses. Phys. Rev. E 2014, 90, 042303. [Google Scholar] [CrossRef]

- Priezjev, N.V. The effect of thermal history on the atomic structure and mechanical properties of amorphous alloys. Comput. Mater. Sci. 2020, 174, 109477. [Google Scholar] [CrossRef] [Green Version]

- Priezjev, N.V. Spatiotemporal analysis of nonaffine displacements in disordered solids sheared across the yielding point. Metall. Mater. Trans. A 2020, 51, 3713. [Google Scholar] [CrossRef]

- Singh, M.; Ozawa, M.; Berthier, L. Brittle yielding of amorphous solids at finite shear rates. Phys. Rev. Mater. 2020, 4, 025603. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Concustell, A.; Greer, A.L. Thermomechanical processing of metallic glasses: Extending the range of the glassy state. Nat. Rev. Mater. 2016, 1, 16039. [Google Scholar] [CrossRef] [Green Version]

- Wakeda, M.; Saida, J.; Li, J.; Ogata, S. Controlled rejuvenation of amorphous metals with thermal processing. Sci. Rep. 2015, 5, 10545. [Google Scholar] [CrossRef] [Green Version]

- Kuchemann, S.; Derlet, P.M.; Liu, C.; Rosenthal, D.; Sparks, G.; Larson, W.S.; Maass, R. Energy storage in metallic glasses via flash annealing. Adv. Funct. Mater. 2018, 28, 1805385. [Google Scholar] [CrossRef]

- Priezjev, N.V. Atomistic modeling of heat treatment processes for tuning the mechanical properties of disordered solids. J. Non-Cryst. Solids 2019, 518, 128–133. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Liu, H.; Li, J.; Jiang, Q.; Yang, W.; Tang, C. Thermal-pressure treatment for tuning the atomic structure of metallic glass Cu-Zr. J. Non-Cryst. Solids 2020, 535, 119963. [Google Scholar] [CrossRef]

- Magagnosc, D.J.; Kumar, G.; Schroers, J.; Felfer, P.; Cairney, J.M.; Gianola, D.S. Effect of ion irradiation on tensile ductility, strength and fictive temperature in metallic glass nanowires. Acta Mater. 2014, 74, 165–182. [Google Scholar] [CrossRef]

- Xue, P.; Pauly, S.; Gan, W.; Jiang, S.; Fan, H.; Ning, Z.; Huang, Y.; Sun, J. Enhanced tensile plasticity of a CuZr-based bulk metallic glass composite induced by ion irradiation. J. Mater. Sci. Technol. 2019, 35, 2221–2226. [Google Scholar] [CrossRef]

- Meng, F.; Tsuchiya, K.; Li, S.; Yokoyama, Y. Reversible transition of deformation mode by structural rejuvenation and relaxation in bulk metallic glass. Appl. Phys. Lett. 2012, 101, 121914. [Google Scholar] [CrossRef]

- Wang, Y.B.; Qu, D.D.; Wang, X.H.; Cao, Y.; Liao, X.Z.; Kawasaki, M.; Ringer, S.P.; Shan, Z.W.; Langdon, T.G.; Shen, J. Introducing a strain-hardening capability to improve the ductility of bulk metallic glasses via severe plastic deformation. Acta Mater. 2012, 60, 253–260. [Google Scholar] [CrossRef]

- Mear, F.O.; Vaughan, G.; Yavari, A.R.; Greer, A.L. Residual-stress distribution in shot-peened metallic-glass plate. Philos. Mag. Lett. 2008, 88, 757–766. [Google Scholar] [CrossRef]

- Gonzalez, S.; Fornell, J.; Pellicer, E.; Surinach, S.; Baro, M.D.; Greer, A.L.; Belzunce, F.J.; Sort, J. Influence of the shot-peening intensity on the structure and near-surface mechanical properties of Ti40Zr10Cu38Pd12 bulk metallic glass. Appl. Phys. Lett. 2013, 103, 211907. [Google Scholar] [CrossRef] [Green Version]

- Park, K.-W.; Lee, C.-M.; Wakeda, M.; Shibutani, Y.; Falk, M.L.; Lee, J.-C. Elastostatically induced structural disordering in amorphous alloys. Acta Mater. 2008, 56, 5440–5450. [Google Scholar] [CrossRef]

- Lee, C.-M.; Park, K.-W.; Lee, B.-J.; Shibutani, Y.; Lee, J.-C. Structural disordering of amorphous alloys: A molecular dynamics analysis. Scr. Mater. 2009, 61, 911–914. [Google Scholar] [CrossRef]

- Tong, Y.; Dmowski, W.; Yokoyama, Y.; Wang, G.; Liaw, P.K.; Egami, T. Recovering compressive plasticity of bulk metallic glasses by high-temperature creep. Scr. Mater. 2013, 69, 570–573. [Google Scholar] [CrossRef]

- Wang, Y.M.; Zhang, M.; Liu, L. Mechanical annealing in the homogeneous deformation of bulk metallic glass under elastostatic compression. Scr. Mater. 2015, 102, 67–70. [Google Scholar] [CrossRef]

- Zhao, L.Z.; Xue, R.J.; Li, Y.Z.; Wang, W.H.; Bai, H.Y. Revealing localized plastic flow in apparent elastic region before yielding in metallic glasses. J. Appl. Phys. 2015, 118, 244901. [Google Scholar] [CrossRef]

- Greer, A.L.; Sun, Y.H. Stored energy in metallic glasses due to strains within the elastic limit. Philos. Mag. 2016, 96, 1643–1663. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Wang, Y.M.; Li, F.X.; Jiang, S.Q.; Li, M.Z.; Liu, L. Mechanical relaxation-to-rejuvenation transition in a Zr-based bulk metallic glass. Sci. Rep. 2017, 7, 625. [Google Scholar] [CrossRef]

- Pan, J.; Wang, Y.X.; Guo, Q.; Zhang, D.; Greer, A.L.; Li, Y. Extreme rejuvenation and softening in a bulk metallic glass. Nat. Commun. 2018, 9, 560. [Google Scholar] [CrossRef]

- Priezjev, N.V. Aging and rejuvenation during elastostatic loading of amorphous alloys: A molecular dynamics simulation study. Comput. Mater. Sci. 2019, 168, 125–130. [Google Scholar] [CrossRef] [Green Version]

- Priezjev, N.V. Accelerated rejuvenation in metallic glasses subjected to elastostatic compression along alternating directions. J. Non-Cryst. Solids 2020, 120562. [Google Scholar] [CrossRef]

- Ketov, S.V.; Sun, Y.H.; Nachum, S.; Lu, Z.; Checchi, A.; Beraldin, A.R.; Bai, H.Y.; Wang, W.H.; Louzguine-Luzgin, D.V.; Carpenter, M.A.; et al. Rejuvenation of metallic glasses by non-affine thermal strain. Nature 2015, 524, 200–203. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Saida, J.; Zhao, M.; Lu, S.; Wu, S. Rejuvenation of Zr-based bulk metallic glass matrix composite upon deep cryogenic cycling. Mater. Lett. 2019, 247, 135–138. [Google Scholar] [CrossRef]

- Priezjev, N.V. The effect of cryogenic thermal cycling on aging, rejuvenation, and mechanical properties of metallic glasses. J. Non-Cryst. Solids 2019, 503, 131–138. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.-L.; Priezjev, N.V. The influence of complex thermal treatment on mechanical properties of amorphous materials. Comput. Mater. Sci. 2019, 161, 93–98. [Google Scholar] [CrossRef] [Green Version]

- Priezjev, N.V. Potential energy states and mechanical properties of thermally cycled binary glasses. J. Mater. Res. 2019, 34, 2664–2671. [Google Scholar] [CrossRef] [Green Version]

- Samavatian, M.; Gholamipour, R.; Amadeh, A.A.; Mirdamadi, S. Correlation between plasticity and atomic structure evolution of a rejuvenated bulk metallic glass. Metall. Mater. Trans. A 2019, 50, 4743–4749. [Google Scholar] [CrossRef]

- Ketkaew, J.; Yamada, R.; Wang, H.; Kuldinow, D.; Schroers, B.S.; Dmowski, W.; Egami, T.; Schroers, J. The effect of thermal cycling on the fracture toughness of metallic glasses. Acta Mater. 2020, 184, 100. [Google Scholar] [CrossRef]

- Meylan, C.M.; Papparotto, F.; Nachum, S.; Orava, J.; Miglierini, M.; Basykh, V.; Ferenc, J.; Kulik, T.; Greer, A.L. Stimulation of shear-transformation zones in metallic glasses by cryogenic thermal cycling. J. Non-Cryst. Solids 2020, 584, 120299. [Google Scholar] [CrossRef]

- Du, Y.; Han, W.; Zhou, Q.; Xu, Y.; Zhai, H.; Bhardwaj, V.; Wang, H. Enhancing the plasticity of a Ti-based bulk metallic glass composite by cryogenic cycling treatments. J. Alloys Compd. 2020, 835, 155247. [Google Scholar] [CrossRef]

- Lacks, D.J.; Osborne, M.J. Energy landscape picture of overaging and rejuvenation in a sheared glass. Phys. Rev. Lett. 2004, 93, 255501. [Google Scholar] [CrossRef] [Green Version]

- Fiocco, D.; Foffi, G.; Sastry, S. Oscillatory athermal quasistatic deformation of a model glass. Phys. Rev. E 2013, 88, 020301(R). [Google Scholar] [CrossRef] [Green Version]

- Priezjev, N.V. Molecular dynamics simulations of the mechanical annealing process in metallic glasses: Effects of strain amplitude and temperature. J. Non-Cryst. Solids 2018, 479, 42–48. [Google Scholar] [CrossRef] [Green Version]

- Priezjev, N.V. Slow relaxation dynamics in binary glasses during stress-controlled, tension-compression cyclic loading. Comput. Mater. Sci. 2018, 153, 235–240. [Google Scholar] [CrossRef] [Green Version]

- Jana, P.K.; Priezjev, N.V. Structural relaxation in amorphous materials under cyclic tension-compression loading. J. Non-Cryst. Solids 2020, 540, 120098. [Google Scholar] [CrossRef]

- Priezjev, N.V. Accelerated relaxation in disordered solids under cyclic loading with alternating shear orientation. J. Non-Cryst. Solids 2019, 525, 119683. [Google Scholar] [CrossRef] [Green Version]

- Priezjev, N.V. Alternating shear orientation during cyclic loading facilitates yielding in amorphous materials. J. Mater. Eng. Perform. 2020, 29, 7328–7335. [Google Scholar] [CrossRef]

- Mota, R.; Lund, E.; Sohn, S.; Browne, D.; Schroers, J. Pulling metallic glasses ductile. Res. Sq. 2020. [Google Scholar] [CrossRef]

- Kob, W.; Andersen, H.C. Testing mode-coupling theory for a supercooled binary Lennard-Jones mixture: The van Hove correlation function. Phys. Rev. E 1995, 51, 4626–4641. [Google Scholar] [CrossRef] [Green Version]

- Weber, T.A.; Stillinger, F.H. Local order and structural transitions in amorphous metal-metalloid alloys. Phys. Rev. B 1985, 31, 1954–1963. [Google Scholar] [CrossRef] [Green Version]

- Plimpton, S.J. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon: Oxford, UK, 1987. [Google Scholar]

- Fan, M.; Wang, M.; Zhang, K.; Liu, Y.; Schroers, J.; Shattuck, M.D.; O’Hern, C.S. The effects of cooling rate on particle rearrangement statistics: Rapidly cooled glasses are more ductile and less reversible. Phys. Rev. E 2017, 95, 022611. [Google Scholar] [CrossRef] [Green Version]

- Vollmayr, K.; Kob, W.; Binder, K. How do the properties of a glass depend on the cooling rate? A computer simulation study of a Lennard-Jones system. J. Chem. Phys. 1996, 105, 4714–4728. [Google Scholar] [CrossRef] [Green Version]

- Utz, M.; Debenedetti, P.G.; Stillinger, F.H. Atomistic simulation of aging and rejuvenation in glasses. Phys. Rev. Lett. 2000, 84, 1471–1474. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Priezjev, N.V. Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility. Metals 2021, 11, 67. https://doi.org/10.3390/met11010067

Priezjev NV. Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility. Metals. 2021; 11(1):67. https://doi.org/10.3390/met11010067

Chicago/Turabian StylePriezjev, Nikolai V. 2021. "Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility" Metals 11, no. 1: 67. https://doi.org/10.3390/met11010067