Process Optimization and Formation Analysis of Friction Plug Welding of 6082 Aluminum Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

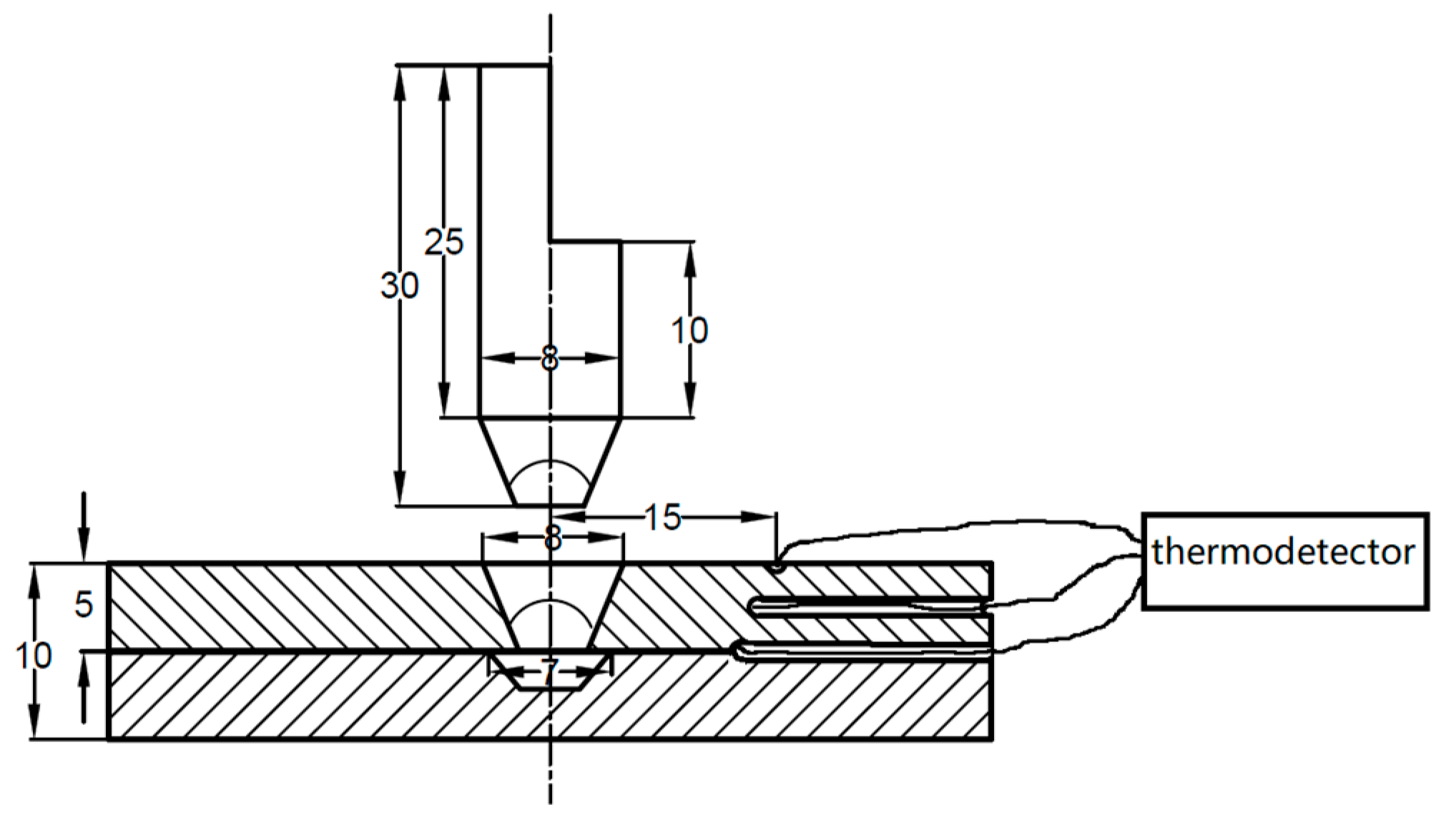

2.2. Welding Process of FPW

2.3. Microstructure Characterization

2.4. Mechanical Performance Test

3. Results

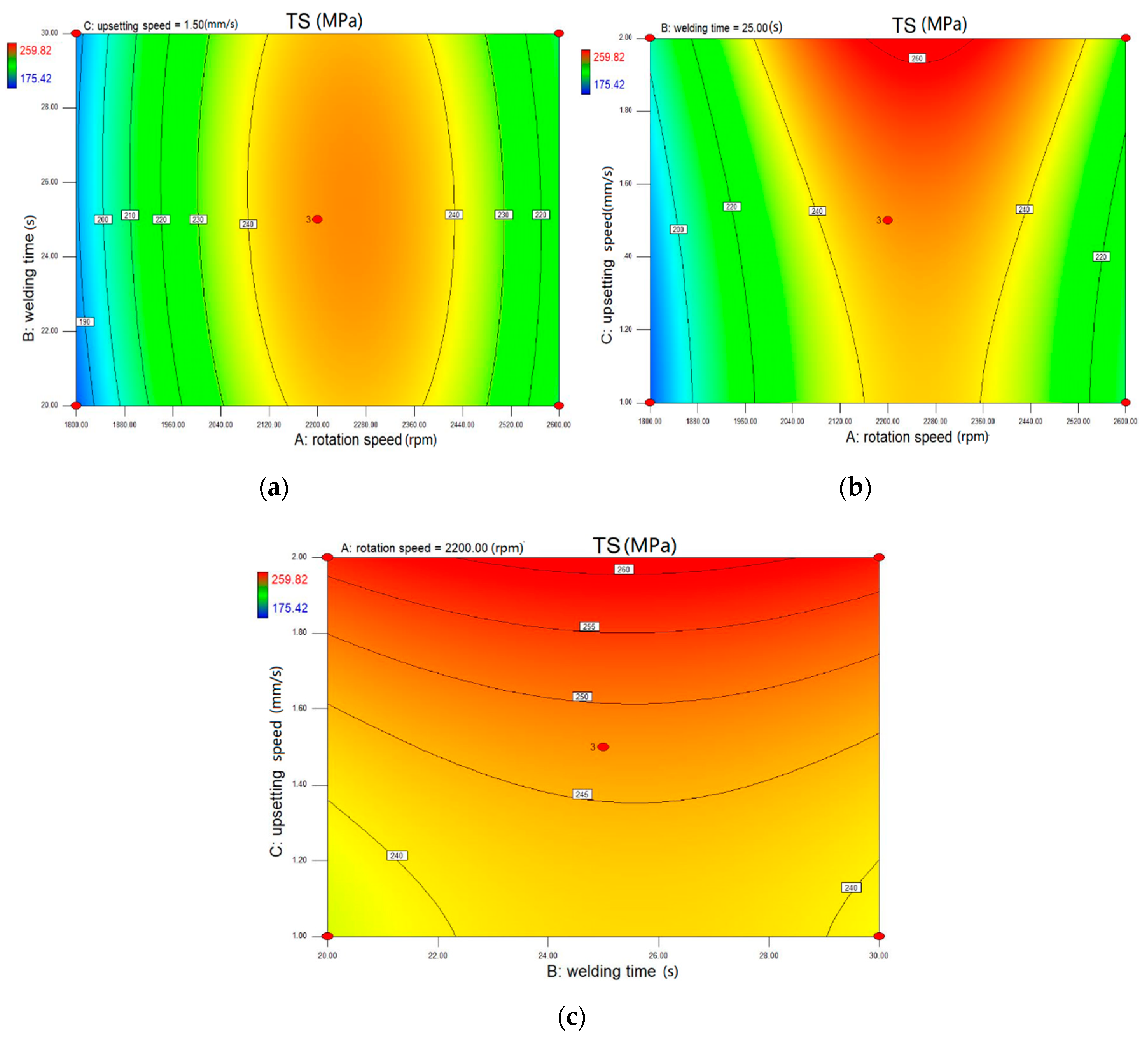

3.1. Optimization of FPW Process

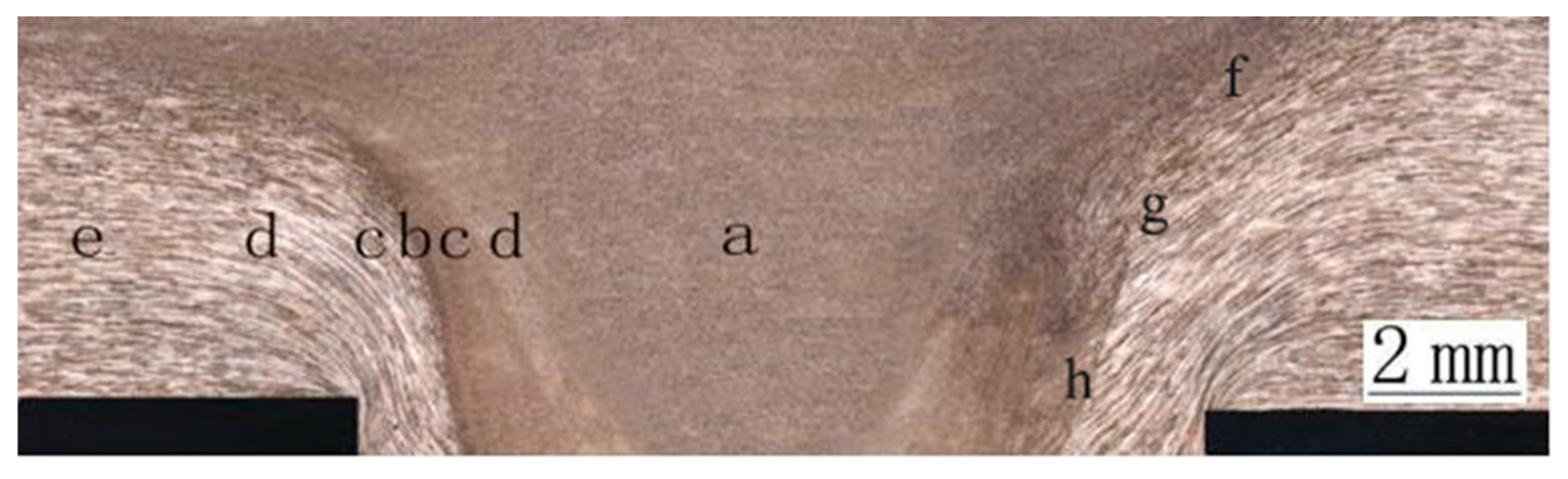

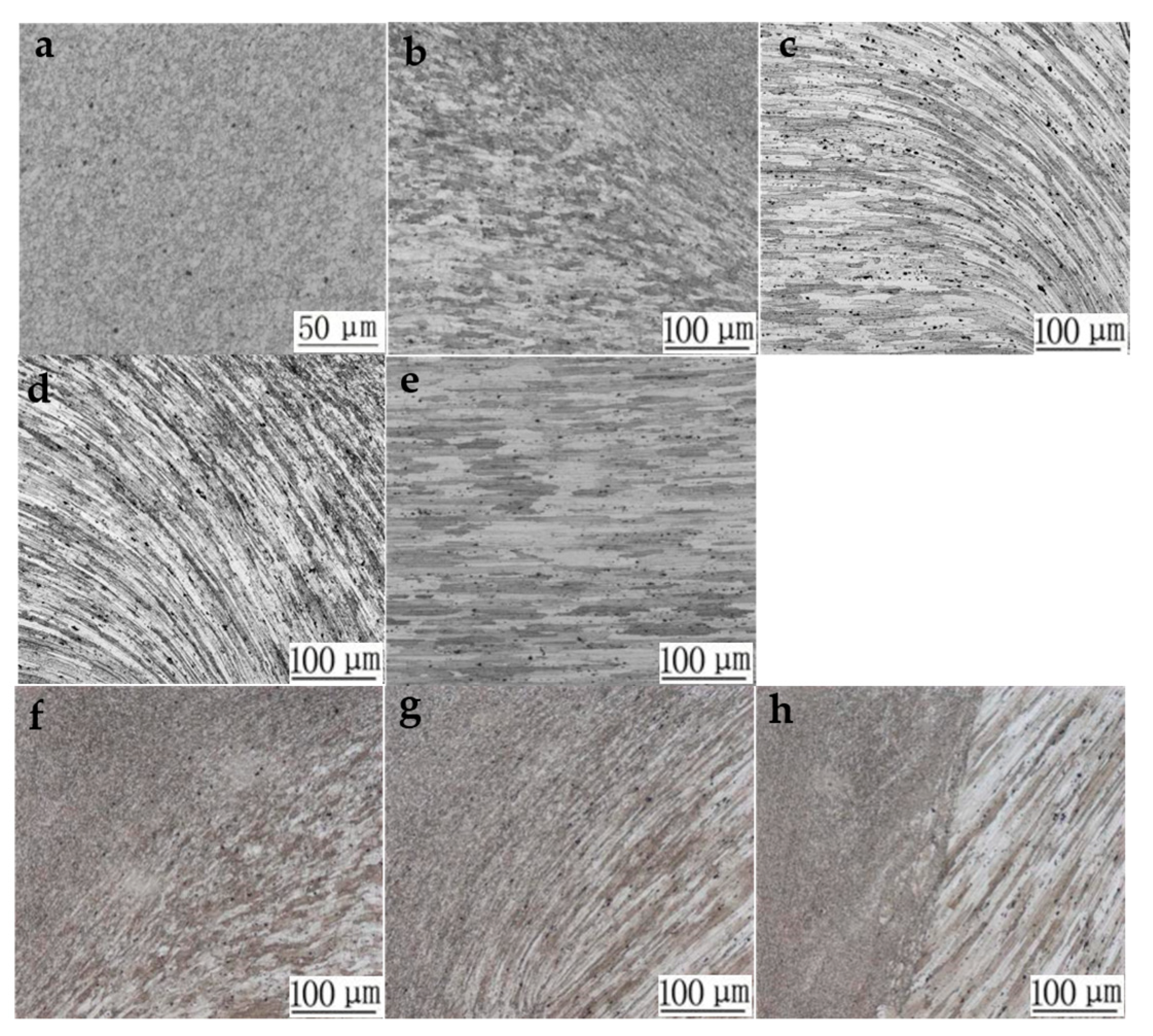

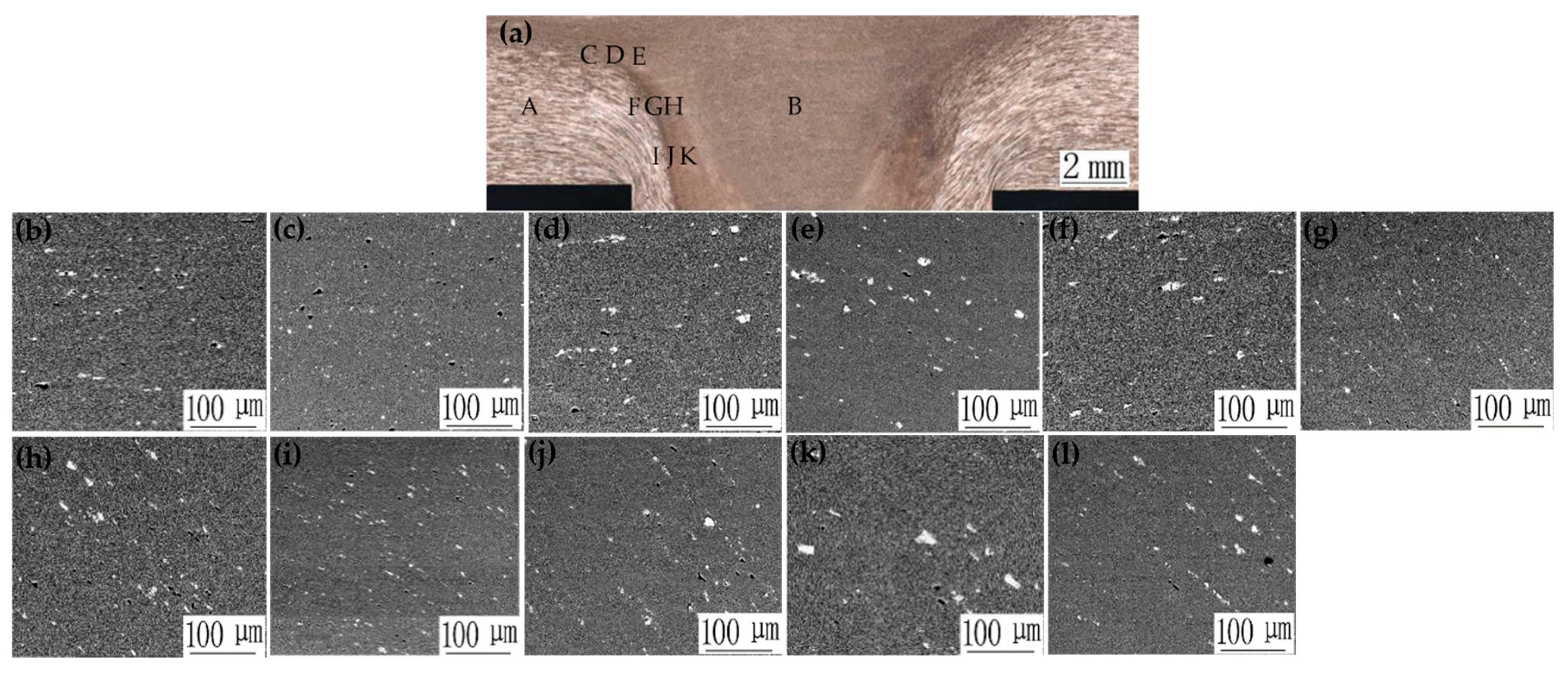

3.2. Microstructure and Second-Phase Distribution of the FPW Joint

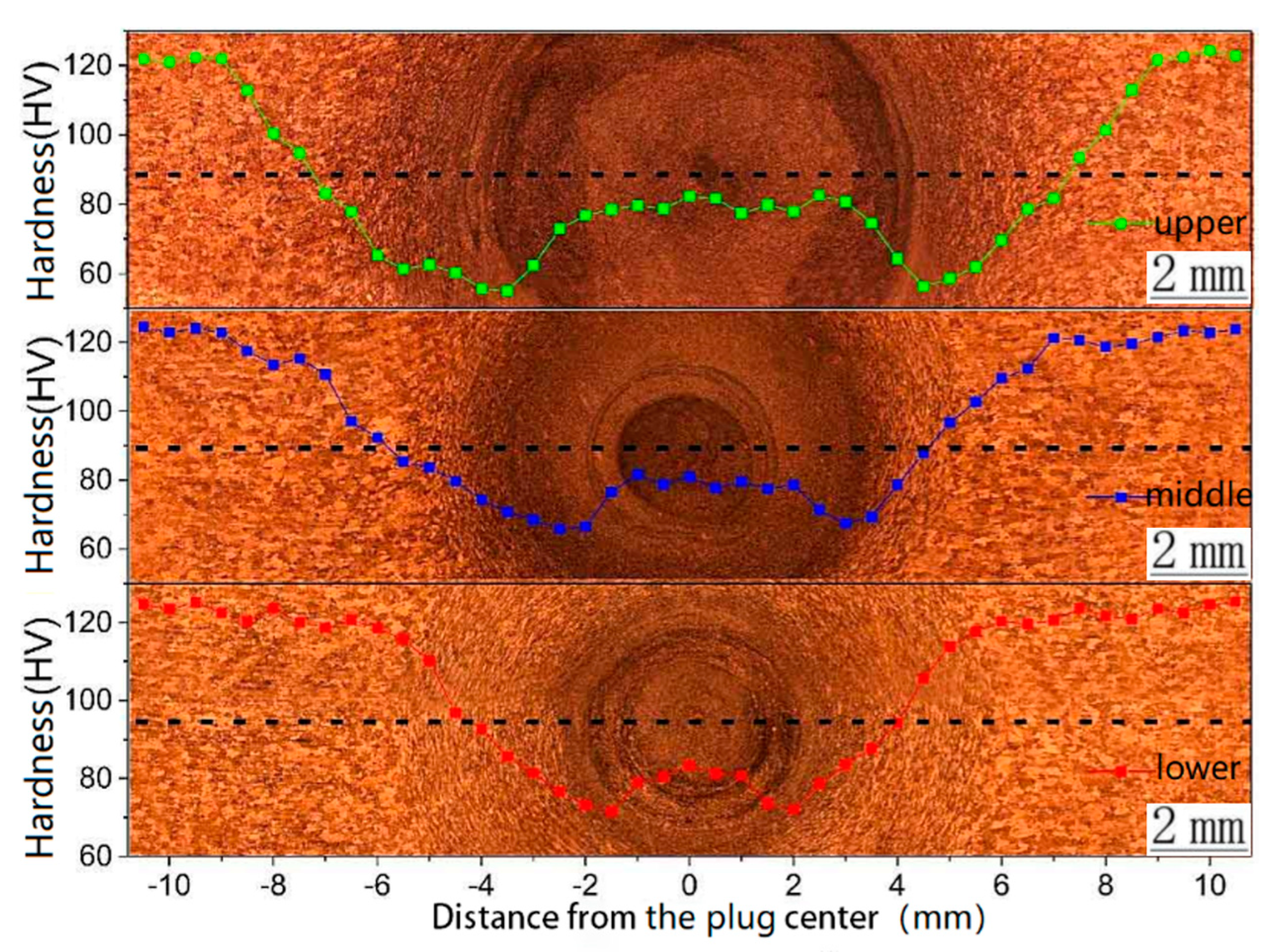

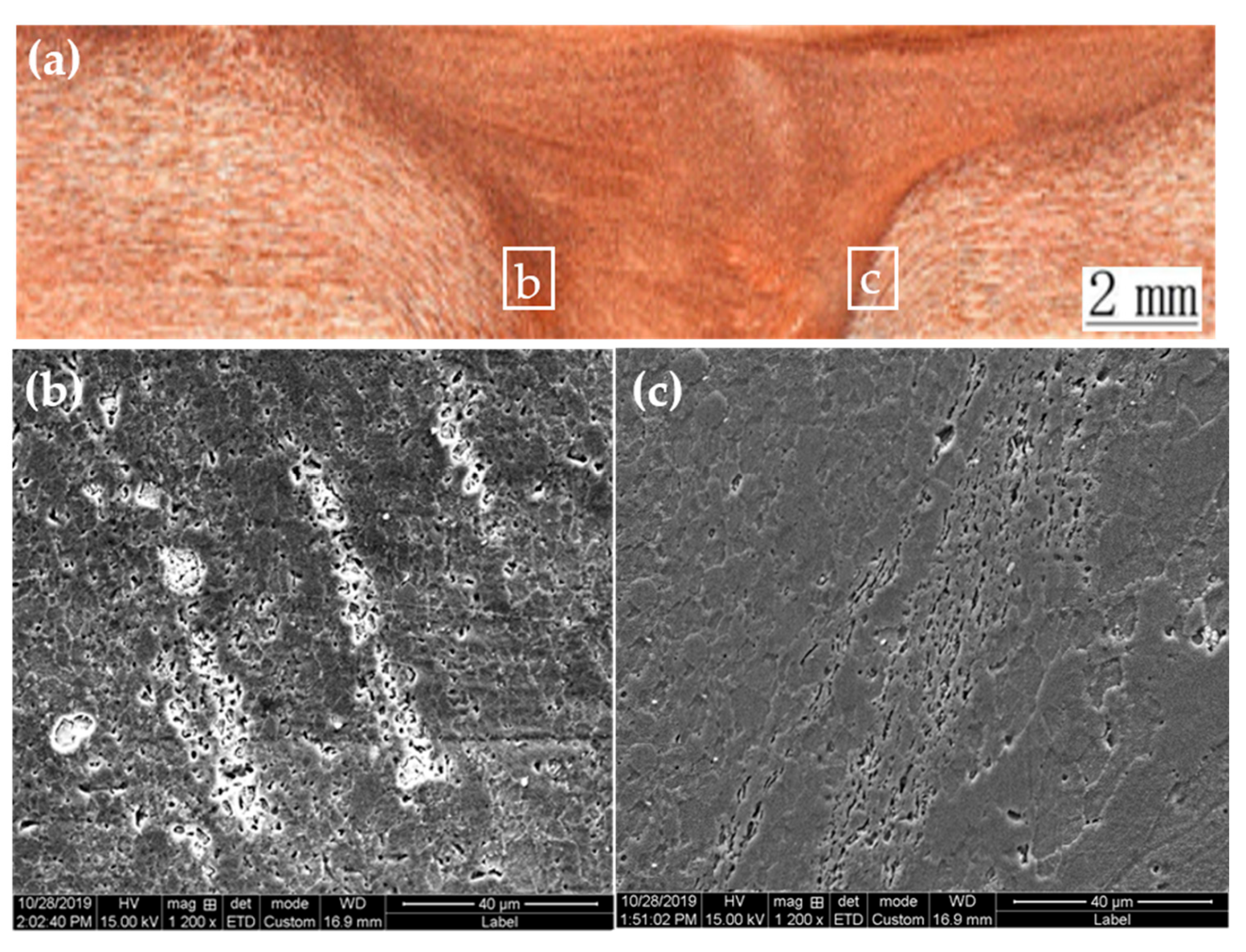

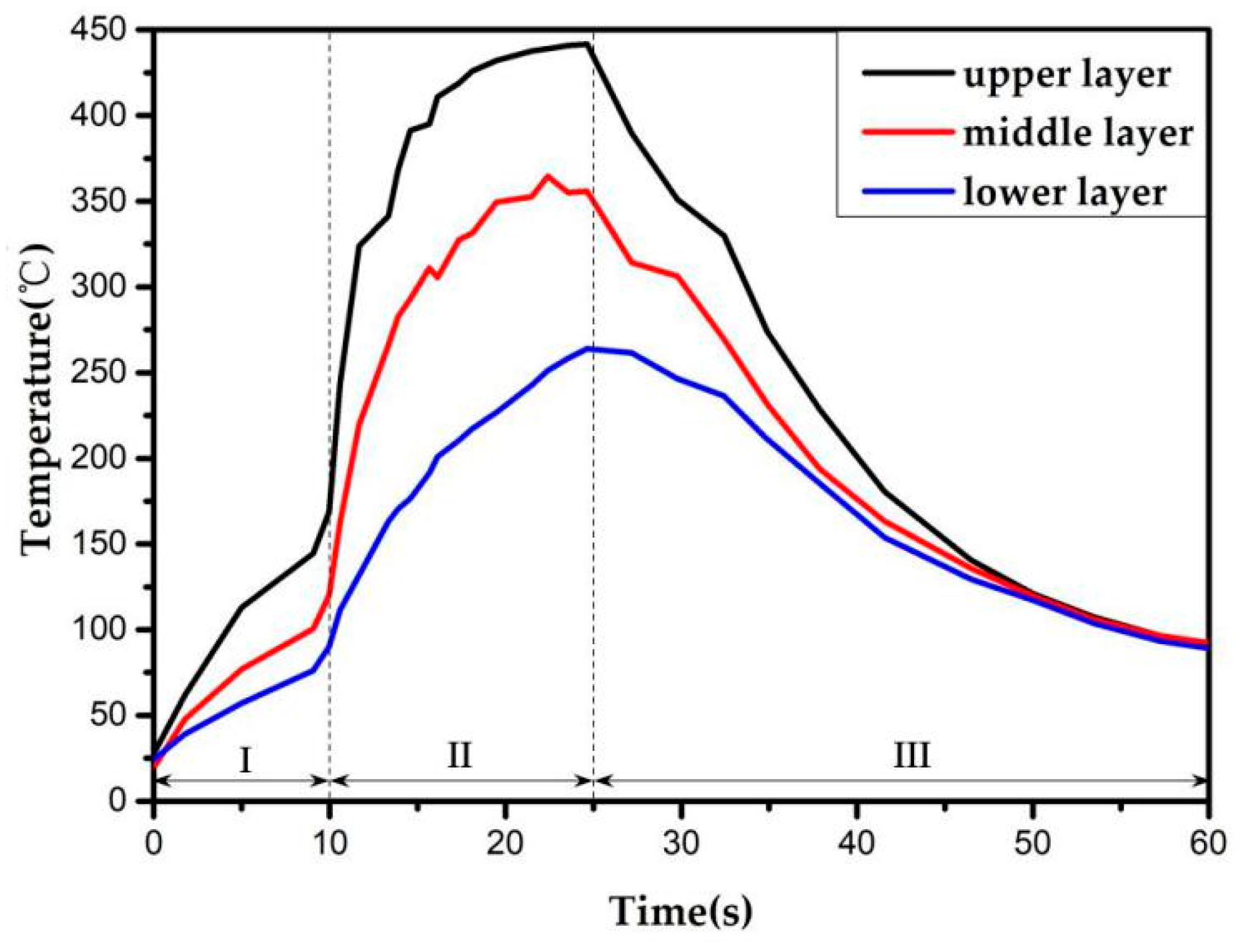

3.3. Flow and Hardness of FPW Joint Metal

3.4. Analysis of the Axial Force

4. Discussion

5. Conclusions

- This study adopted the response surface optimization method and found that the degree of influence of the welding parameters on the tensile strength of the joint was ω > v > t. The optimal welding parameters were: rotational speed, 2254 rpm; welding time, 25 s; and upsetting speed 2 mm/s. The maximal tensile strength of the FPW joint was 262.34 MPa.

- In the welding process, a reasonable coordination of the rotational speed and upsetting speed can enhance the plastic metal fluidity at the joint to improve its mechanical properties.

- The fundamental reason for the weak connection at the root of the FPW joint is that the interaction force between the plastic metals on the bonding surface is not strong, and improving the axial force can enhance the interaction force between interfaces to achieve a reliable connection.

Author Contributions

Funding

Conflicts of Interest

References

- Kazuhiro, N. Friction stir welding of magnesium alloys. Weld. Int. 2009, 23, 328–332. [Google Scholar]

- Li, K.; Liu, X.-M.; Zhao, Y. Research Status and Prospect of Friction Stir Processing Technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef] [Green Version]

- Magalhães, V.M.; Leitão, C.; Rodrigues, D. Friction stir welding industrialisation and research status. Sci. Technol. Weld. Join. 2017, 23, 400–409. [Google Scholar] [CrossRef]

- Beamish, K. Friction taper plug welding of 10mm AA6082-T6. Wti Rep. 2003. No. 768. [Google Scholar]

- Li, W.; Jiang, D.; Yang, L.; Pan, J.; Qu, R.; Sun, T. Numerical simulation of temperature field and prediction of microstructure in friction hydro pillar processing. J. Mater. Process. Technol. 2018, 252, 370–380. [Google Scholar] [CrossRef]

- Sun, Y.; Fujii, H.; Sato, Y.; Morisada, Y. Friction stir spot welding of SPCC low carbon steel plates at extremely low welding temperature. J. Mater. Sci. Technol. 2019, 35, 733–741. [Google Scholar] [CrossRef]

- Hartley Paula, J. Friction plug weld repair of space shuttle external tank. Weld. Metal. Fabric. 2000, 68, 6–8. [Google Scholar]

- Metz, D.; Barkey, M.E. Fatigue behavior of friction plug welds in 2195 Al–Li alloy. Int. J. Fatigue 2012, 43, 178–187. [Google Scholar] [CrossRef]

- Du, B.; Cui, L.; Yang, X.; Wang, D.; Sun, Z. Weakening mechanism and tensile fracture behavior of AA 2219-T87 friction plug welds. Mater. Sci. Eng. A 2017, 693, 129–135. [Google Scholar] [CrossRef]

- Hynes, N.R.J.; Velu, P.S.; Nithin, A.M. Friction push plug welding in airframe structures using Ti-6Al-4V plug. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 158. [Google Scholar] [CrossRef]

- Cui, L.; Yang, X.; Wang, D.; Hou, X.; Cao, J.; Xu, W. Friction taper plug welding for S355 steel in underwater wet conditions: Welding performance, microstructures and mechanical properties. Mater. Sci. Eng. A 2014, 611, 15–28. [Google Scholar] [CrossRef]

- Du, B.; Yang, X.; Liu, K.; Sun, Z.; Wang, D. Effects of supporting plate hole and welding force on weld formation and mechanical property of friction plug joints for AA2219-T87 friction stir welds. Weld. World 2019, 63, 989–1000. [Google Scholar] [CrossRef]

- Metz, D.F.; Weishaupt, E.R.; Barkey, M.E.; Fairbee, B.S. A Microstructure and Microhardness Characterization of a Friction Plug Weld in Friction Stir Welded 2195 Al-Li. J. Eng. Mater. Technol. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Landell, R.; Kanan, L.F.; Buzzatti, D.; Vicharapu, B.; De, A.; Clarke, T. Material flow during friction hydro-pillar processing. Sci. Technol. Weld. Join. 2019, 25, 228–234. [Google Scholar] [CrossRef]

- Cui, L.; Yang, X.; Wang, D.; Cao, J.; Xu, W. Experimental study of friction taper plug welding for low alloy structure steel: Welding process, defects, microstructures and mechanical properties. Mater. Des. 2014, 62, 271–281. [Google Scholar] [CrossRef]

- Gao, J.; Yang, L.; Cui, L.; Lu, P.; Yang, J.; Gao, Y. Improving the Weld Formation and Mechanical Properties of the AA-5A06 Friction Pull Plug Welds by Axial Force Control. Acta Met. Sin. English Lett. 2020, 33, 828–838. [Google Scholar] [CrossRef]

- Du, B.; Yang, X.Q.; Tang, W.; Sun, Z.; Wang, D. Numerical analyses of material flows and thermal processes during friction plug welding for AA2219 aluminum alloy. J. Mater. Process. Technol. 2020, 278, 116466. [Google Scholar] [CrossRef]

- Wang, Z.; Teng, J.; Wang, D.P.; Cui, L.; Liu, H.; Yang, J.; Zhang, Y.; Zhu, H. Observations of repair process by friction stitch welding in simulated wet conditions—Flaws, microstructure and hardness evolutions in overlapping welds. J. Mater. Process. Technol. 2019, 264, 220–233. [Google Scholar] [CrossRef]

- Mohammadzadeh, A.; Azadbeh, M.; Danninger, H. New concept in analysis of supersolidus liquid phase sintering of alpha brass. Powder Met. 2014, 58, 123–132. [Google Scholar] [CrossRef]

- Johannes, A.Ö.; Manoj, K.; Andreas, S.; Sabine, S.; Gilles, R.B. Secondary precipitation during homogenization of Al-Mg-Si alloys: Influence on high temperature flow stress. Mater. Sci. Eng. 2017, 687, 175–180. [Google Scholar]

- Yan, Y.; Shen, Y.; Liu, W.; Li, J.; Gao, J. Friction plug welding of glass fiber reinforced PA6 sheets using a newly designed tool. J. Manuf. Process. 2019, 45, 614–623. [Google Scholar] [CrossRef]

- Li, J.; Shen, Y.; Yan, Y.; Tang, J.; Hou, W.; Huang, G.; Liu, W. Consumable friction plug welding of TC4 plate: Parameters, microstructures, and mechanical properties. Mater. Res. Express 2019, 6, 116520. [Google Scholar] [CrossRef]

- Du, B.; Sun, Z.; Yang, X.; Cui, L.; Song, J.; Zhang, Z. Characteristics of friction plug welding to 10 mm thick AA2219-T87 sheet: Weld formation, microstructure and mechanical property. Mater. Sci. Eng. A 2016, 654, 21–29. [Google Scholar] [CrossRef]

| Materials | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 6082-T6 aluminum alloy | 255 | 320 | 12 |

| Mg | Si | Mn | Fe | Cr | Zn | Cu | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.6–1.2 | 0.7–1.3 | 0.8 | 0.5 | 0.25 | 0.2 | 0.1 | 0.1 | Bal. |

| Parameters | Unit | Levels | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Rotational Speed (ω) | rpm | 1800 | 2200 | 2600 |

| Welding Time (t) | s | 20 | 25 | 30 |

| Upsetting Speed (υ) | mm/s | 1.0 | 1.5 | 2.0 |

| No. | Coded Values of Parameters | Tensile Strength (MPa) | ||

|---|---|---|---|---|

| ω | t | v | ||

| 1 | −1 | −1 | 0 | 175.42 |

| 2 | 1 | −1 | 0 | 221.38 |

| 3 | −1 | 1 | 0 | 176.51 |

| 4 | 1 | 1 | 0 | 216.53 |

| 5 | −1 | 0 | −1 | 191.21 |

| 6 | 1 | 0 | −1 | 200.25 |

| 7 | −1 | 0 | 1 | 212.14 |

| 8 | 1 | 0 | 1 | 219.38 |

| 9 | 0 | −1 | −1 | 234.84 |

| 10 | 0 | 1 | −1 | 240.76 |

| 11 | 0 | −1 | 1 | 254.81 |

| 12 | 0 | 1 | 1 | 259.82 |

| 13 | 0 | 0 | 0 | 247.63 |

| 14 | 0 | 0 | 0 | 246.38 |

| 15 | 0 | 0 | 0 | 248.47 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value | Significance Level |

|---|---|---|---|---|---|---|

| Model | 10,942.19 | 9 | 1215.80 | 13.15 | 0.0013 | Significant |

| ω | 1307.14 | 1 | 1307.14 | 14.14 | 0.0071 | - |

| t | 6.43 | 1 | 6.43 | 0.07 | 0.7996 | - |

| v | 781.90 | 1 | 781.90 | 8.46 | 0.0227 | - |

| Ω—t | 8.82 | 1 | 8.82 | 0.095 | 0.7664 | - |

| Ω—v | 0.81 | 1 | 0.81 | 0.0087 | 0.9280 | - |

| t—v | 0.21 | 1 | 0.21 | 0.0022 | 0.9636 | - |

| ω2 | 8670.26 | 1 | 8670.26 | 93.78 | <0.0001 | - |

| t2 | 53.54 | 1 | 53.54 | 0.58 | 0.4715 | - |

| v2 | 93.77 | 1 | 93.77 | 1.01 | 0.3474 | - |

| Residual | 647.17 | 7 | 92.54 | - | - | - |

| Lack of Fit | 634.37 | 3 | 211.46 | 66.06 | 0.0637 | Not significant |

| Pure error | 12.80 | 4 | 3.20 | - | - | - |

| Sum | 11,589.36 | 16 | - | - | - | - |

| Optimal Condition | Tensile Strength (MPa) | |||

|---|---|---|---|---|

| Rotational Speed (rpm) | Welding Time (s) | Upsetting Speed (mm/s) | Predicted | Experimental |

| 2254 | 25 | 2 | 263.86 | 262.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Li, X.; Zhao, Z.; Jiang, C.; Zhao, H. Process Optimization and Formation Analysis of Friction Plug Welding of 6082 Aluminum Alloy. Metals 2020, 10, 1454. https://doi.org/10.3390/met10111454

Zhang Z, Li X, Zhao Z, Jiang C, Zhao H. Process Optimization and Formation Analysis of Friction Plug Welding of 6082 Aluminum Alloy. Metals. 2020; 10(11):1454. https://doi.org/10.3390/met10111454

Chicago/Turabian StyleZhang, Zhongke, Xuanbai Li, Zaolong Zhao, Changming Jiang, and Huaxia Zhao. 2020. "Process Optimization and Formation Analysis of Friction Plug Welding of 6082 Aluminum Alloy" Metals 10, no. 11: 1454. https://doi.org/10.3390/met10111454