Kinetic Friction of Sport Fabrics on Snow

Abstract

:1. Introduction

2. Method

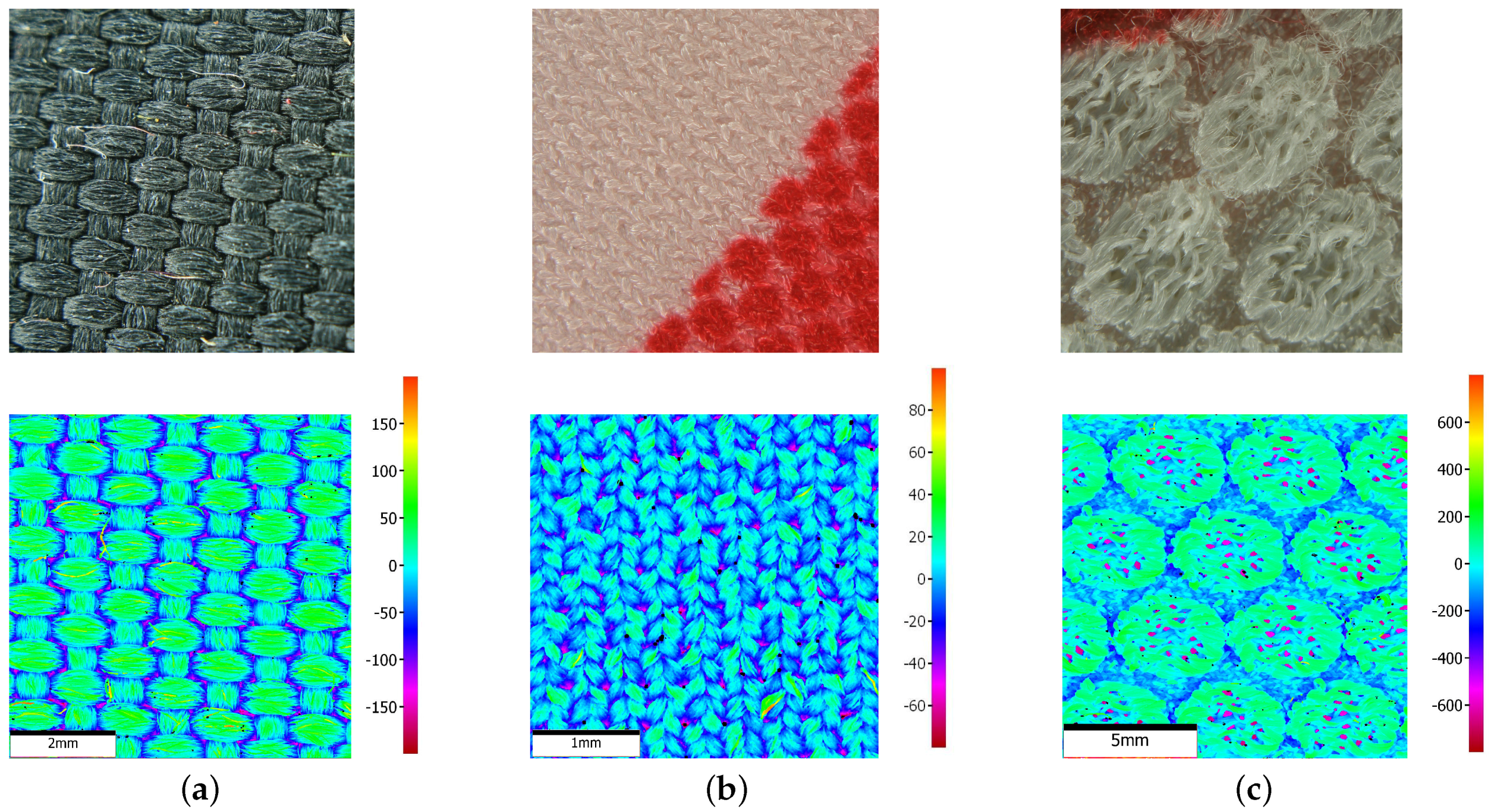

2.1. Fabrics

2.2. Friction Measurements

3. Results

4. Discussion

4.1. Measurement Values

4.2. Safety Issue

4.3. Limitations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gupta, B. Friction in Textile Materials; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Das, A.; Kothari, V.; Vandana, N. A study on frictional characteristics of woven fabrics. Autex Res. J. 2005, 5, 133–140. [Google Scholar]

- Sülar, V.; Öner, E.; Okur, A. Roughness and frictional properties of cotton and polyester woven fabrics. Indian J. Fibre Text. 2013, 38, 349–356. [Google Scholar]

- vonAllmen, B. Sliding Control of Ski Garments; Skiing Safety II; Figueras, J., Nelson, R., Morehouse, C., Eds.; University Park Press: Baltimore, MD, USA, 1978; pp. 185–192. [Google Scholar]

- vonAllmen, B.; Glenne, B. Skiing Accident Dynamics; Skiing Safety II; Figueras, J., Nelson, R., Morehouse, C., Eds.; University Park Press: Baltimore, MD, USA, 1978; pp. 199–208. [Google Scholar]

- Prokop, L. Untersuchungen mit rutschfester Skibekleidung (Investigations with anti-slip ski garments). In Zur Biomechanik des Schilaufs (On Biomechanics of Skiing); Fetz, F., Ed.; Inn Verlag: Innsbruck, Austria, 1977; pp. 37–45. [Google Scholar]

- Nachbaur, H. Reibungskoeffizienten von Skibekleidung (Friction Coefficients of Ski Garments); Internal Report; Department of Sport Science, University of Innsbruck: Innsbruck, Austria, 1994. [Google Scholar]

- Belloni, E.; Milani, D.; Braghin, F. An innovative tribometer for measurements between sport fabrics and ice. In Proceedings of the 33rd IMAC, A Conference and Exposition on Structural Dynamics, Orlando, FL, USA, 2–5 February 2015; Sensors and Instrumentation. Sit, E.W., Ed.; Springer: New York, NY, USA, 2015; Volume 5, pp. 37–44. [Google Scholar]

- Brown, C.; Hoffman, A.; Heinzmann, R. Skier trajectories after loss of control. In Proceedings of the ASTM STP 1266 Skiing Trauma and Safety; Mote, C., Johnson, R., Hauser, W., Schaff, P., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1996; Volume 10, pp. 186–195. [Google Scholar]

- Hasler, M.; Schindelwig, K.; Nachbauer, W. Friction Coefficient of Fabrics on Snow; Book of Abstracts of the 21st Internetional Congress on Ski Trauma and Skiing Safety; San Vito di Cadore—Cortina d’Ampezzo, IT; Petrone, N., Marcolin, G., Eds.; International Society for Skiing Safety: Aviemore, Scotland, 2015; p. 68. [Google Scholar]

- Colbeck, S. A Review of the Processes That Control Snow Friction; Technical Report 92-2; Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1992. [Google Scholar]

- Bäurle, L.; Szabó, D.; Fauve, M.; Rhyner, H.; Spencer, N. Sliding friction of polyethylene on ice: Tribometer measurements. Tribol. Lett. 2006, 24, 77–84. [Google Scholar] [CrossRef]

- Linnamo, V.; Ohtonen, O.; Rapp, W.; Lemmettylä, T.; Göpfert, C.; Komi, P.; Ishikawa, M.; Holmberg, H.; Vähäsöyrinki, P.; Mikkola, J.; et al. Sports technology, science and coaching. In Proceedings of the 2nd Internetional Congress on Science and Nordic Skiing, Vuokatti, Finland, 28–31 May 2012; pp. 28–31.

- Nachbauer, W.; Kaps, P.; Hasler, M.; Mössner, M. Friction between ski and snow. In The Engineering Approach to Winter Sports; Braghin, F., Cheli, F., Maldifassi, S., Melzi, S., Sabbioni, E., Eds.; Springer: New York, NY, USA, 2016; pp. 17–32. [Google Scholar]

- Rohm, S.; Hasler, M.; Knoflach, C.; van Putten, J.; Unterberger, S.; Schindelwig, K.; Lackner, R.; Nachbauer, W. Friction between steel and snow in dependence of the steel roughness. Tribol. Lett. 2015, 59. [Google Scholar] [CrossRef]

- Nwaogu, U.; Tiedje, N.; Hansen, H. A non-contact 3D model to characterize the surface roughness of castings. J. Mater. Process. Technol. 2013, 213, 59–68. [Google Scholar] [CrossRef]

- Leach, R. Characterization of Areal Surface Texture; Springer: New York, NY, USA, 2013. [Google Scholar]

- Bowden, F.; Hughes, T. The mechanism of sliding on ice and snow. Proc. R. Soc. Lond. 1939, A172, 280–298. [Google Scholar] [CrossRef]

- Ambach, W.; Mayr, B. Ski gliding and water film. Cold Reg. Sci. Technol. 1981, 5, 59–65. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Mechanisms of dry friction, their scaling and linear properties. In Multiscale Dissipative Mechanisms and Hierarchical Surfaces; Nosonovsky, M., Bhushan, B., Eds.; Springer: Berlin, Germany, 2008; pp. 27–45. [Google Scholar]

- Holmberg, K.; Matthews, A. Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Ruedl, G.; Sommersacher, R.; Woldrich, T.; Kopp, M.; Nachbauer, W.; Burtscher, M. Durchschnittsgeschwindigkeit von Wintersportlern in Abhängigkeit verschiedener Einflussfaktoren (Mean speed of winter sport participants depending on various factors). Sportverletz Sportsc 2010, 24, 150–153. [Google Scholar] [CrossRef] [PubMed]

- Austrian Standards Institute (ON). Skipisten—Klassifizierung und Grundlegende Schilder (Ski Runs—Classification and Basic Sings); Austrian Standards Institute (ON): Vienna, Austria, 2003. [Google Scholar]

| (μ) | (μ) | |

|---|---|---|

| ski overall | 35 | 398 |

| smooth racing suit | 11 | 185 |

| dimpled racing suit | 101 | 1539 |

| / | / | / | ||

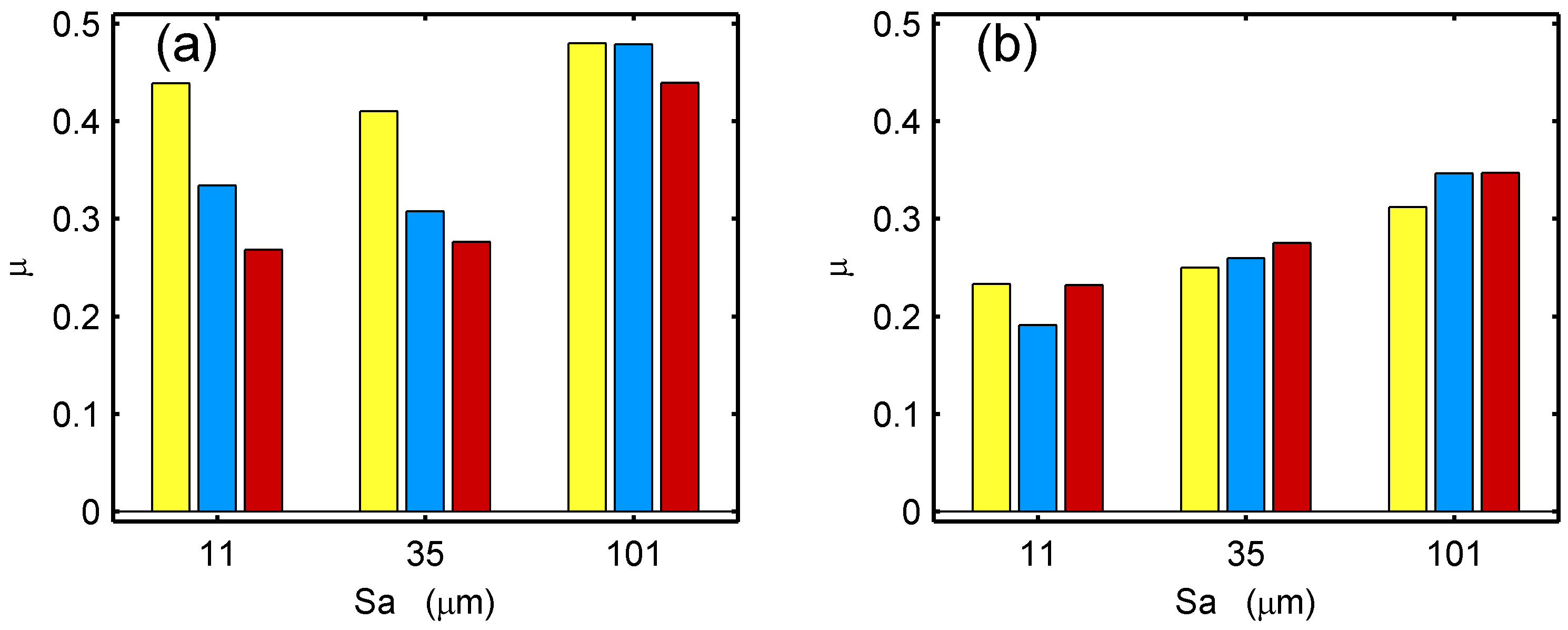

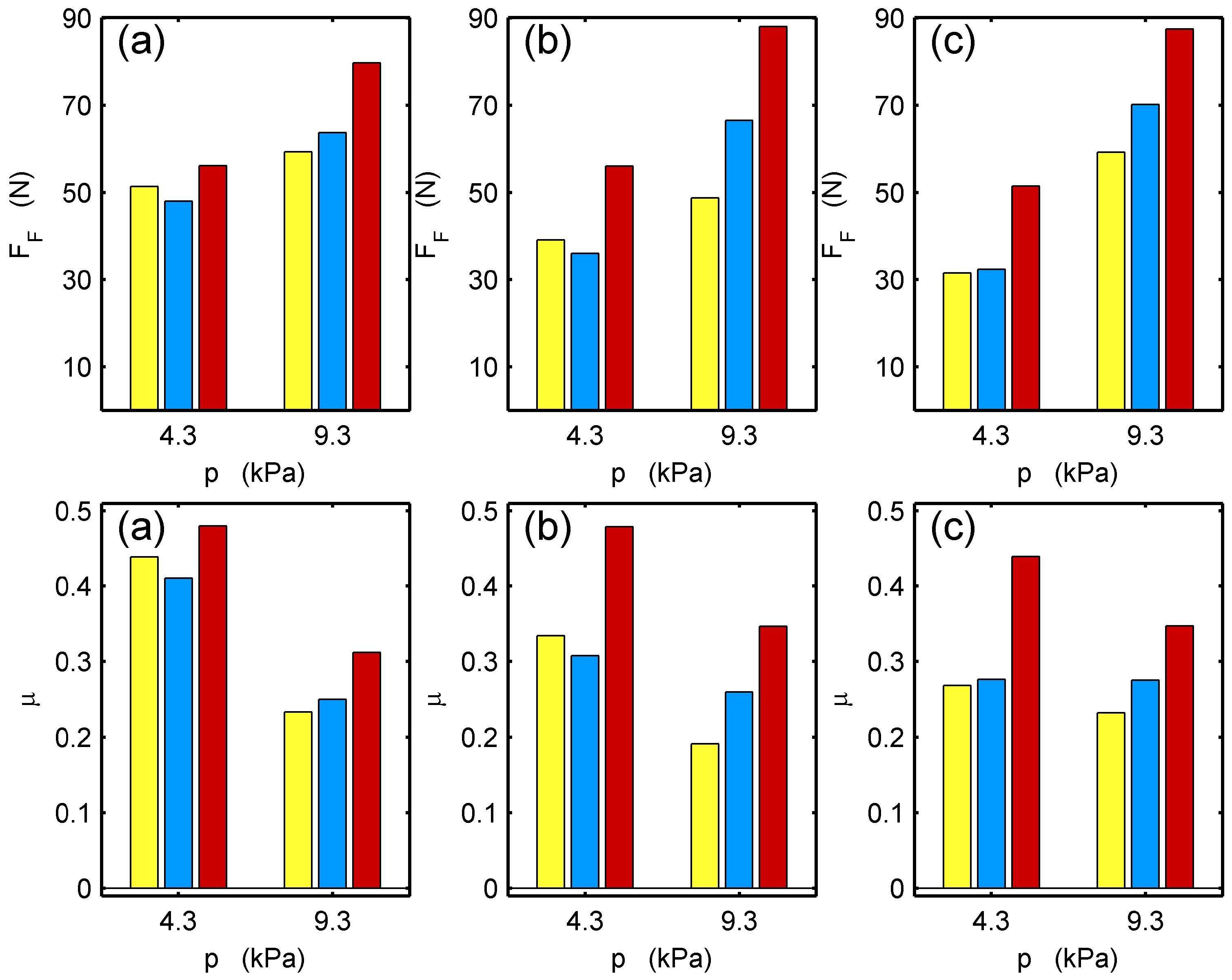

| smooth racing suit | ( μ) | 0.44 | 0.33 | 0.27 |

| ski overall | ( μ) | 0.41 | 0.31 | 0.28 |

| dimpled racing suit | ( μ) | 0.48 | 0.48 | 0.44 |

| / | / | / | ||

| smooth racing suit | ( μ) | 0.23 | 0.19 | 0.23 |

| ski overall | ( μ) | 0.25 | 0.26 | 0.28 |

| dimpled racing suit | ( μ) | 0.31 | 0.35 | 0.35 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nachbauer, W.; Mössner, M.; Rohm, S.; Schindelwig, K.; Hasler, M. Kinetic Friction of Sport Fabrics on Snow. Lubricants 2016, 4, 7. https://doi.org/10.3390/lubricants4010007

Nachbauer W, Mössner M, Rohm S, Schindelwig K, Hasler M. Kinetic Friction of Sport Fabrics on Snow. Lubricants. 2016; 4(1):7. https://doi.org/10.3390/lubricants4010007

Chicago/Turabian StyleNachbauer, Werner, Martin Mössner, Sebastian Rohm, Kurt Schindelwig, and Michael Hasler. 2016. "Kinetic Friction of Sport Fabrics on Snow" Lubricants 4, no. 1: 7. https://doi.org/10.3390/lubricants4010007