Cold Rolling of Steel Strips with Metal-Working Coolants

Abstract

:1. Introduction

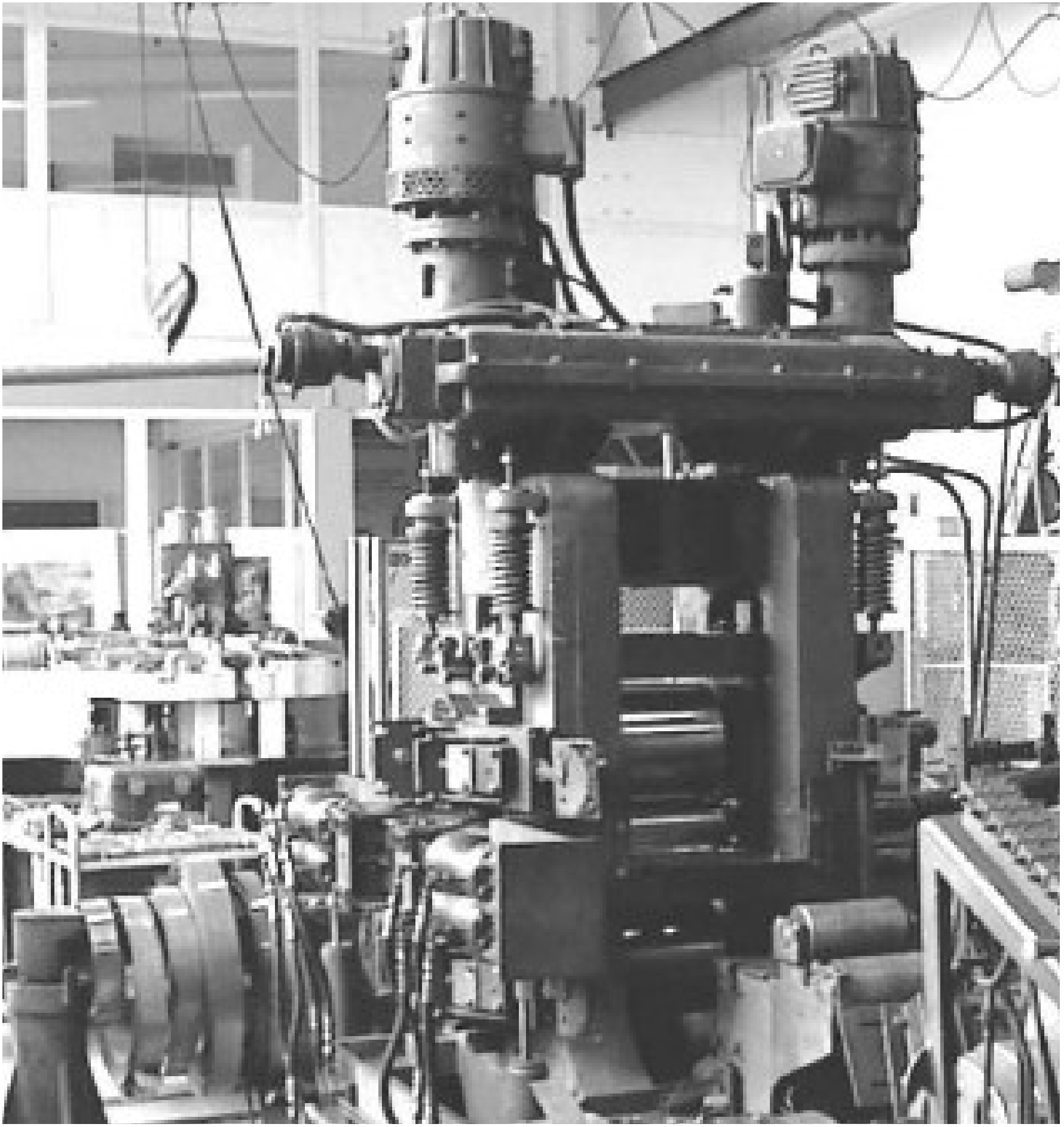

2. Materials and Methods

- -

- the coolant «Universal-1TC» developed and used in Ilyich Iron and Steel Works, Mariupol, Ukraine, TU U23.2-31023384.002–2004 (No. 7) (see Table 1);

- -

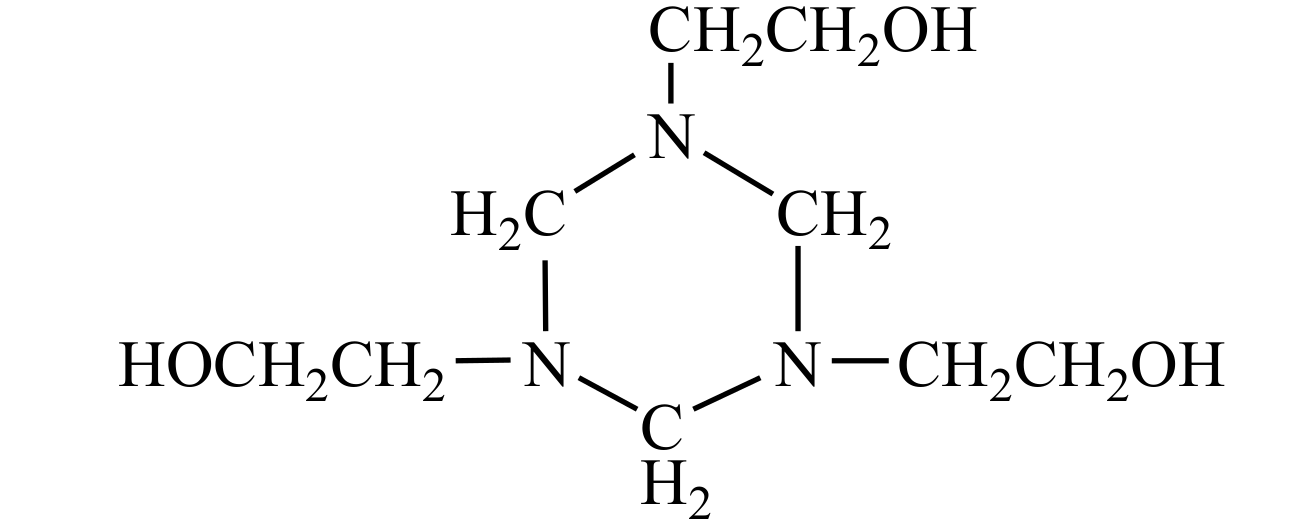

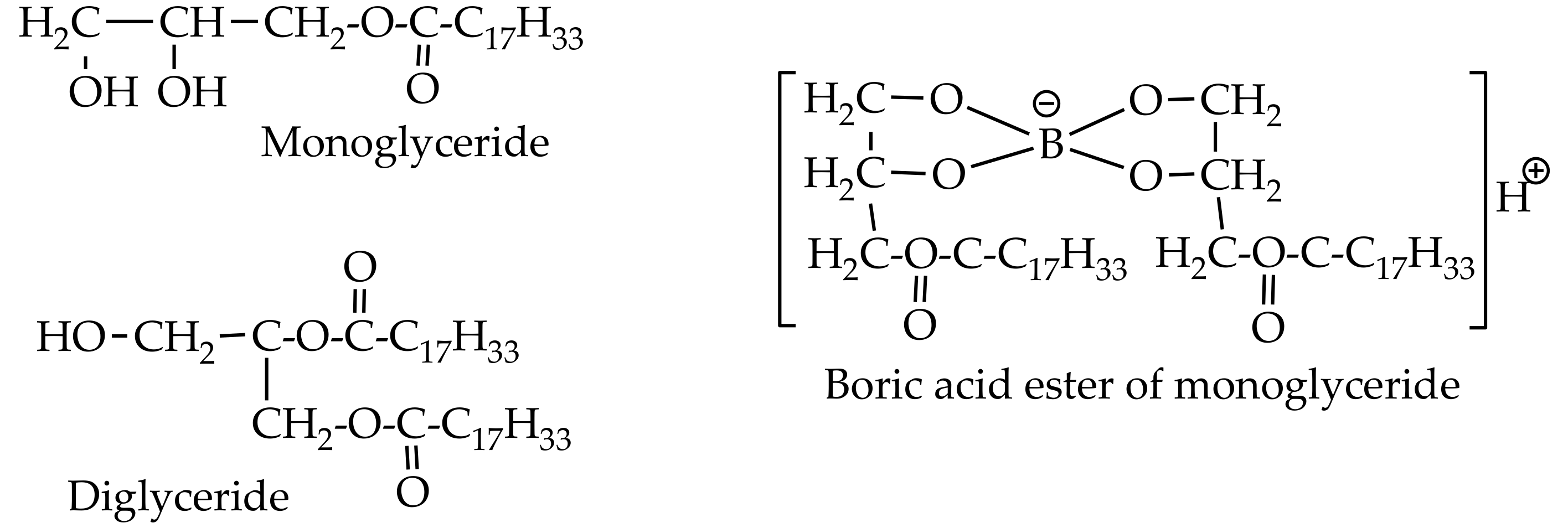

- metalworking coolant with 100% concentration of mono- and diglycerides obtained from sunflower oil (No. 8) (see Table 1);

- -

- the lubricant SP-3, GOST 5702-75 (No. 13) (see Table 2).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lin, J.F.; Huang, T.K.; Hsu, C.T. Evaluation of lubricants for cold strip rolling. Wear 1991, 147, 79–91. [Google Scholar] [CrossRef]

- Lenard, J.G. The effect of lubricant additives on the coefficient of friction in cold rolling. J. Mater. Process. Technol. 1998, 80–81, 232–238. [Google Scholar] [CrossRef]

- McConnell, C.; Lenard, J.G. Friction in cold rolling of a low carbon steel with lubricants. J. Mater. Process. Technol. 2000, 99, 86–93. [Google Scholar] [CrossRef]

- Kosanov, J.; Lenard, J.G.; Uhrig, J.; Wallfarth, B. The effect of lubricant additives on the coefficient of friction in the flat-die test. Mater. Sci. Eng. A 2006, 427, 274–281. [Google Scholar] [CrossRef]

- Avdeenko, A.P.; Konovalova, S.A.; Avdeenko, E.A.; Fedorinov, M.V.; Gribkov, E.P. Application of greases and metalworking coolants in steel rolling: Report 1. In 14th International Conference Research and Development in Mechanical Industry RADMI 2014, Volume 1, Proceedings of the RADMI 2014, Tolopa, Serbia, 18–21 September 2014; Dašić, P.V., Ed.; SaTCIP Ltd.: Vrnjačka Banja, Serbia, 2014; pp. 155–161. ISBN 978-86-6075-047-3. [Google Scholar]

- Avdeenko, A.P.; Konovalova, S.A.; Avdeenko, E.A.; Fedorinov, M.V.; Gribkov, E.P. Application of greases and metalworking coolants in steel rolling: Report 2. In 14th International Conference Research and Development in Mechanical Industry RADMI 2014, Volume 1, Proceedings of the RADMI 2014, Tolopa, Serbia, 18–21 September 2014; Dašić, P.V., Ed.; SaTCIP Ltd.: Vrnjačka Banja, Serbia, 2014; pp. 162–165. ISBN 978-86-6075-047-3. [Google Scholar]

- Avdeenko, A.P.; Konovalova, S.A.; Avdeenko, E.A.; Fedorinov, M.V.; Gribkov, E.P. Application of greases and metalworking coolants in steel rolling: Report 3. In 14th International Conference Research and Development in Mechanical Industry RADMI 2014, Volume 1, Proceedings of the RADMI 2014, Tolopa, Serbia, 18–21 September 2014; Dašić, P.V., Ed.; SaTCIP Ltd.: Vrnjačka Banja, Serbia, 2014; pp. 166–168. ISBN 978-86-6075-047-3. [Google Scholar]

- Avdeenko, A.P.; Lutovac, M.; Konovalova, S.A.; Fedorynov, M.V. Investigation of Efficiency of use of High-Temperature Greases in Steel Rolling. Part 1. Appl. Mech. Mater. 2015, 806, 3–9. [Google Scholar] [CrossRef]

- Avdeenko, A.P.; Lutovac, M.; Konovalova, S.A.; Fedorynov, M.V. Investigation of Efficiency of use of High-Temperature Greases in Steel Rolling. Part 2. Appl. Mech. Mater. 2015, 806, 10–15. [Google Scholar] [CrossRef]

- Avdeenko, A.P.; Fedorinov, V.A.; Fedorinov, M.V.; Burmistrov, K.S.; Toropin, N.V.; Konovalova, S.A. New Compositions of Metalworking Coolants for Steel Rolling. J. Res. Dev. Mech. Ind. 2016, 8, 1–8. [Google Scholar]

- Nagendramma, P.; Shukla, B.M.; Adhikari, D.K. Synthesis, Characterization and Tribological Evaluation of New Generation Materials for Aluminum Cold Rolling Oils. Lubricants 2016, 4, 23. [Google Scholar] [CrossRef]

- Mahanti, S.; Bhatta, A.K.; Biswas, R.N.; Bhatia, J.; Singh, S.N. Development of a meta-stable semi-synthetic lubricant for cold rolling of steel. J. Synth. Lubr. 1990, 6, 285–298. [Google Scholar] [CrossRef]

- Okabe, H.; Kanno, T. Behaviour of polar compounds in lubricating oil films. ASLE Trans. 1981, 24, 459–466. [Google Scholar] [CrossRef]

- Grudev, A.P. Vneshnee Treniye Pri Prokatke; Metallurgiya: Moscow, Russia, 1973; p. 288. (In Russian) [Google Scholar]

- Wusatowski, Z. Fundamentals of rolling processes. In Fundamentals of Rolling; SLASK: Katowice, Poland, 1969; Chapter 3; pp. 69–202. [Google Scholar]

- Potapkin, V.F. Metod Poleyi Liniyi Skol’zheniya V Teorii Prokatki Shirokih Polos: Monograph; DDMA: Kramatorsk, Ukraine, 2005; p. 316. ISBN 966-379-019-9. (In Russian) [Google Scholar]

| Composition Number | Component, % by Mass | |||

|---|---|---|---|---|

| Boric Acid Esters of Mono- and Diglycerides Based on Sunflower Oil * | Industrial Oil | Chlorinated Paraffin Wax XP-470 | Calcium Stearate | |

| No. 1 | 30 | 30 | 20 | 20 |

| No. 2 | 40 | 20 | 20 | 20 |

| No. 3 | 50 | 10 | 20 | 20 |

| No. 4 | 60 | - | 20 | 20 |

| No. 5 | 80 | - | 10 | 10 |

| No. 6 | 100 | - | - | - |

| No. 7 | Coolant «Universal-1TC» | |||

| No. 8 | Mono- and diglycerides based on sunflower oil, 100% by mass | |||

| Composition Number | Component, % by Mass | ||

|---|---|---|---|

| Chicken Fat | Emulsifier * | Antibacterial Additive ** | |

| No. 9 | 100 | – | – |

| No. 10 | 92 | 5 | 3 |

| No. 11 | 87 | 10 | 3 |

| No. 12 | 82 | 15 | 3 |

| No. 13 | SP-3 | ||

| Composition Number | Component, % by Mass | |||

|---|---|---|---|---|

| Boric Acid Esters of Mono- and Diglycerides Based on Rapeseed oil * | Industrial Oil I-40 | Emulsifier ** | Water | |

| No. 18 | 25 | 5 | 70 | - |

| No. 19 | 7.5 | 1.5 | 21 | 70 |

| No. 20 | 5 | 1 | 14 | 80 |

| No. 21 | 2.5 | 0.5 | 7 | 90 |

| No. 22 | 1.25 | 0.25 | 3.5 | 95 |

| No. 23 | 0.75 | 0.15 | 2.1 | 97 |

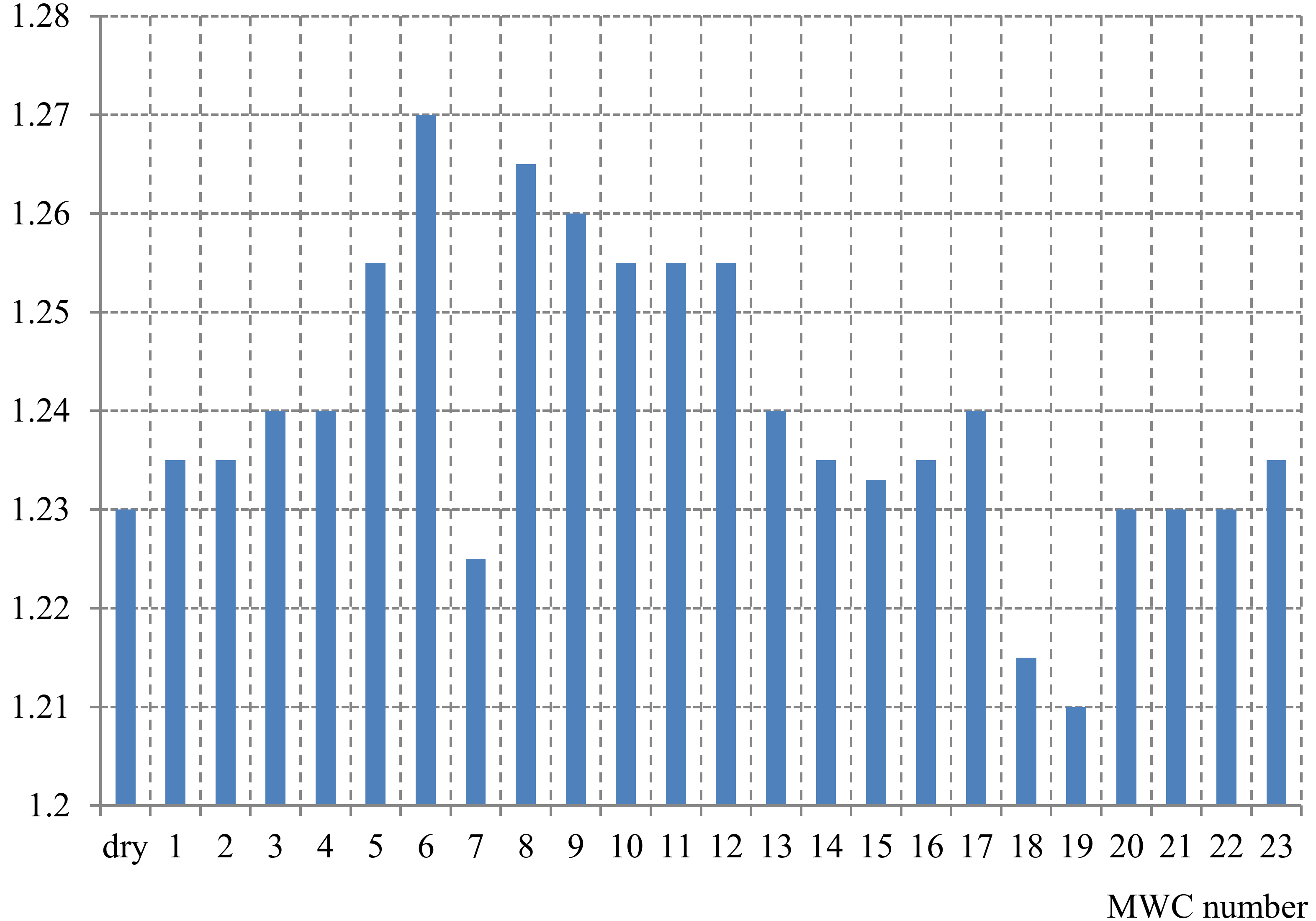

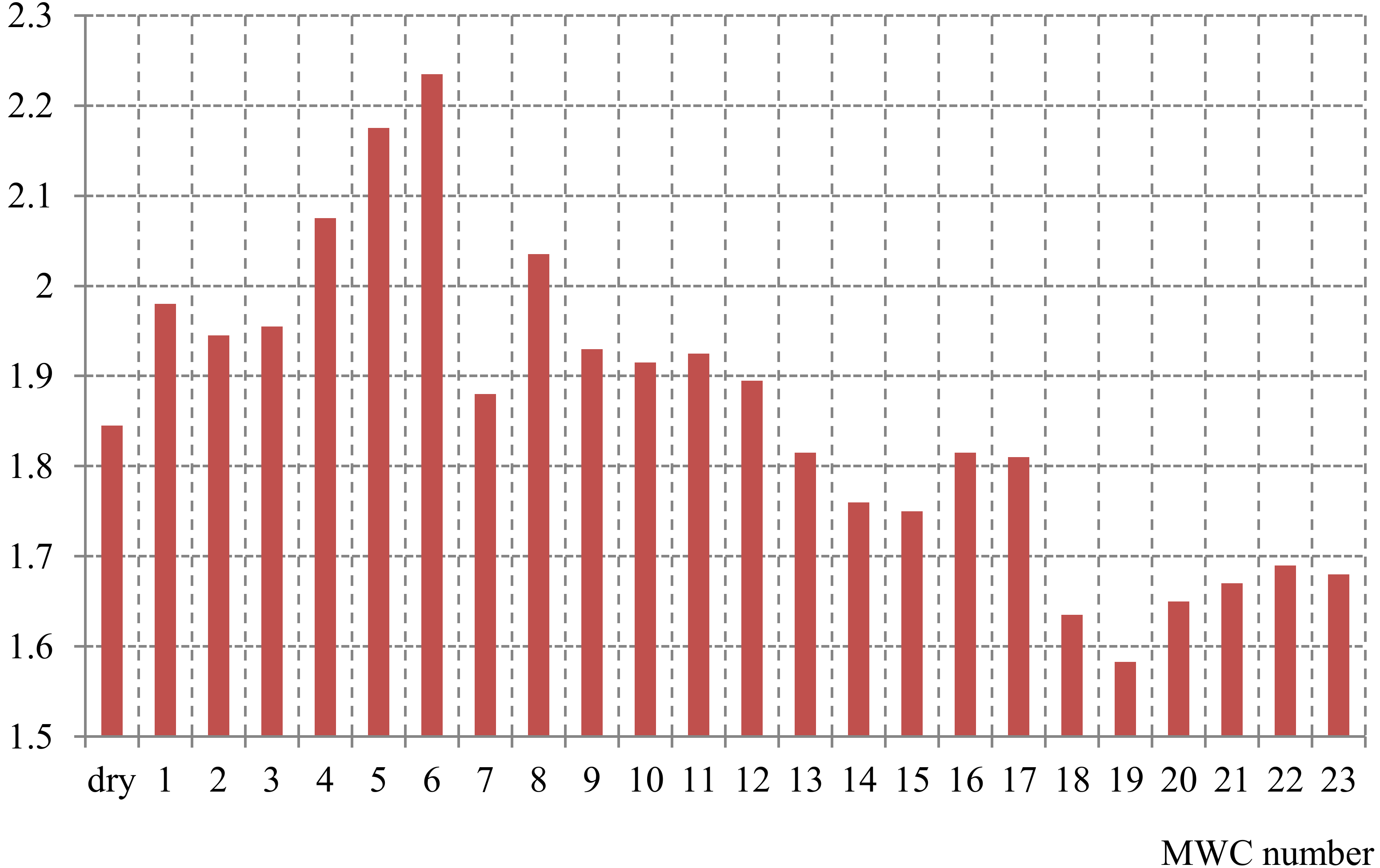

| MWC Number | h0, mm | h1, mm | Δh, mm | ε, % | L1, mm | λ | l1, mm | α, rad | S, % | γ, rad | μ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1st level of reduction (εavg ≈ 19.11%) | |||||||||||

| Dry * | 1.89 | 1.55 | 0.34 | 18 | 246 | 1.23 | 154.25 | 0.05 | 2.83 | 0.019 | 0.1045 |

| 1 | 1.91 | 1.56 | 0.35 | 18.3 | 247 | 1.235 | 153.2 | 0.05 | 2.13 | 0.018 | 0.0895 |

| 2 | 1.91 | 1.57 | 0.34 | 17.8 | 247 | 1.235 | 152.85 | 0.05 | 1.9 | 0.015 | 0.0626 |

| 3 | 1.9 | 1.56 | 0.34 | 17.9 | 248 | 1.24 | 152.19 | 0.05 | 1.46 | 0.013 | 0.0521 |

| 4 | 1.89 | 1.55 | 0.34 | 18 | 248 | 1.24 | 151.76 | 0.05 | 1.17 | 0.012 | 0.0481 |

| 5 | 1.88 | 1.51 | 0.37 | 19.68 | 251 | 1.255 | 153.1 | 0.05 | 2.1 | 0.016 | 0.0586 |

| 6 | 1.9 | 1.5 | 0.4 | 21.05 | 254 | 1.27 | 152.39 | 0.05 | 1.59 | 0.014 | 0.0569 |

| 7 | 1.89 | 1.57 | 0.32 | 16.9 | 245 | 1.225 | 153.44 | 0.05 | 2.29 | 0.017 | 0.0783 |

| 8 | 1.91 | 1.53 | 0.38 | 19.89 | 253 | 1.265 | 153.8 | 0.05 | 2.53 | 0.017 | 0.0783 |

| 9 | 1.89 | 1.53 | 0.36 | 19.05 | 252 | 1.26 | 153.38 | 0.05 | 2.25 | 0.016 | 0.0696 |

| 10 | 1.89 | 1.52 | 0.37 | 19.58 | 251 | 1.255 | 153.6 | 0.05 | 2.4 | 0.017 | 0.0783 |

| 11 | 1.88 | 1.53 | 0.35 | 18.62 | 251 | 1.255 | 153.32 | 0.05 | 2.21 | 0.016 | 0.0696 |

| 12 | 1.89 | 1.52 | 0.37 | 19.58 | 251 | 1.255 | 153.77 | 0.05 | 2.29 | 0.016 | 0.0696 |

| 13 | 1.88 | 1.54 | 0.34 | 18.09 | 248 | 1.24 | 154.66 | 0.05 | 3.11 | 0.019 | 0.1045 |

| 14 | 1.88 | 1.5 | 0.38 | 20 | 247 | 1.235 | 152.44 | 0.05 | 1.62 | 0.014 | 0.0569 |

| 15 | 1.9 | 1.52 | 0.38 | 20 | 246.5 | 1.233 | 152.57 | 0.05 | 1.71 | 0.014 | 0.0569 |

| 16 | 1.9 | 1.52 | 0.38 | 20 | 247.5 | 1.235 | 152.57 | 0.05 | 1.71 | 0.014 | 0.0569 |

| 17 | 1.9 | 1.5 | 0.4 | 21 | 248 | 1.24 | 152.15 | 0.05 | 1.43 | 0.013 | 0.0521 |

| 18 | 1.9 | 1.53 | 0.37 | 19 | 243 | 1.215 | 153.22 | 0.05 | 2.15 | 0.016 | 0.0696 |

| 19 | 1.89 | 1.54 | 0.35 | 19 | 242 | 1.21 | 153.83 | 0.05 | 2.55 | 0.017 | 0.0783 |

| 20 | 1.88 | 1.54 | 0.34 | 18 | 246 | 1.23 | 153.84 | 0.05 | 2.56 | 0.017 | 0.0783 |

| 21 | 1.9 | 1.51 | 0.39 | 21 | 246 | 1.23 | 153.06 | 0.05 | 2.04 | 0.015 | 0.0626 |

| 22 | 1.9 | 1.52 | 0.38 | 20 | 246 | 1.23 | 153.2 | 0.05 | 2.13 | 0.016 | 0.0696 |

| 23 | 1.9 | 1.54 | 0.36 | 19 | 247 | 1.235 | 152.57 | 0.05 | 1.71 | 0.014 | 0.0569 |

| 2nd level of reduction (εavg ≈ 45.53%) | |||||||||||

| Dry * | 1.91 | 1.13 | 0.78 | 40.84 | 369 | 1.845 | 160 | 0.08 | 6.67 | 0.024 | 0.1003 |

| 1 | 1.89 | 1.01 | 0.88 | 46.56 | 396 | 1.98 | 155 | 0.08 | 3.33 | 0.016 | 0.0668 |

| 2 | 1.9 | 0.96 | 0.94 | 49.47 | 389 | 1.945 | 154.49 | 0.09 | 2.99 | 0.015 | 0.0676 |

| 3 | 1.89 | 0.98 | 0.91 | 48.15 | 391 | 1.955 | 153.98 | 0.08 | 2.65 | 0.014 | 0.0616 |

| 4 | 1.91 | 0.96 | 0.95 | 49.74 | 415 | 2.075 | 151.25 | 0.09 | 0.83 | 0.008 | 0.0548 |

| 5 | 1.88 | 0.89 | 0.99 | 52.66 | 435 | 2.175 | 150.53 | 0.09 | 0.35 | 0.005 | 0.0507 |

| 6 | 1.88 | 0.87 | 1.01 | 53.72 | 447 | 2.235 | 148.82 | 0.09 | −0.79 | 0 | 0.045 |

| 7 | 1.88 | 1.01 | 0.87 | 46.28 | 376 | 1.88 | 156.19 | 0.08 | 4.13 | 0.018 | 0.0729 |

| 8 | 1.88 | 0.9 | 0.98 | 52.13 | 407 | 2.035 | 151 | 0.09 | 0.67 | 0.007 | 0.0533 |

| 9 | 1.89 | 1 | 0.89 | 47.09 | 386 | 1.93 | 153.9 | 0.08 | 2.6 | 0.014 | 0.0616 |

| 10 | 1.89 | 1 | 0.89 | 47.09 | 383 | 1.915 | 154.6 | 0.08 | 3.07 | 0.015 | 0.0641 |

| 11 | 1.91 | 1 | 0.91 | 47.64 | 385 | 1.925 | 154.81 | 0.08 | 3.21 | 0.016 | 0.0668 |

| 12 | 1.88 | 1.01 | 0.87 | 46.28 | 379 | 1.895 | 155.11 | 0.08 | 3.41 | 0.016 | 0.0668 |

| 13 | 1.88 | 1.05 | 0.83 | 44.15 | 363 | 1.815 | 158.25 | 0.08 | 5.5 | 0.021 | 0.0844 |

| 14 | 1.88 | 1.05 | 0.83 | 44 | 352 | 1.76 | 155.34 | 0.08 | 3.56 | 0.017 | 0.0697 |

| 15 | 1.88 | 1.05 | 0.83 | 44 | 350 | 1.75 | 155.52 | 0.08 | 3.68 | 0.017 | 0.0697 |

| 16 | 1.89 | 1.02 | 0.87 | 46 | 363 | 1.815 | 153.99 | 0.08 | 2.66 | 0.014 | 0.0616 |

| 17 | 1.9 | 1.03 | 0.87 | 46 | 362 | 1.81 | 153.77 | 0.08 | 2.51 | 0.014 | 0.0616 |

| 18 | 1.89 | 1.13 | 0.76 | 40 | 327 | 1.635 | 158.8 | 0.08 | 5.87 | 0.023 | 0.0944 |

| 19 | 1.9 | 1.2 | 0.7 | 37 | 316.5 | 1.583 | 159.5 | 0.08 | 6.33 | 0.024 | 0.1003 |

| 20 | 1.9 | 1.13 | 0.77 | 41 | 330 | 1.65 | 158.5 | 0.08 | 5.67 | 0.022 | 0.0891 |

| 21 | 1.9 | 1.1 | 0.8 | 42 | 334 | 1.67 | 157 | 0.08 | 4.67 | 0.02 | 0.0802 |

| 22 | 1.89 | 1.12 | 0.77 | 41 | 338 | 1.69 | 157 | 0.08 | 4.67 | 0.02 | 0.0802 |

| 23 | 1.89 | 1.13 | 0.76 | 40 | 336 | 1.68 | 157 | 0.08 | 4.67 | 0.02 | 0.0802 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avdeenko, A.P.; Fedorynov, V.A.; Dašić, P.V.; Turmanidze, R.; Fedorynov, M.V.; Konovalova, S.A.; Burmistrov, K.S.; Toropin, N.V. Cold Rolling of Steel Strips with Metal-Working Coolants. Machines 2018, 6, 29. https://doi.org/10.3390/machines6030029

Avdeenko AP, Fedorynov VA, Dašić PV, Turmanidze R, Fedorynov MV, Konovalova SA, Burmistrov KS, Toropin NV. Cold Rolling of Steel Strips with Metal-Working Coolants. Machines. 2018; 6(3):29. https://doi.org/10.3390/machines6030029

Chicago/Turabian StyleAvdeenko, Anatoly P., Vladimir A. Fedorynov, Predrag V. Dašić, Raul Turmanidze, Mykhailo V. Fedorynov, Svetlana A. Konovalova, Konstantin S. Burmistrov, and Nikolay V. Toropin. 2018. "Cold Rolling of Steel Strips with Metal-Working Coolants" Machines 6, no. 3: 29. https://doi.org/10.3390/machines6030029