Theoretical and Experimental Studies of Over-Polishing of Silicon Carbide in Annular Polishing

Abstract

:1. Introduction

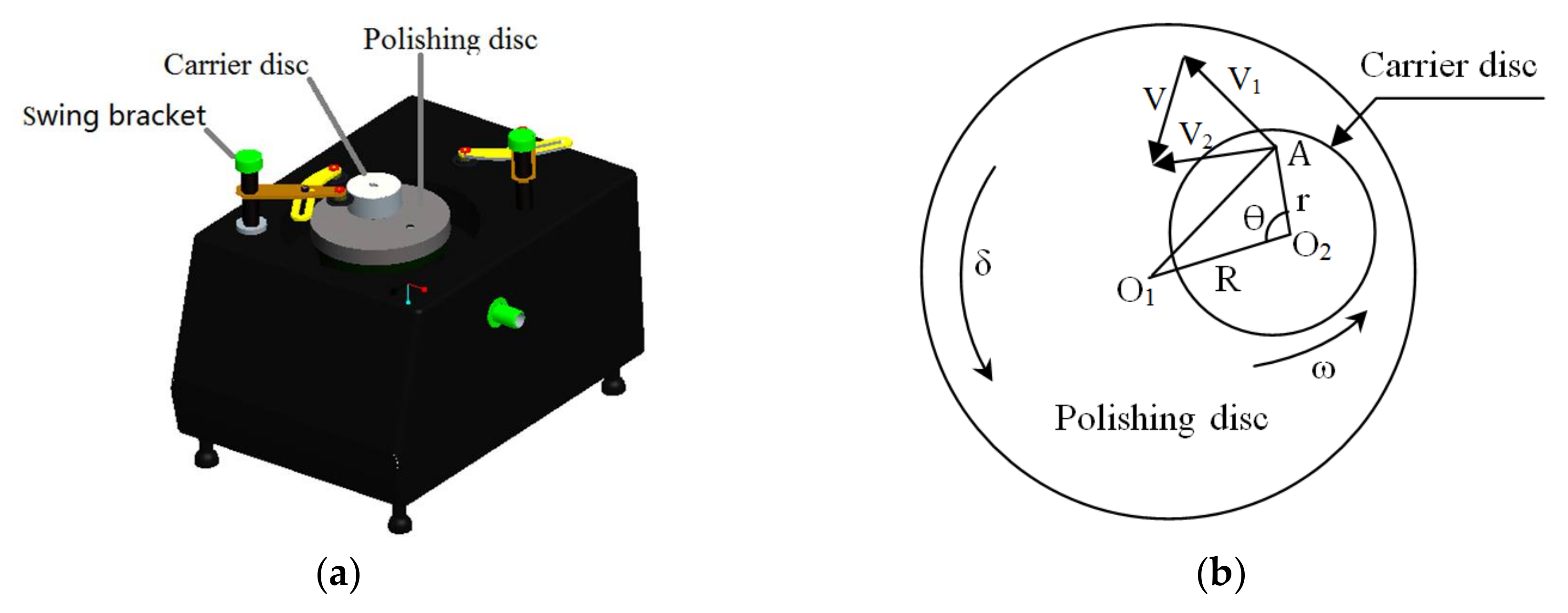

2. Analytical Investigation of Annular Polishing

2.1. Kinematic Coupling of Motions

2.2. Preston Equation

2.3. Rigid Body Contact Model

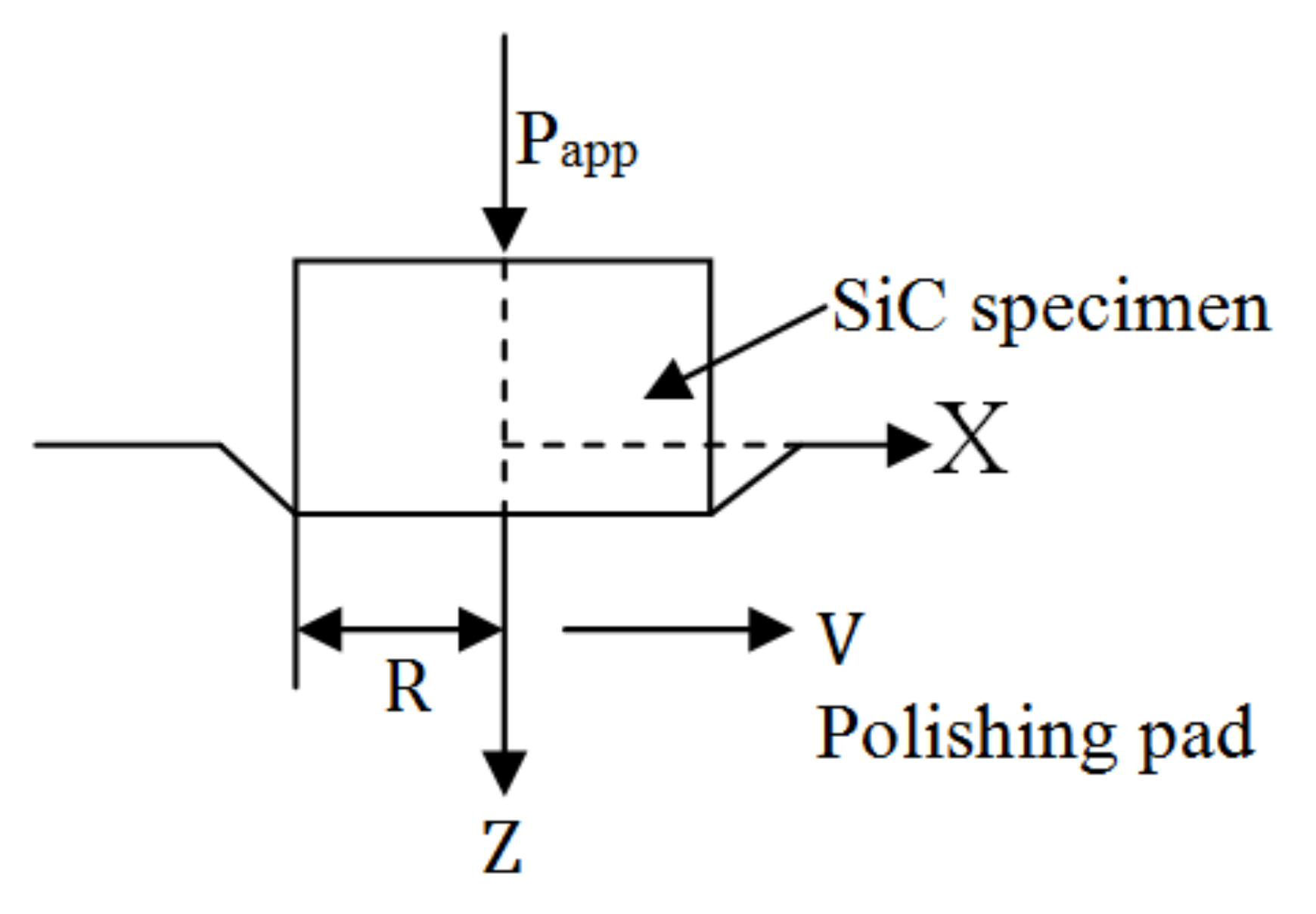

3. FE Simulation of Annular Polishing

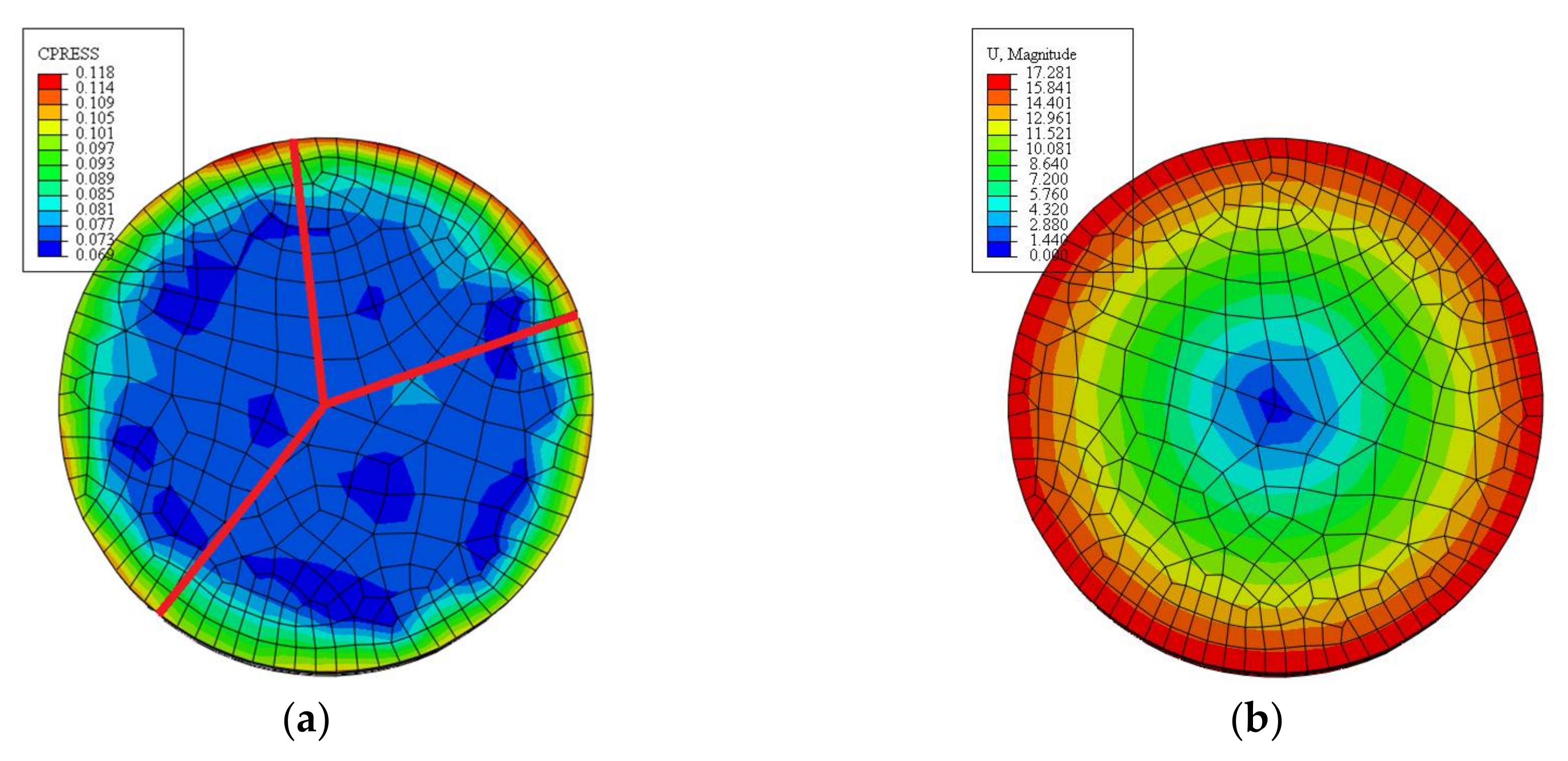

3.1. FE Modeling

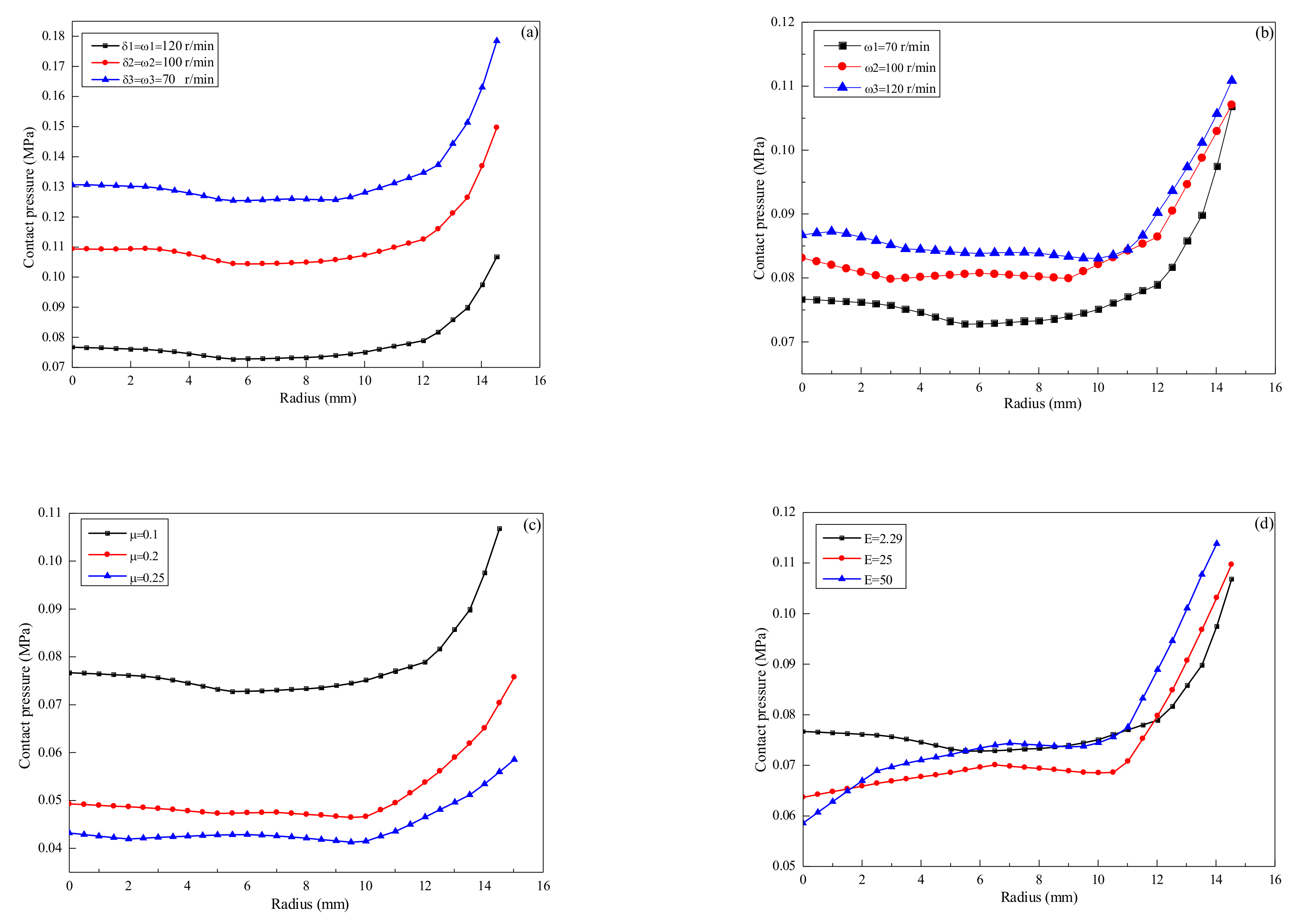

3.2. Simulation Results and Discussion

4. Experimental Study of Annular Polishing of SiC

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Robichaud, J.L.; Schwartz, J.; Landry, D.; Glenn, W.; Rider, B.; Chung, M. Recent advances in reaction bonded silicon carbide optics and optical systems. SPIE 2005, 5868, 586802. [Google Scholar]

- Wang, X.C.; Wang, C.C.; Shen, X.T.; Sun, F.H. Potential material for fabricating optical mirrors: Polished diamond coated silicon carbide. Appl. Opt. 2017, 56, 4113–4122. [Google Scholar] [CrossRef] [PubMed]

- Cook, F.; Brown, N.; Prochnow, E. Annular lapping of precision optical flatware. Opt. Eng. 1976, 15, 450–458. [Google Scholar] [CrossRef]

- Gritti, F.; Guiochon, G. Gradient chromatography under constant frictional heat: Realization and application. J. Chromatogr. A 2013, 1289, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Hutchings, I.M.; Xu, Y.; Sanchez, E.; Ibanez, M.J.; Quereda, M.F. Development of surface finish during the polishing of porcelain ceramic tiles. J. Mater. Sci. 2005, 40, 37–42. [Google Scholar] [CrossRef]

- Fan, Q.T.; Zhu, J.Q.; Zhang, B.A. Effect of the geometry of workpiece on polishing velocity in free annular polishing. Chin. Opt. Lett. 2007, 5, 298–300. [Google Scholar]

- Hashimoto, Y.; Oshika, S.; Suzuki, N.; Shamoto, E. A new contact model of pad surface asperities utilizing measured geometrical features. In Proceedings of the International Conference on Planarization/CMP Technology (ICPT), Chandler, AZ, USA, 30 September–2 October 2015; pp. 1–4. [Google Scholar]

- Yongji, J.I.N. Study on Mechanism of CMP Polishing Motion. Equip. Electron. Prod. Manuf. 2005, 34, 37–41. [Google Scholar]

- Wenski, G.; Altmann, T.; Winkler, W.; Heier, G.; Hölker, G. Doubleside polishing—A technology mandatory for 300 mm wafer manufacturing. Mater. Sci. Semicond. Process. 2003, 5, 375–380. [Google Scholar] [CrossRef]

- Nanz, G.; Lawrence, E.C. Modeling of chemical mechanical polishing: A review. IEEE Trans. Semicond. Manuf. 1995, 8, 382–389. [Google Scholar] [CrossRef]

- Qin, K.D.; Moudgil, B.; Park, C.W. A chemical mechanical polishing model incorporating both the chemical and mechanical effects. Thin Solid Film 2004, 446, 227–286. [Google Scholar] [CrossRef]

- Luo, Q.; Ramarajan, S.; Babuu, S.V. Modification of the Preston equation for the chemical mechanical polishing of copper. Thin Solid Film 1998, 335, 160–167. [Google Scholar] [CrossRef]

- Goedecke, A.; Jackson, R.L.; Mock, R. A fractal expansion of a three dimensional elastic-plastic multi-scale rough surface contact model. Tribol. Int. 2013, 59, 230–239. [Google Scholar] [CrossRef]

- Preston, F. The theory and design of plate glass polishing machines. J. Soc. Glass Technol. 1927, 11, 214–256. [Google Scholar]

- Li, S.X.; Gang, Y.; Zhang, J.C. Single-row laser beam with energy strengthened ends for annular scanning laser surface hardening of largemetal components. Sci. Chin. Phys. Mech. Astron. 2013, 56, 1074–1078. [Google Scholar] [CrossRef]

- Zhao, D.L.; Ma, X.; Liu, B.; Xie, L. Rainfall effect on wind waves and the turbulence beneath air-sea interface. Acta Oceanol. Sin. 2013, 32, 10–20. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; pp. 44–48. [Google Scholar]

| Elastic Modulus/Mpa | Poisson’s Ratio | Density Kg/m3 | |

|---|---|---|---|

| Silicon carbide (SiC) specimen | 362,390 | 0.163 | 3080 |

| Polishing pad | 3 | 0.1 | 260 |

| Polishing disc | 148,000 | 0.31 | 7200 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Han, L.; Liu, H.; Shi, Y.; Yan, Y.; Sun, T. Theoretical and Experimental Studies of Over-Polishing of Silicon Carbide in Annular Polishing. Machines 2018, 6, 15. https://doi.org/10.3390/machines6020015

Zhang J, Han L, Liu H, Shi Y, Yan Y, Sun T. Theoretical and Experimental Studies of Over-Polishing of Silicon Carbide in Annular Polishing. Machines. 2018; 6(2):15. https://doi.org/10.3390/machines6020015

Chicago/Turabian StyleZhang, Junjie, La Han, Haiying Liu, Yikai Shi, Yongda Yan, and Tao Sun. 2018. "Theoretical and Experimental Studies of Over-Polishing of Silicon Carbide in Annular Polishing" Machines 6, no. 2: 15. https://doi.org/10.3390/machines6020015