Rotating Electrical Machine Condition Monitoring Automation—A Review

Abstract

:1. Introduction

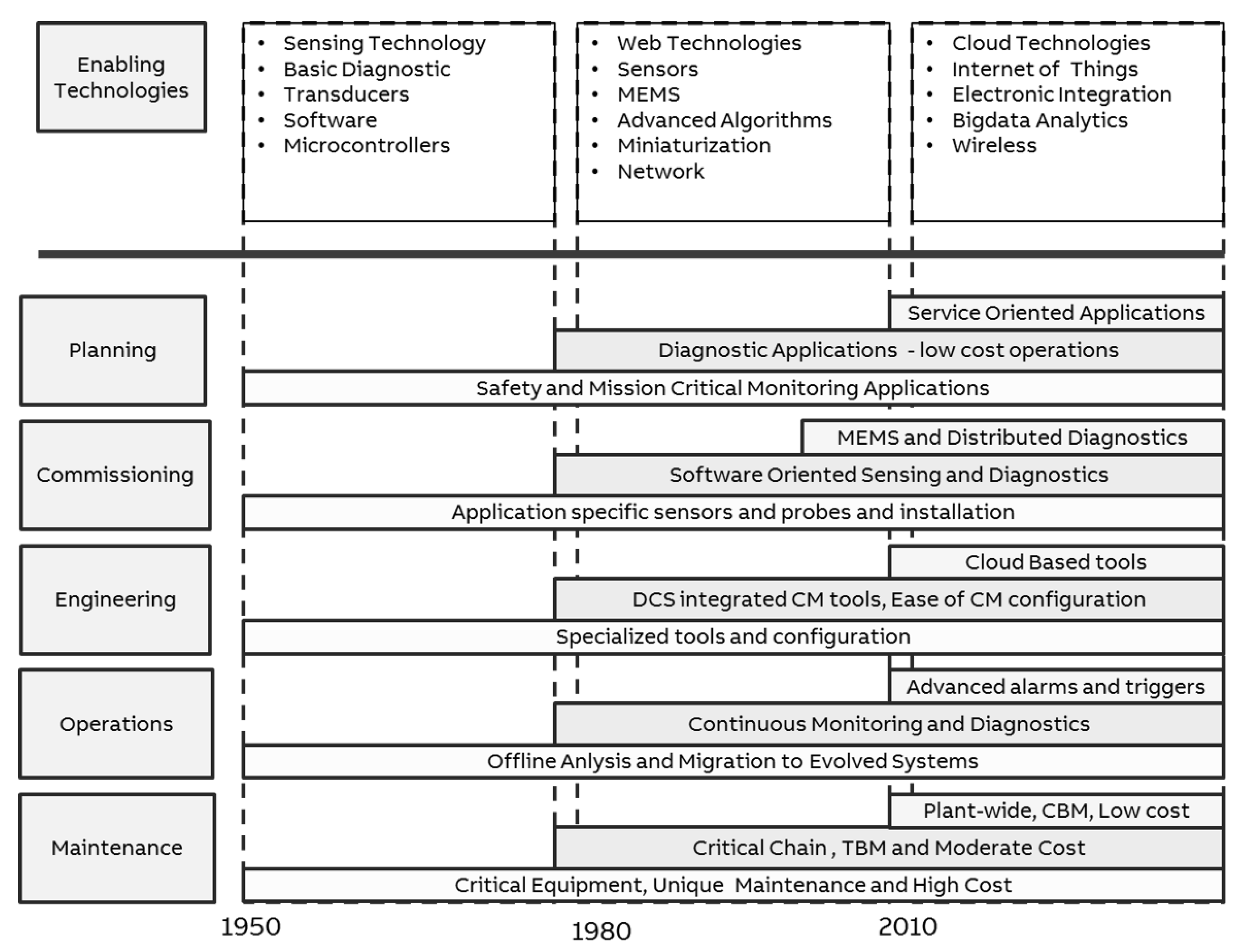

2. Machine Condition Monitoring: An Evolution

- Efficient maintenance and reliable operation: accurate detection of incipient faults with sufficient lead time; thus, evolutions of health monitoring technologies are motivated by the increased productivity and/or reduced investments for maintenance.

- Maximized overall profitability: the monitoring technologies should have a low cost, to the point where further reduction would deteriorate the monitoring quality significantly.

- A sustainable business based on reliable monitoring systems whose service life equals that of the monitored equipment and at the same time offers lower total operating cost.

3. Recent Trends in Rotating Machine Fault Diagnostics

- Monitoring and distributed control system (DCS) integration,

- Diagnostic algorithms,

- Advanced diagnostic algorithms.

3.1. Monitoring and Distributed Control System (DCS) Integration

3.2. Diagnostic Algorithms

- Inter-turn short or open circuit in stator winding,

- Rotor eccentricities,

- Broken rotor bar or cracked rotor end rings,

- Static and/or dynamic air gap irregularities,

- Bent shaft (in the case of machine fleet),

- Bent shaft (fleet of turbine in case of utility),

- Shorted rotor field winding,

- Bearing and gearbox failures,

- Extremities of electrical loading and their dynamics (utilities),

- Extremities of mechanical loading and their dynamics (process plants),

- Interplay between electrical and mechanical counterparts (SSR).

3.3. Advanced Diagnostic Algorithms

3.4. Machine Diagnostics Using Artificial Intelligence

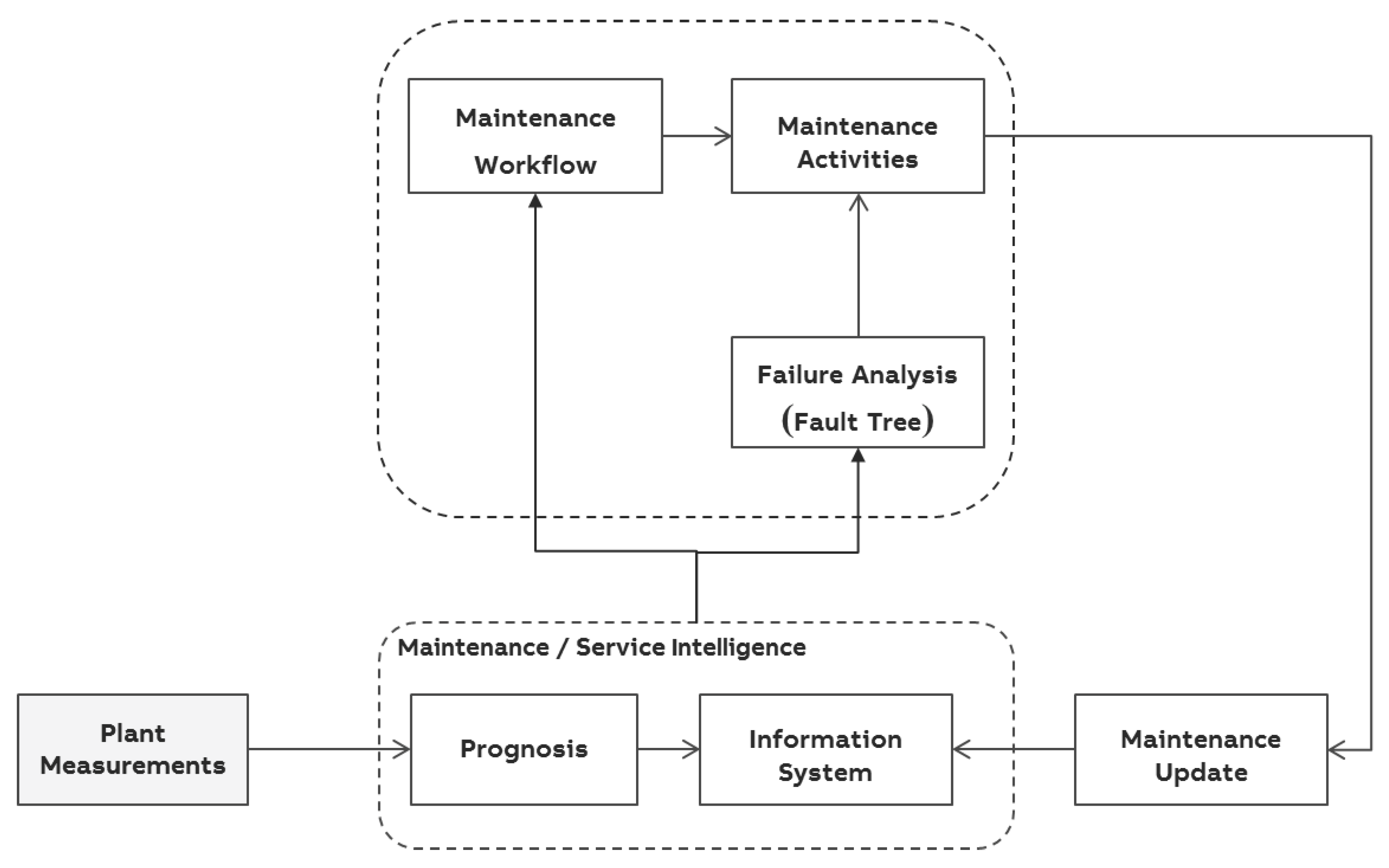

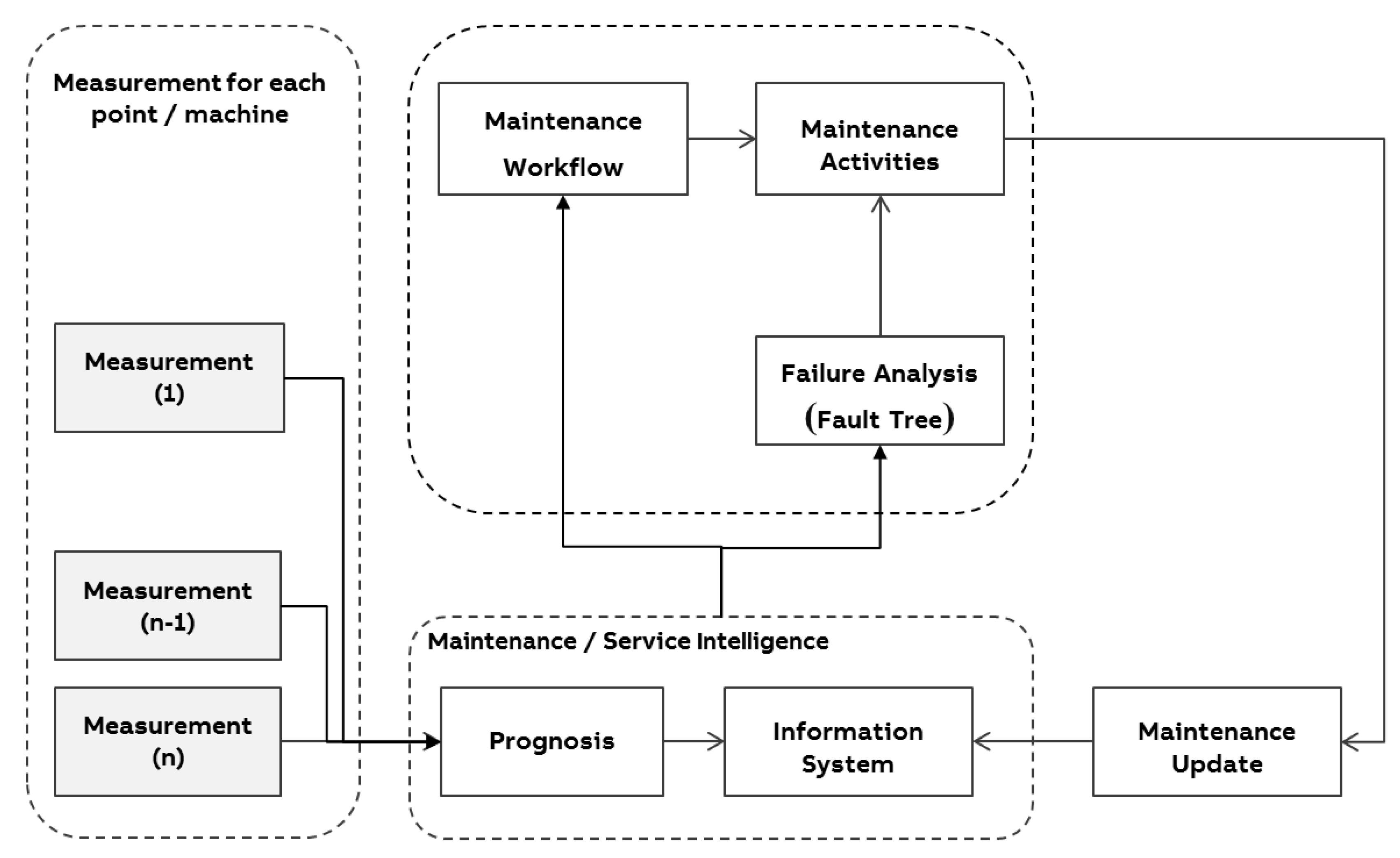

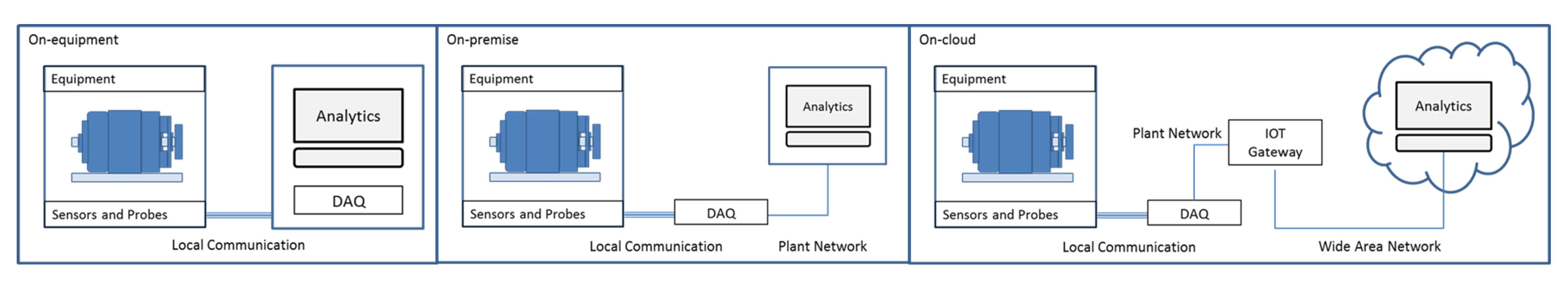

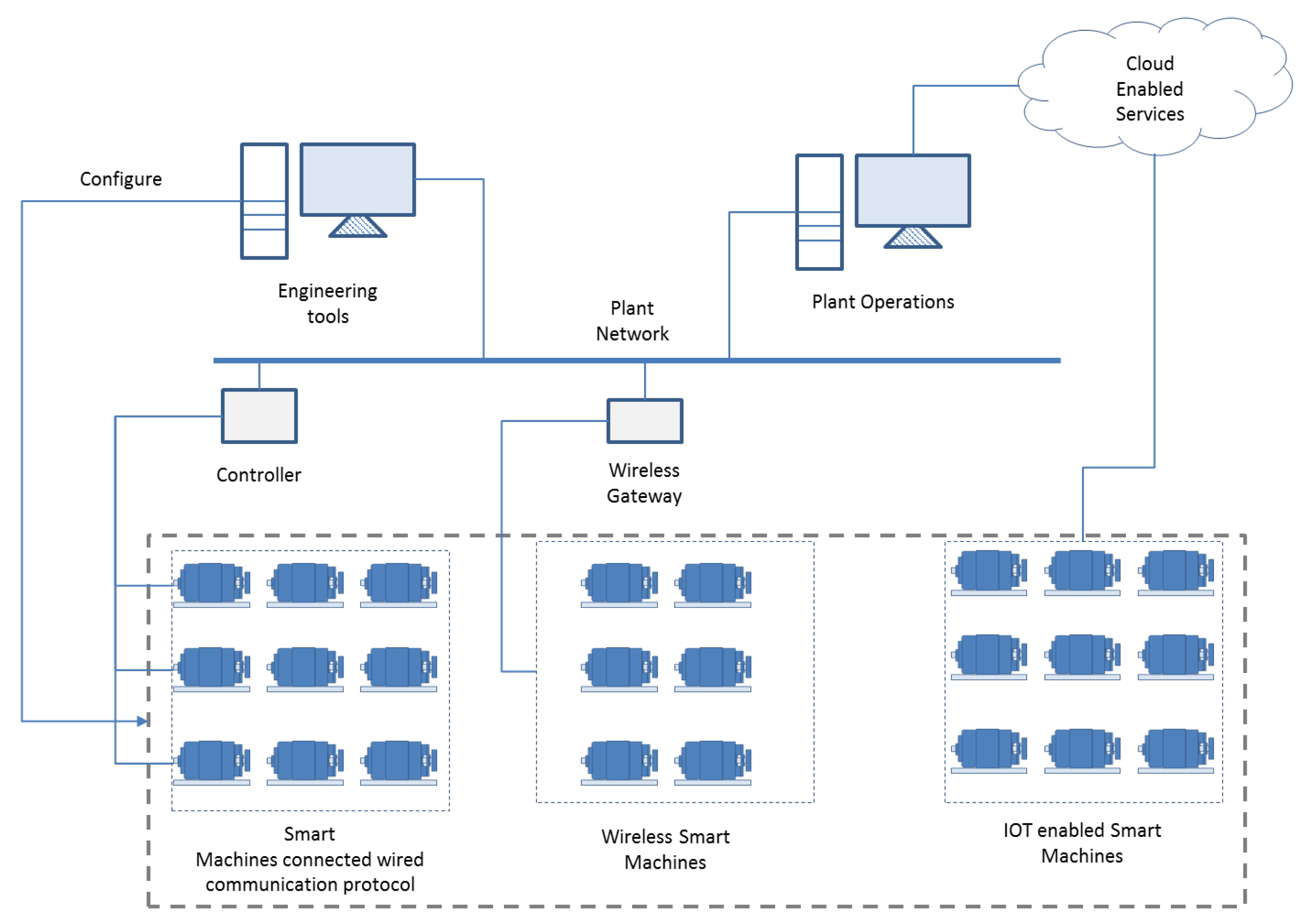

4. Plant-Wide Condition Monitoring

- Integration of sensing, computing and communication,

- Integrated monitoring, maintenance and service,

- Reliability and failure prediction performance,

- Shared and distributed platform, reduced overall cost per monitoring point.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kohler, J.L.; Sottile, J.; Trutt, F.C. Condition-based maintenance of electrical machines. In Proceedings of the Conference Record of the 1999 IEEE Industry Applications Conference, Thirty-Forth IAS Annual Meeting, Phoenix, AZ, USA, 3–7 October 1999; Volume 1, pp. 205–211. [Google Scholar]

- Bram de Jonge, R.T.; Tinga, T. The influence of practical factors on the benefits of condition-based maintenance over time-based maintenance. Reliab. Eng. Syst. Saf. 2017, 158, 21–30. [Google Scholar] [CrossRef]

- Minou, C.A.; Olde Keizer, S.D.P.F.; Teunter, R.H. Condition-based maintenance policies for systems with multiple dependent components: A review. Eur. J. Oper. Res. 2017, 261, 405–420. [Google Scholar] [CrossRef]

- Walker, M. The Diagnosing of Troubles in Electrical Machines; Longmans Green and Co.: Harlow, UK, 1921; pp. 1–20. [Google Scholar]

- Foster, G.B. Recent Developments in Machine Vibration Monitoring. IEEE Trans. Ind. Gen. Appl. 1967, IGA-3, 149–158. [Google Scholar] [CrossRef]

- Kurtz, M.; Stone, G.C. Partial discharge testing of generator insulation. In Proceedings of the 1978 IEEE International Conference on Electrical Insulation, Philadelphia, PA, USA, 12–14 June 1978; pp. 73–77. [Google Scholar]

- Timperley, J.E. Incipient Fault Identification Through Neutral RF Monitoring of Large Rotating Machines. IEEE Trans. Power Appar. Syst. 1983, PAS-102, 693–698. [Google Scholar] [CrossRef]

- Harrold, R.T.; Emery, F.T. Radio Frequency Diagnostic Monitoring of Electrical Machines. IEEE Electr. Insulation Mag. 1986, 2, 18–24. [Google Scholar] [CrossRef]

- Kwan, C.; Ayhan, B.; Yin, J.; Liu, X.; Ballal, P.; Athamneh, A.; Ramani, A.; Lee, W.; Lewis, F. Real-time system condition monitoring using wireless sensors. In Proceedings of the 2009 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2009; pp. 1–8. [Google Scholar]

- Amaro, J.P.; Ferreira, F.J.T.E.; Cortesão, R.; Vinagre, N.; Bras, R.P. Low cost wireless sensor network for in-field operation monitoring of induction motors. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Vina del Mar, Chile, 14–17 March 2010; pp. 1044–1049. [Google Scholar]

- Bratthall, L.G.; van der Geest, R.; Hofmann, H.; Jellum, E.; Korendo, Z.; Martinez, R.; Orkisz, M.; Zeidler, C.; Andersson, J.S. Integrating hundred’s of products through one architecture—The industrial IT architecture. In Proceedings of the 24th International Conference on Software Engineering (ICSE 2002), Orlando, FL, USA, 19–25 May 2002; pp. 604–614. [Google Scholar]

- Kolacinski, R.M.; Theeranaew, W.; Loparo, K.A. An information-theoretic architecture for advanced condition monitoring and control of power generating plants. In Proceedings of the 2012 Future of Instrumentation International Workshop (FIIW), Gatlinburg, TN, USA, 8–9 October 2012; pp. 1–4. [Google Scholar]

- Vasel, J. One plant, one system: Benefits of integrating process and power automation. In Proceedings of the 65th Annual Conference for Protective Relay Engineers, College Station, TX, USA, 2–5 April 2012; pp. 215–250. [Google Scholar]

- Loutfi, M.Y. Online condition monitoring network for critical equipment at Holcim’s STE. genevieve plant. In Proceedings of the 2011 IEEE-IAS/PCA 53rd Cement Industry Technical Conference, St. Louis, MO, USA, 22–26 May 2011; pp. 1–11. [Google Scholar]

- Simon, C.; Theilliol, D.; Sauter, D.; Orkisz, M. Remaining useful life assessment via residual generator approach—A SOH virtual sensor concept. In Proceedings of the 2014 IEEE Conference on Control Applications (CCA), Antibes/Nice, France, 8–10 October 2014; pp. 1202–1207. [Google Scholar]

- Abu-Rub, H.; Bayhan, S.; Moinoddin, S.; Malinowski, M.; Guzinski, J. Medium-Voltage Drives: Challenges and existing technology. IEEE Power Electron. Mag. 2016, 3, 29–41. [Google Scholar] [CrossRef]

- Orkisz, M.; Wnek, M.; Kryczka, K.; Joerg, P. Variable frequency drive as a source of condition monitoring data. In Proceedings of the 2008 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008; pp. 179–183. [Google Scholar]

- Han, Y.; Song, Y.H. Condition monitoring techniques for electrical equipment—A literature survey. IEEE Trans. Power Deliv. 2003, 18, 4–13. [Google Scholar] [CrossRef]

- Bonnett, A.H.; Soukup, G.C. Rotor Failures in Squirrel Cage Induction Motors. IEEE Trans. Ind. Appl. 1986, IA-22, 1165–1173. [Google Scholar] [CrossRef]

- Milimonfared, J.; Kelk, H.M.; Nandi, S.; Minassians, A.D.; Toliyat, H.A. A novel approach for broken-rotor-bar detection in cage induction motors. IEEE Trans. Ind. Appl. 1999, 35, 1000–1006. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H.; Kliman, G.B. What stator current processing-based technique to use for induction motor rotor faults diagnosis? IEEE Trans. Energy Convers. 2003, 18, 238–244. [Google Scholar] [CrossRef]

- Nandi, S.; Toliyat, H.A.; Li, X. Condition monitoring and fault diagnosis of electrical motors—A review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Eltabach, M.; Charara, A.; Zein, I. A comparison of external and internal methods of signal spectral analysis for broken rotor bars detection in induction motors. IEEE Trans. Ind. Electron. 2004, 51, 107–121. [Google Scholar] [CrossRef]

- Kliman, G.B.; Koegl, R.A.; Stein, J.; Endicott, R.D.; Madden, M.W. Noninvasive detection of broken rotor bars in operating induction motors. IEEE Trans. Energy Convers. 1988, 3, 873–879. [Google Scholar] [CrossRef]

- Filippetti, F.; Franceschini, G.; Tassoni, C.; Vas, P. Recent developments of induction motor drives fault diagnosis using AI techniques. IEEE Trans. Ind. Electron. 2000, 47, 994–1004. [Google Scholar] [CrossRef]

- Kia, S.H.; Henao, H.; Capolino, G.A. A High-Resolution Frequency Estimation Method for Three-Phase Induction Machine Fault Detection. IEEE Trans. Ind. Electron. 2007, 54, 2305–2314. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Franceschini, G.; Tassoni, C.; Kliman, G.B. Quantitative evaluation of induction motor broken bars by means of electrical signature analysis. IEEE Trans. Ind. Appl. 2001, 37, 1248–1255. [Google Scholar] [CrossRef]

- Arthur, N.; Penman, J. Induction machine condition monitoring with higher order spectra. IEEE Trans. Ind. Electron. 2000, 47, 1031–1041. [Google Scholar] [CrossRef]

- Jung, J.H.; Lee, J.J.; Kwon, B.H. Online Diagnosis of Induction Motors Using MCSA. IEEE Trans. Ind. Electron. 2006, 53, 1842–1852. [Google Scholar] [CrossRef]

- Bellini, A. Quad Demodulation: A Time-Domain Diagnostic Method for Induction Machines. IEEE Trans. Ind. Appl. 2009, 45, 712–719. [Google Scholar] [CrossRef]

- Ayhan, B.; Chow, M.Y.; Song, M.H. Multiple Discriminant Analysis and Neural-Network-Based Monolith and Partition Fault-Detection Schemes for Broken Rotor Bar in Induction Motors. IEEE Trans. Ind. Electron. 2006, 53, 1298–1308. [Google Scholar] [CrossRef]

- Su, H.; Chong, K.T. Induction Machine Condition Monitoring Using Neural Network Modeling. IEEE Trans. Ind. Electron. 2007, 54, 241–249. [Google Scholar] [CrossRef]

- Bazine, I.B.A.; Tnani, S.; Poinot, T.; Champenois, G.; Jelassi, K. On-line detection of stator and rotor faults occurring in induction machine diagnosis by parameters estimation. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics Drives, Bologna, Italy, 5–8 September 2011; pp. 105–112. [Google Scholar]

- Kral, C.; Wieser, R.S.; Pirker, F.; Schagginger, M. Sequences of field-oriented control for the detection of faulty rotor bars in induction machines-the Vienna Monitoring Method. IEEE Trans. Ind. Electron. 2000, 47, 1042–1050. [Google Scholar] [CrossRef]

- Cardoso, A.J.M.; Cruz, S.M.A.; Carvalho, J.F.S.; Saraiva, E.S. Rotor cage fault diagnosis in three-phase induction motors, by Park’s vector approach. In Proceedings of the Industry Applications Conference, Thirtieth IAS Annual Meeting, IAS ’95, Conference Record of the 1995 IEEE, Orlando, FL, USA, 8–12 October 1995; Volume 1, pp. 642–646. [Google Scholar]

- Aboubou, A.; Sahraoui, M.; Zouzou, S.E.; Razik, H.; Rezzoug, A. Broken bars and/or end rings detection in three-phase induction motors by the extended Park’s vector approach. In Proceedings of the 9th IEEE International Power Electronics Congress (CIEP 2004), Celaya, Gto., Mexico, 17–22 October 2004; pp. 128–133. [Google Scholar]

- Zagirnyak, M.; Mamchur, D.; Kalinov, A. Induction motor diagnostic system based on spectra analysis of current and instantaneous power signals. In Proceedings of the IEEE SOUTHEASTCON 2014, Lexington, KY, USA, 13–16 March 2014; pp. 1–7. [Google Scholar]

- Drif, M.; Cardoso, A.J.M. The instantaneous power factor approach for rotor cage faults diagnosis in three-phase induction motors. In Proceedings of the 2008 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008; pp. 173–178. [Google Scholar]

- Drif, M.; Cardoso, A.J.M. Stator Fault Diagnostics in Squirrel Cage Three-Phase Induction Motor Drives Using the Instantaneous Active and Reactive Power Signature Analyses. IEEE Trans. Ind. Inform. 2014, 10, 1348–1360. [Google Scholar] [CrossRef]

- Bell, R.N.; Mcwilliams, D.W.; O’Donnell, P.; Singh, C.; Wells, S.J. Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part I. IEEE Trans. Ind. Appl. 1985, IA-21, 853–864. [Google Scholar]

- Bell, R.N.; Heising, C.R.; O’Donnell, P.; Singh, C.; Wells, S.J. Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part II. IEEE Trans. Ind. Appl. 1985, IA-21, 865–872. [Google Scholar]

- O’Donnell, P.; Heising, C.; Singh, C.; Wells, S.J. Report of Large Motor Reliability Survey of Industrial and Commercial Installations: Part 3. IEEE Trans. Ind. Appl. 1987, IA-23, 153–158. [Google Scholar]

- Thorsen, O.V.; Dalva, M. A survey of faults on induction motors in offshore oil industry, petrochemical industry, gas terminals, and oil refineries. IEEE Trans. Ind. Appl. 1995, 31, 1186–1196. [Google Scholar] [CrossRef]

- Siddique, A.; Yadava, G.S.; Singh, B. A review of stator fault monitoring techniques of induction motors. IEEE Trans. Energy Convers. 2005, 20, 106–114. [Google Scholar] [CrossRef]

- Orman, M.; Orkisz, M.; Pinto, C.T. Slip estimation of a large induction machine based on MCSA. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics Drives, Bologna, Italy, 5–8 September 2011; pp. 568–572. [Google Scholar]

- Yazici, B.; Kliman, G.B. An adaptive statistical time-frequency method for detection of broken bars and bearing faults in motors using stator current. IEEE Trans. Ind. Appl. 1999, 35, 442–452. [Google Scholar] [CrossRef]

- Garcia-Perez, A.; de Jesus Romero-Troncoso, R.; Cabal-Yepez, E.; Osornio-Rios, R.A. The Application of High-Resolution Spectral Analysis for Identifying Multiple Combined Faults in Induction Motors. IEEE Trans. Ind. Electron. 2011, 58, 2002–2010. [Google Scholar] [CrossRef]

- Vetterli, M.; Herley, C. Wavelets and filter banks: Theory and design. IEEE Trans. Signal Process. 1992, 40, 2207–2232. [Google Scholar] [CrossRef]

- Burnett, R.; Watson, J.F.; Elder, S. The application of modern signal processing techniques to rotor fault detection and location within three phase induction motors. In Proceedings of the Integrating Intelligent Instrumentation and Control Instrumentation and Measurement Technology Conference (IMTC/95.), Waltham, MA, USA, 23–26 April 1995. [Google Scholar]

- Eren, L.; Devaney, M.J. Motor bearing damage detection via wavelet analysis of the starting current transient. In Proceedings of the 18th IEEE Instrumentation and Measurement Technology Conference (IMTC 2001), Budapest, Hungary, 21–23 May 2001; Volume 3, pp. 1797–1800. [Google Scholar]

- Rajagopalan, S.; Aller, J.M.; Restrepo, J.A.; Habetler, T.G.; Harley, R.G. Analytic-Wavelet-Ridge-Based Detection of Dynamic Eccentricity in Brushless Direct Current (BLDC) Motors Functioning Under Dynamic Operating Conditions. IEEE Trans. Ind. Electron. 2007, 54, 1410–1419. [Google Scholar] [CrossRef]

- CusidÓCusido, J.; Romeral, L.; Ortega, J.A.; Rosero, J.A.; Espinosa, A.G. Fault Detection in Induction Machines Using Power Spectral Density in Wavelet Decomposition. IEEE Trans. Ind. Electron. 2008, 55, 633–643. [Google Scholar] [CrossRef]

- Gu, F.; Wang, T.; Alwodai, A.; Tian, X.; Shao, Y.; Ball, A. A new method of accurate broken rotor bar diagnosis based on modulation signal bispectrum analysis of motor current signals. Mech. Syst. Signal Process. 2015, 50, 400–413. [Google Scholar] [CrossRef]

- Ngote, N.; Guedira, S.; Ouassaid, M.; Cherkaoui, M. Comparison of wavelet-functions for induction-motor rotor fault detection based on the hybrid Time Synchronous Averaging—Discrete Wavelet Transform approach. In Proceedings of the 2015 International Conference on Electrical and Information Technologies (ICEIT), Marrakech, Morocco, 25–27 March 2015; pp. 94–99. [Google Scholar]

- Soualhi, A.; Clerc, G.; Razik, H. Detection and Diagnosis of Faults in Induction Motor Using an Improved Artificial Ant Clustering Technique. IEEE Trans. Ind. Electron. 2013, 60, 4053–4062. [Google Scholar] [CrossRef]

- Wu, S.; Chow, T.W.S. Induction machine fault detection using SOM-based RBF neural networks. IEEE Trans. Ind. Electron. 2004, 51, 183–194. [Google Scholar] [CrossRef]

- Escamilla-Ambrosio, P.J.; Liu, X.; Lieven, N.A.J.; Ramírez-Cortés, J.M. Wavelet-fuzzy logic approach to structural health monitoring. In Proceedings of the 2011 Annual Meeting of the North American Fuzzy Information Processing Society, El Paso, TX, USA, 18–20 March 2011; pp. 1–6. [Google Scholar]

- Zhong, J.; Yang, Z.; Wong, S.F. Machine condition monitoring and fault diagnosis based on support vector machine. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 7–10 December 2010; pp. 2228–2233. [Google Scholar]

- Sun, L.; Liu, M.; Qian, H.; Qiao, C. A New Method to Mechanical Fault Classification with Support Vector Machine. In Proceedings of the 2011 2nd International Conference on Digital Manufacturing Automation, Hunan, China, 5–7 August 2011; pp. 68–73. [Google Scholar]

- Sheng, Z.; Liu, Z.; Wang, J.; Lu, Y. Development and application of condition monitoring system for plant production. In Proceedings of the 24th Chinese Control and Decision Conference (CCDC), Taiyuan, China, 23–25 May 2012; pp. 2490–2493. [Google Scholar]

- Cardoso, F.J.A.; Faria, S.P.S.; Oliveira, J.E.G. A smart sensor for the condition monitoring of industrial rotating machinery. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012; pp. 1–4. [Google Scholar]

- Cabal-Yepez, E.; Osornio-Rios, R.A.; Romero-Troncoso, R.J.; Razo-Hernandez, J.R.; Lopez-Garcia, R. FPGA-Based Online Induction Motor Multiple-Fault Detection with Fused FFT and Wavelet Analysis. In Proceedings of the 2009 International Conference on Reconfigurable Computing and FPGAs, Quintana Roo, Mexico, 9–11 December 2009; pp. 101–106. [Google Scholar]

- Wildermuth, S.; Ahrend, U.; Byner, C.; Rzeszucinski, P.; Lewandowski, D.; Orman, M. Condition monitoring of electric motors based on magnetometer measurements. In Proceedings of the 2015 IEEE 20th Conference on Emerging Technologies Factory Automation (ETFA), Luxembourg, 8–11 September 2015; pp. 1–4. [Google Scholar]

- Stein, J.L.; Park, Y. Modeling and Sensing Issues for Machine Diagnostics. In Proceedings of the 1988 American Control Conference, Atlanta, GA, USA, 15–17 June 1988; pp. 1924–1930. [Google Scholar]

- Su, C.Q. Smart condition monitoring. In Proceedings of the 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014; pp. 138–141. [Google Scholar]

- Zygmunt, M.; Budyn, M.; Orkisz, M.; Ottewill, J.; Jaramillo, V.; Nowak, A. Visual modeling of condition monitoring systems. In Proceedings of the 2012 IEEE 17th International Conference on Emerging Technologies Factory Automation (ETFA 2012), Krakow, Poland, 17–21 September 2012; pp. 1–4. [Google Scholar]

- Romero-Troncoso, R.J.; Saucedo-Gallaga, R.; Cabal-Yepez, E.; Garcia-Perez, A.; Osornio-Rios, R.A.; Alvarez-Salas, R.; Miranda-Vidales, H.; Huber, N. FPGA-Based Online Detection of Multiple Combined Faults in Induction Motors Through Information Entropy and Fuzzy Inference. IEEE Trans. Ind. Electron. 2011, 58, 5263–5270. [Google Scholar] [CrossRef]

- Wasif, H.; Aboutalebi, A.; Brown, D.; Axel-Berg, L. Condition monitoring system for process industries a business approach. In Proceedings of the 2012 IEEE Symposium on Industrial Electronics and Applications, Bandung, Indonesia, 23–26 September 2012; pp. 251–256. [Google Scholar]

- Josifovic, A.; Corney, J. Development of industrial process characterisation through data analysis. In Proceedings of the 2016 IEEE Symposium Series on Computational Intelligence (SSCI), Athens, Greece, 6–9 December 2016; pp. 1–7. [Google Scholar]

- Xu, B.; Kumar, S.A. Big Data Analytics Framework for System Health Monitoring. In Proceedings of the 2015 IEEE International Congress on Big Data, New York, NY, USA, 27 June–2 July 2015; pp. 401–408. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kande, M.; Isaksson, A.J.; Thottappillil, R.; Taylor, N. Rotating Electrical Machine Condition Monitoring Automation—A Review. Machines 2017, 5, 24. https://doi.org/10.3390/machines5040024

Kande M, Isaksson AJ, Thottappillil R, Taylor N. Rotating Electrical Machine Condition Monitoring Automation—A Review. Machines. 2017; 5(4):24. https://doi.org/10.3390/machines5040024

Chicago/Turabian StyleKande, Mallikarjun, Alf J. Isaksson, Rajeev Thottappillil, and Nathaniel Taylor. 2017. "Rotating Electrical Machine Condition Monitoring Automation—A Review" Machines 5, no. 4: 24. https://doi.org/10.3390/machines5040024