1. Introduction

Dehulling is a process employed to get rid of the outer pericarp and testa (hull) of most cereal grains, grain legumes, nuts and oilseeds using mechanical means [

1]. Generally, this process through seed material bulk density reduction offers advantages such as increased temperature distribution management and other rate transfer processes in downstream processing [

2].

African breadfruit which belongs to the botanical family Maraceae is a source of highly rated and delicious traditional food in Africa including the eastern and southern regions of Nigeria. It has high nutritional value, containing about 40% carbohydrate and 17% protein with several minerals and vitamins, and is a rich source of vegetable oil [

3]. Potential commercial and industrial benefits of breadfruit include raw materials for breakfast cereals and beverages, the production of soap, pharmaceuticals, flour for making biscuits, and paints [

4]. Another highlighted potential of breadfruit is the shell which is rich in potash and may be used as filler, bedding, feed cakes and meals for livestock and the polishing of abrasives [

5].

African breadfruit is characterized by a spherical shape, and a hard and spongy texture filled with seeds. The seeds are made up of the hull and inner edible endosperm. There are three main varieties of breadfruit:

VarAfricana,

Var Molis and

Var Inverse [

6]. There are abundant breadfruit trees both in the savanna region and the eastern part of the country. However, the price of the processed breadfruit seeds is still relatively high compared to other seeds in the local market and there is often not enough quantity to satisfy local market demand.

Many researchers believe that the potential of the breadfruit seed has not been fully harnessed [

7,

8,

9,

10]. This is mainly due to the traditional manual means of processing the seed which produces a low yield and increases the cost of processed seeds. The market price of the processed breadfruit can be lowered for local consumption as a staple food and enough quantity can be processed for raw material or industrial feedstock if the manual dehulling approach is replaced with mechanized dehulling and a storage process is adopted.

Currently, the throughput of the existing and reported breadfruit seed dehulling machines is well below other seed shelling machine throughputs. To increase the presence of breadfruit seed to compete with other seeds as a field for food materials, an affordable shelling machine with efficient and reasonable capacity is required as part of the processing processes.

This paper presents a breadfruit seed dehuller machine designed using information from open literatures and existing machines. This is envisaged to increase efficacy of the desired dehuller machine parameters. The performance evaluation of the prototyped machine was done to ascertain efficacy of the machine given the design parameters and results compared with existing machines.

2. Design and Development

2.1. Design Approach

The African breadfruit seed dehulling machine was designed and constructed using a modular concept for a low cost, easy adjustability, and easy maintenance. The hopper, dehulling unit, drying unit and aspiration unit are the main units attached to the frame. These major units of the machine can be changed, for instance to increase the throughput. The concept enables individual components to be produced separately and assembled together as a unit with bolts and nuts. This way, the underperforming components are easy to sort out, replace or modify during the testing stage and it is envisaged that this will also be beneficial during the maintenance stage.

2.2. Operational Mode

The electric motor provides the primary motion which rotates the dehulling disk. The breadfruit seeds are introduced through the hopper, while the spiral on the supporting shaft for the disk conveys and compresses the breadfruit seeds into the space between the rotating disk and the fixed disk. An adjustment is provided to determine the length of the gap between the disks.

After the dehulling, the seeds along with the chaff drop into the drying unit where their moisture content is reduced to enhance the separation process in the aspiration unit.

The rubbing action of the disks peels the shell of the breadfruit seed and it moves along with the cracked shell in the direction of rotation to the exit channel, leading to the drying unit. The blower with a heater runs independently and it is to dry the peeled breadfruit seeds and shell of their moisture content, for efficient separation.

The blower in the aspiration unit sifts the hull from the endosperm, thereby delivering a certain quantity of air which is channeled to meet the dropping shells and dehulled seed from the drying unit. The cracked shells are lighter than the dehulled seeds and are carried away by the air in a different direction while the white seeds drop into a receiver where they are collected.

2.3. Prototype of Proposed Dehulling Machine

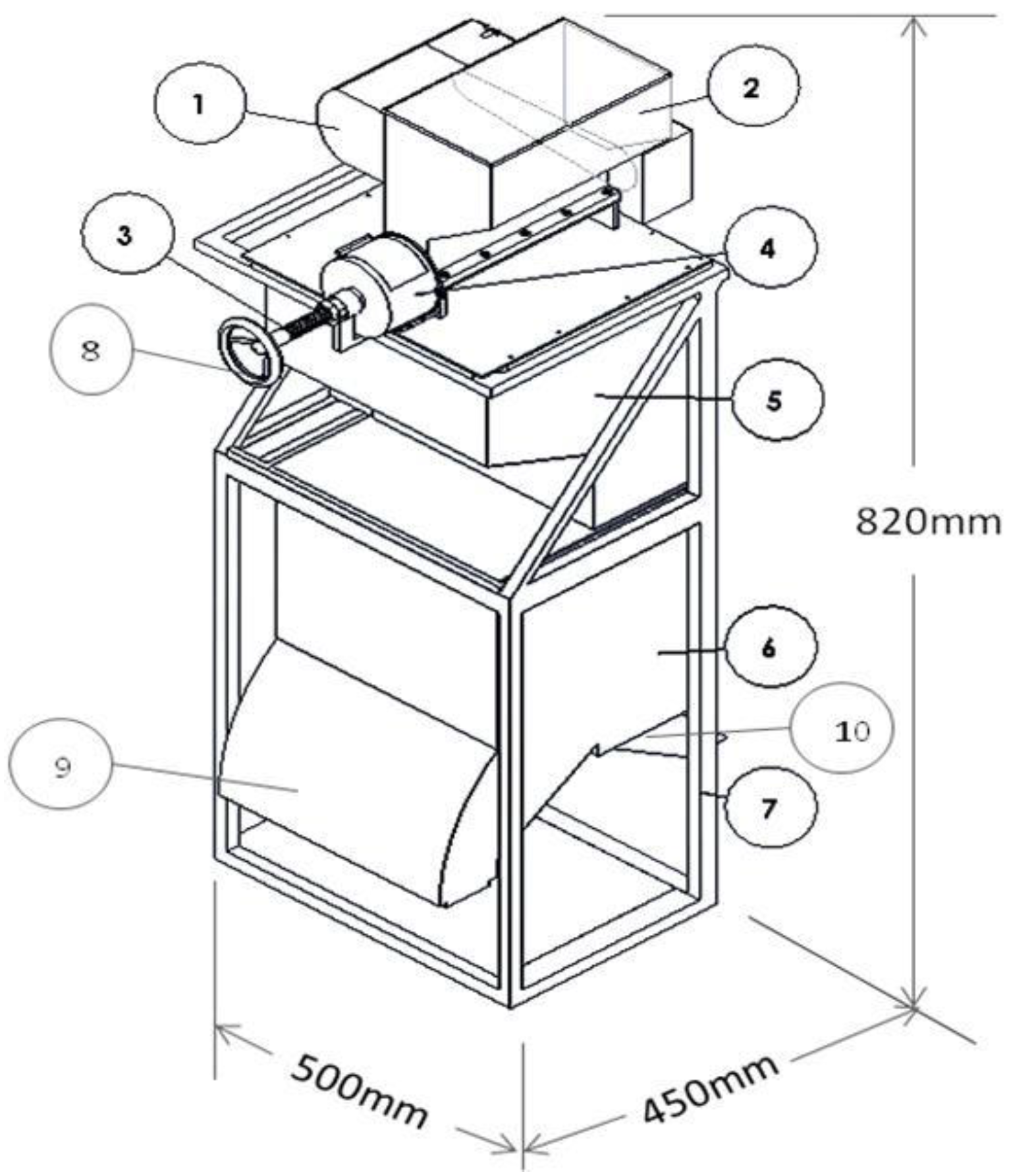

The overall size of the machine is 500 × 450 × 820 mm

3 (

Figure 1). The machine is made up of the frame, the hopper, an electric motor, the dehulling unit, the drying unit and the separation unit. The machine frame is the rigid structure where all the machine components are assembled. The frame is constructed with a hollow, square bar steel material. All the units, including the hopper and hopper under-cover, are fastened with bolts and nuts for ease of disassembling during maintenance and repairs.

1. The Hopper

This is the unit through which the machine is charged with the parboiled breadfruit seeds. The hopper has a rectangular base with the sides inclined at different angles to eliminate the effect of tunneling and arching. At the base of the hopper, a shaft with a spiral around its circumference (power shaft) is located. This shaft is supported with two bearings, one each at both ends. The shaft is driven by an electric motor connected by a belt via a pulley on one end of the shaft.

2. The Dehulling Unit

This unit does the dehulling operation by the attrition method using two disks. It is enclosed by the dehulling unit casing. Within the casing, there are two concentric disks mounted on disk holders and supported on two shafts. One of the disks is mounted on one end of the power shaft with the spiral, while the other disk is clamped on a threaded shaft. Also, the disk mounted on the power shaft with the spiral around its circumference is the rotating disk (it rotates by the motion of the electric motor), while the disk on the threaded shaft is the fixed disk (it does not rotate by the motion of the electric motor), but it has a linear motion which is obtained by adjusting the hand-wheel on other end of the threaded shaft. Both disks can be enclosed together. The gap in between the two disks is adjusted using the threaded shaft supporting the fixed disk. By rotating the hand-wheel on the threaded shaft, the gap in between the two disks is adjusted.

3. The Drying Unit

This unit reduces the moisture content of the breadfruit seeds after dehulling, thereby eliminating the possibility of the cotyledon sticking on the endosperm. This unit has its inlet directly under the discharge hole of the dehulling unit. The unit is comprised of electric fan with a heating element. The heating element supplies the heat required to reduce the moisture content of the cracked seeds. As the dehulled seeds and shells drop, they fall on a part of the drying unit that increases the resident time in which the seeds and shells stay in this unit for proper moisture reduction, and it is stepped and inclined at an angle of 60° to the horizontal.

4. The Separation Unit

This unit completes the separation of the white seeds (endosperm) from the cotyledon. The separation process is achieved by the density differential of the white seeds and the chaff. This unit is comprised of an aspirator (fan) with two discharge holes. The hole directly under the aspirator is for the seeds, while the hole opposite the aspirator (inclined at 30°) is for the chaffs.

2.4. Machine Design Parameters Correlation

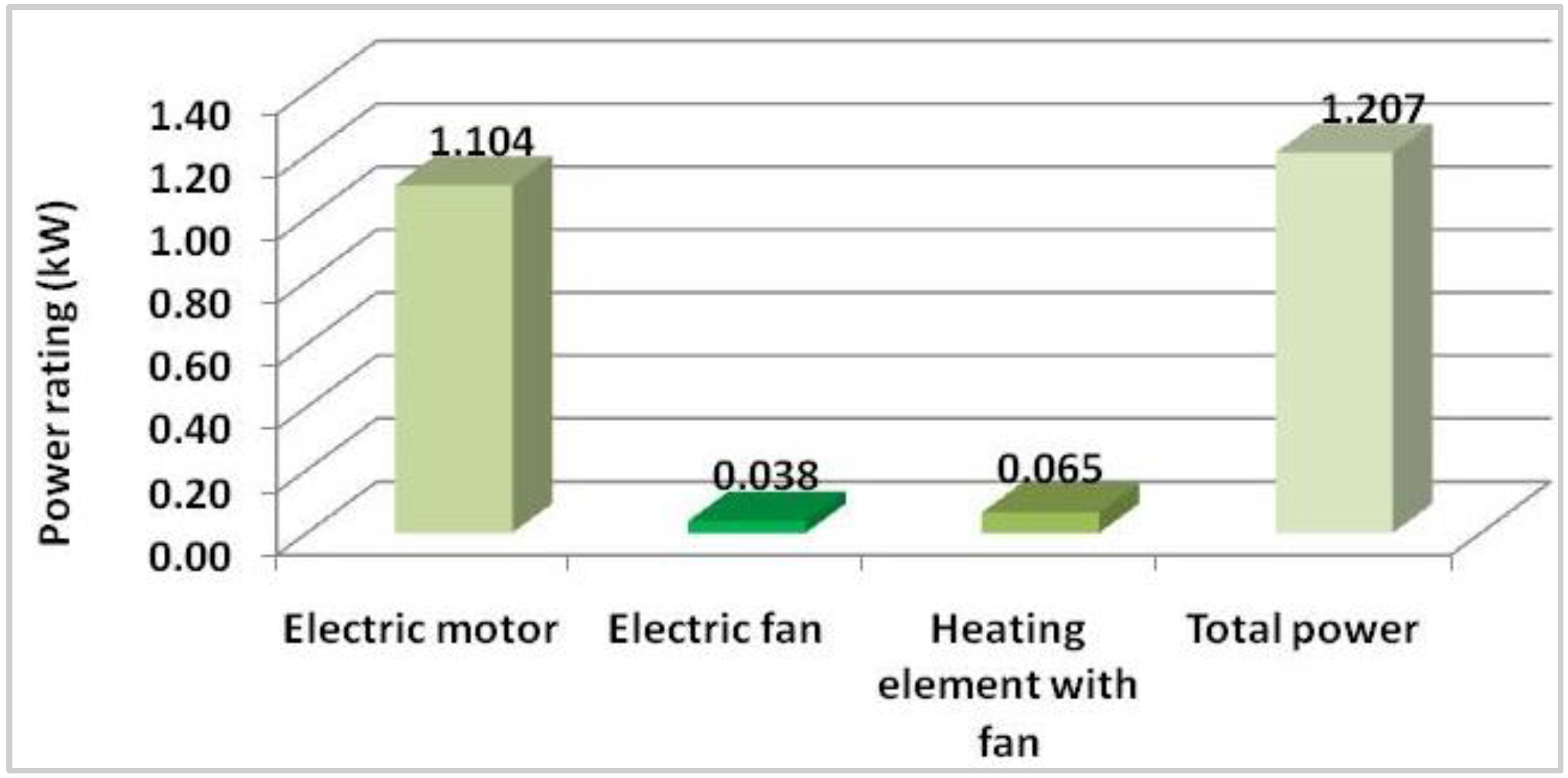

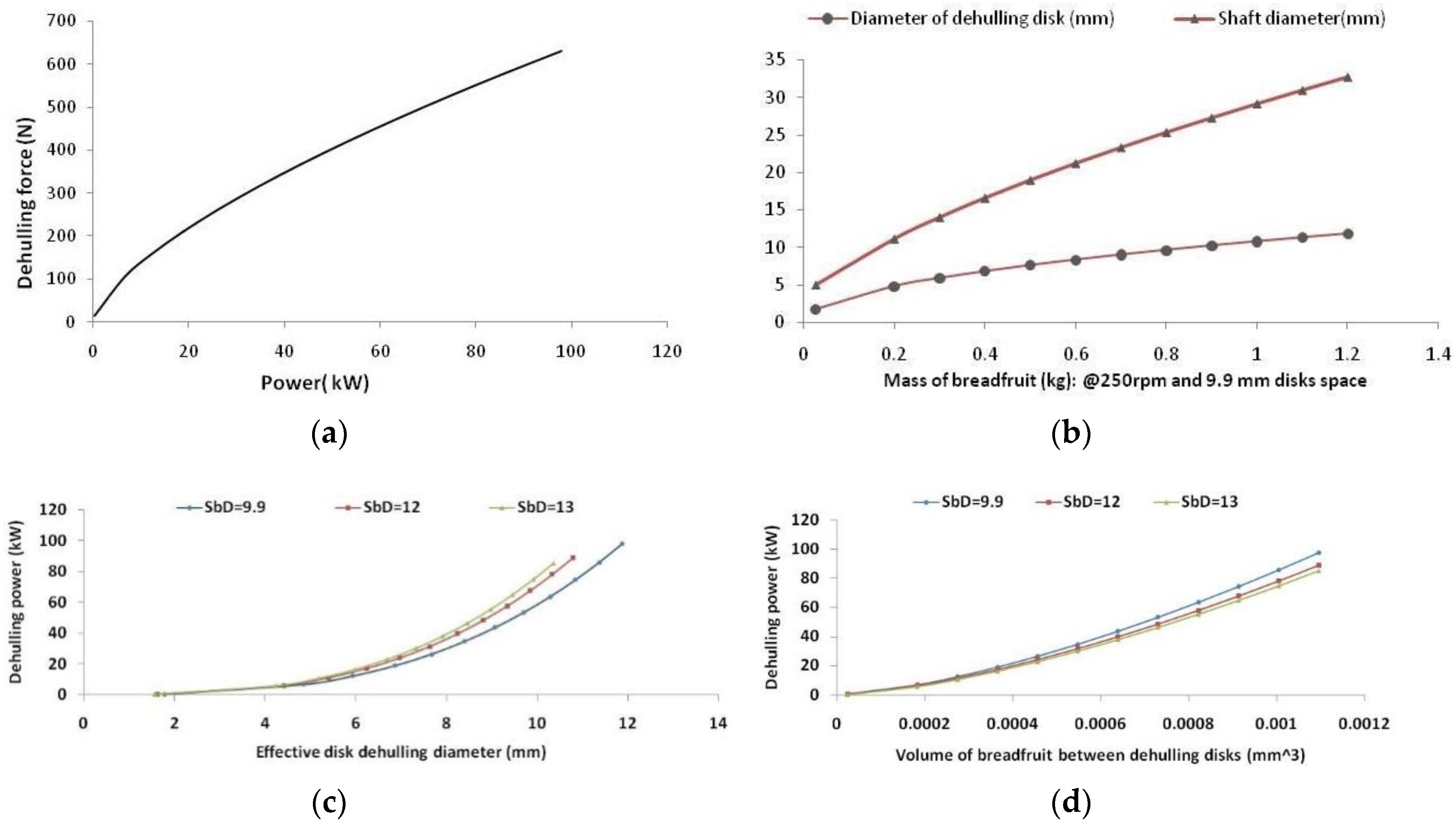

The machine parameters affecting the throughput are important for economic appraisal. These parameters include: the space between disks; the effective disk dehulling diameter; and the speed of the rotating dehulling disk. Changes in these parameters affect the power consumption of the dehulling machine. As shown in

Figure 2, the prime mover (electric motor) carries more power and is more susceptible to changes in power due to variations in the dehulling force as the dehulling capacity of the machine increases. This relationship between the dehulling force and prime mover power requirement is highlighted in

Figure 3a.The relationship betweenthe dehulling disk diameter and the diameter ofthe shaft conecting the dehulling disk and prime mover via a pulley (feeder shaft) is shown in

Figure 3b for different breadfruit seed mass at a constant feed with aconstant space between the dehulling disks.

Figure 3c,d shows that more breafruit seeds between dehulling disks requires more dehulling power.

3. Machine Performance Analysis

Three variable performance parameters, namely the space between the fixed and rotating dehulling disks (mm), the dehulling speed (rpm), and the moisture content of the breadfruit seeds (%), were used as an off-design performance handle. The machine performance indicators include: throughput (kg/h); electric power consumption (kWh); completely dehulled seeds (%); undehulled seeds; partially dehulled seeds; breakage (%); and sifting efficiency (%).

3.1. Sample Breadfruit Seeds

A commonly available local variety of breadfruit seed bought from Eke Awka market in Anambra State, Nigeria, was used to test the dehuller performance. The seeds were washed with clean warm water and parboiled for 10 min at a temperature of 70 °C. The parboiled sample was divided into three portions to obtain varying moisture content between 10% and 50%. The samples were stored in polythene bags to maintain their moisture content before the dehulling process.

3.2. Test Procedure

The three samples of breadfruit seeds with different moisture contents of approximately 10%, 35% and 50% were tested separately, varying one machine handle at a time. Starting with the space between the fixed and rotating dehulling disks, the regulating handle for the fixed disk is adjusted between 9 mm and 13 mm for a constant speed. This is done for continuous seed feeding for a duration of an hour for each of 9.9 mm, 12 mm and 13 mm spaces between disks. Similarly, the dehulling speed was adjusted from 200 rpm to 400 rpm each time, for a constant space between the fixed and rotating dehulling disks (9.9 mm, 12 mm and 13 mm), lasting an hour for each space setting. The method employed in feeding the breadfruit into the hopper is a continuous feeding approach because the size of the hopper cannot hold all the required quantity for an hour of operation. The performance indicators were calculated using the average of three runs.

4. Results and Discussion

The results presented in

Table 1 are far more promising compared to any other set of parameters for the prototype dehuller at the given breadfruit seed moisture content for this experiment. The results show an increase in throughput compared to existing breadfruit seed dehullers. The 214 kg/h capacity is about a 70% increase compared to 64 kg/h reported by [

1] with a 150 rpm dehulling speed. The increment in dehulling speed is 40% with 250 rpm for the present work.

The increased throughput could be attributed partly due to the increased dehulling speed and probably the dehulling mechanism employed.

Comparing the roller or cam arrangement in [

1] with the disks arrangement in this work, it is obvious that disk will have more contact surface area than the roller or cam. Thus, for every revolution of the prime mover disk with more shearing surfaces, there should be arguably more throughput.

There is an increase in breakage, though less than 1%, which could be a result of the increase in the dehulling speed or the variation in moisture content. All other dehuller performance parameters slightly showed recommended improvement.

The regulating handle for the space between the fixed and rotating disks played a vital role in ensuring appropriate space is provided for a particular dehulling speed. In this design, with a clearance between disks of less than 9.9 mm, the breadfruit seeds were crushed for any value of moisture content.

5. Conclusions

A modular African breadfruit seed dehulling machine with higher throughput has been developed. The result of the performance test showed an improvement compared to reported dehulling machines. The material used for the disks were mild steel; however, disks with lighter weight will save energy and operating costs. Further improvement can be done to reduce the breakage and partially dehulled seeds. A reduction in time taken for the moisture content of the parboiled breadfruit seeds to drop before it is introduced into the machine is necessary.

Author Contributions

Nnamdi Anosike (N.A.), Emmanuel Brown (E.B.) and Chukwnonso Maduka (C.M.) conceived the idea and design development; Nnamdi Anosike (N.A.) conceived and designed the experiments; Emmanuel Brown (E.B.) and Chukwnonso Maduka (C.M.) performed the experiments; Nnamdi Anosike (N.A.), Emmanuel Brown (E.B.) and Chukwnonso Maduka (C.M.) analyzed the data; Emmanuel Brown (E.B.) and Chukwnonso Maduka (C.M.) contributed reagents/materials/analysis tools; Nnamdi Anosike (N.A.) wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Omobuwajo, T.O.; Ikegwuoha, H.C.; Koya, O.A.; Ige, M.T. Design, construction and testing of a dehuller for African breadfruit (Treculia africana) seeds. J. Food Eng. 1999, 42, 173–176. [Google Scholar] [CrossRef]

- Deshpande, S.S.; Sathe, S.K.; Salunke, D.K.; Cornforth, D.P. Effects of Dehulling on Phytic Acid, Polyphenols, and Enzyme Inhibitors of Dry Beans (Phaseolus vulgaris L.). J. Food Sci. 1982, 47, 1846–1850. [Google Scholar] [CrossRef]

- Etoamaihe, U.J.; Ndubueze, K.C. Evaluation of a Dehulling Machine for African Breadfruit (Treculia African). J. Eng. Appl. Sci. 2010, 5, 312–315. [Google Scholar]

- Nwaigbo, S.C.; Chinwuko, E.C.; Achebe, C.H.; Tagbo, D.A. Design of breadfruit shelling machine. Afr. Res. Rev. 2008, 2, 1–16. [Google Scholar]

- Nwabueze, T.U.; Iwe, M.O.; Akobundu, E.N.T. Physical characteristic and acceptability of extruded African breadfruit-based snacks. J. Food Qual. 2008, 31, 142–155. [Google Scholar] [CrossRef]

- Okafor, J.C. Delimitation of a new variety of Treculia africana Decaisne subspecie Africana (Moraceae) Bull. Jard. Bot. Nat. Belg. 1981, 51, 191–199. [Google Scholar] [CrossRef]

- Bassey, M.W.; Schmidt, O.G. Abrasive-disk dehullers in Africa: From research to dissemination. Available online: http://www.idrc.ca/EN/Resources/Publications/Documents/Abrasive-disk-Dehullers-in-Africa-from-Research-to-Dissemination.pdf (accessed on 9 December 2015).

- Omobuwajo, T.O.; Akande, E.A.; Sanni, L.A. Selected physical, mechanical and aerodynamic properties of African breadfruit (Treculia africana) seeds. J. Food Eng. 1999, 40, 241–244. [Google Scholar] [CrossRef]

- Reichert, R.D.; Oomah, B.D.; Youngs, C.G. Factors affecting the efficiency of abrasive-type grain legumes investigated with a new intermediate-sized, batch dehuller. J. Food Sci. 1984, 49, 267–272. [Google Scholar] [CrossRef]

- Reichert, R.D.; Youngs, C.G. Dehulling cereal grains and grain legumes for developing countries Quantitative comparison between attrition and abrasive type mills. Cereal Chem. 1976, 53, 829–839. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).